Patents

Literature

201results about How to "Accurate adjustment position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Recessed luminaire adjustment mechanism

ActiveUS20150241039A1Convenient aiming of light beamEasy to lockLighting support devicesFixed installationLight beamEngineering

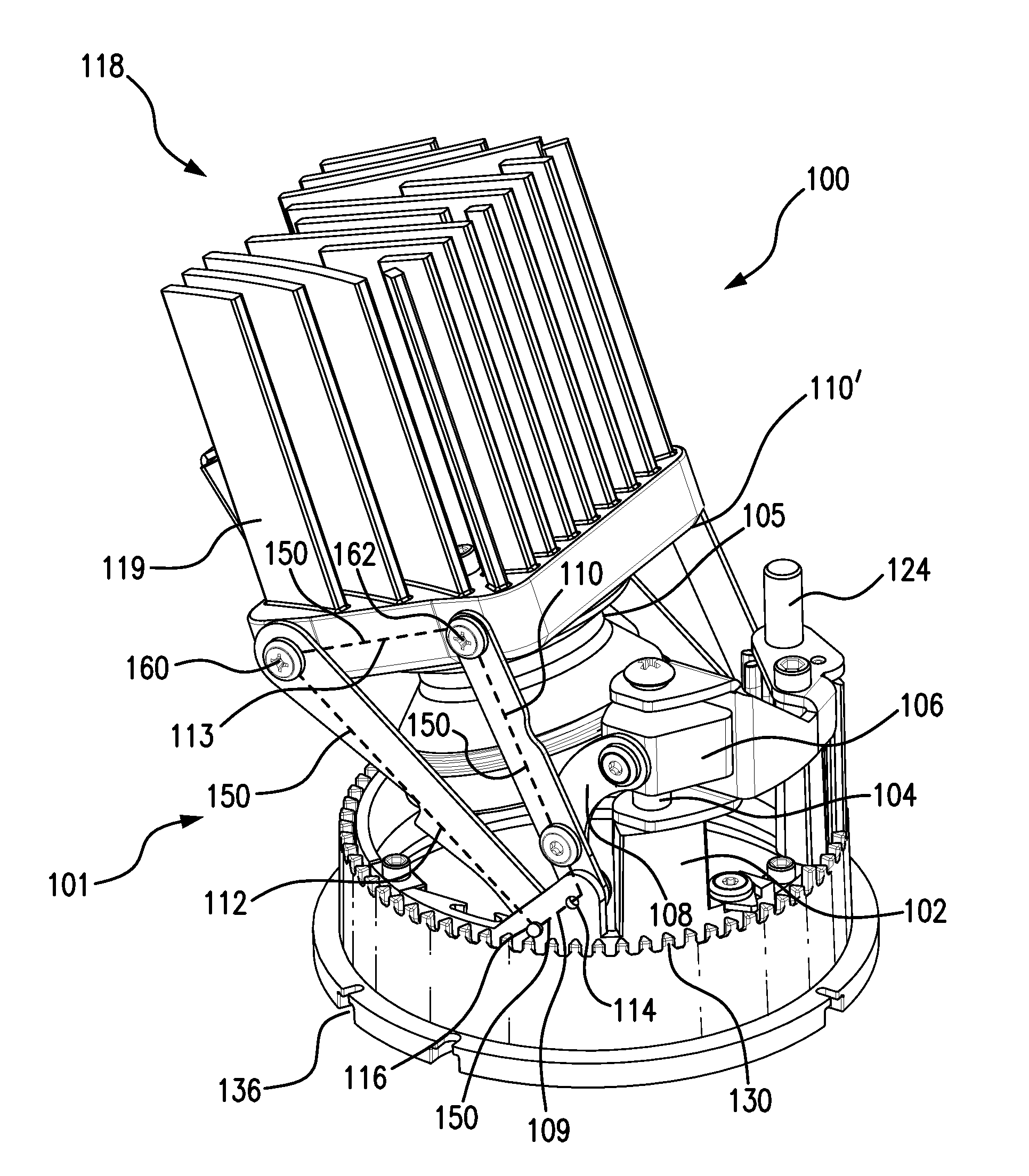

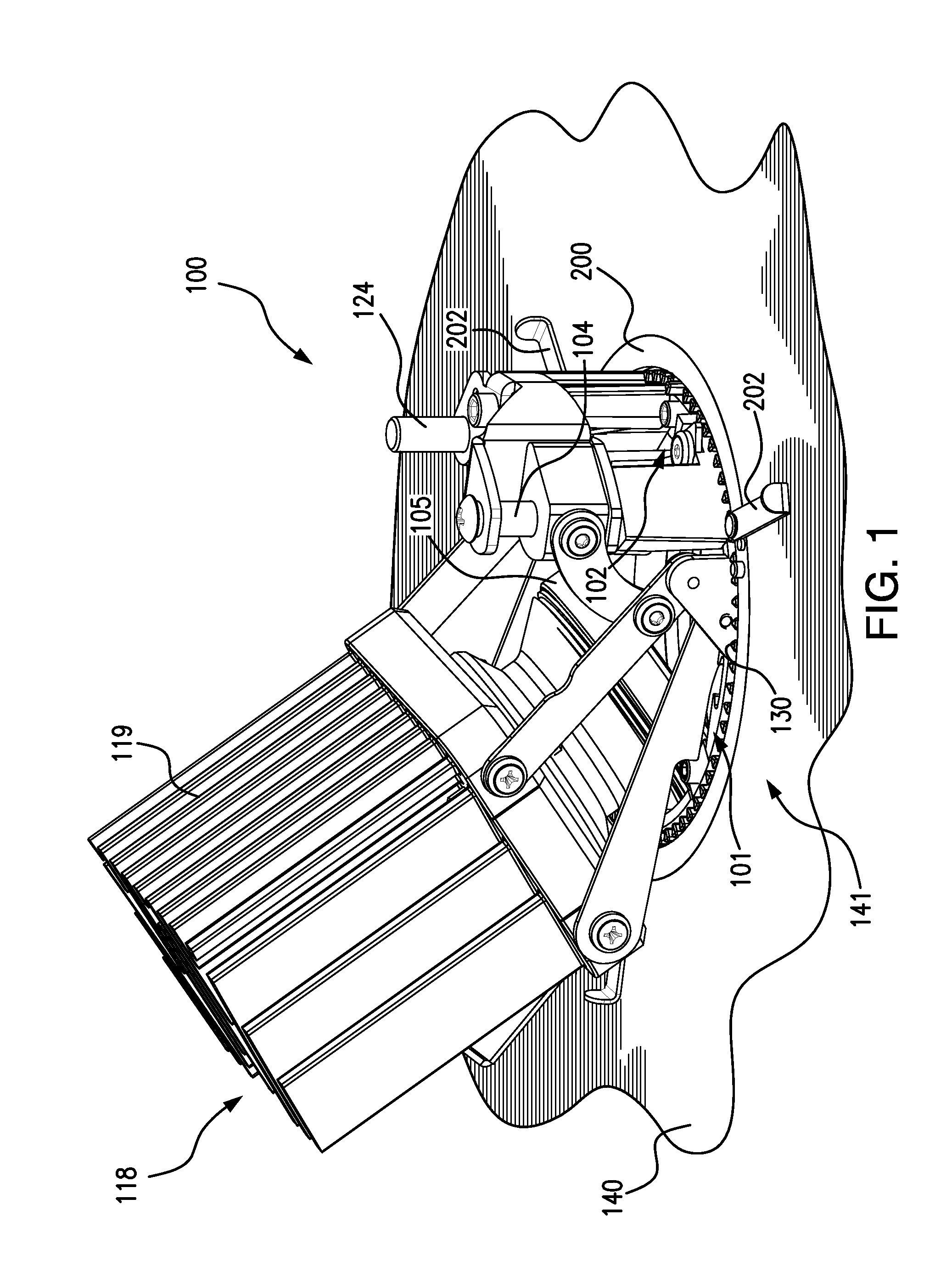

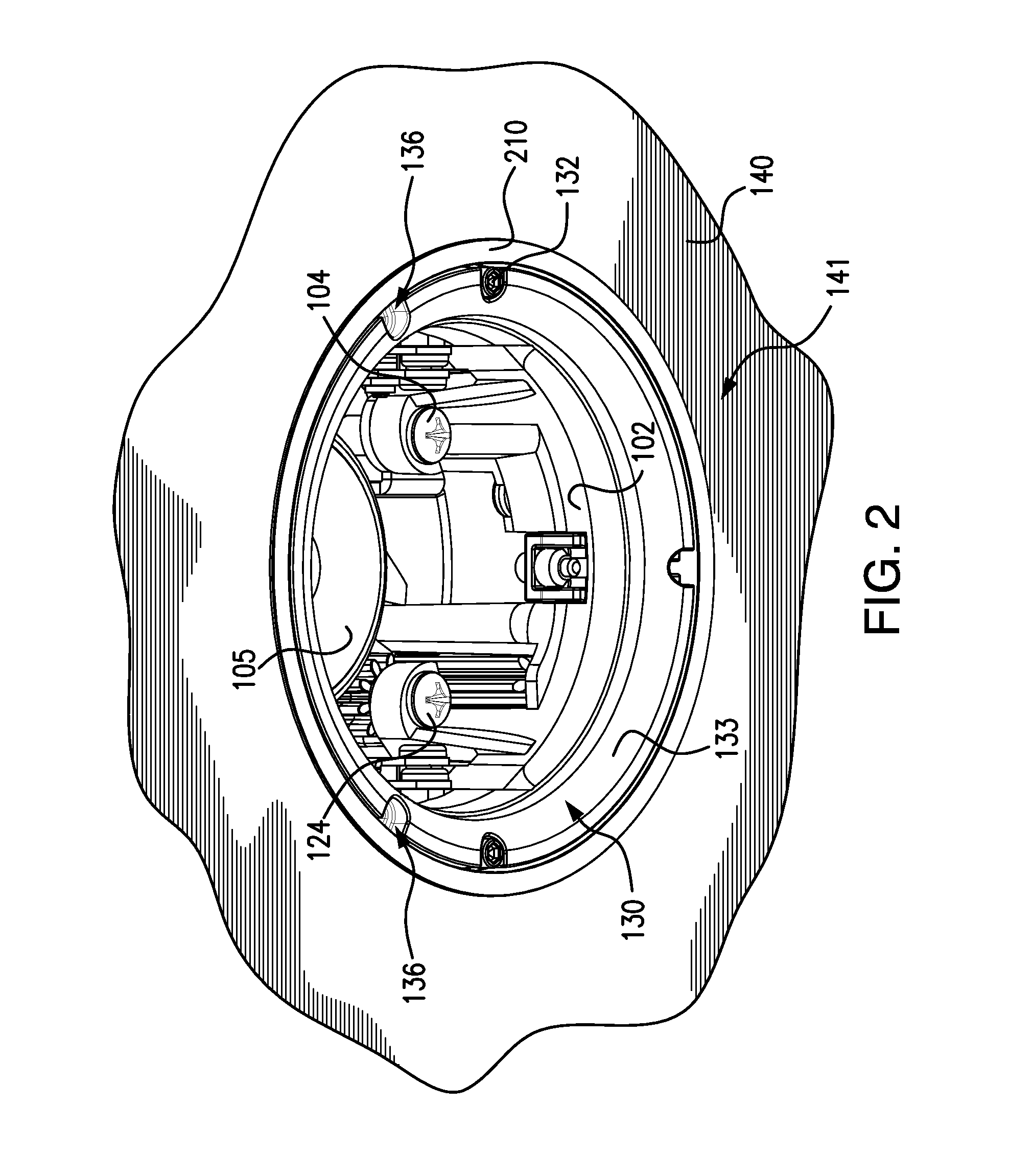

An adjustment mechanism for directional recessed luminaires includes a tilt adjustment screw 104 and rotation adjustment screw 124 supported in adjacent positions on a bearing ring 102, the screws being oriented vertically and conveniently accessible through an open center of the bearing ring. Follower 106 travels vertically on the tilt adjustment screw when rotated. Drive link 108 connected to both the follower and a four bar linkage (110), transfers force from the follower to the linkage when the tilt screw is rotated. The linkage pivots about anchor points 114,116 and is pivotally connected to lamp carrier frame 118 supporting light source 105. When the tilt adjustment screw is rotated, light source moves along a path (FIG. 6, 7) to aim the light beam. After aiming, the mechanism locks the light source into place. The mechanism is compact and the adjustment screws are easily accessible from beneath the mechanism.

Owner:ABL IP HLDG

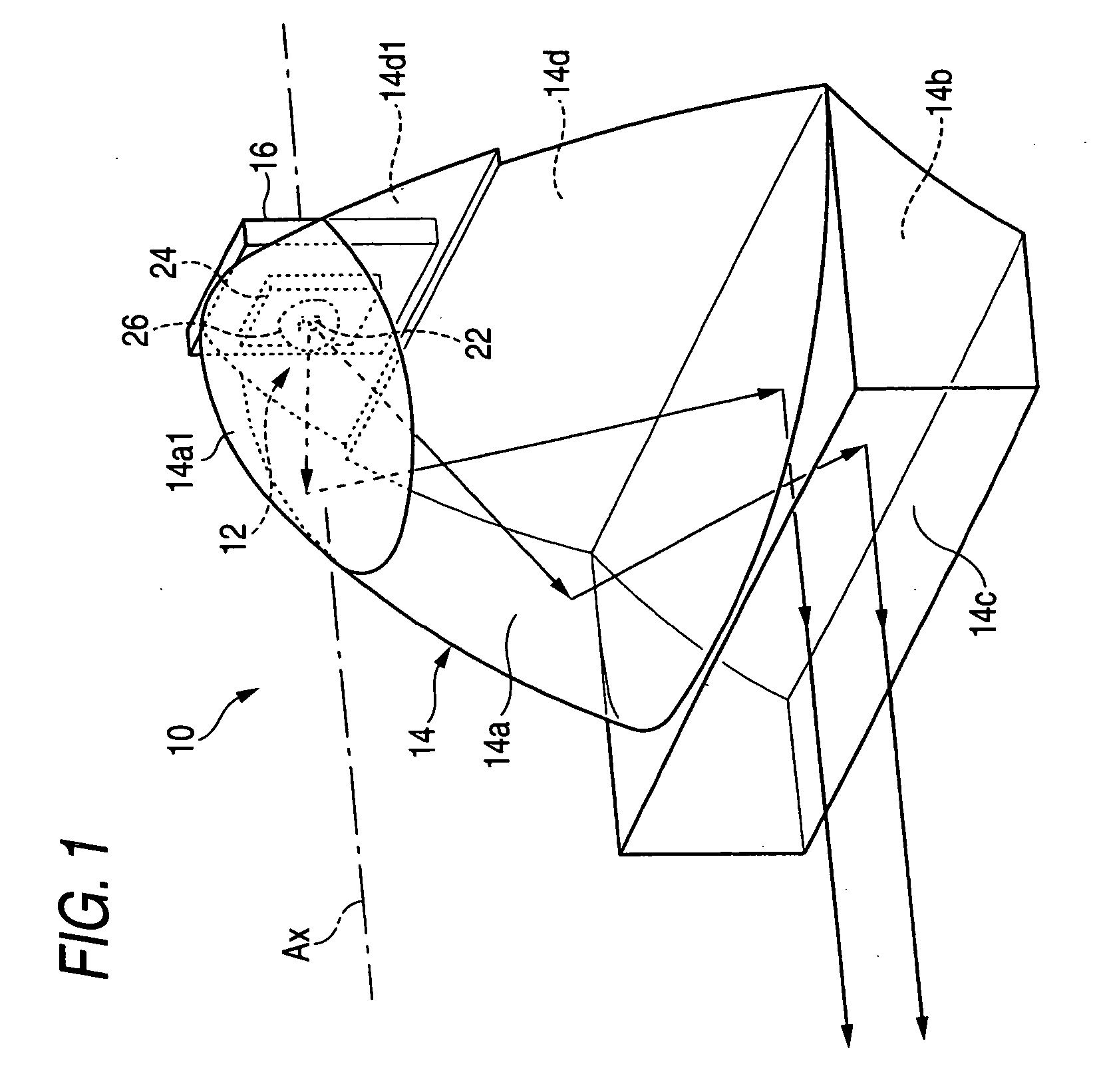

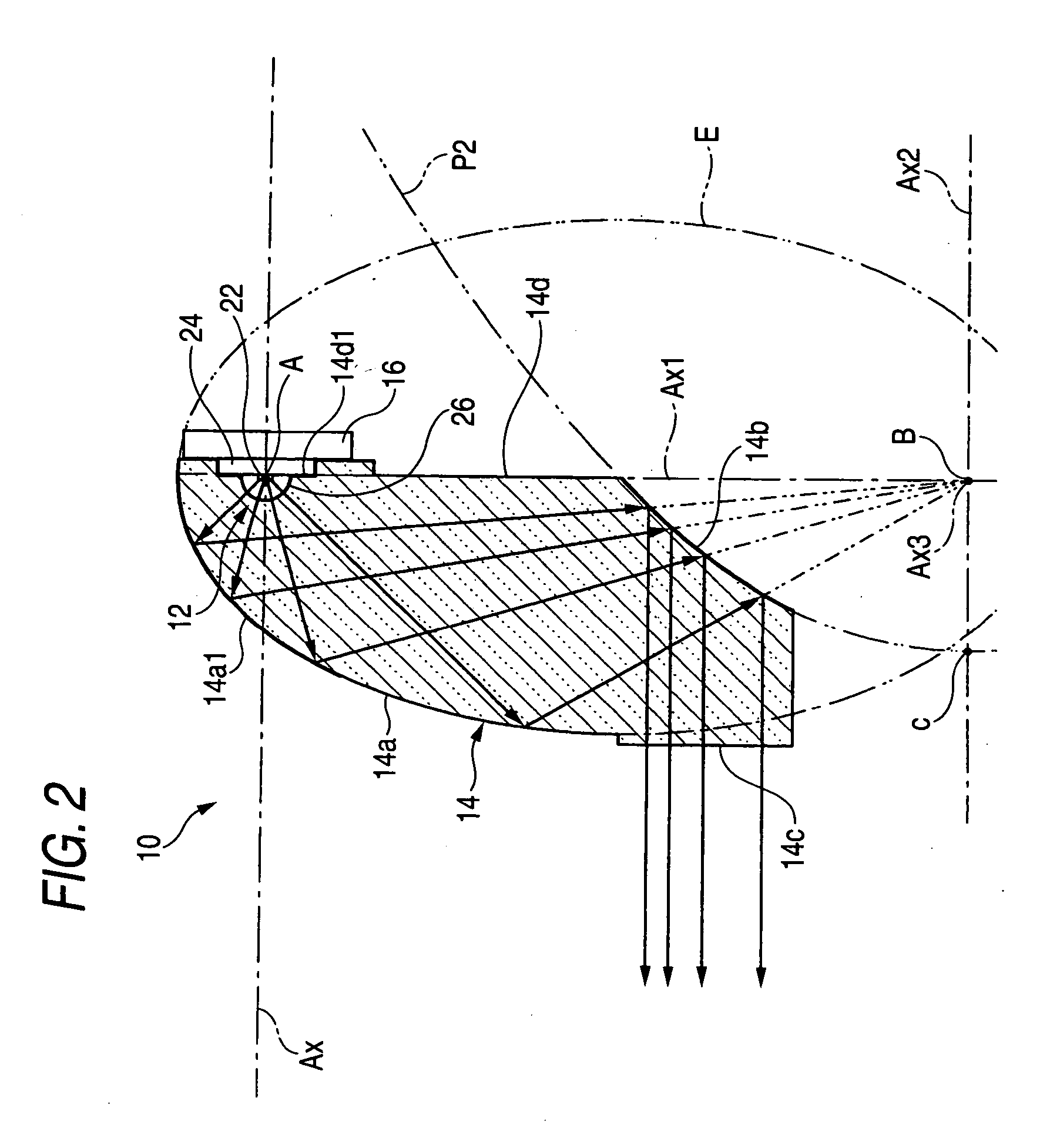

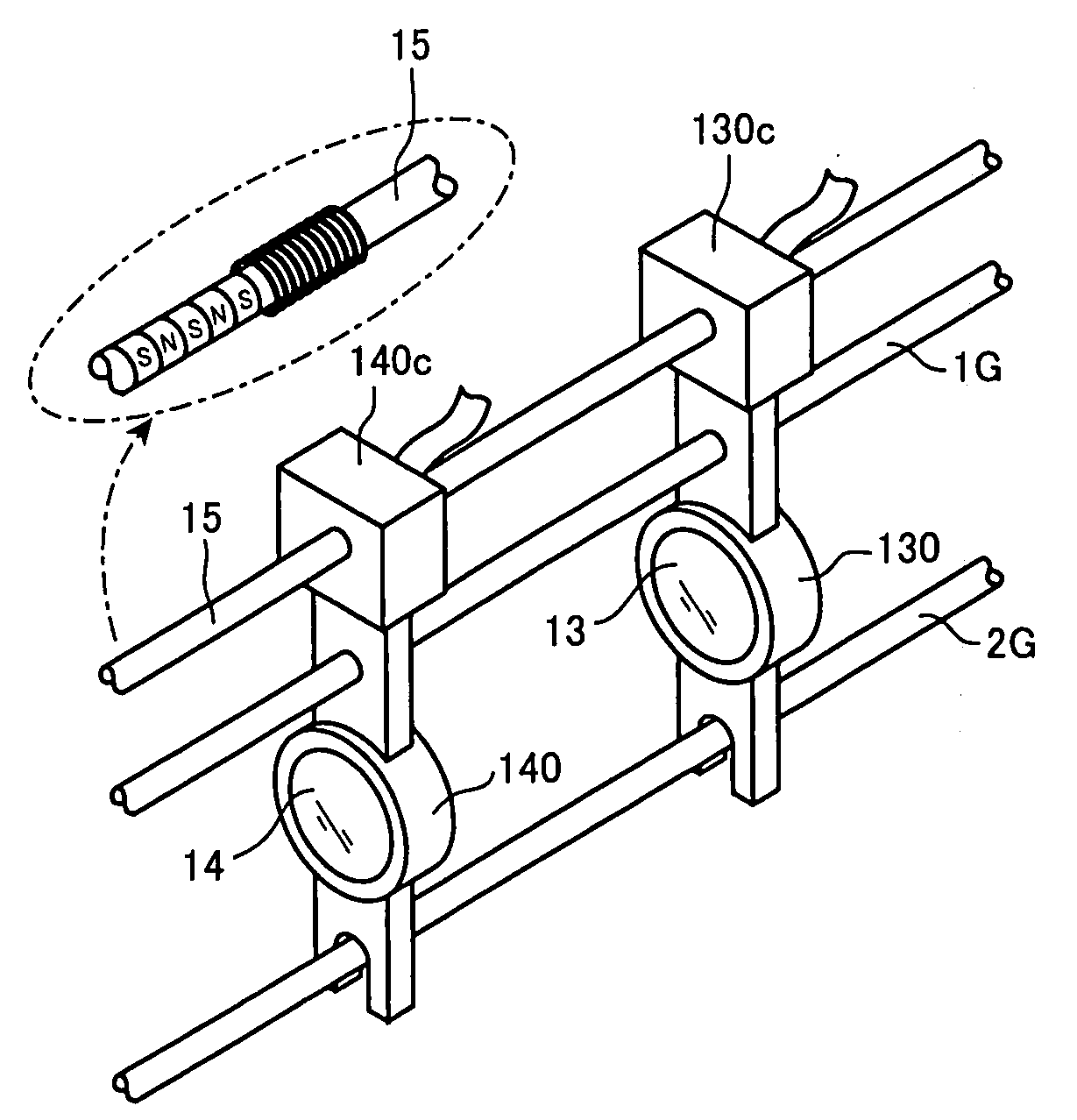

Lighting device for vehicle

InactiveUS20060285347A1Improve accuracyWell formedVehicle headlampsVehicle interior lightingOptical axisEllipse

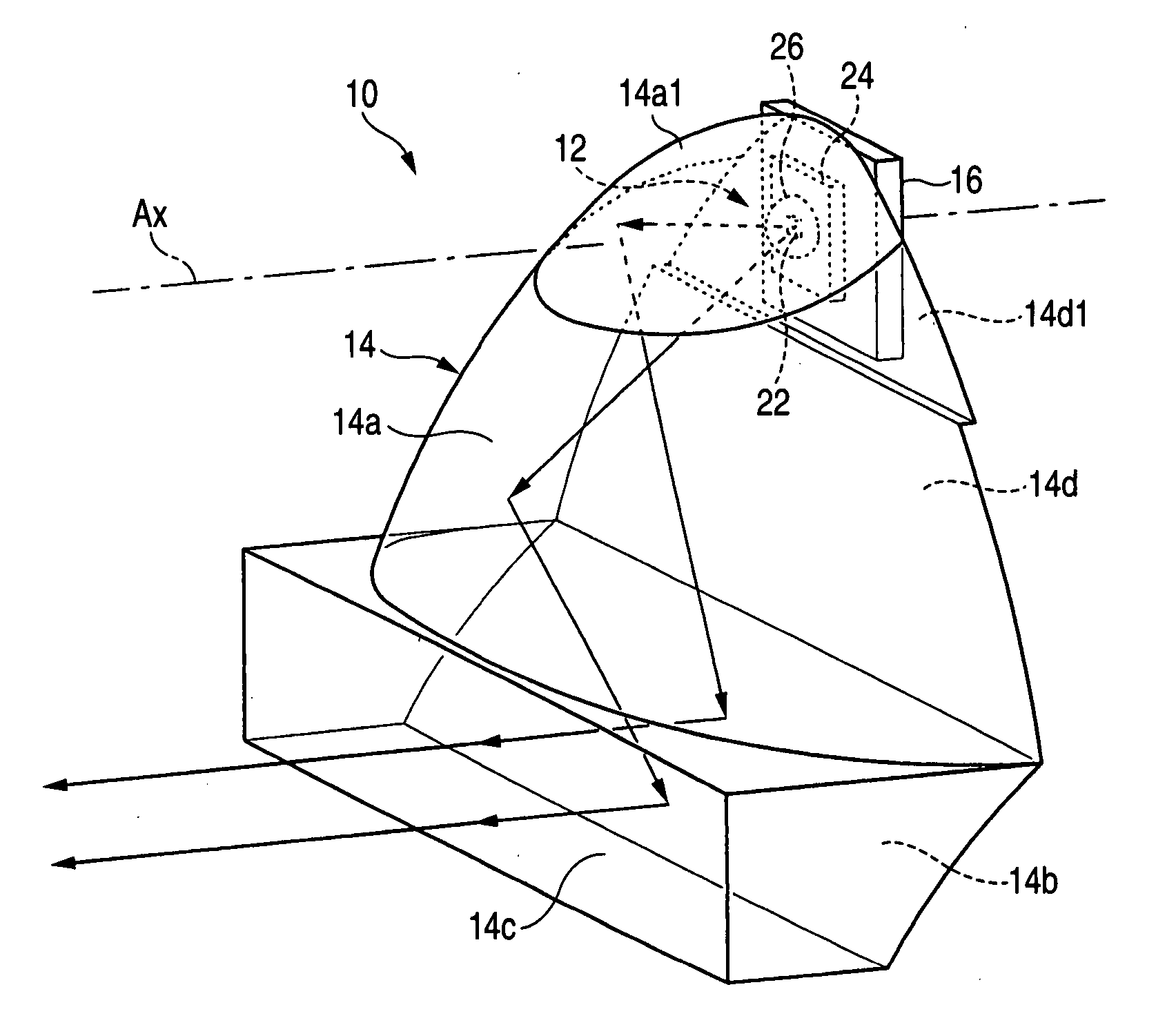

A first reflection surface reflects light from the light-emitting element disposed on an optical axis Ax extending in the forward and backward direction of the lighting device downward, and the light is reflected in the forward direction by the second reflection surface. A cross-sectional shape taken along a vertical surface including the optical axis Ax is an ellipse E having a light-emitting center A of the light-emitting element as a first focus, and an axis line Ax1 orthogonal to the optical axis Ax as a major axis. In addition, the second reflection surface is disposed between the first focus A and the second focus B of the ellipse E. A cross-sectional shape of the second reflection surface taken along the predetermined plane is the parabola P2 having the second focus B as its focus, and the point C located ahead of the focus B as its fixed point. In this way, as the light reflected by the first reflection surface 14a is incident on the second reflection surface 14b before being converged at the second focus B, the lighting device can be made thin.

Owner:KOITO MFG CO LTD

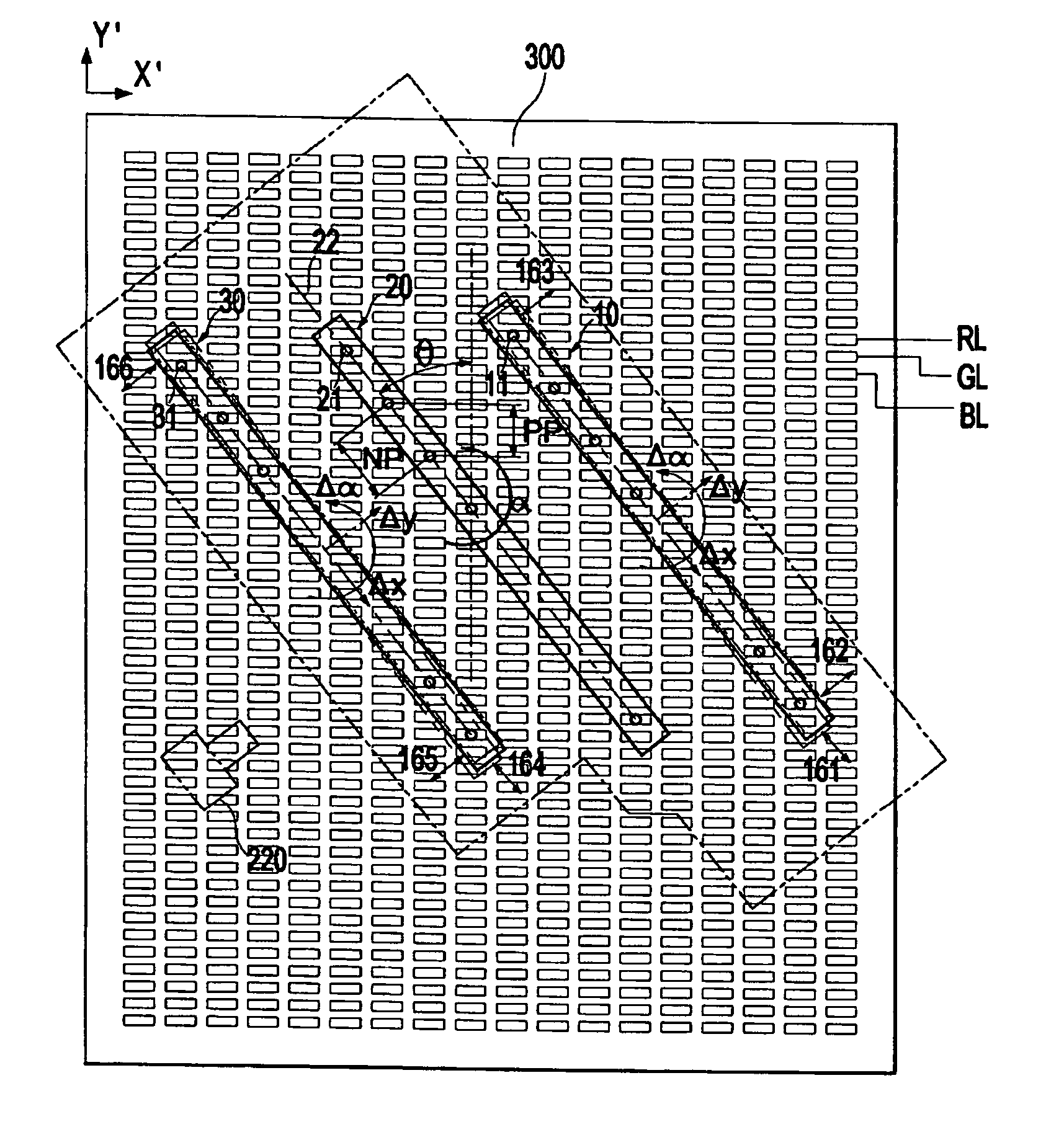

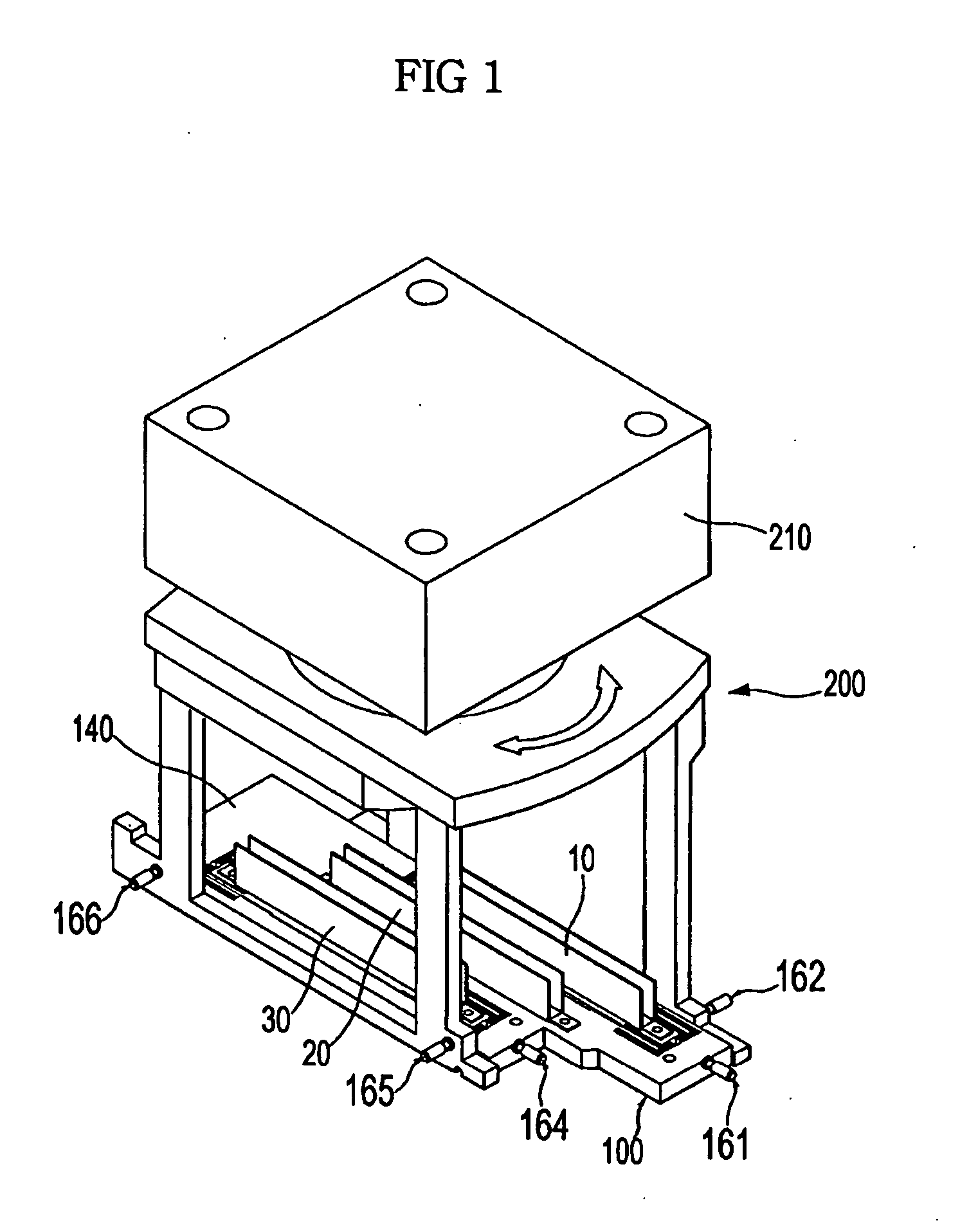

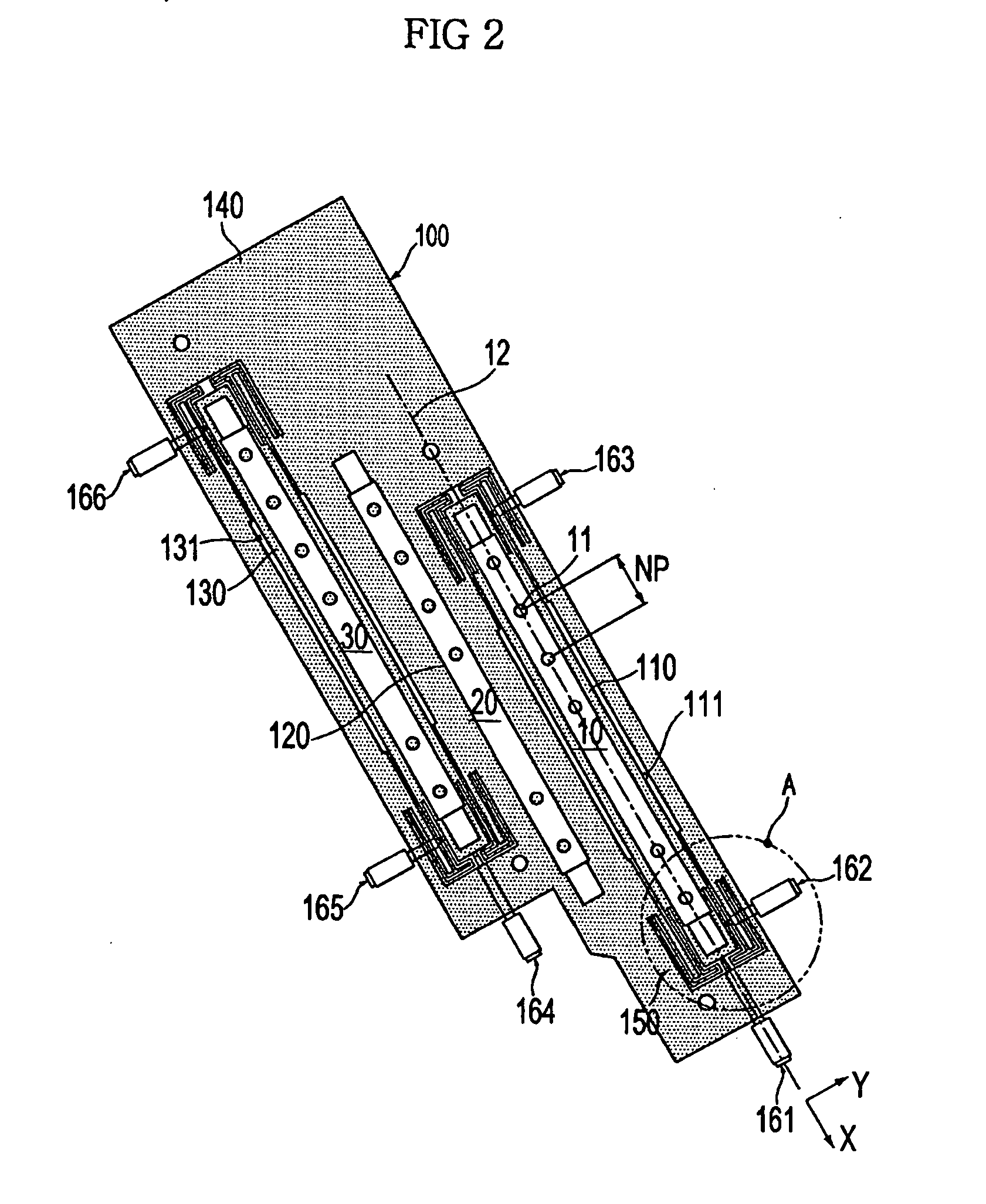

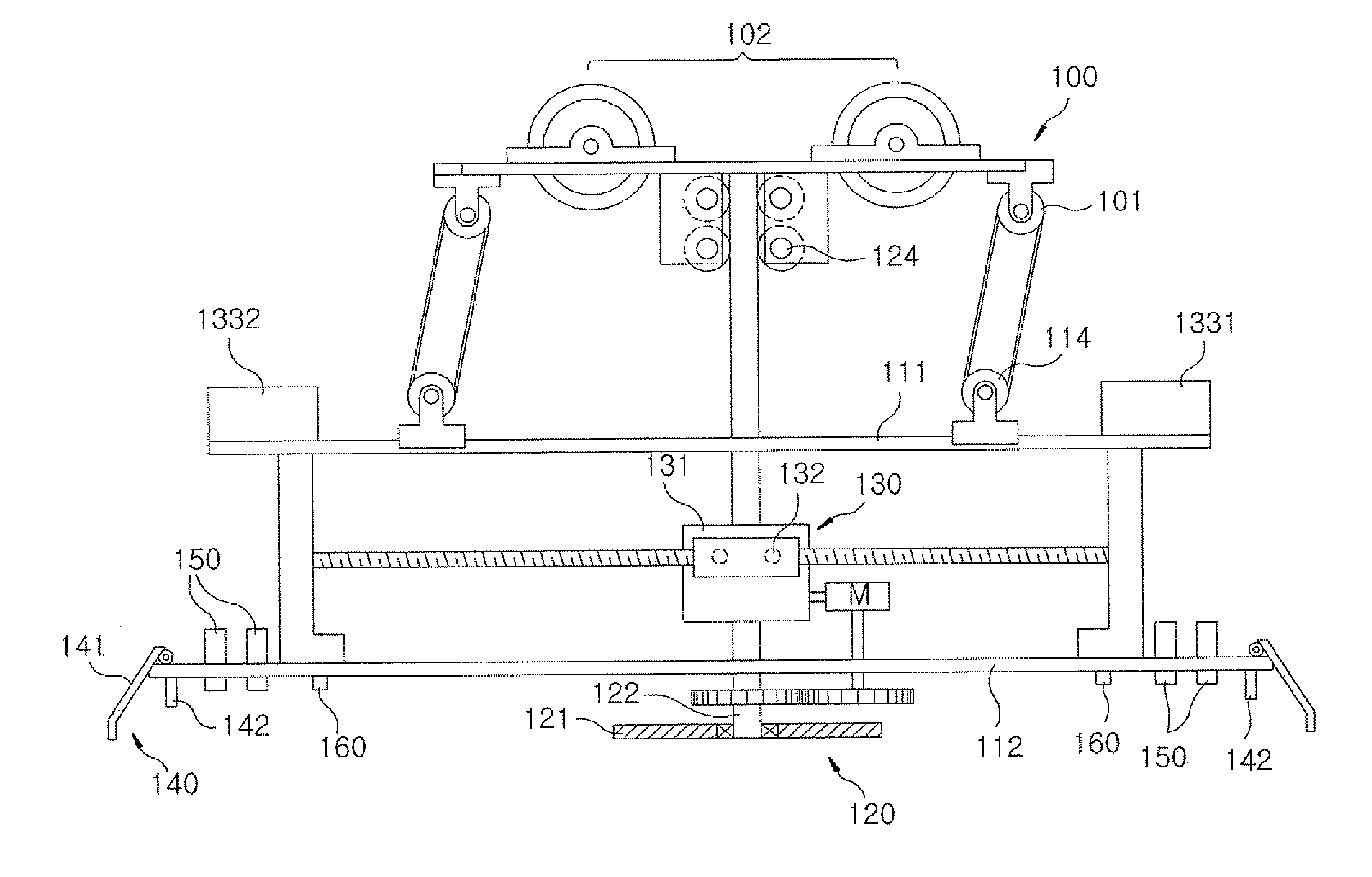

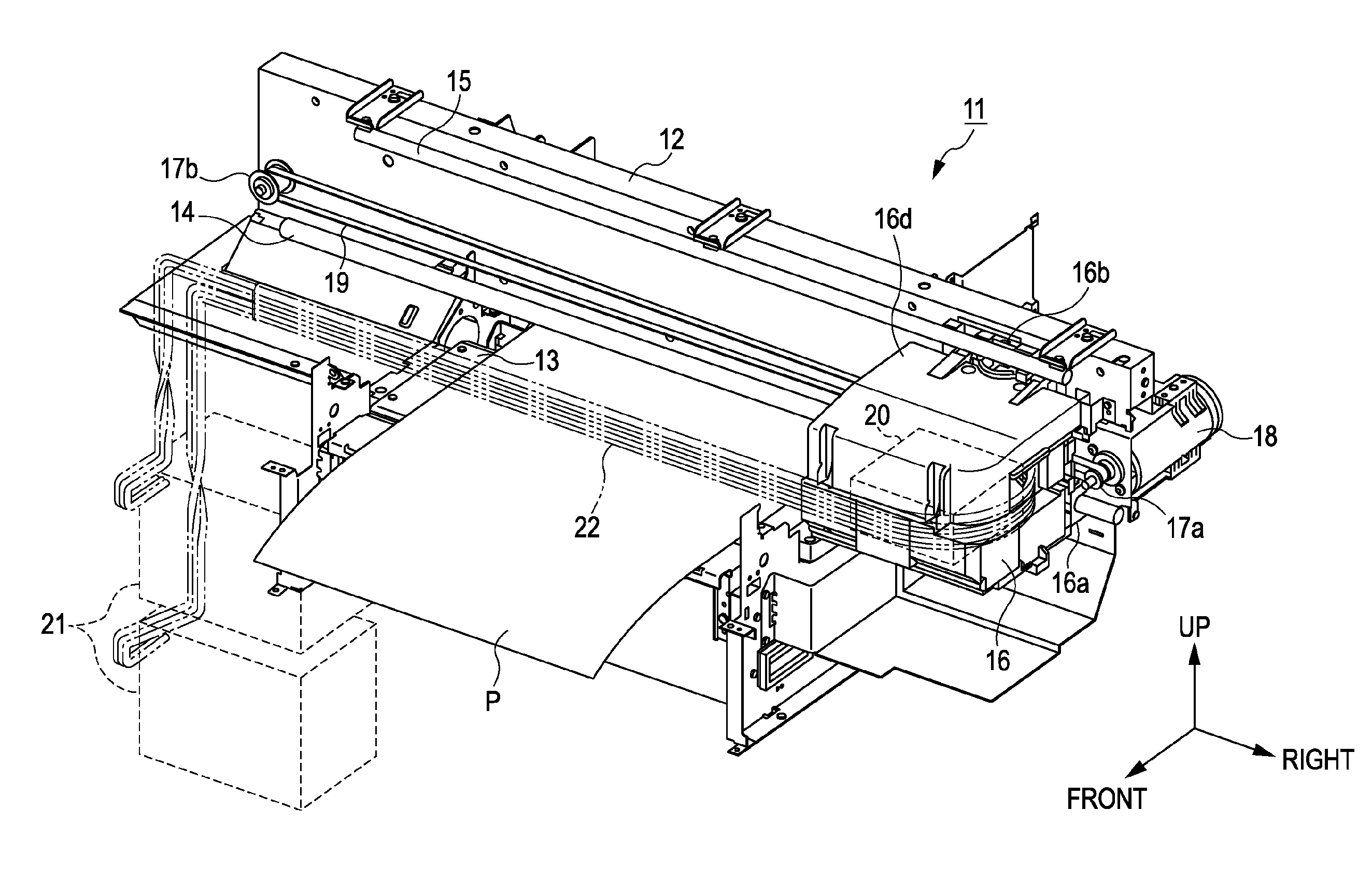

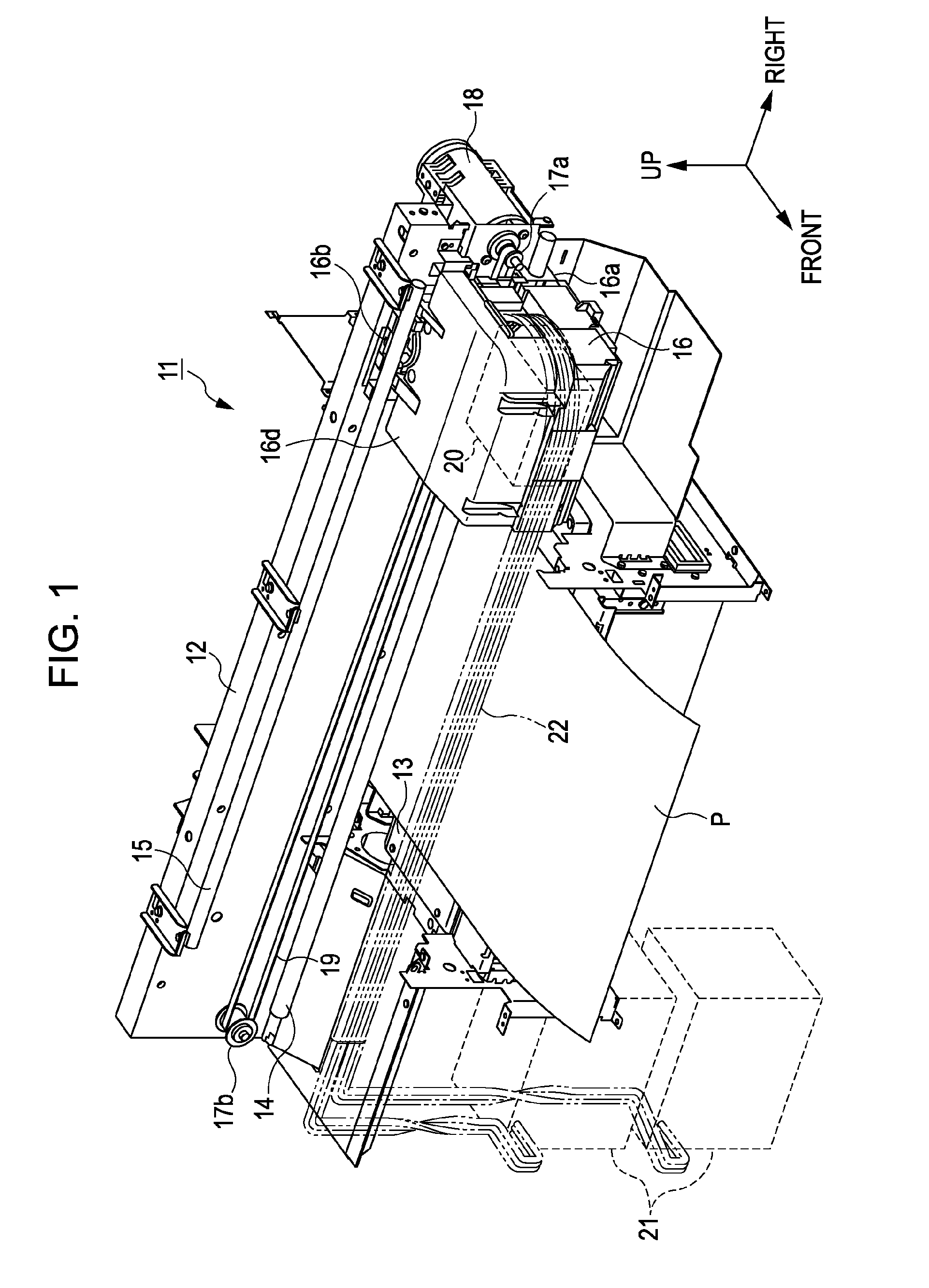

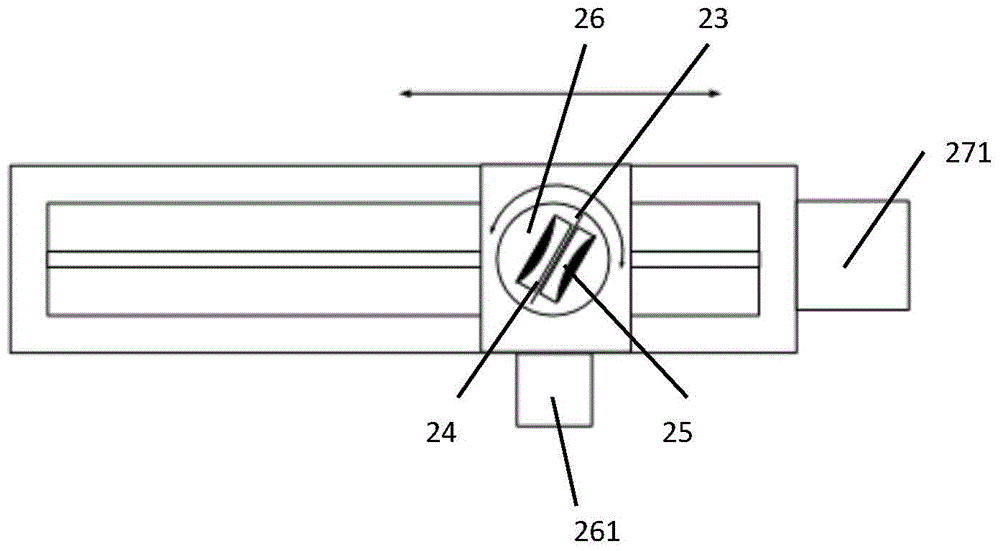

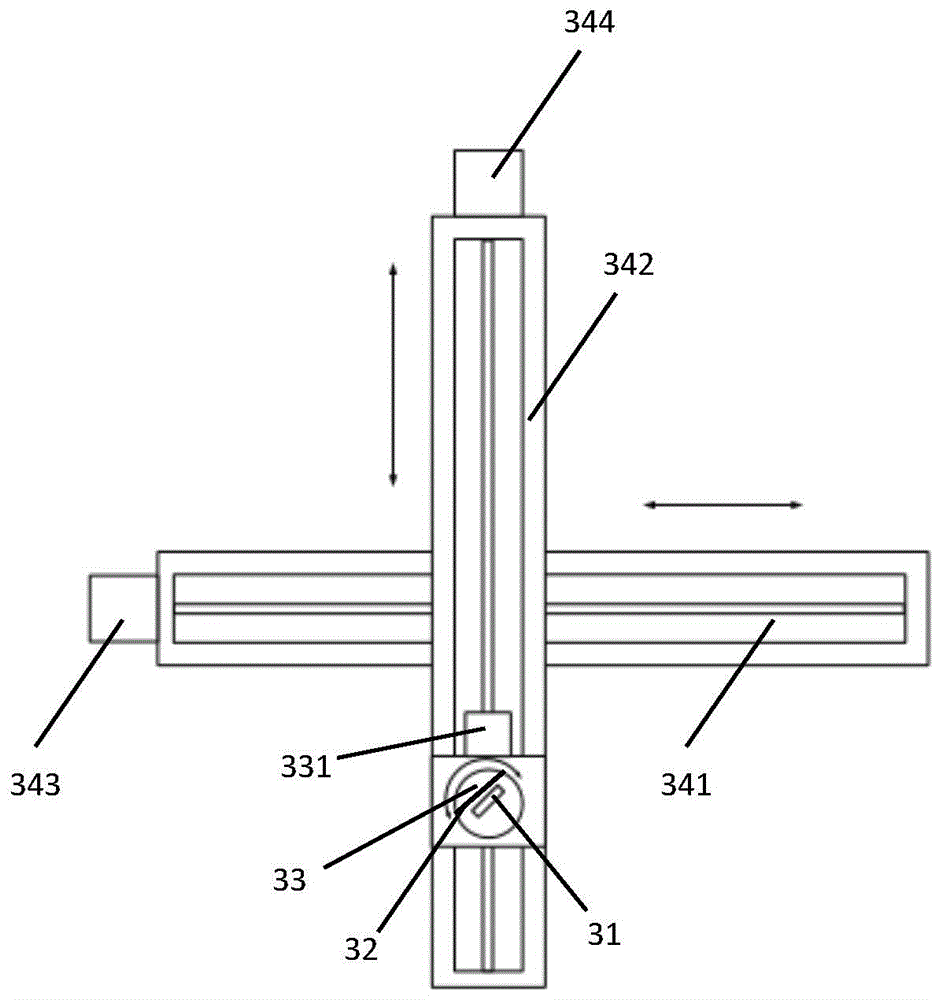

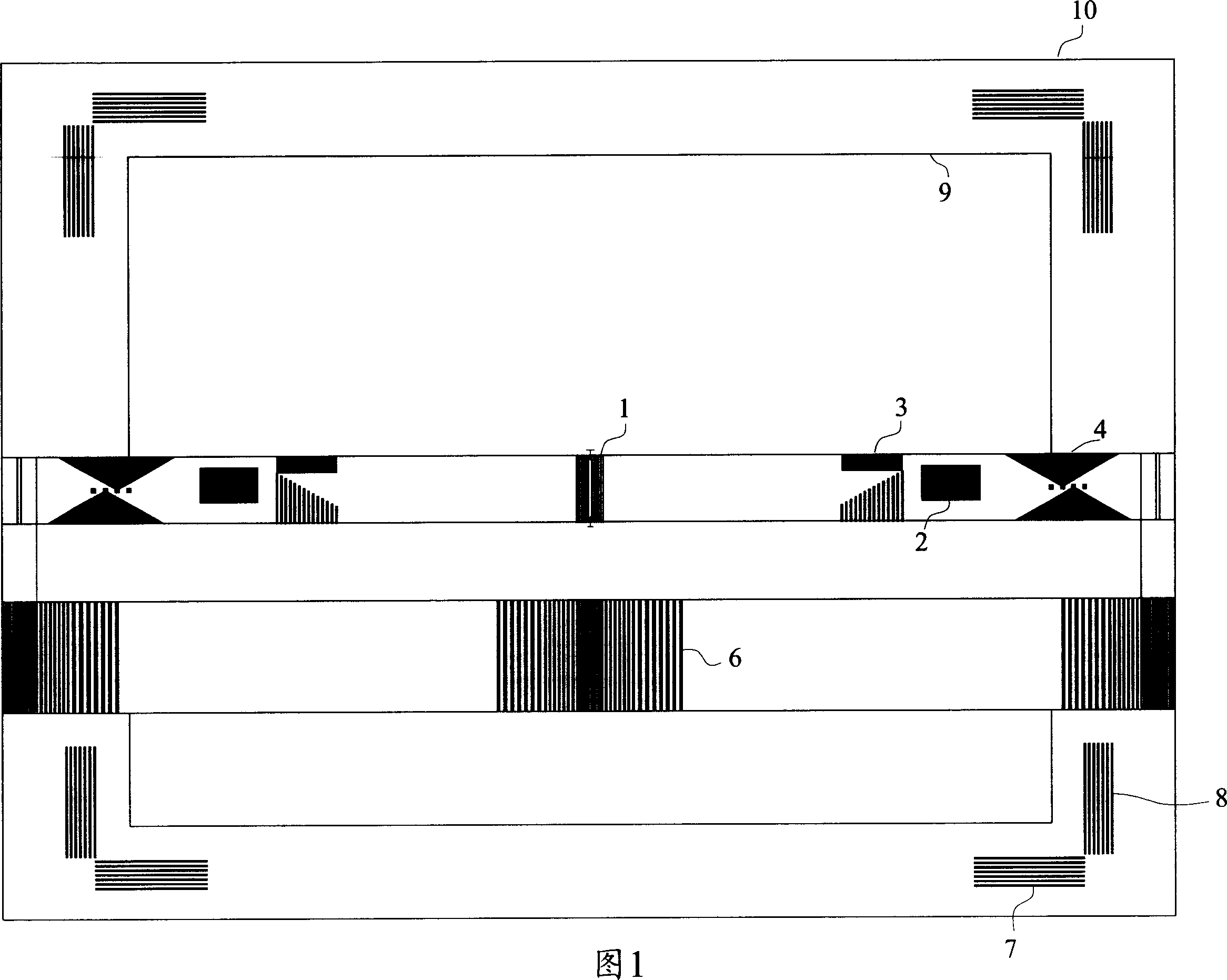

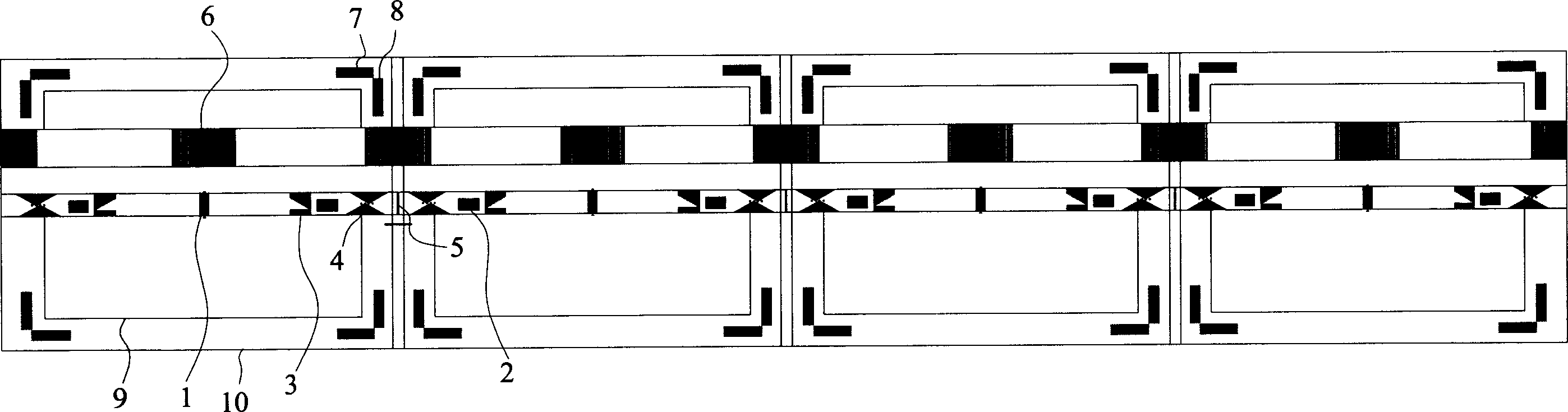

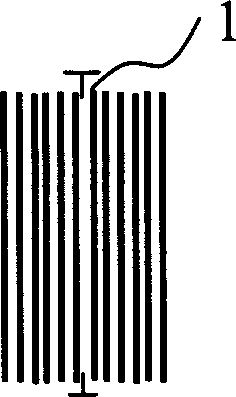

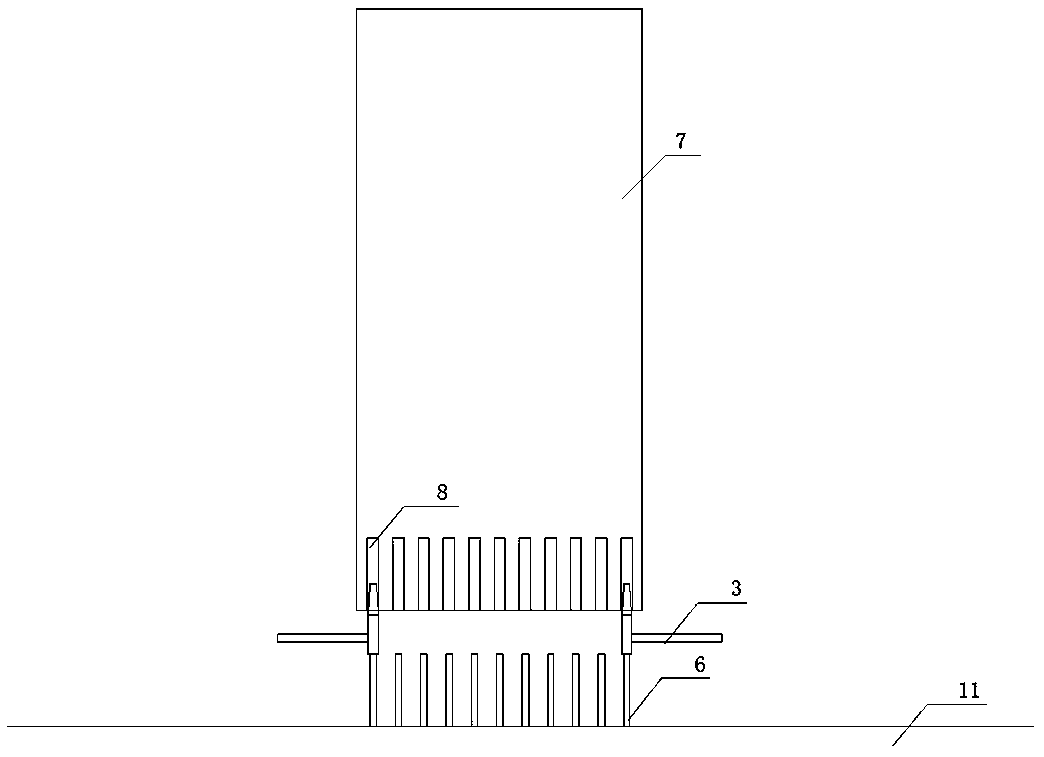

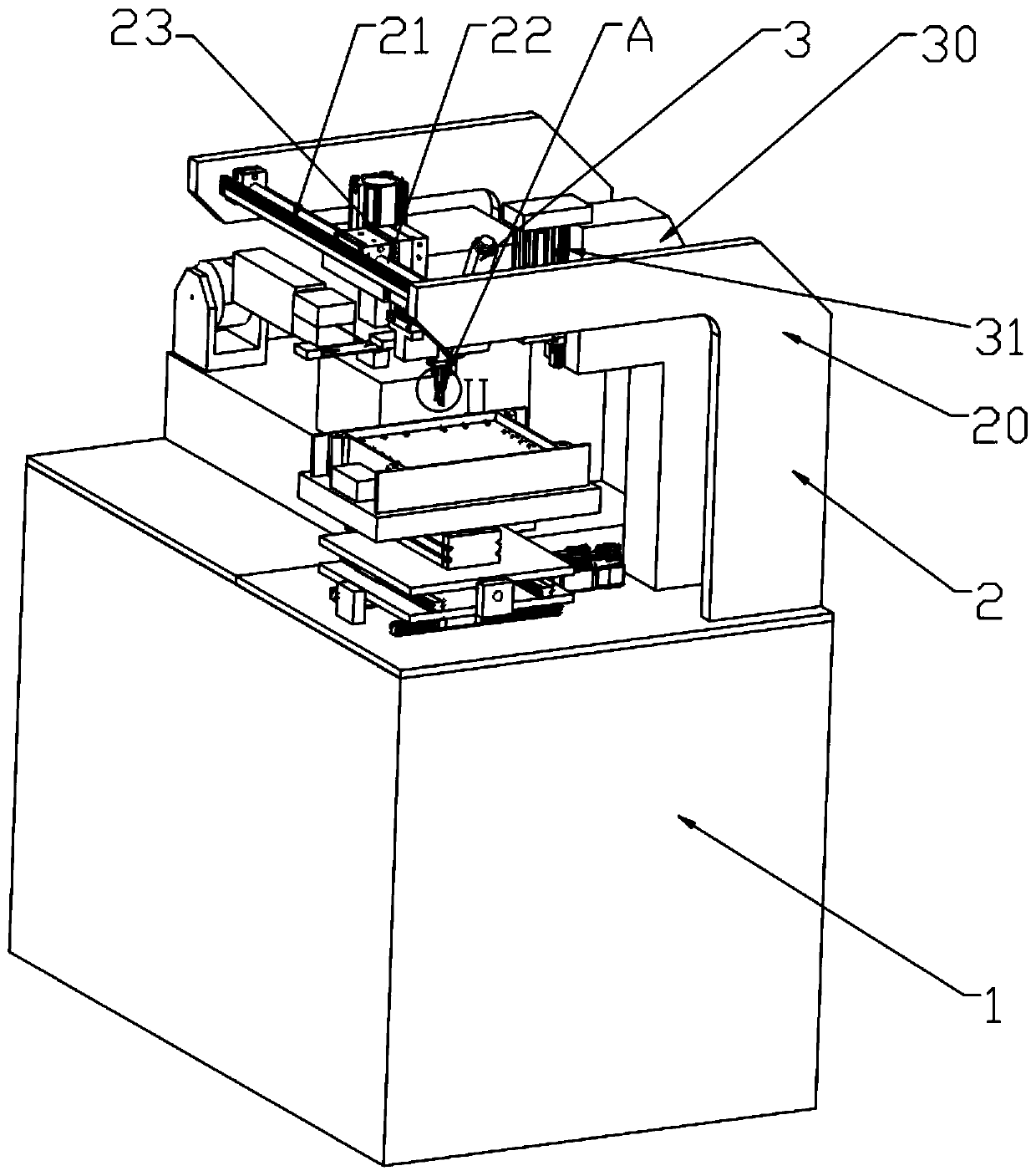

Ink-jet head mount and ink-jet printing apparatus using the same

InactiveUS20060077225A1Accurate adjustment positionInking apparatusPower drive mechanismsThree degrees of freedomEngineering

An ink-jet head mount to guide positions of ink-jet heads with a high precision and an ink-jet printing apparatus including the same. The ink-jet printing apparatus includes an ink-jet head having a plurality of nozzles to eject ink, an ink-jet head mount in which the ink-jet head is installed and is movable according to three-degrees-of-freedom, and a frame in which the ink-jet head mount is installed.

Owner:SAMSUNG ELECTRONICS CO LTD

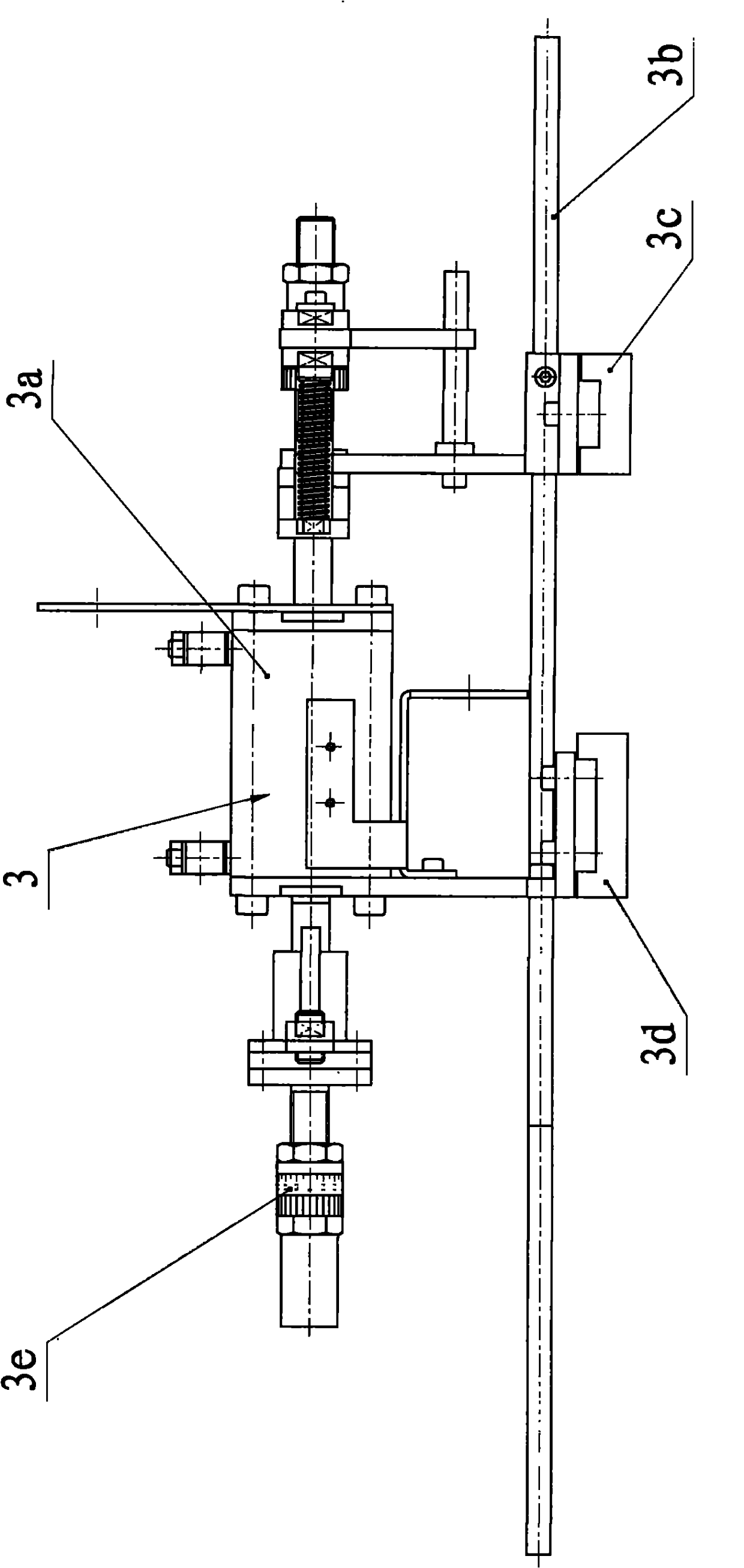

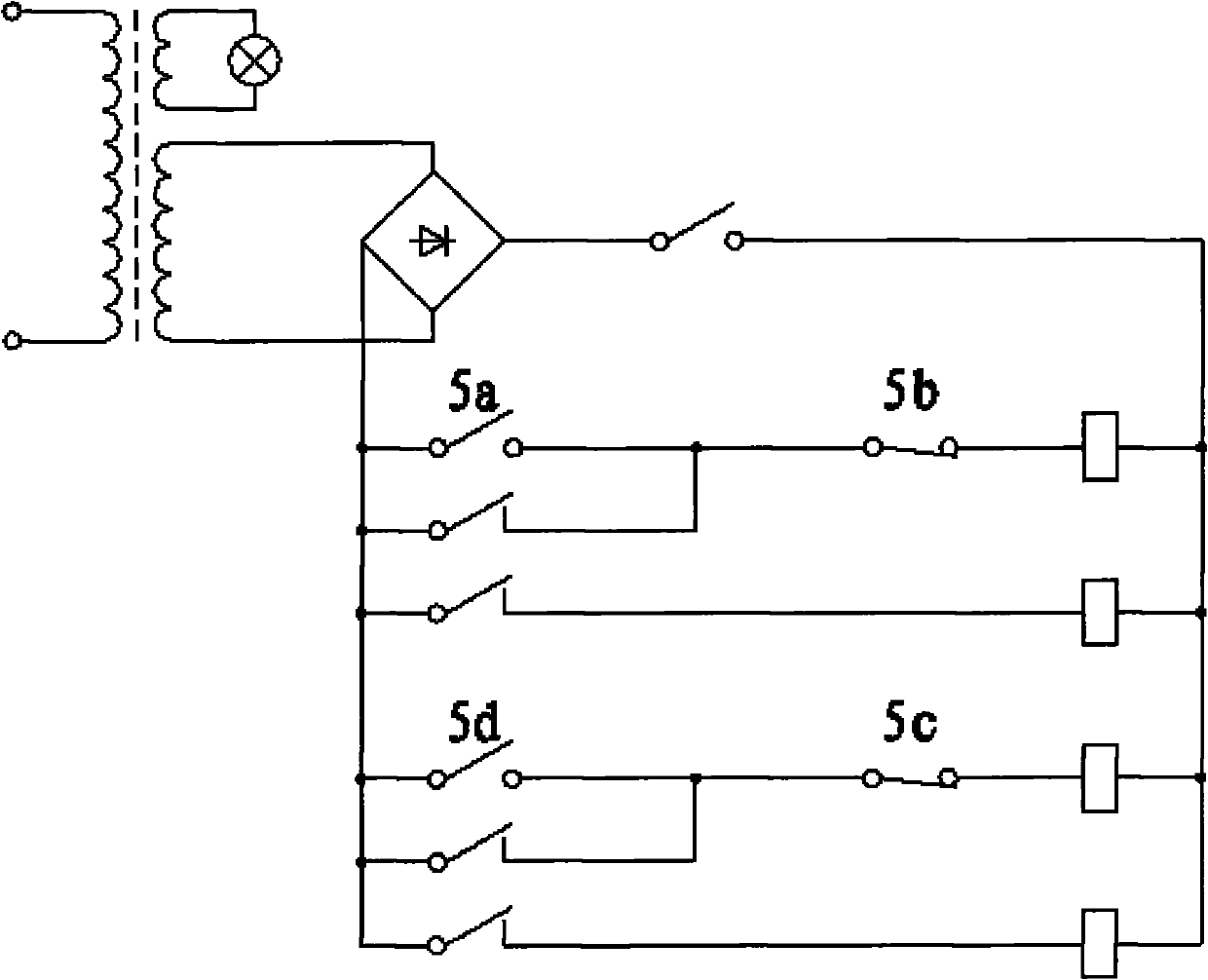

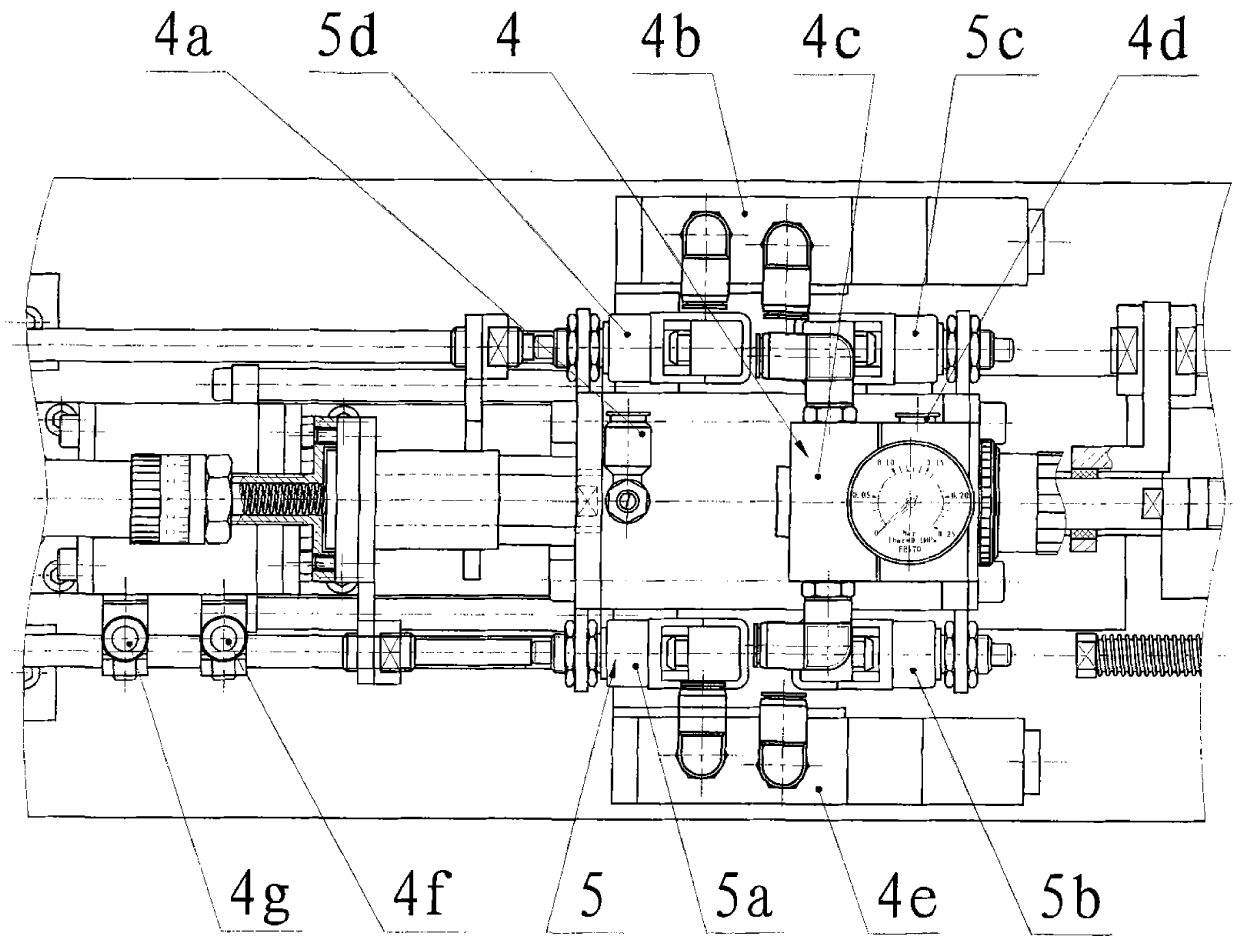

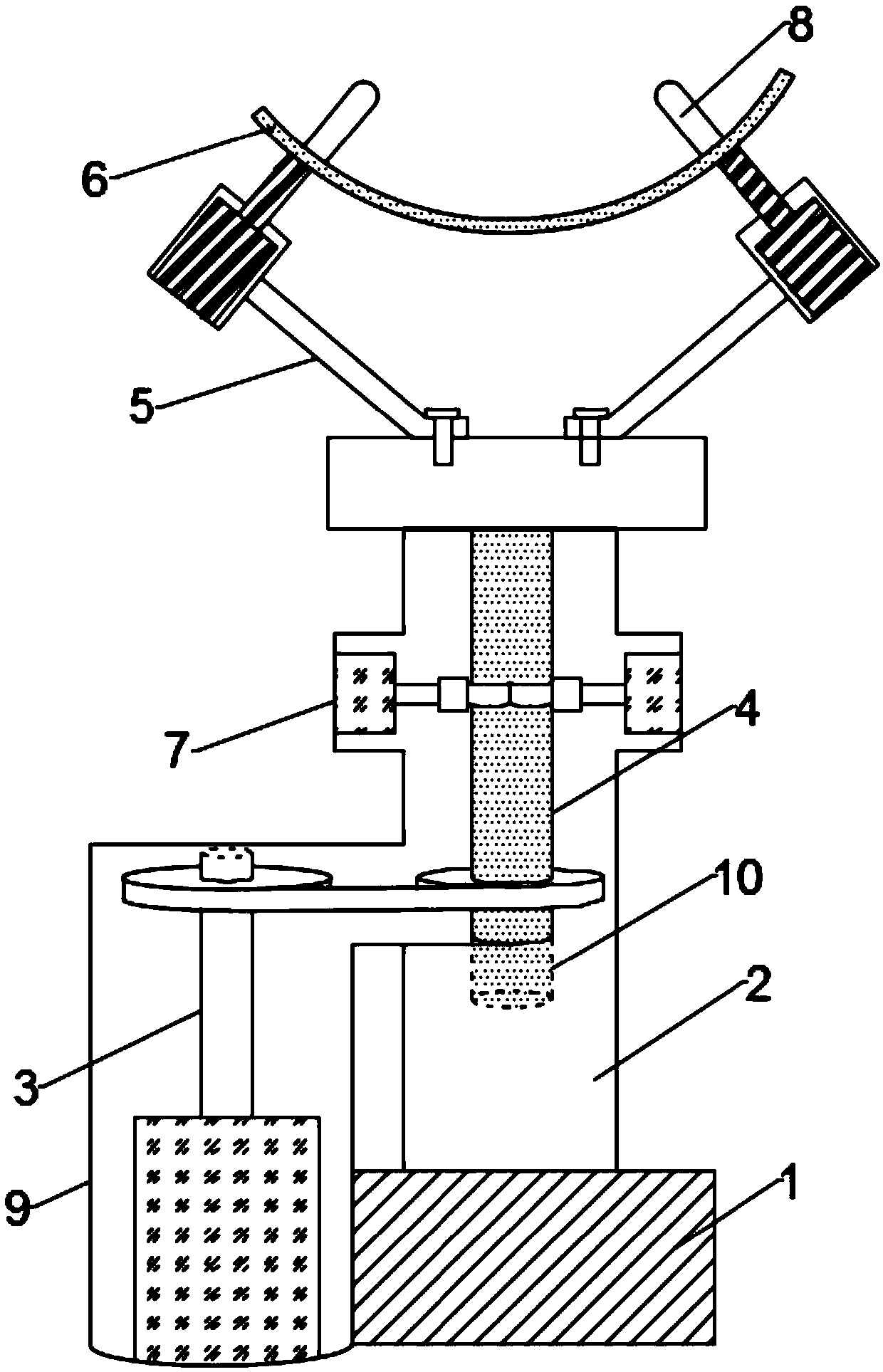

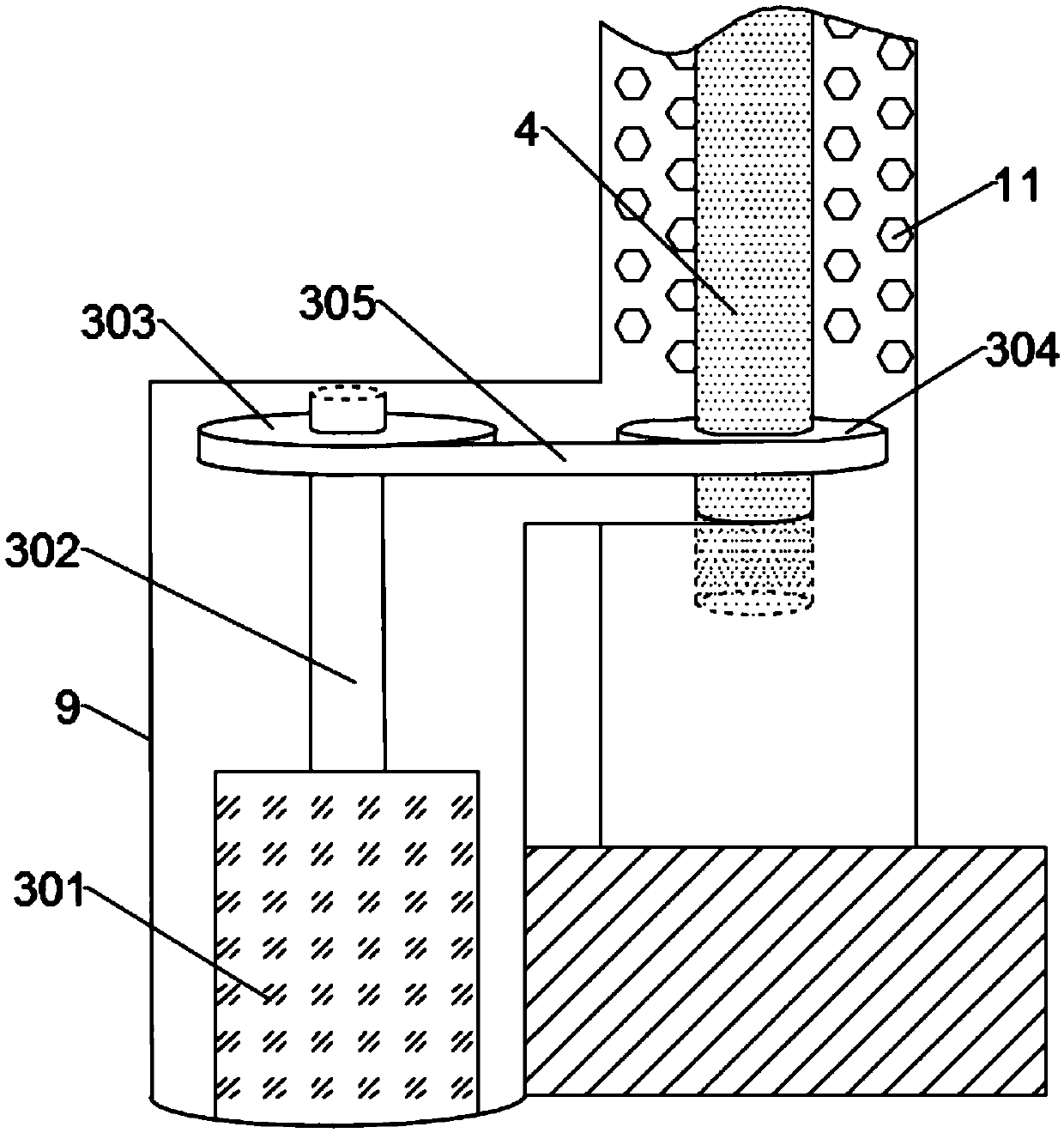

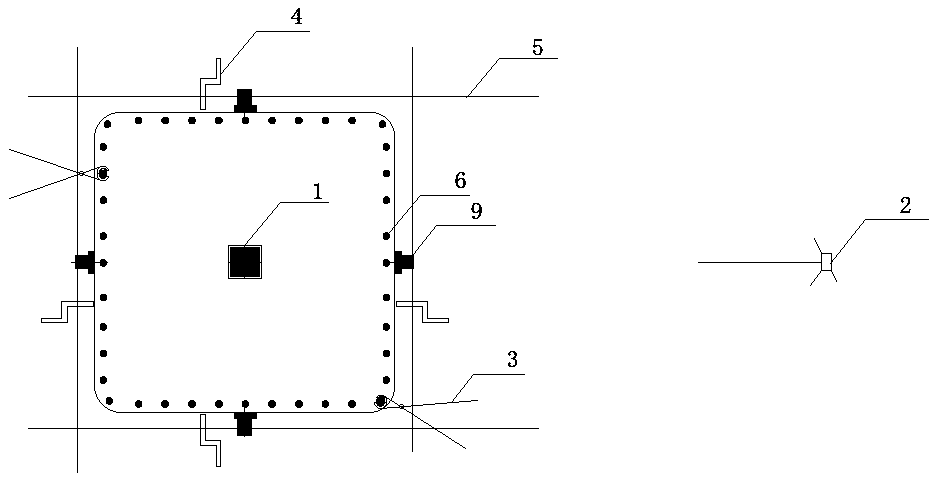

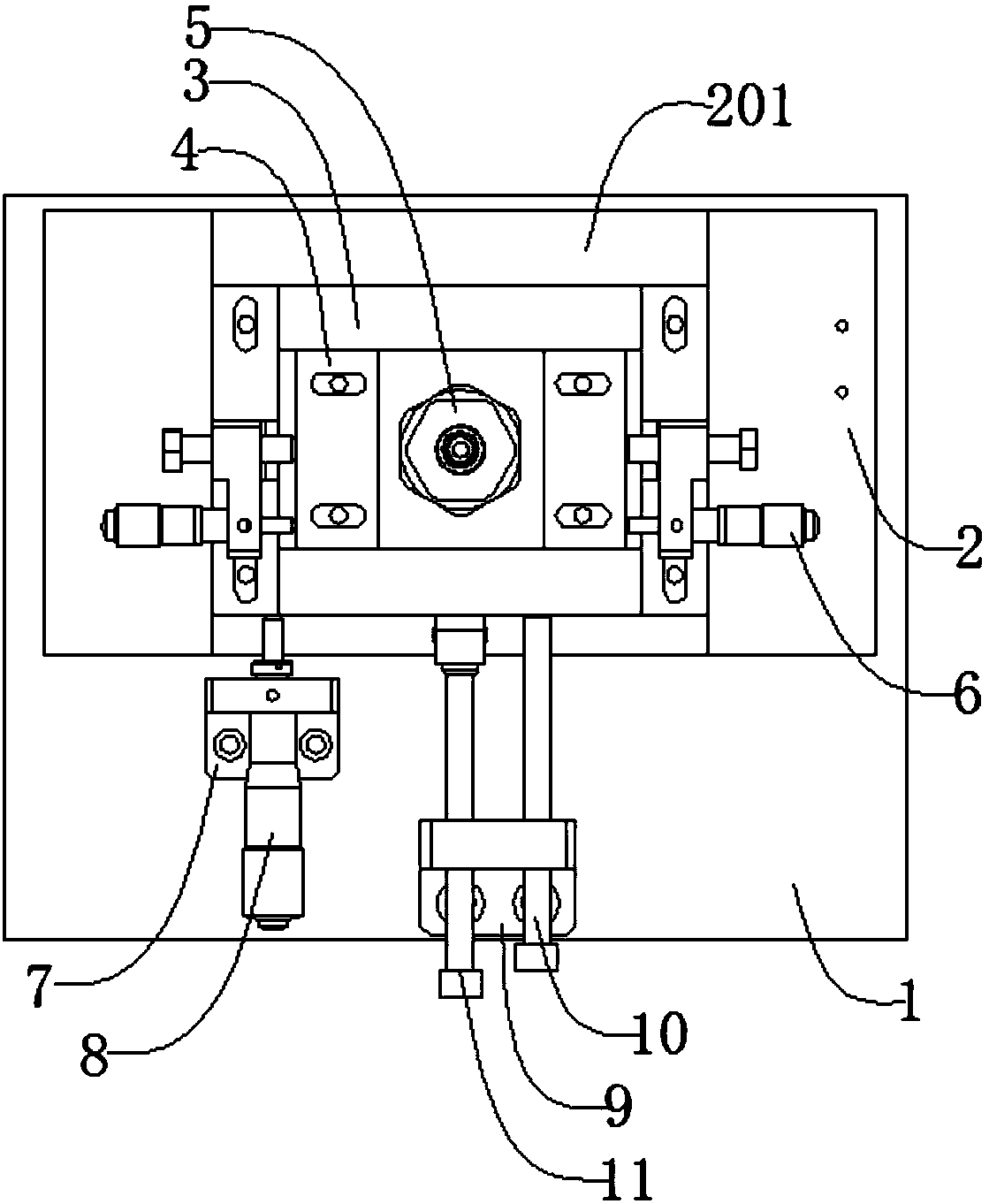

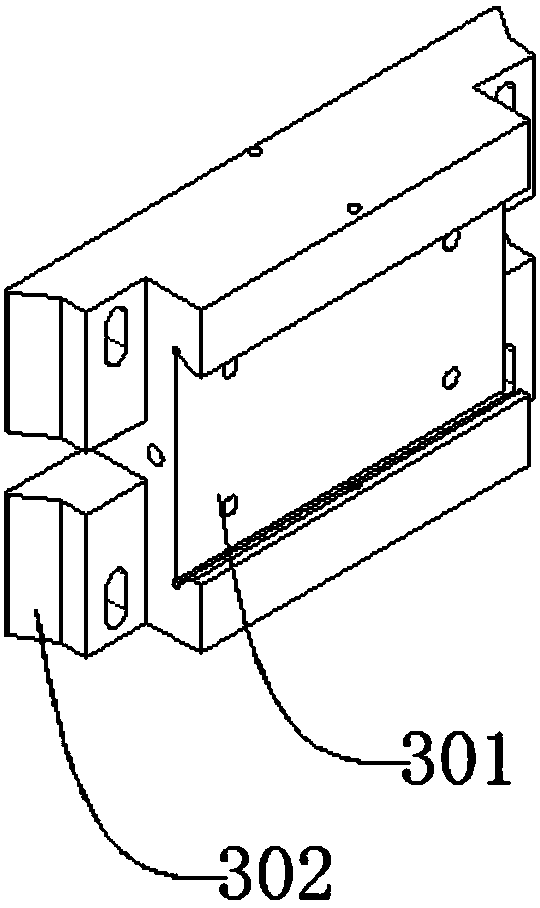

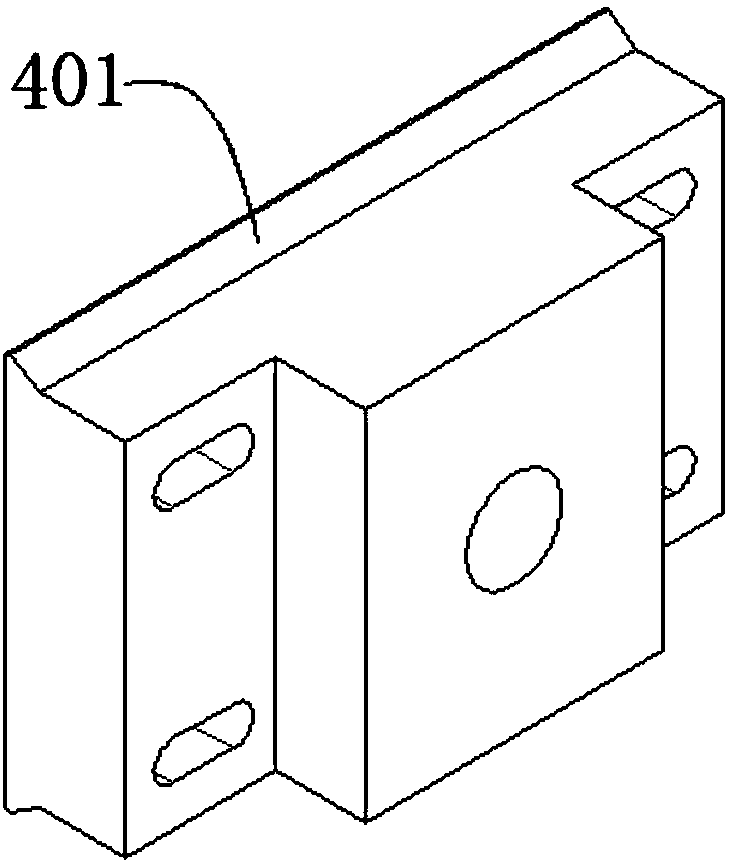

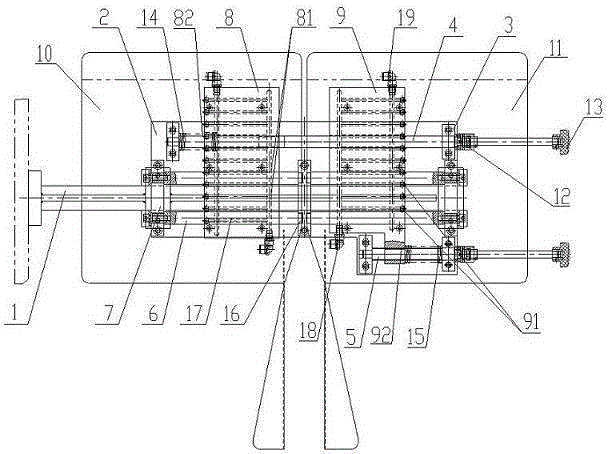

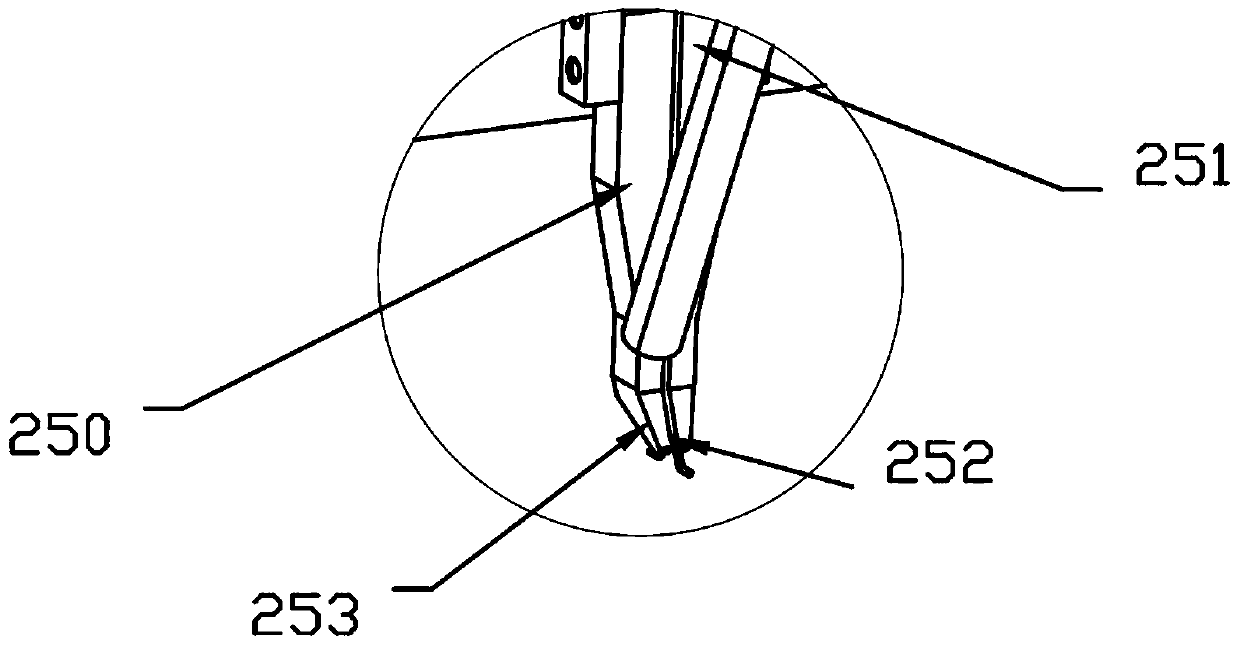

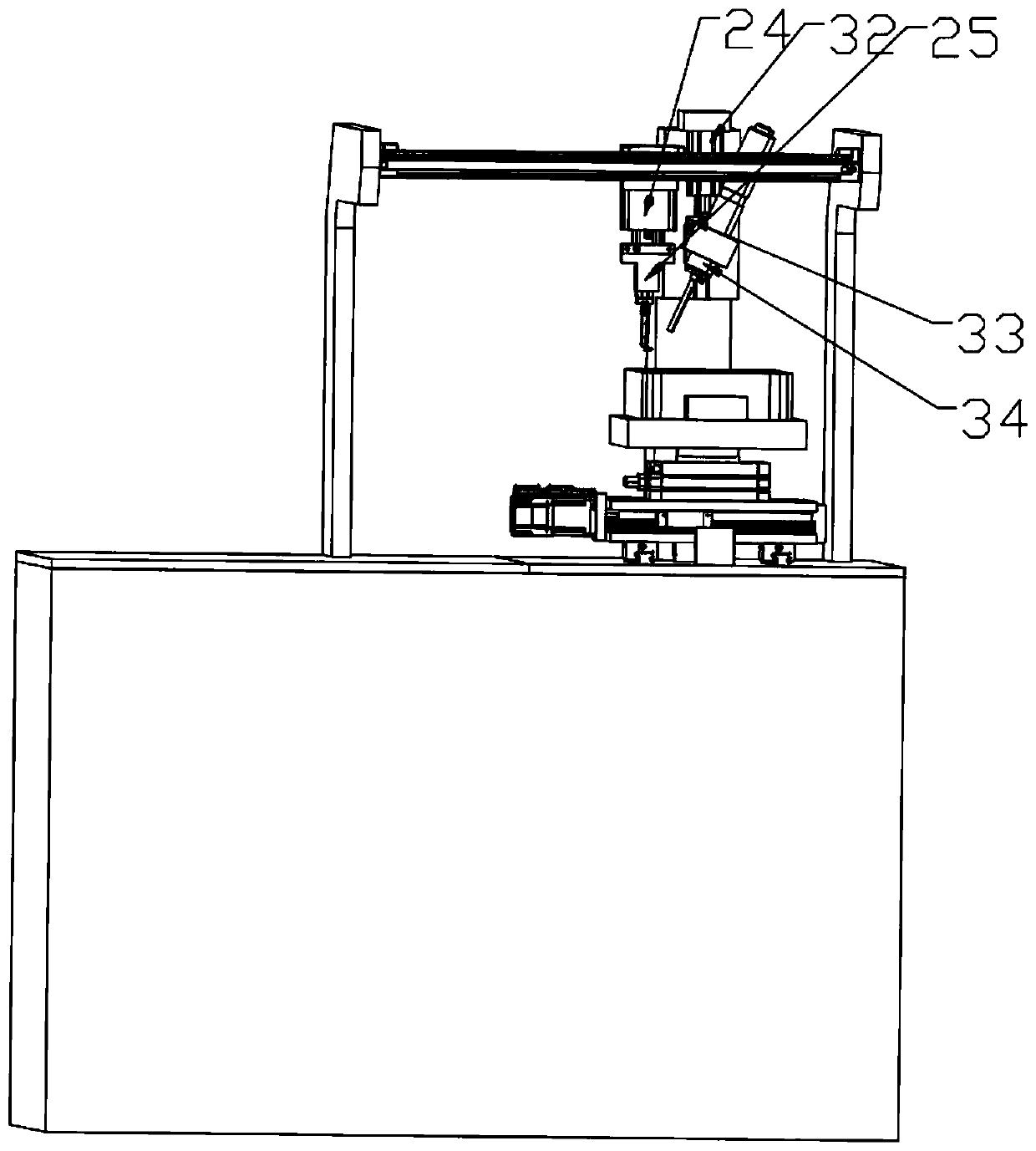

Pre-gluing machine of bolt

ActiveCN101816996AGuaranteed lengthGuaranteed positionLiquid surface applicatorsCoatingsGas cylinderElectric control

The invention discloses a pre-gluing machine of a bolt. The machine is characterized in comprising a gluing head, a gluing opening turning on-off mechanism, a pushing mechanism, an electric control device system, a glue storing cylinder and an adjusting component, wherein the glue storing cylinder is connected with a glue inlet of the gluing head; the gluing head comprises a baffle ring of an opening of a gluing cavity, a gluing cavity sleeve, a gluing cavity sleeve seat, a pushing rod, a gluing cavity, a gluing opening and a glue storing cavity; an annular gluing opening is formed between the baffle ring of the gluing cavity and the gluing cavity sleeve; the pushing mechanism and the gluing opening turning on-off mechanism respectively comprises a gas cylinder; the gluing opening turning on-off mechanism and the pushing mechanism are driven by the gas cylinders to realize the sequential linkage; the pushing rod gradually and axially pushes a bolt of a work piece; glue liquid is peripherally, axially and continuously injected among screw thread teeth of the bolt of the work piece from the gluing opening along the bolt of the work piece; and the adjusting component can adjust the action position of the pushing rod, the turning on-off position of the gluing opening, the opening width of the gluing opening, and the opening pressure of the gluing opening. The pre-gluing machine can peripherally, axially and fast inject the glue into an elastic die cavity, can evenly and exactly glue, guarantees the gluing length and position, and guarantees the quality.

Owner:FAWER AUTOMOTIVE PARTS

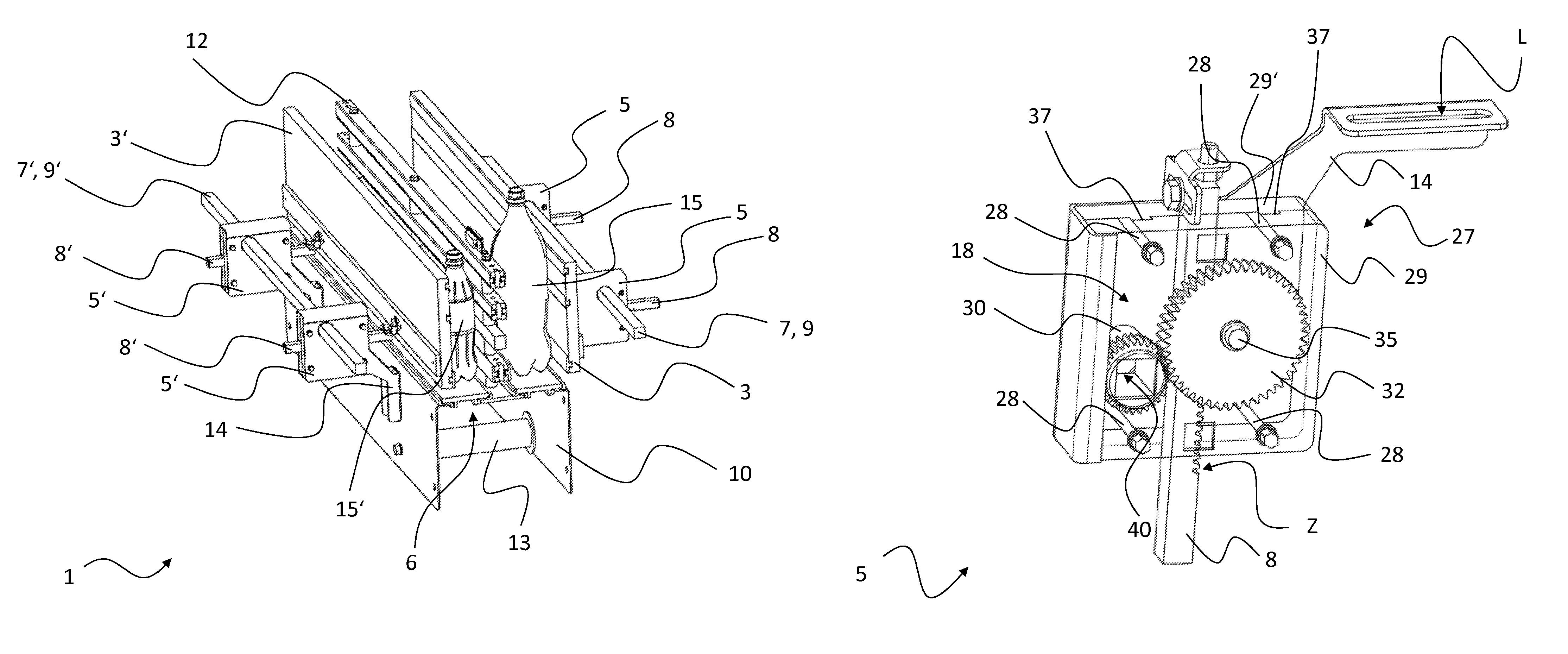

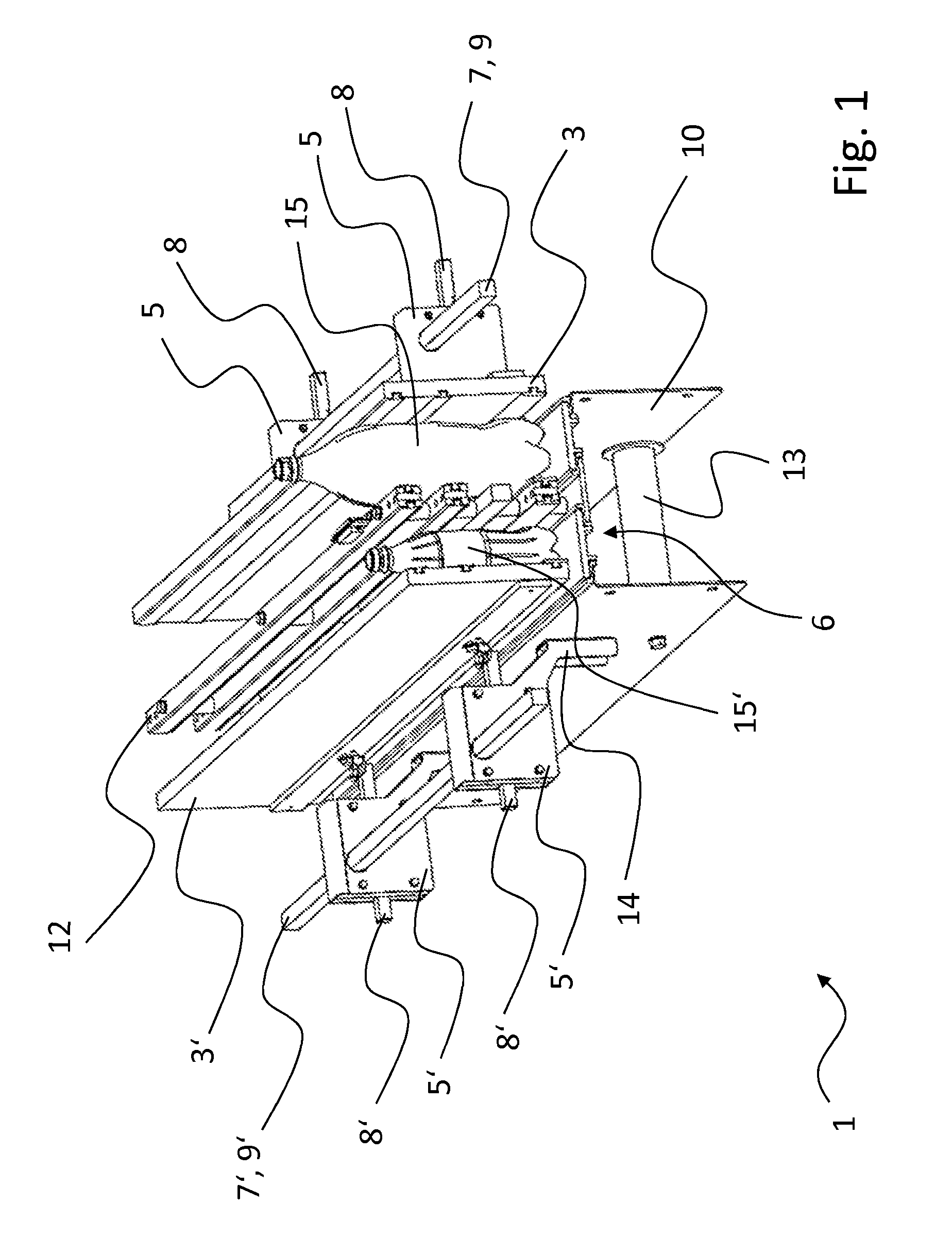

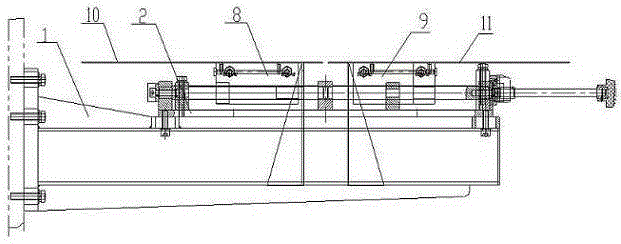

Transport section of a horizontal conveyor device with at least one adjustable guide element

A transport section of a horizontal conveyor device for conveying articles moved along in a standing or hanging position on a transport support surface extending in a horizontal conveying direction between two guide elements arranged approximately in parallel to each other and spaced from each other at a distance corresponding to at least the article or container width. At least one of the two guide elements arranged facing each other is adjustable in its distance to the other of the guide elements and transverse to the conveying direction via several adjustment elements attached to a machine frame or base frame. The adjustment elements are coupled with each other via a common rotary drive and are approximately synchronized and each adjustment element transmits a rotatory drive of the common rotary drive via one or more transmissions to a linear adjustment movement of the guide element linked to it.

Owner:KRONES AG

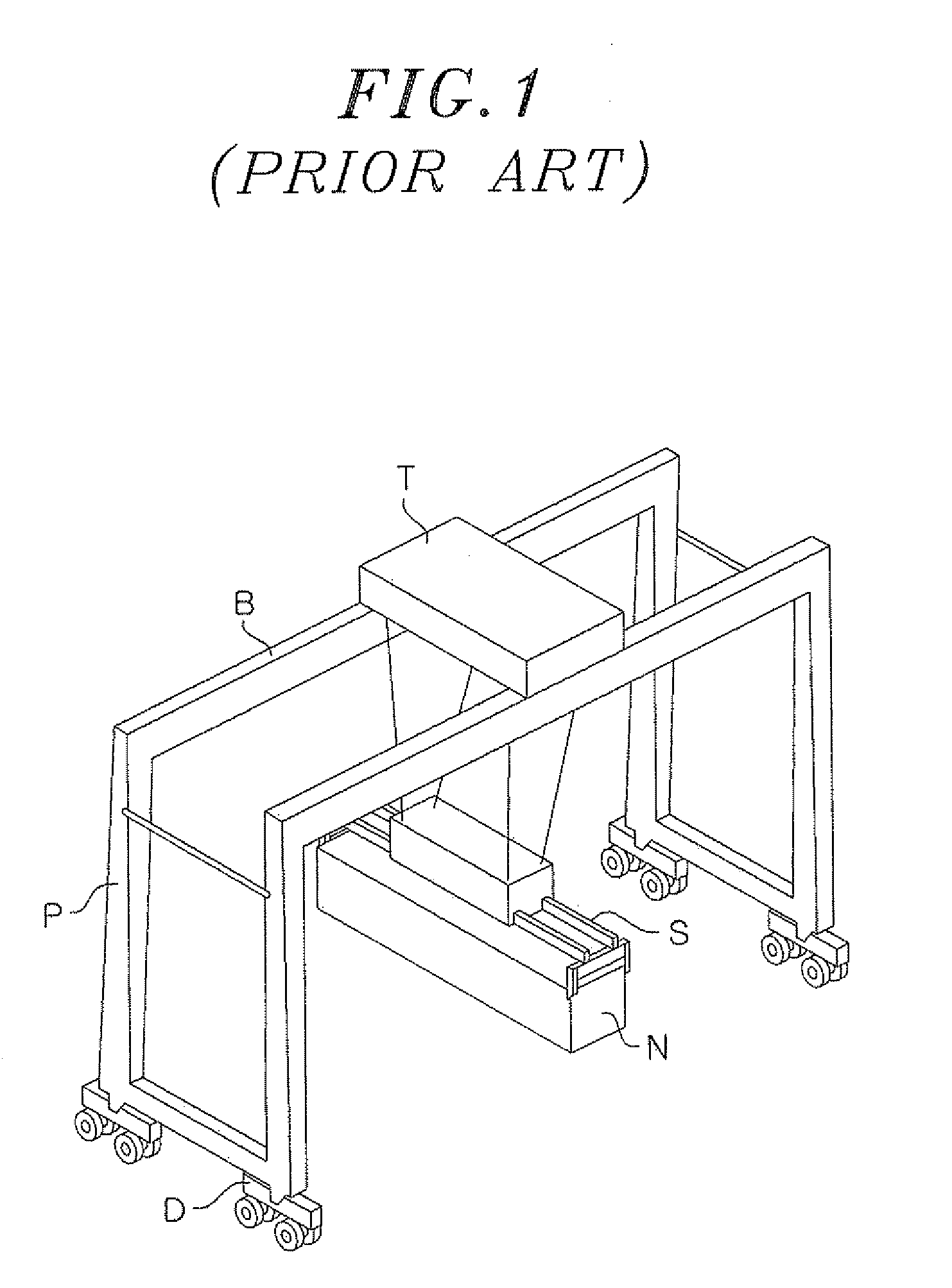

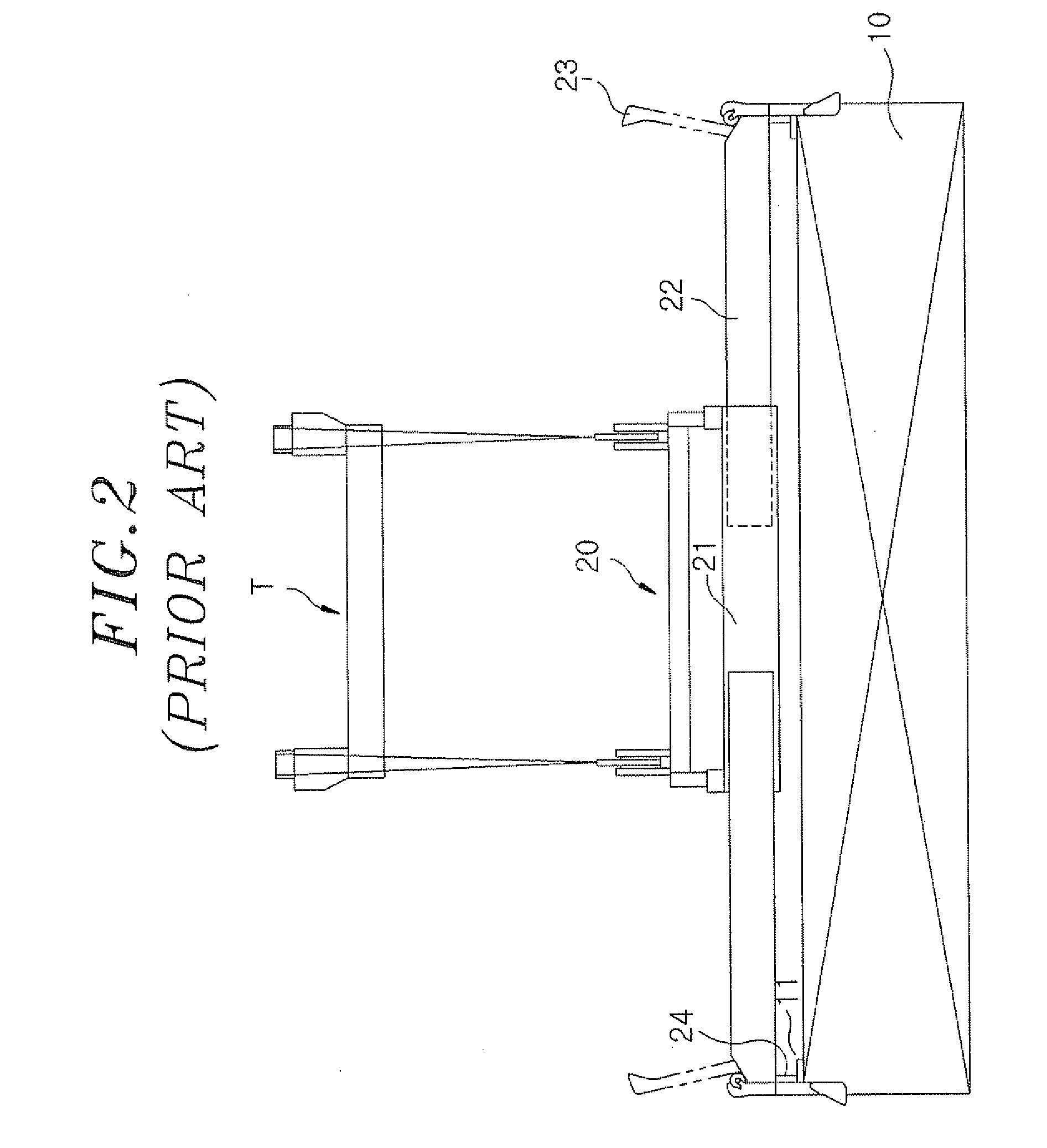

Crane spreader and method for automatically landing the same

InactiveUS20110155683A1Easy to adjustAccurate adjustment positionTravelling cranesLoad-engaging elementsEngineeringPulley

A crane spreader for use in lifting a container includes an attachment unit, a head block, a frame unit, a position adjustment unit and a fixation unit. The attachment unit detachably attaches the crane spreader to an upper surface of the container. The head block has a pulley connected to a trolley of a crane through a cable and coupled to the attachment unit to restrict a horizontal movement the attachment unit with respect to the head block. The frame unit is supported by the head block to be horizontally movable with respect to the head block, the frame unit being disposed below the head block with a gap therebetween. The position adjustment unit aligns the frame unit with the container by displacing the frame unit with respect to the attachment unit. The fixation unit engages the container with the frame unit.

Owner:KOREA ADVANCED INST OF SCI & TECH

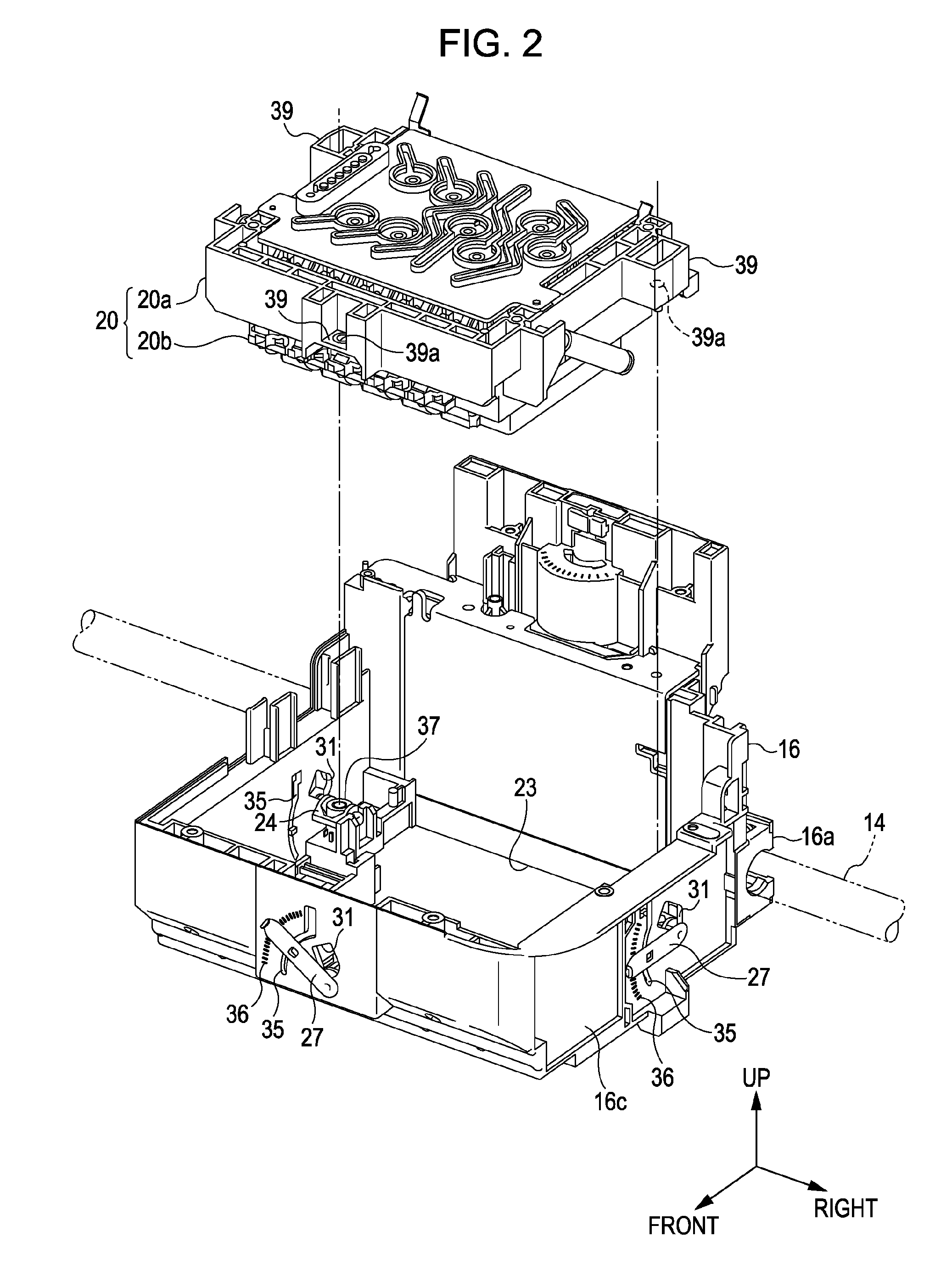

Position adjustment mechanism and recording apparatus

A position adjustment mechanism is provided to adjust a position of second member with respect to a first member. The position adjustment mechanism includes: a cam that is provided in the first member so that a cam surface of the cam abuts the second member; and a fixing portion that is provided in a forming area of the cam surface in the first member and fixes the second member to the first member by screw in a state where the position of the second member with respect to the first member is adjusted by the cam.

Owner:SEIKO EPSON CORP

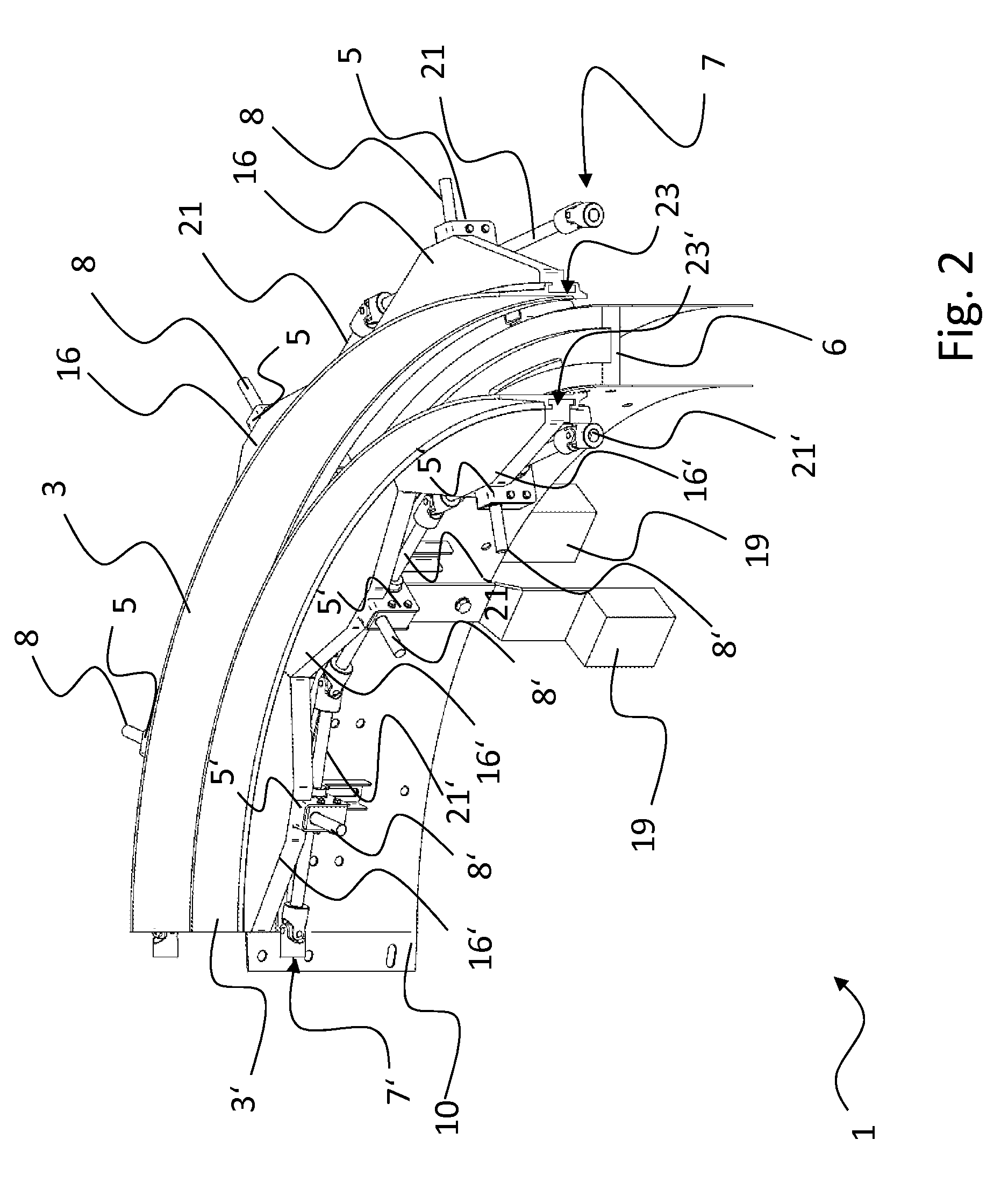

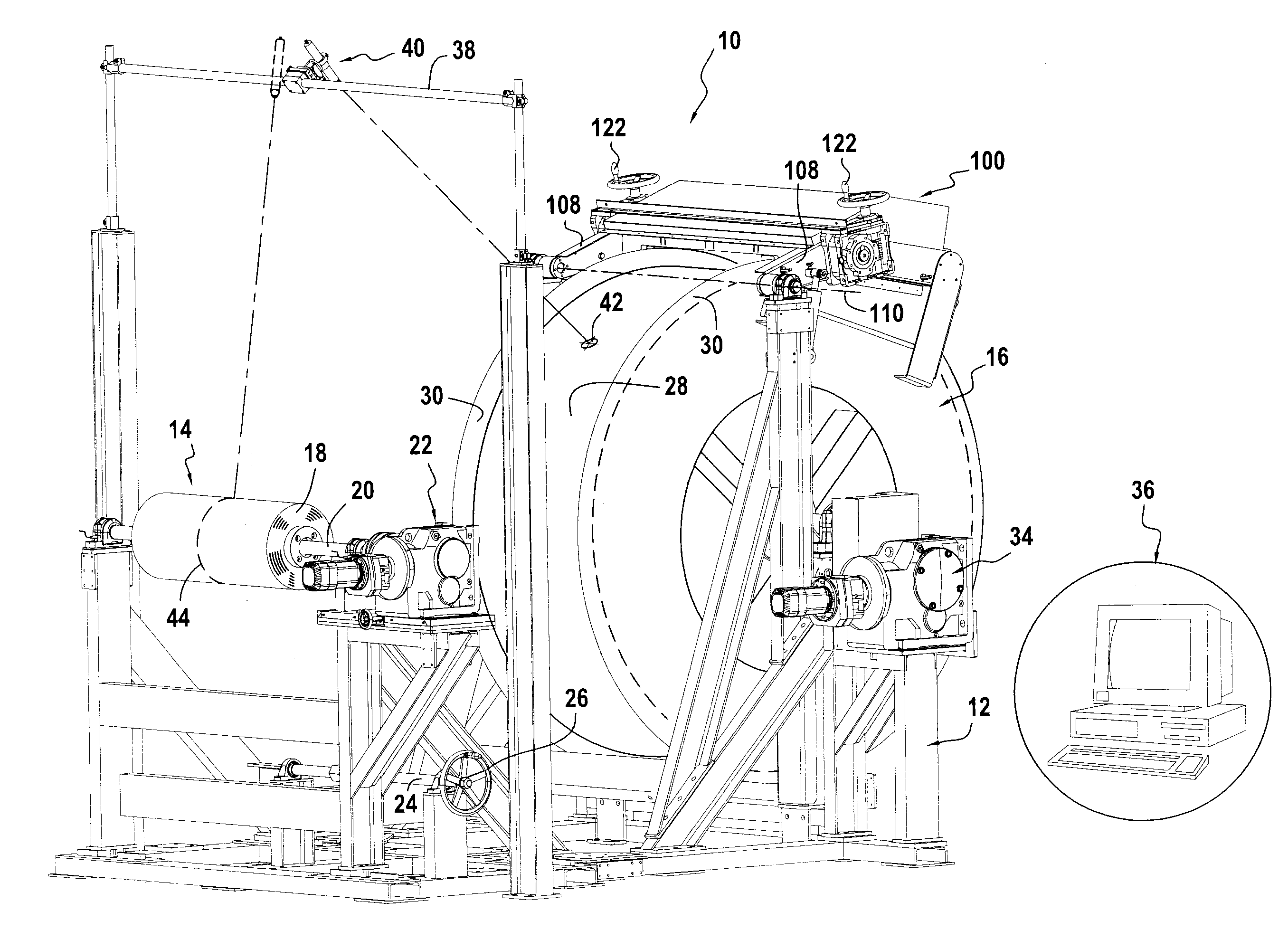

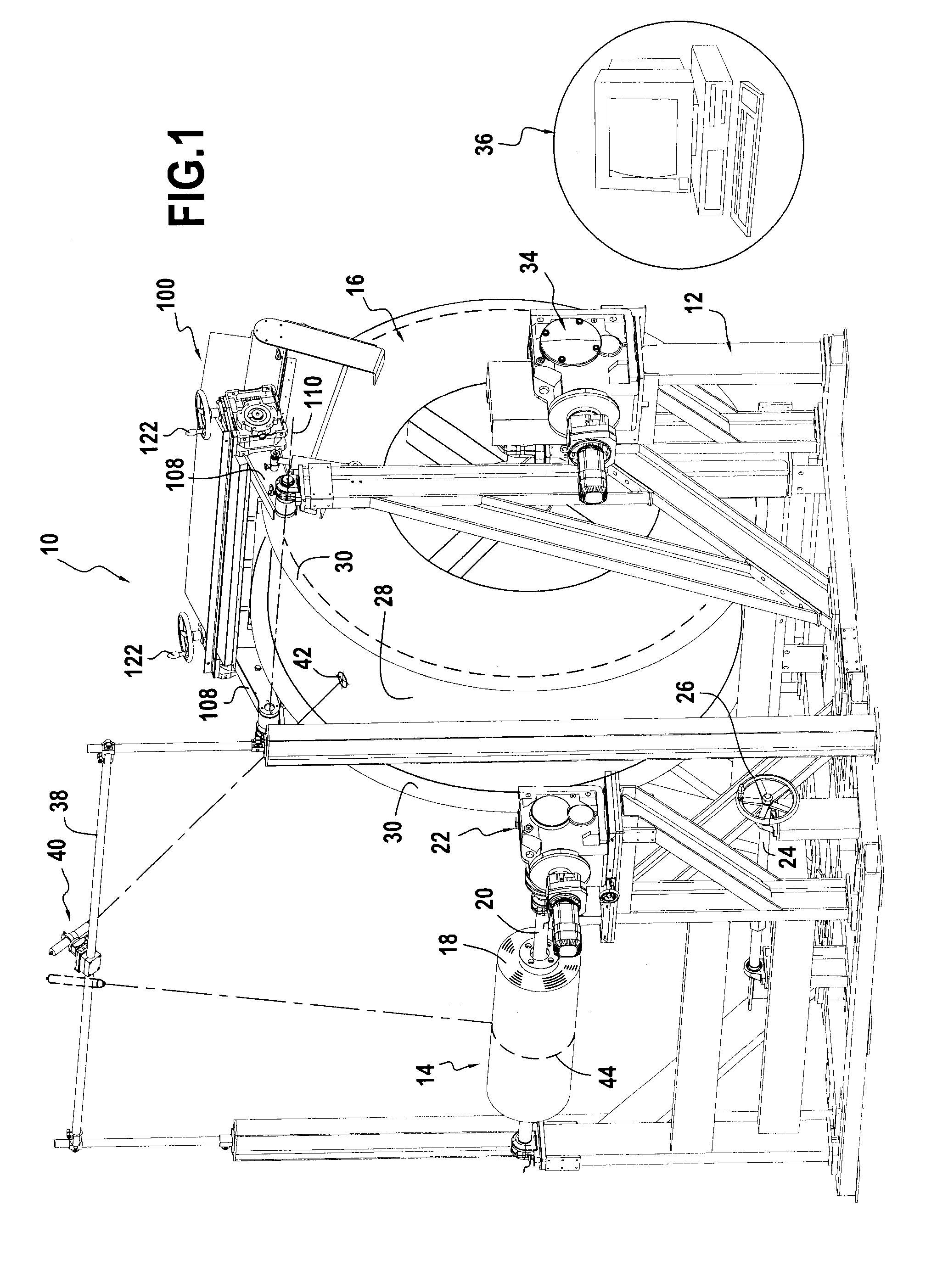

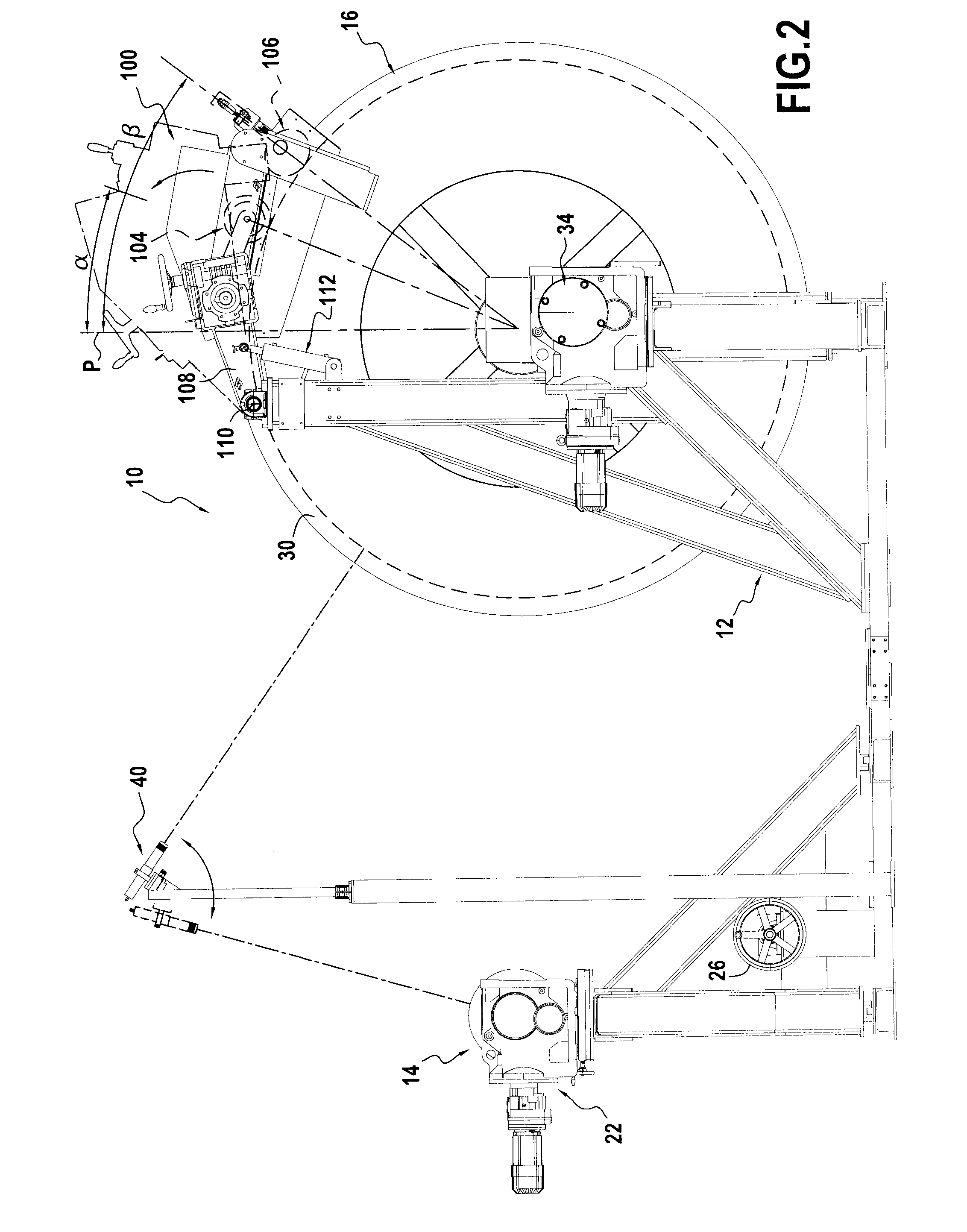

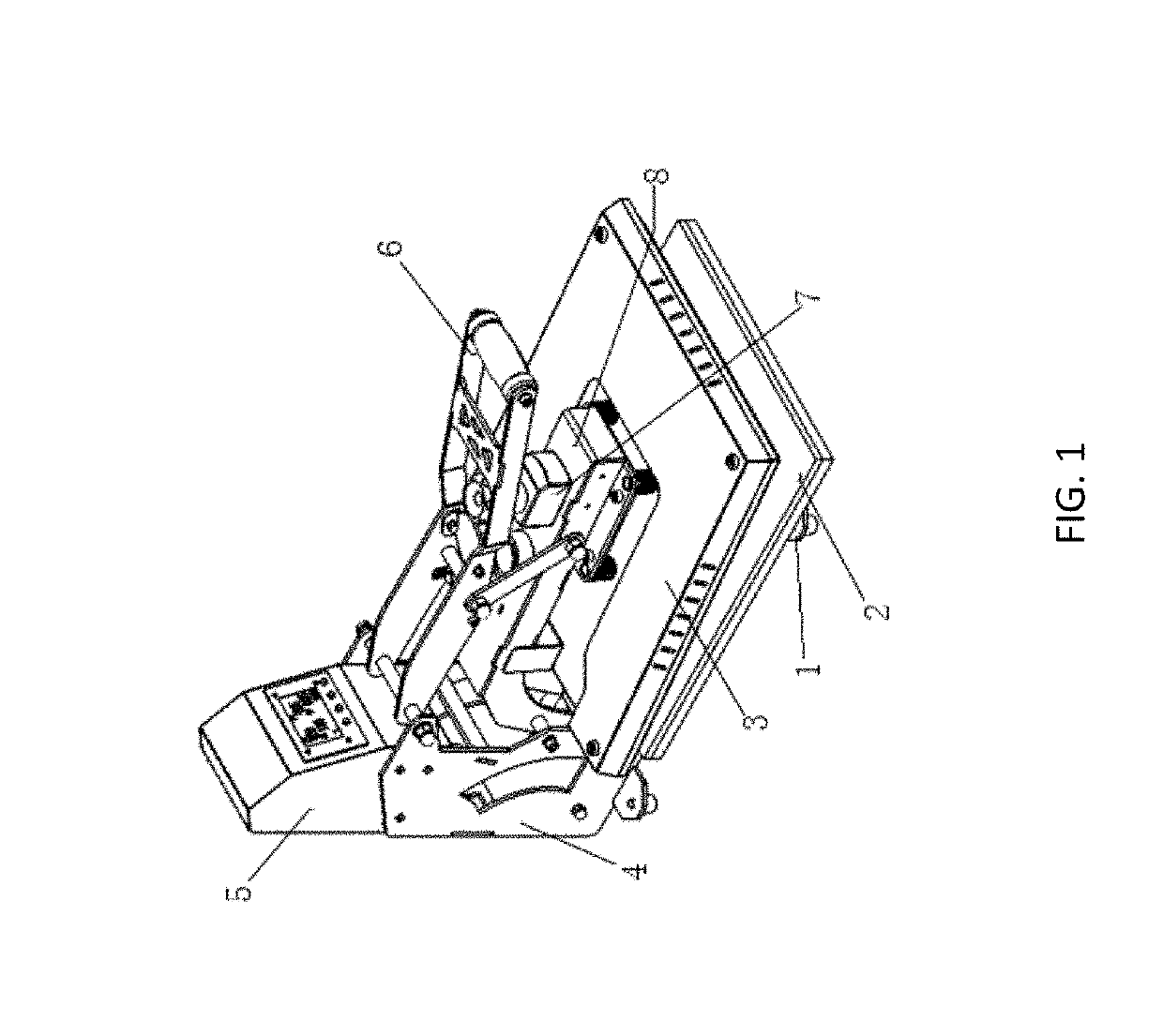

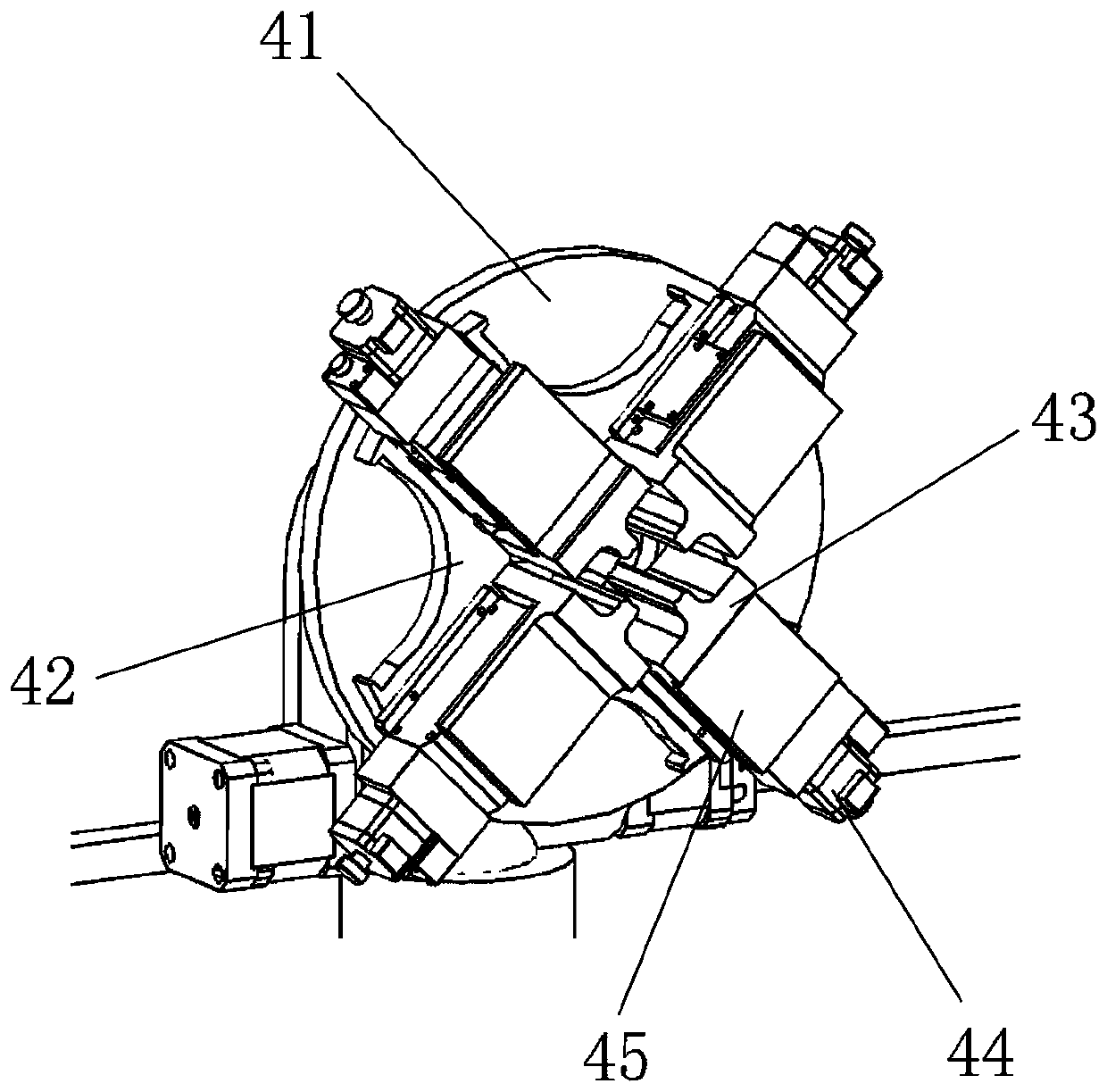

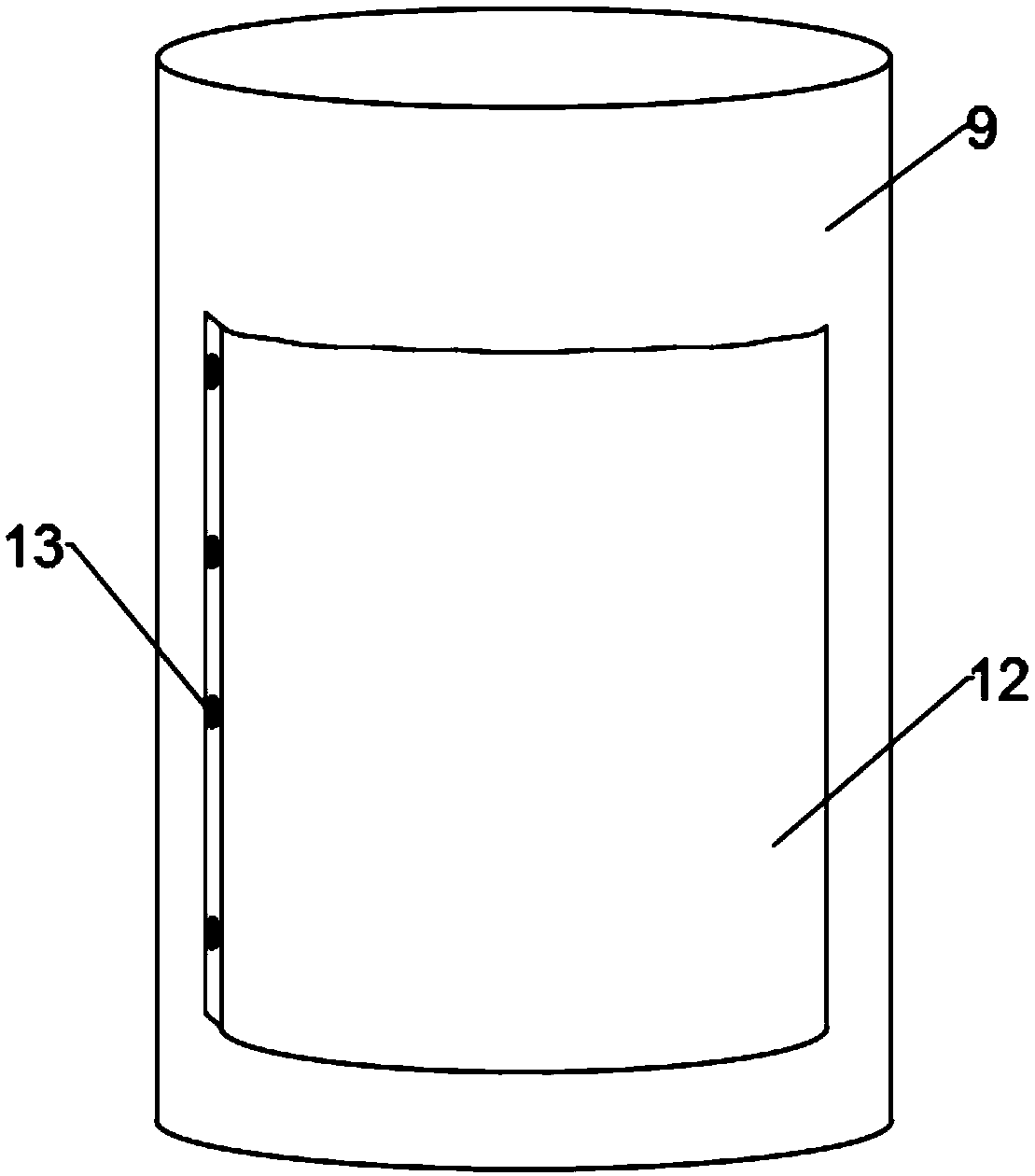

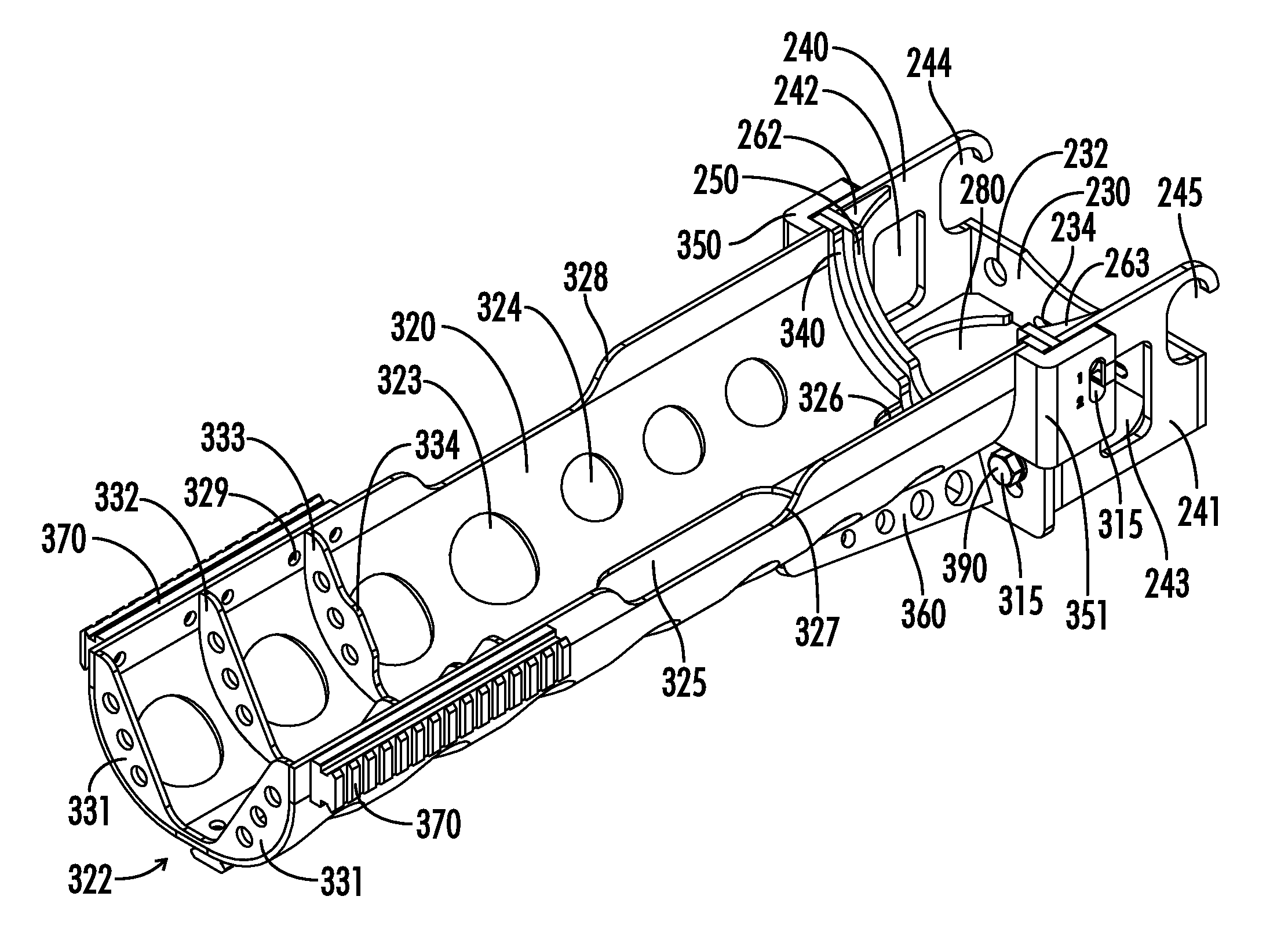

Compacting device for a machine for winding a fibrous texture onto an impregnation mandrel

ActiveUS20140110063A1Efficient use ofLevel of compactingWelding/cutting auxillary devicesLaminationWinding machineFiber

A compacting device for a machine for winding a fiber texture on an impregnation mandrel, the device including a frame including mounted thereon a compacting roller for bearing against an outside surface of an impregnation mandrel of a winding machine, and two compacting wheels, each configured to bear against a corner formed between the outside surface and a side plate of the impregnation mandrel.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

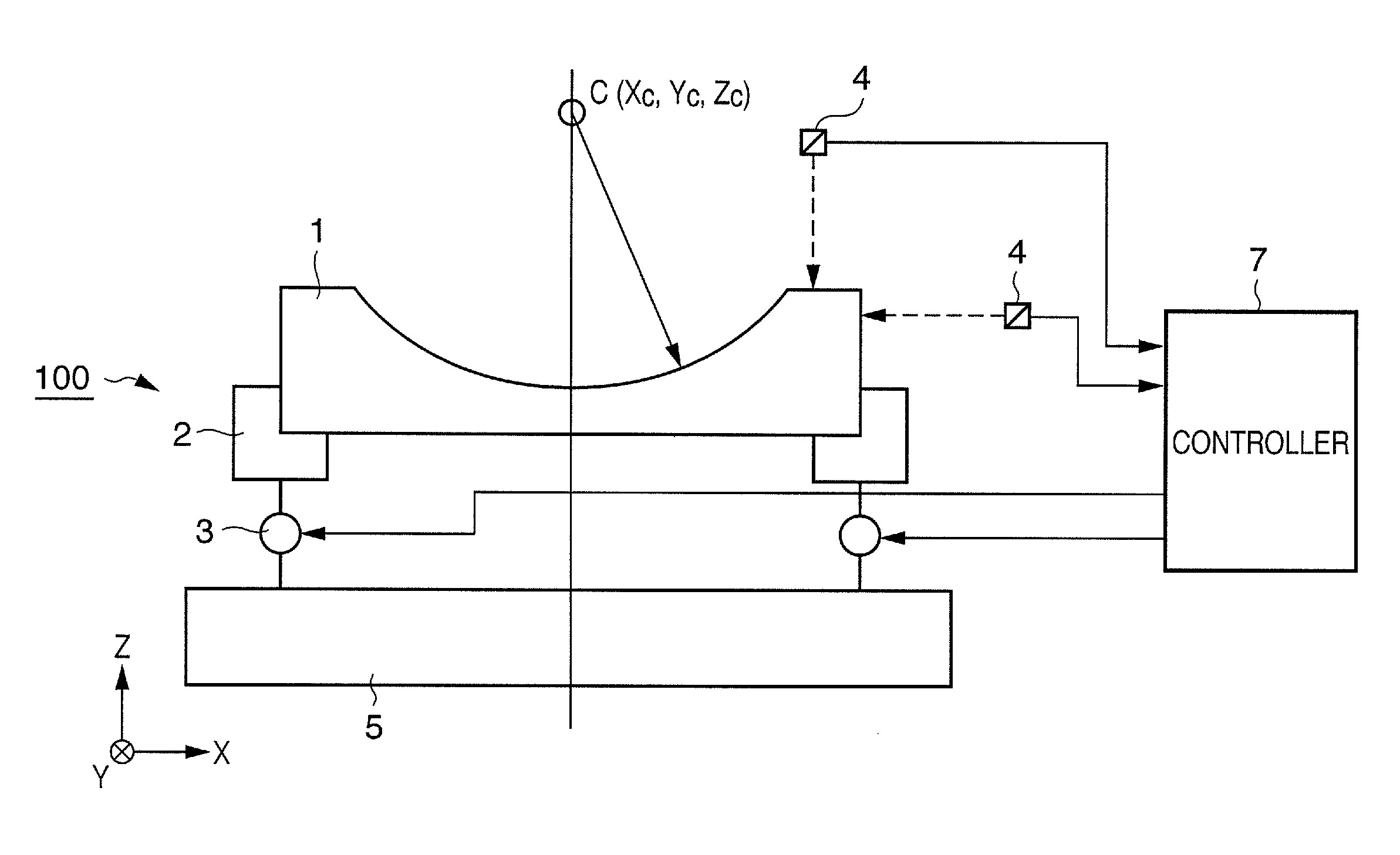

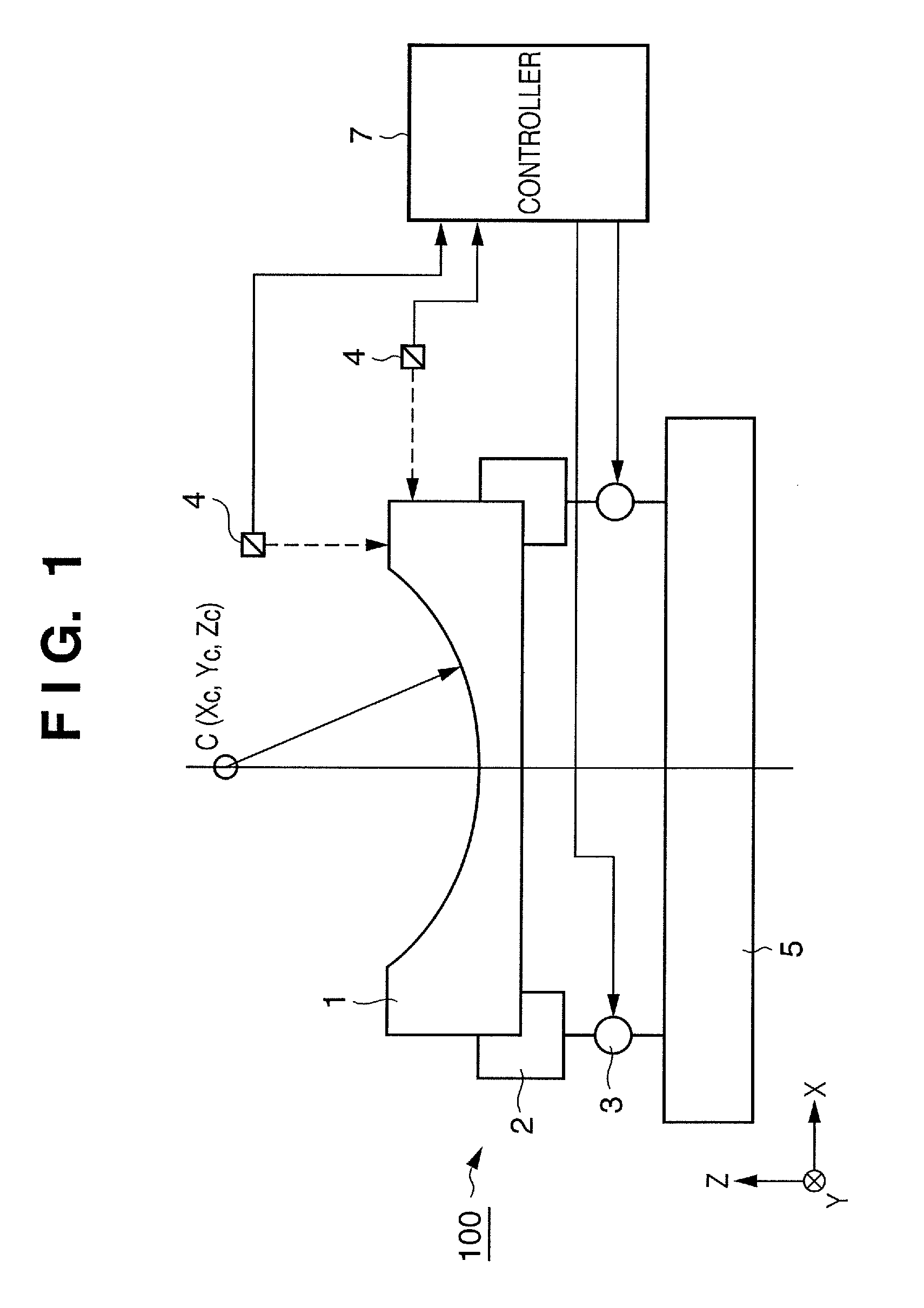

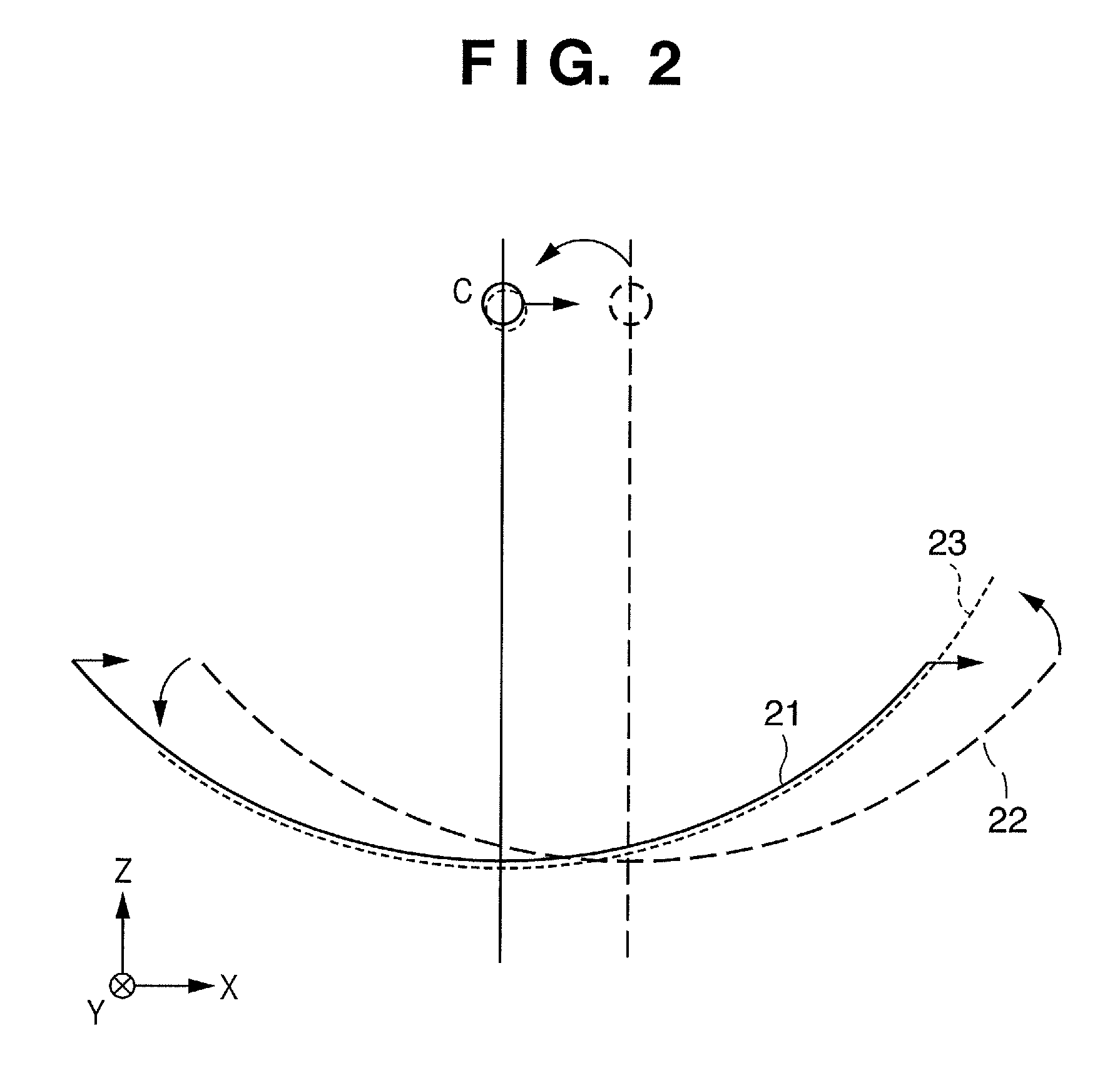

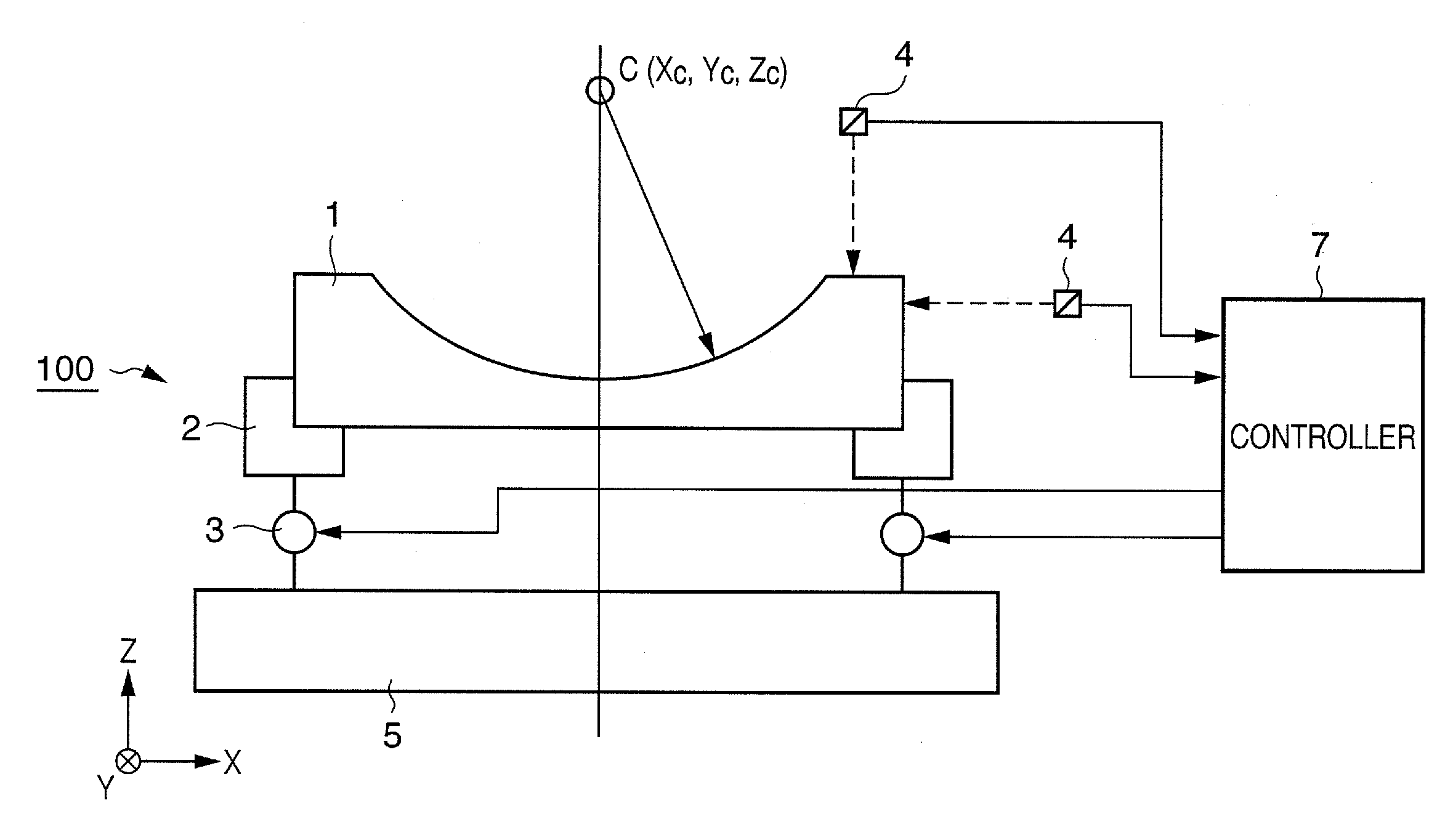

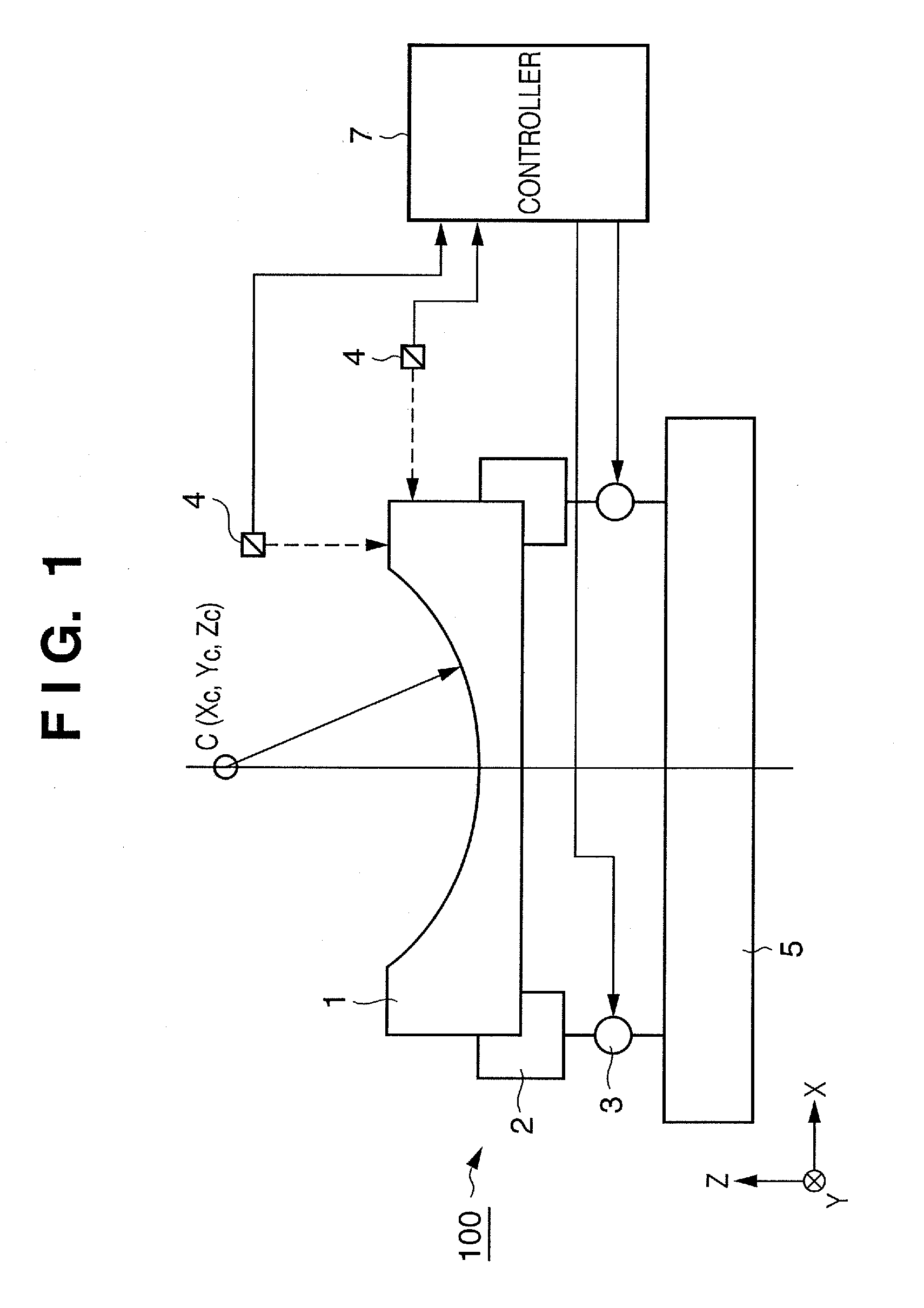

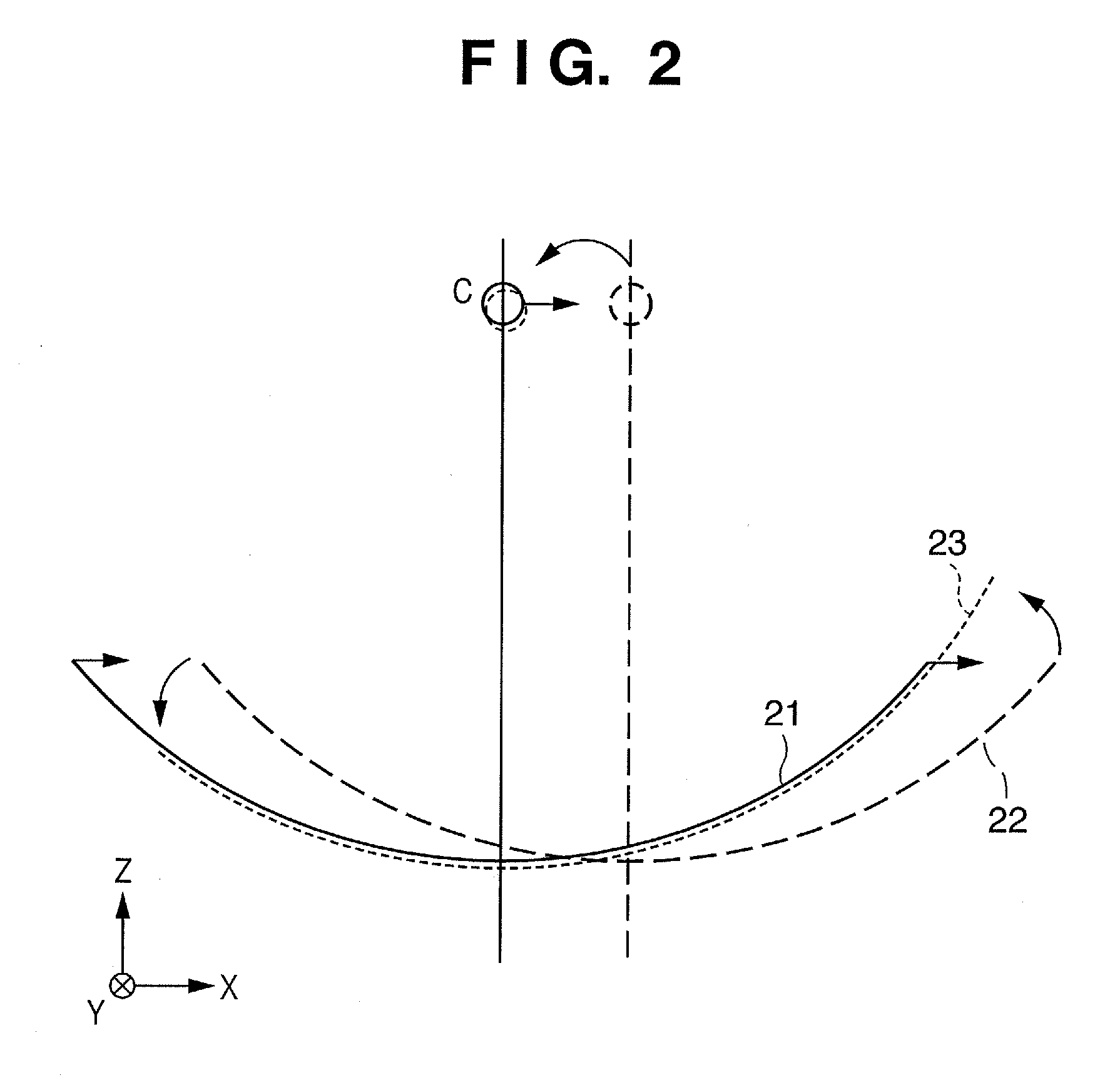

Apparatus for moving curved-surface mirror, exposure apparatus and device manufacturing method

InactiveUS7859643B2Accurate adjustment positionPhotomechanical apparatusMountingsThree degrees of freedomEngineering

Owner:CANON KK

Heat press machine

InactiveUS20190184667A1Quick pressure adjustmentAvoiding of adjustment pressure accuracy problemTransfer printingPress ramEngineeringHeat press

The position adjusting indicator device for manual heat press machine, comprising a pedestal, and there is a fixed or sliding base plate on the upper plane pedestal, there assembles heating element on the upper plane of the base plate. The middle of the rear end of the pedestal connects to the rack, and on the middle of the rack installs the housing. A handle can be assembled on the near side of the housing; An arm can be assembled with position adjusting indicator device components below the handle. And the arm is installed on the heating element, one side of the arm is fixedly connected with the rack. The up and down of heating element is controlled by adjusting position indicator device in order to achieve accurate pressure. The heat press device utilizes manual position adjusting pressure to achieve accurate position and better transfer effect, which avoid the disadvantages that the traditional heat press machine can not accurately adjust the position and save adjusting position time.The application discloses a pressure detection device for a manual heat press machine, which comprises a rack chassis, a lower column is installed on the upper end of the chassis bottom plate, the upper column is assembled on the upper end of the pressure sensor. The base plate is on the upper end of the upper column. The heating element is on the upper end of the base plate. And the hand-wheel is above the heating element. The handle is on the front of the hand-wheel. The controller is installed on the rack chassis. The pressure detection device of the manual heating press machine uses a pressure sensor to detect the pressure between the heating element and the base plate, it is directly reflected pressure value on the screen of controller, thereby it can achieve rapid pressure adjustment and avoid the disadvantages of slow adjustment speed and adjustable accuracy are not optimized problems of traditional machines. It enhances the adjusting detection structure and improves production efficiency. The overall structure is simple, easy to operate and fast to adjust.

Owner:ENETSHOPS LLC

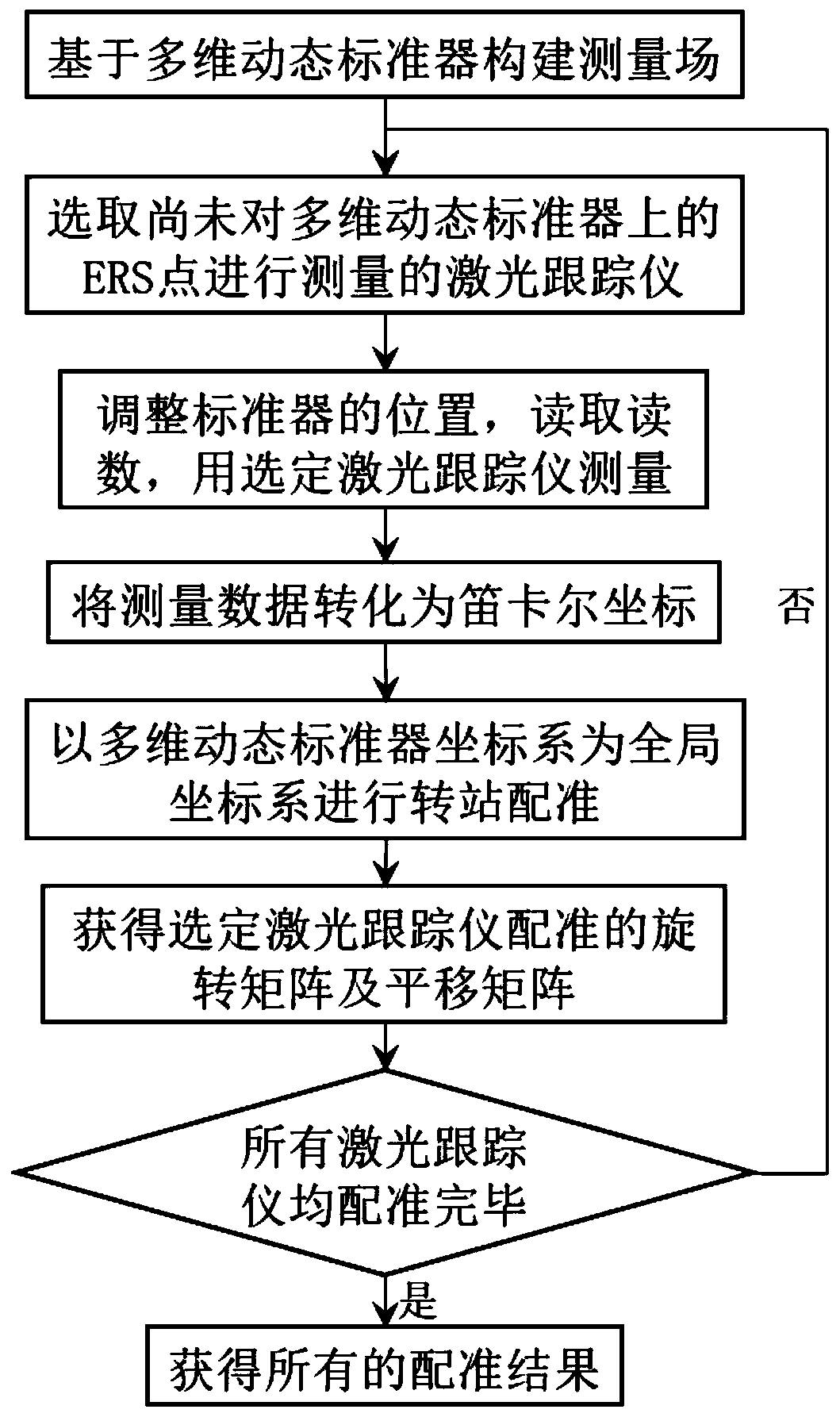

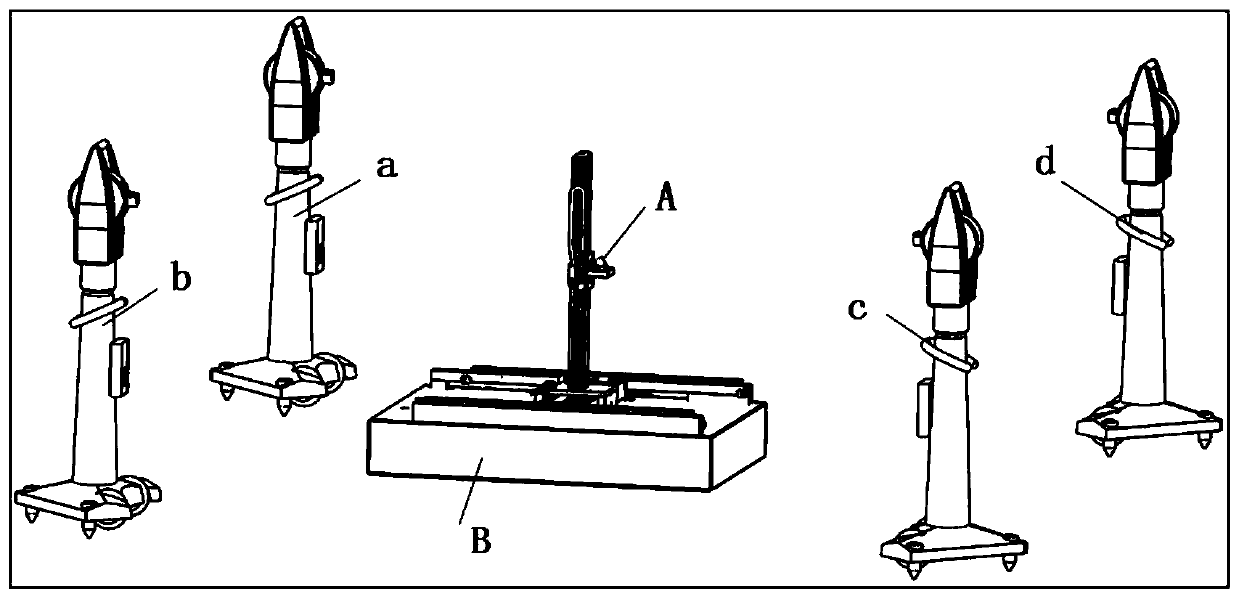

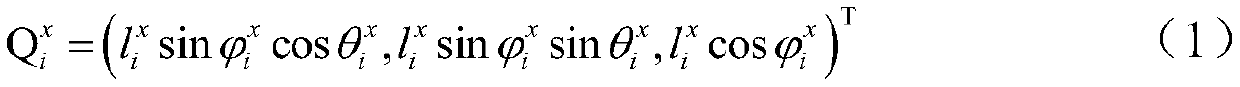

Coordinate conversion method based on multi-dimensional dynamic etalon

ActiveCN110487182AAccurate adjustment positionHigh precisionUsing optical meansUniform systemDimension measurement

The invention discloses a coordinate conversion method based on a multi-dimensional dynamic etalon and belongs to the field of precise measurement. The method comprises steps that firstly, a large-size measurement field is constructed by utilizing a multi-dimensional dynamic etalon provided with an ERS point target ball and a laser tracker; secondly, the position of ERS points is adjusted by utilizing the etalon, laser trackers are utilized for measurement, and reading of the etalons is performed after each adjustment; and lastly, a coordinate system of the multi-dimensional dynamic etalon istaken as a global coordinate system, a translation matrix and a rotation matrix for registering coordinates of the laser trackers to the global coordinate system are calculated, and the coordinates ofthe laser trackers are registered to the global coordinate system. The method can effectively reduce a non-uniform system error of traditional fixed public ERS point transfer registration, greatly inhibits influence of the non-uniform system error in the measurement length direction of the laser trackers, has advantages of high precision and high reliability and has better practicability in the application of the precision measurement technology.

Owner:DALIAN UNIV OF TECH

Apparatus for moving curved-surface mirror, exposure apparatus and device manufacturing method

InactiveUS20080100894A1Accurate adjustment positionPhotomechanical apparatusMountingsThree degrees of freedomEngineering

Owner:CANON KK

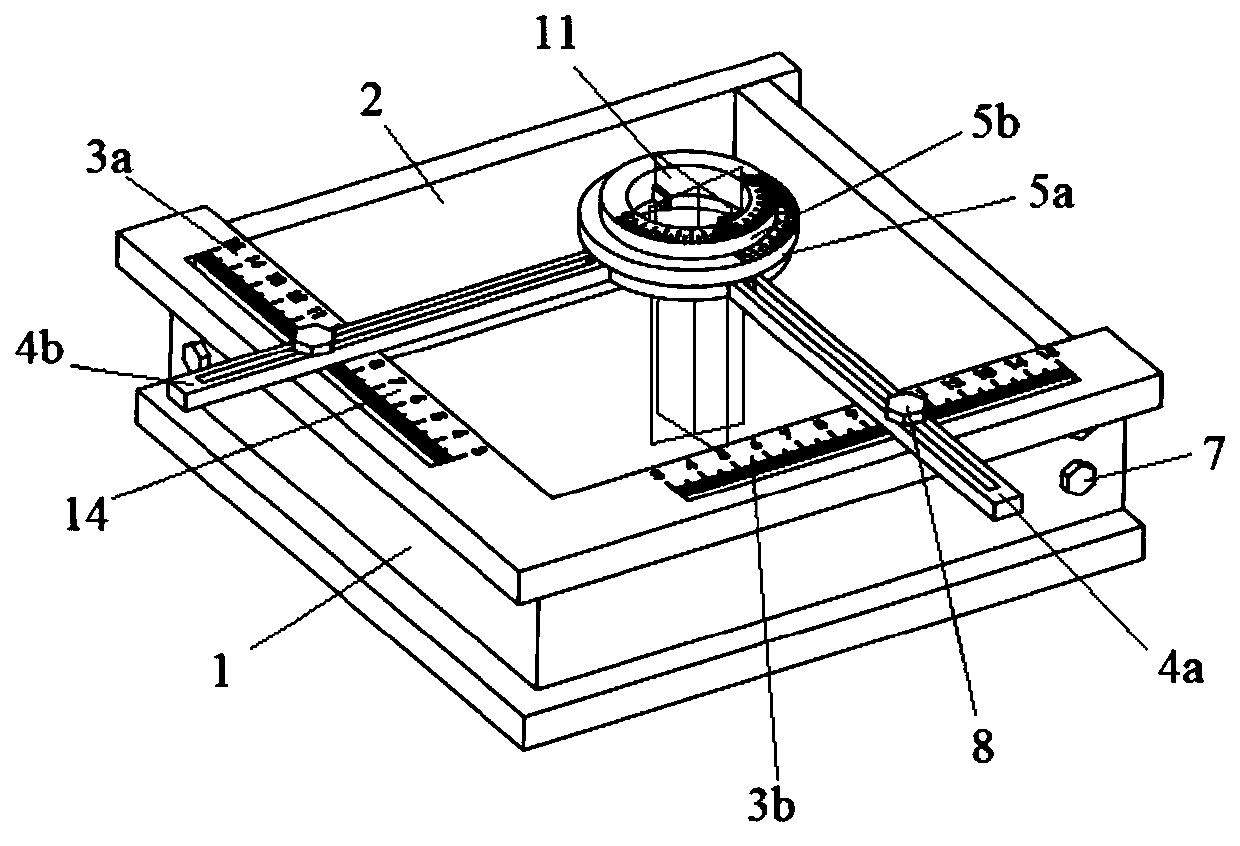

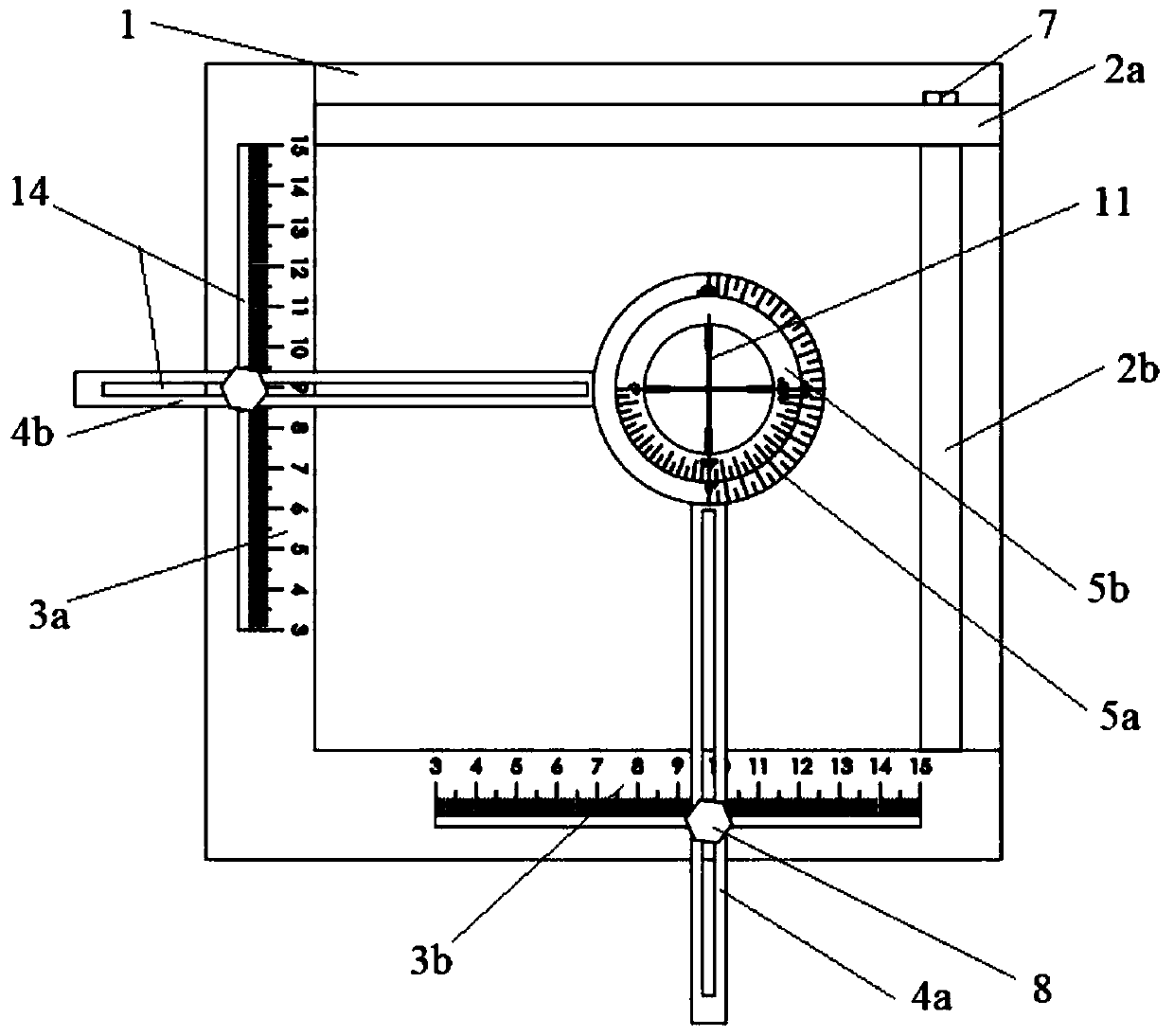

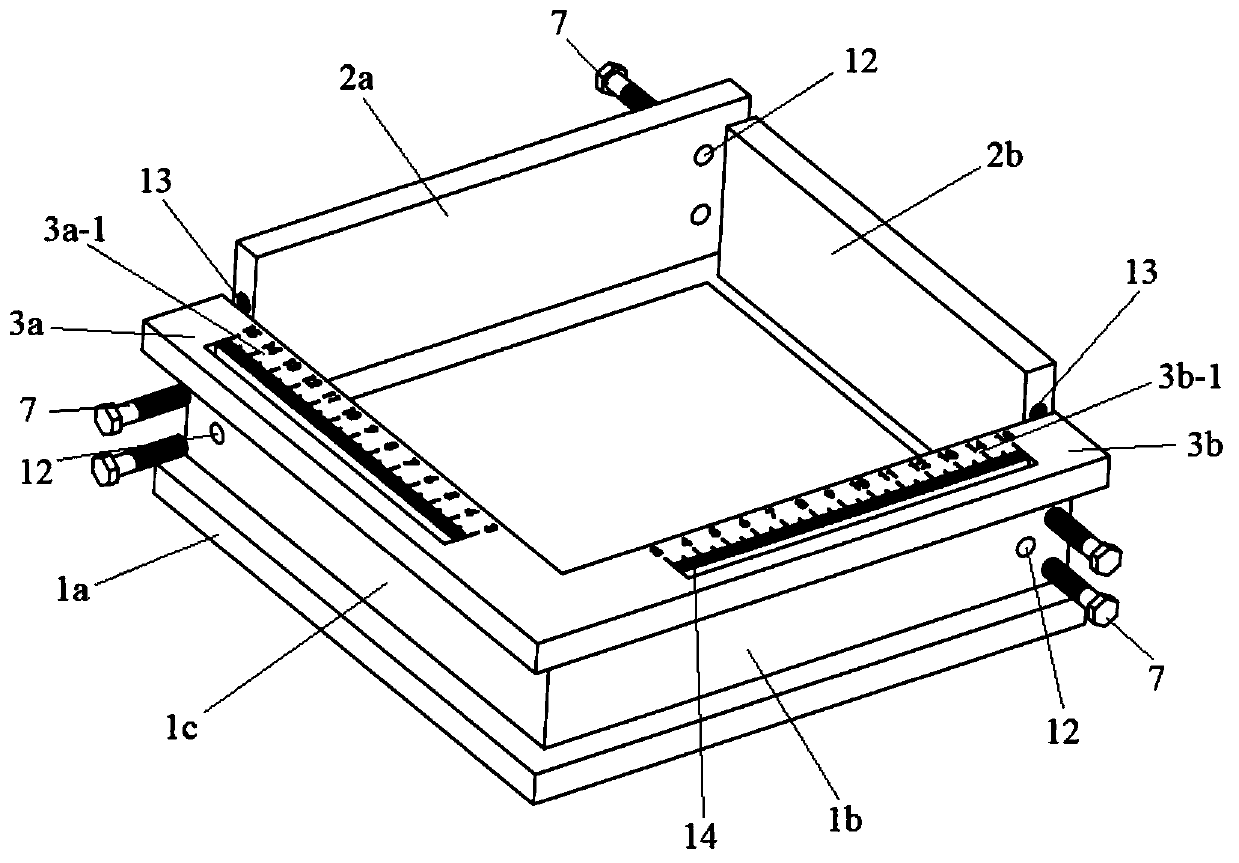

Rock test piece manufacturing mold capable of adjusting joint angle and position and using method

ActiveCN111207972AEasy to makeEasy to processPreparing sample for investigationPolystyreneMechanical engineering

The invention discloses a rock test piece manufacturing mold capable of adjusting the joint angle and position and a using method. The manufacturing mold comprises a detachable rectangular mold groove, a position adjusting device composed of a steel plate ruler and a positioning sliding straight rod, an angle adjusting device internally provided with a mold piece fixing plate, and a mold piece made of polystyrene, wherein all the components are connected and fixed through self-tightening bolts, nuts and other parts, mold dismounting is convenient, and manufacturing of rock-like test pieces isfacilitated. The manufacturing mold is advantaged in that a rock-like sample of a prefabricated cross joint can be manufactured, the included angle and the position of the cross joint can be accurately controlled, research on diversified joint forms of the rock-like sample is facilitated, the obtained result is accurate in size data, and the manufacturing mold is simple in manufacturing mode, capable of being repeatedly used and beneficial to popularization.

Owner:SHANDONG JIANZHU UNIV

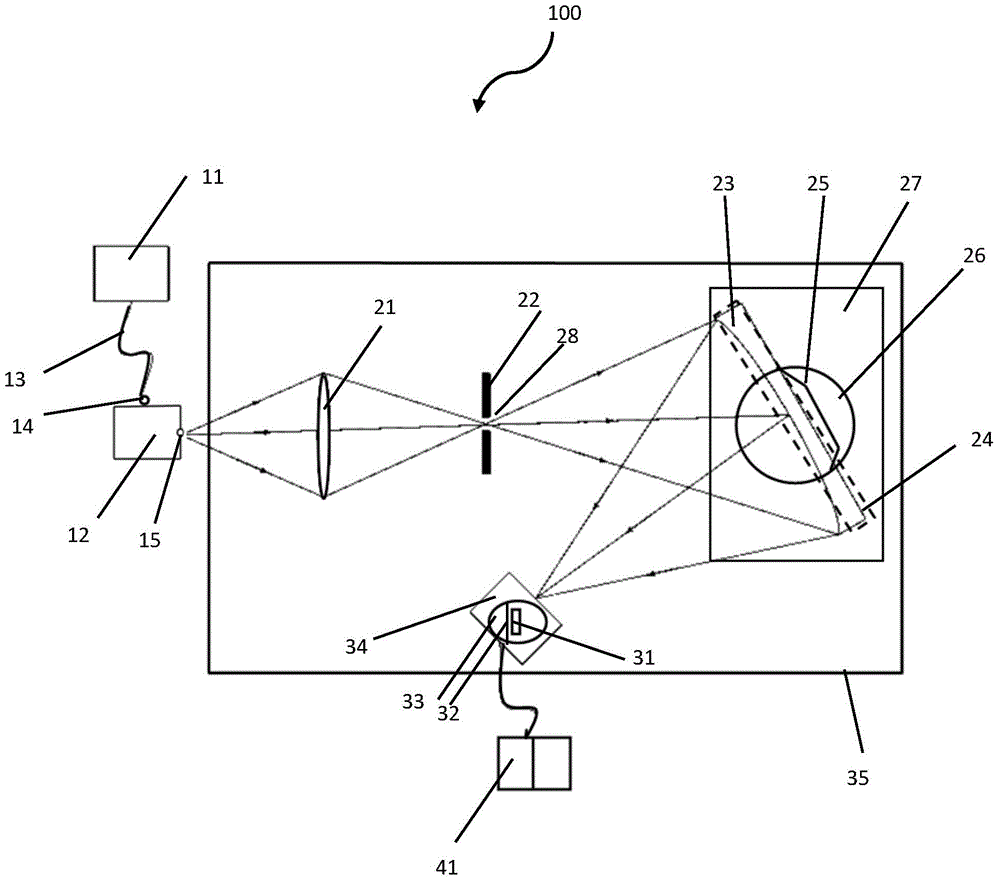

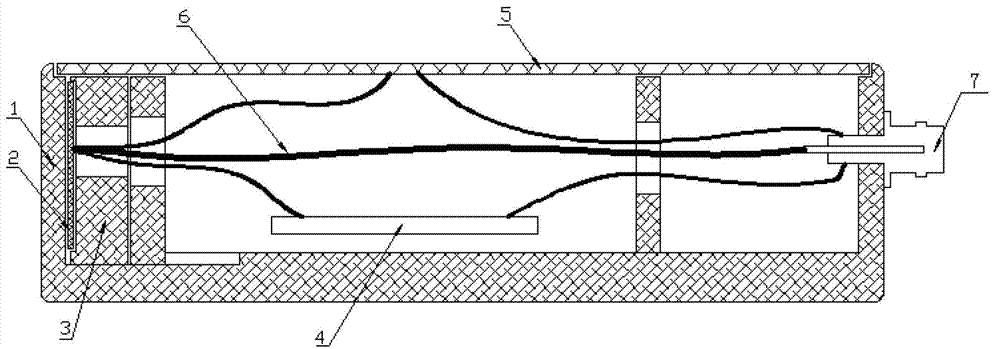

Device and method for detecting concave grating resolution and diffraction efficiency

InactiveCN104101485AFewer optical aidsEasy assembly procedureTesting optical propertiesWave bandImage resolution

The present invention provides a device and method for detecting concave grating resolution and diffraction efficiency. The device comprises a monochromatic light emitting unit, an imaging unit which is arranged on a monochrome light path, a detection unit, a processing unit and a control unit; the monochromatic light emitting unit, the imaging unit, the detection unit, the processing unit and the control unit are connected sequentially; the monochromatic light emitting unit leads test-used monochromatic light into the imaging unit through an optical fiber; spectral intensity is received by a detector in the detection unit; and finally data in the detector are recorded, analyzed and processed by the processing unit, so that data about concave grating resolution and diffraction efficiency can be obtained. The device for detecting the concave grating resolution and diffraction efficiency of the invention is advantageous in simplicity, few required professional devices and simple operation, and can realize simultaneous detection of the resolutions and diffraction efficiencies of various types of concave gratings and can also realize fast detection of the resolutions and diffraction efficiencies of concave gratings of different types and different sizes in a wide band range.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

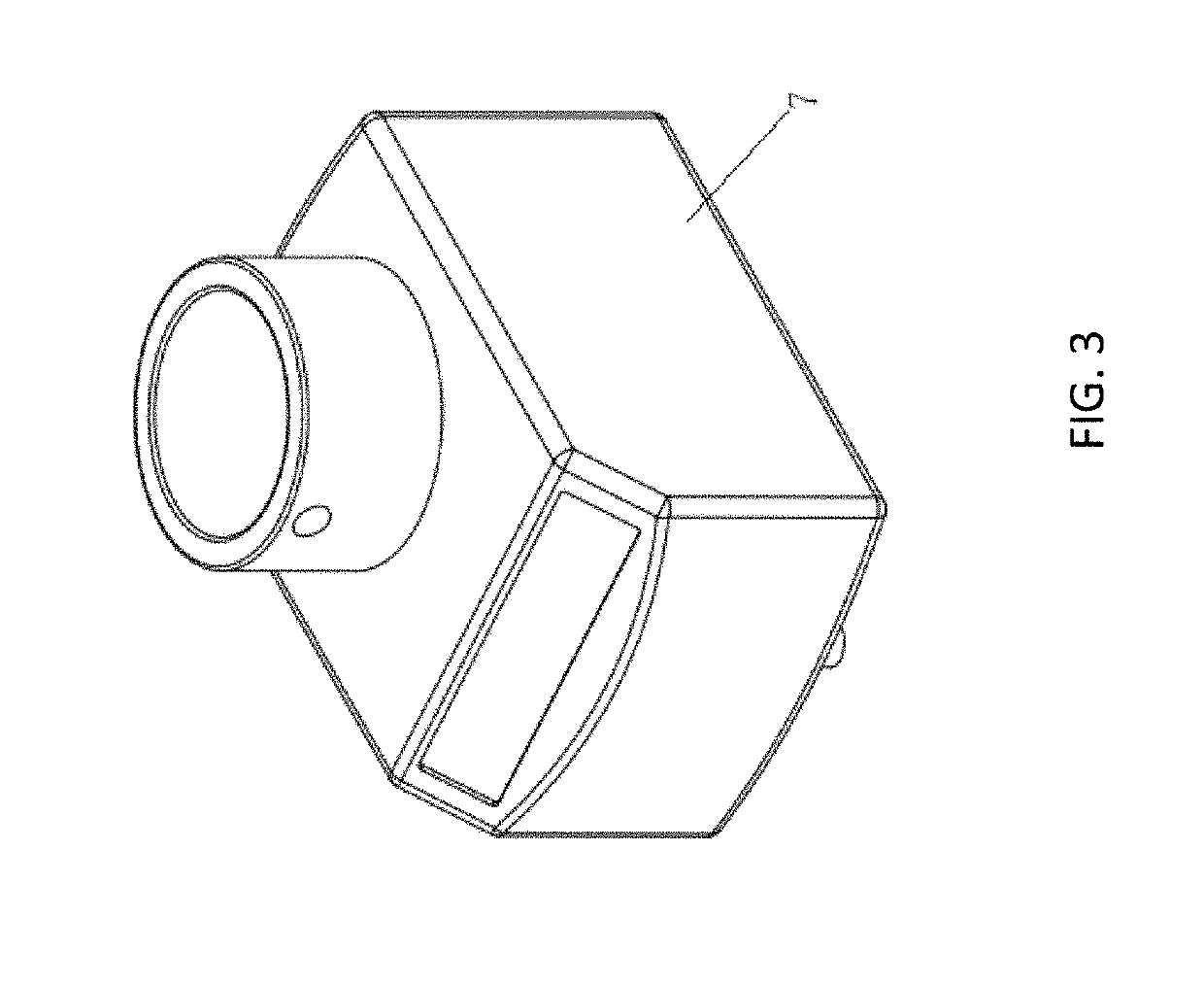

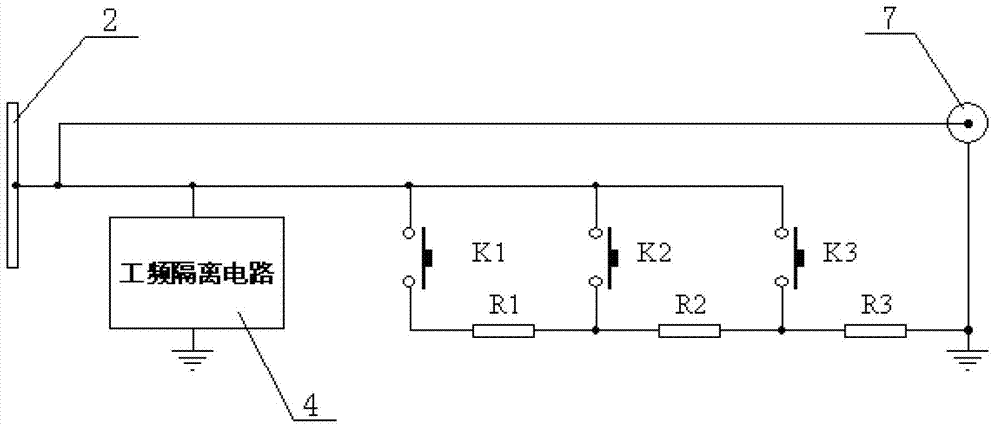

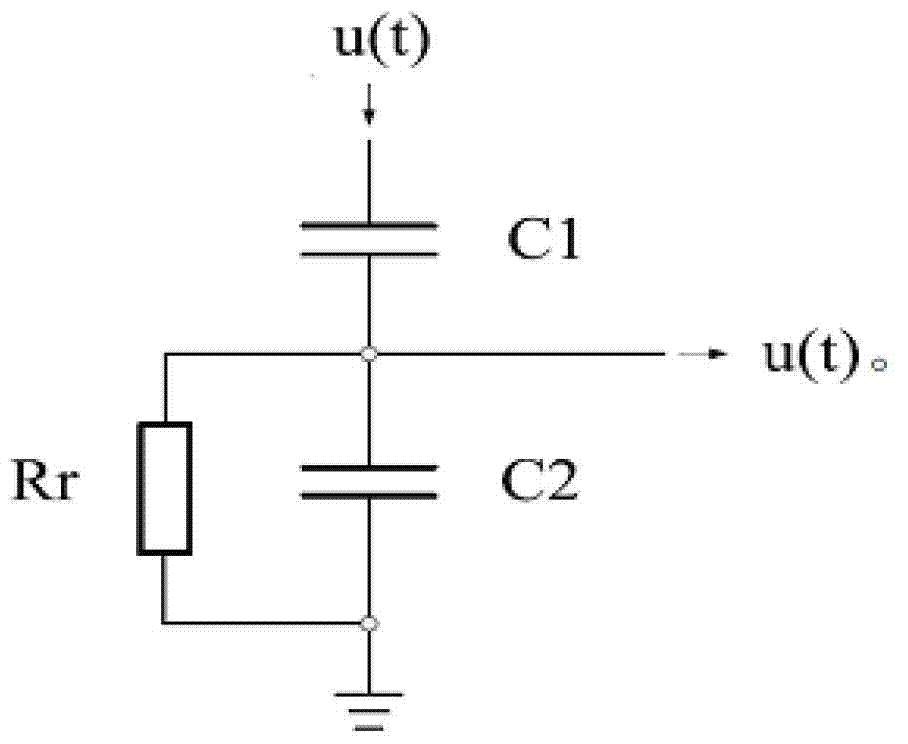

Partial discharge transient earth voltage sensor

InactiveCN103207306AEasy to operateEasy to move frequentlyCurrent/voltage measurementAnti jammingCapacitance

The invention discloses a partial discharge transient earth voltage sensor. The partial discharge transient earth voltage sensor comprises a casing body, a flat-panel coupling capacitor inner electrode, a power frequency isolating circuit, an acquisition control module, an output interface and a cover plate, wherein the casing body and the cover plate form a seal cavity together; the flat-panel coupling capacitor inner electrode is fixed in the seal cavity and forms a coupling capacitor with the metal surface of a sample to be detected with the left side wall of the casing body as a medium; the power frequency isolating circuit is used for performing high-pass filtering on signals detected by the flat-panel coupling capacitor inner electrode; the output interface is used for outputting signals filtered by the power frequency isolating circuit; and the acquisition control module is used for controlling the flat-panel coupling capacitor inner electrode and the output interface. The partial discharge transient earth voltage sensor is simple and rapid in operation, convenient to move frequently and position fine during routing inspection, high in anti-jamming capacity and capable of improving the detection working efficiency and the positioning accuracy.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

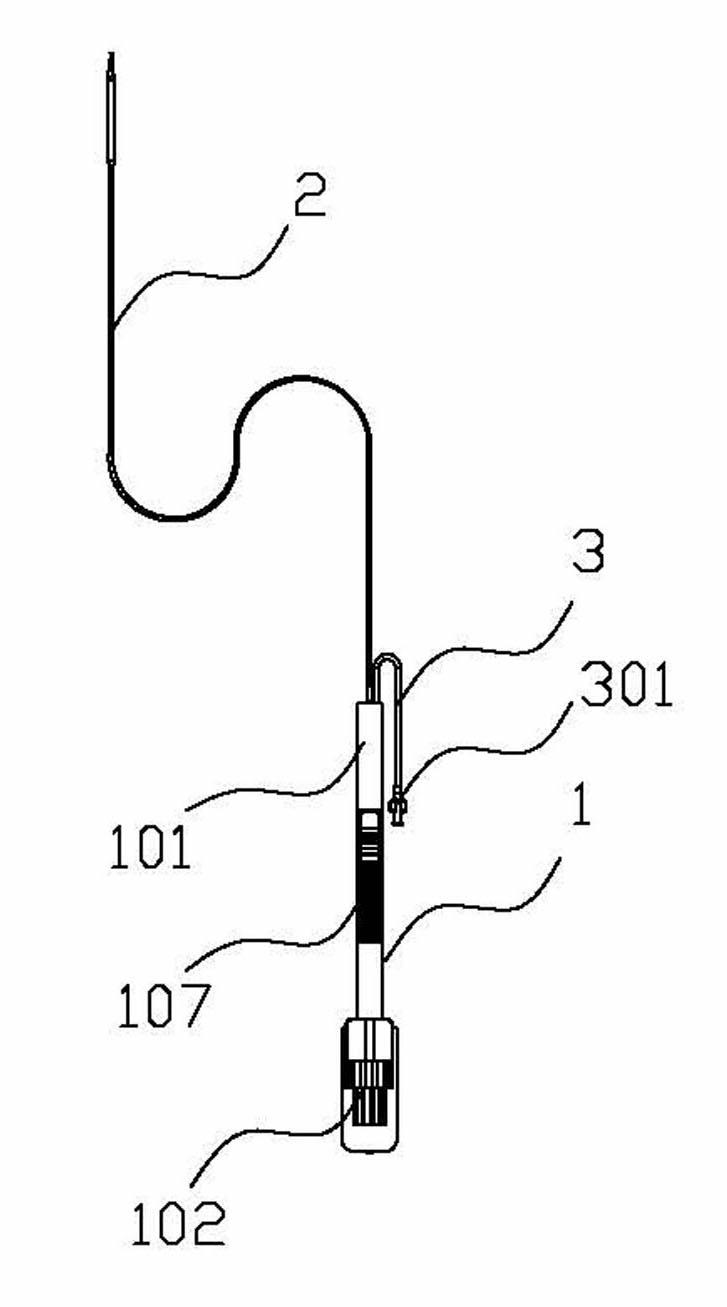

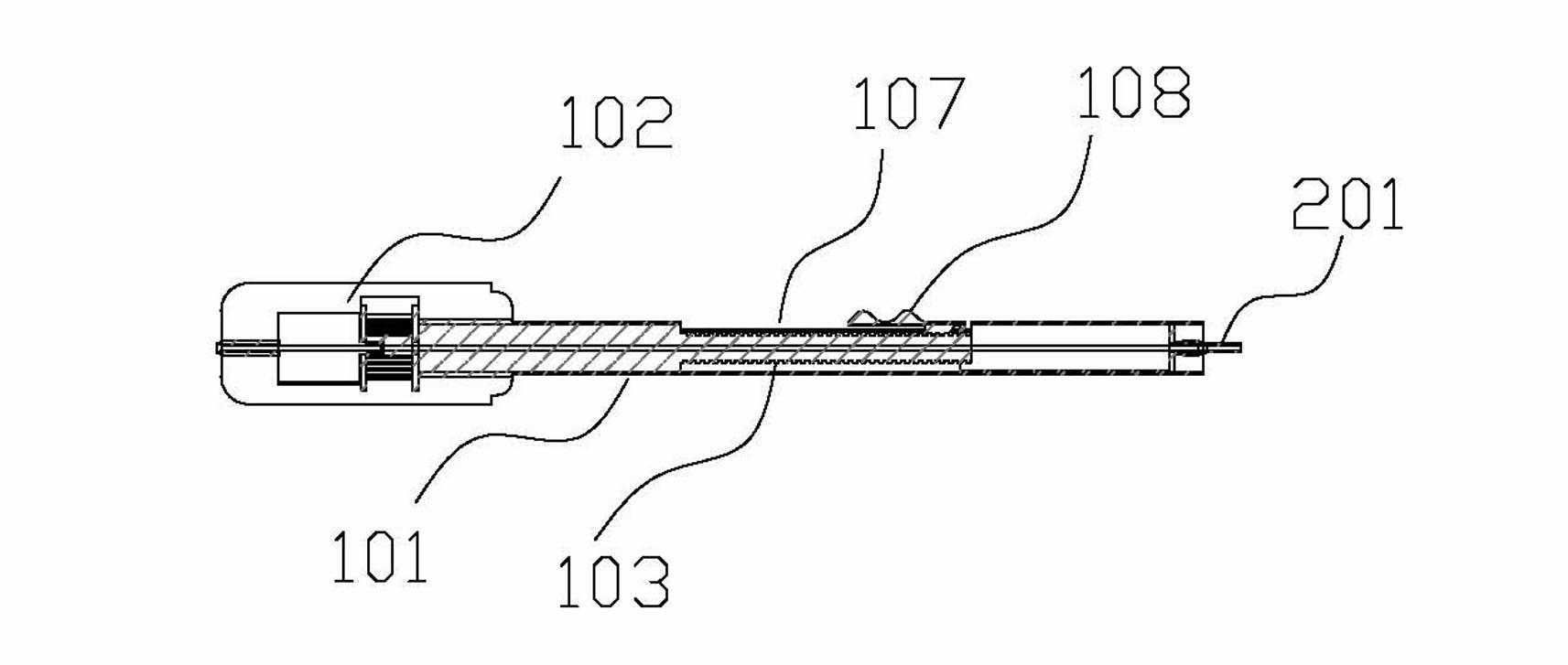

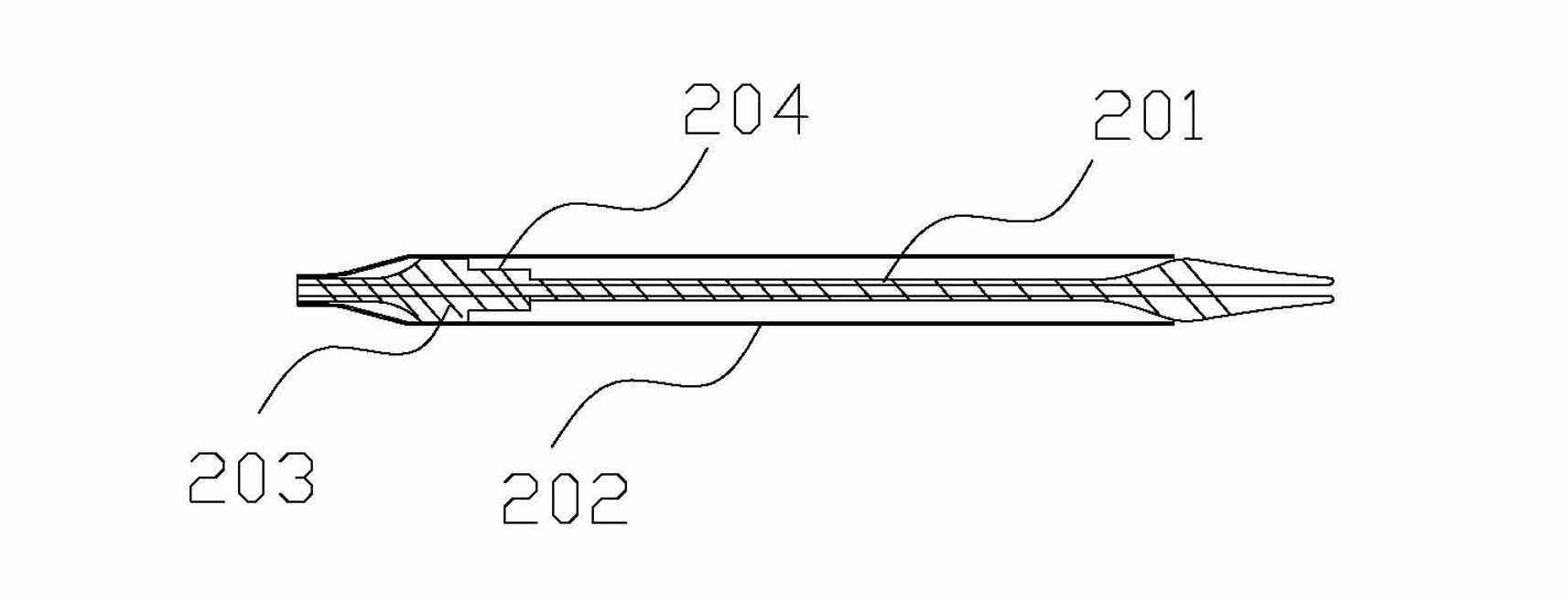

Support delivery device

ActiveCN102688112AAvoid surgical failureIncrease success rateStentsProsthesisFastenerInterventional therapy

The invention discloses a delivery device used for an interventional therapy shape memory support. The delivery device comprises a handle and a conduit, wherein the conduit consists of an inner core and a sheathing canal which are sheathed, and the remote end of the inner core and the sheathing pipe are matched for placing the support; the handle consists of a hollow tubular shell, a speed regulation assembly arranged at the near end of the shell, and a screw rod arranged in the shell; the speed regulation assembly is of a planetary gear structure and comprises a sun gear, an outer gear ring and a plurality of planetary gears, and the outer gear ring and the near end of the screw rod are fixed; the remote end of the shell is connected with the near end of the inner core; the near end of the sheathing pipe is further connected with a fastener structure capable of being meshed with the screw rod. The speed regulation assembly has a two-level speed regulation function, and can be used for accurately regulating the release position and speed of the support, and also recovering the support to the delivery device so as to perform repositioning if displacement exists in the release process.

Owner:GUANGDONG BROSMED MEDICAL DEVICE CO LTD

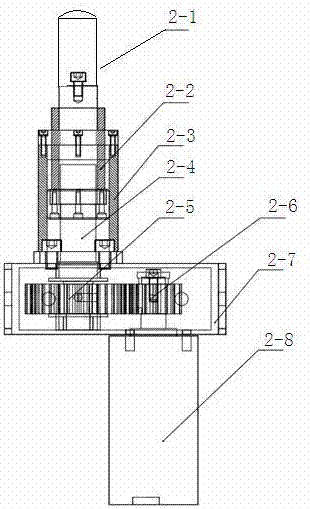

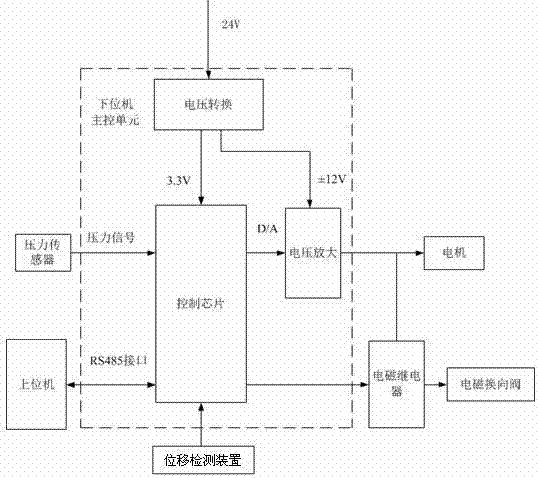

Method for locking clamp on precision machine tool

InactiveCN106903533AAccurate adjustment positionLarge locking forcePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a clamp locking method on a precision machine tool. The clamp includes an electromagnetic chuck, a hydraulic oil device, a hydraulic propulsion mechanism, a displacement detection device, a pressure detection device and a lower computer, wherein the electromagnetic chuck is evenly arranged along the disk circumference Several hydraulic propulsion mechanisms, several hydraulic propulsion mechanisms can lock or loosen the workpiece; each hydraulic propulsion mechanism is connected to the hydraulic oil device through an electromagnetic reversing valve; the displacement detection device is used to detect the position of the workpiece in real time; the The pressure detection device is arranged in the hydraulic circuit of each hydraulic propulsion mechanism; the lower machine is connected with the electromagnetic chuck, hydraulic oil device, electromagnetic reversing valve, displacement detection device and pressure detection device. The clamp locking method on the precision machine tool of the present invention locks the workpiece through several hydraulic propulsion mechanisms, and detects the workpiece through double detection mechanisms to ensure accurate locking of the workpiece.

Owner:SUZHOU YASIKE PRECISION CNC CO LTD

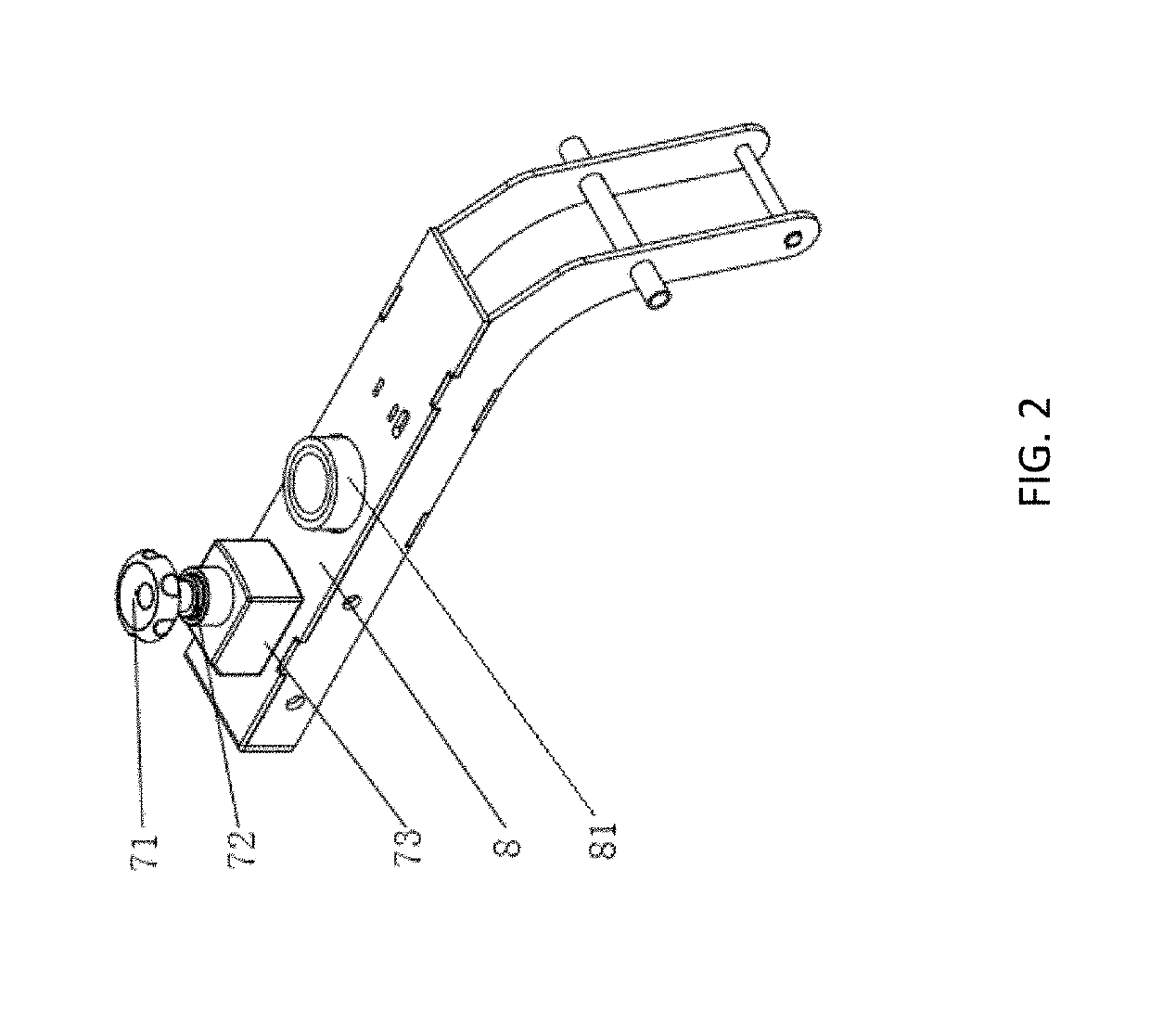

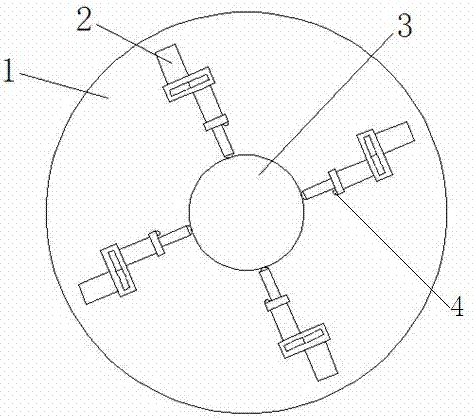

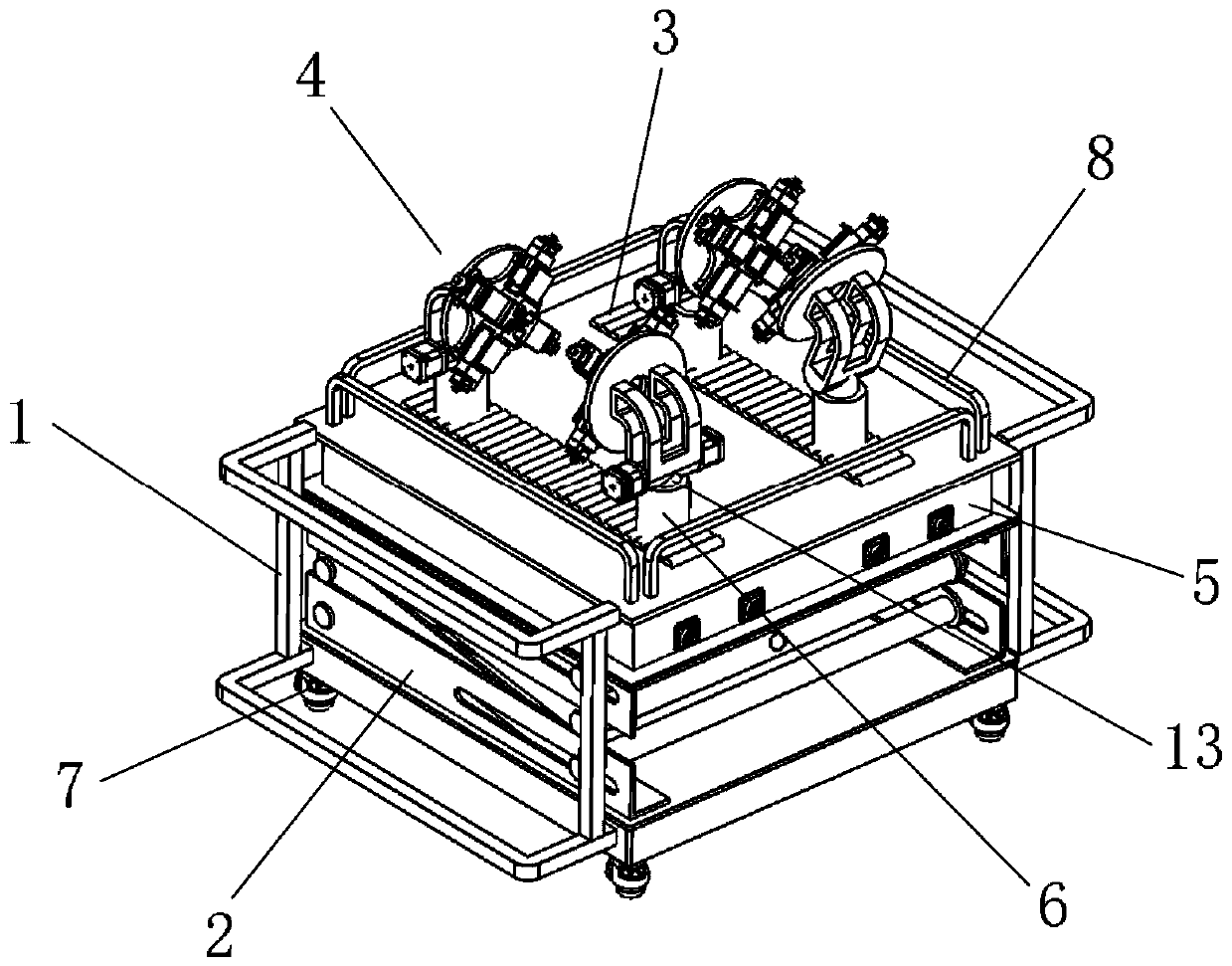

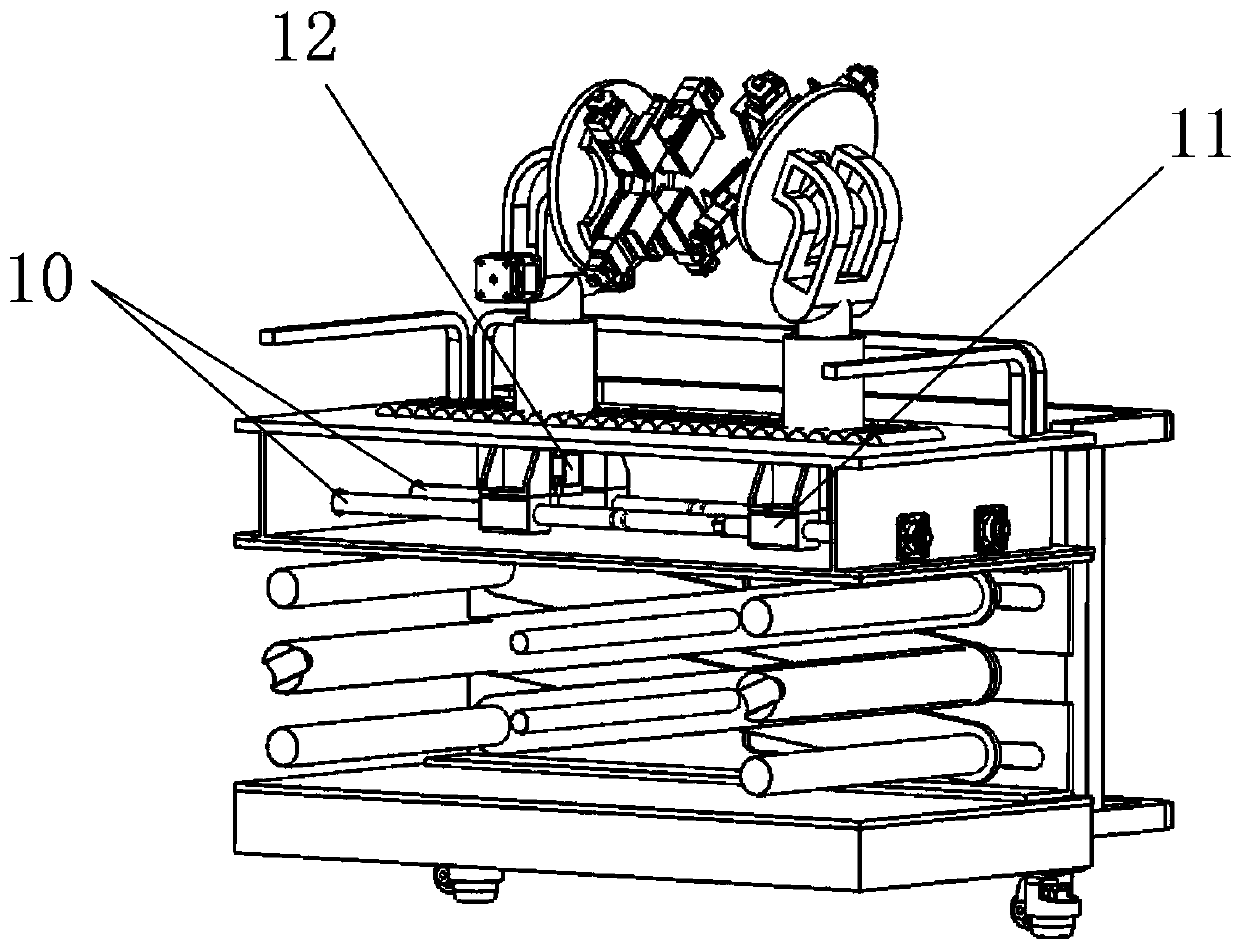

Full-automatic tube sheet welding tool platform

ActiveCN110102948ASave welding learning timeMeet the needs of bonding and weldingWelding/cutting auxillary devicesAuxillary welding devicesCircular discRadiation mode

The invention discloses a full-automatic tube sheet welding tool platform. A working table is provided with a plurality of strip-shaped track grooves, tube sheet clamping mechanisms are arranged in the strip-shaped track grooves correspondingly, and a drive mechanism is arranged in a machine box; the upper end of a curvy swing arm is fixedly connected with a round disc, and the lower end of the curvy swing arm is movably hinged to a telescopic mechanism; a rotating shaft penetrates through the round disc, a clamp base sleeves the rotating shaft, and the clamp base is provided with a pluralityof clamping servo drive modules in a radiation mode; the first side of a L-shaped clamping block is located at the tip of the telescopic movable end, the second side of the L-shaped clamping block islocated on the side surface of the side, back to the round disc, of the telescopic movable end, and the second side of the L-shaped clamping block is further fixedly connected with a clamping stop block. The full-automatic tube sheet welding tool platform is used for welding practical teaching of tube sheets and tube sheets, plates and plates and the tube sheets and the plates, the welding assembling efficiency and welding assembly precision are improved, the labor intensity is relieved, welding operators quickly clamp workpieces in practical teaching and welding skill competitions, and the welding position is flexibly adjusted for welding operation.

Owner:合肥哈工库讯智能科技有限公司

Integrated terminal antenna based on Beidou navigation technology

ActiveCN108682955AAccurate adjustment positionImprove the quality of workAntenna supports/mountingsQuality of workLocking mechanism

The invention discloses an integrated terminal antenna based on Beidou navigation technology. The integrated terminal antenna includes a support base and a cavity mounting column, the cavity mountingcolumn is provided with a transition connecting rod through a steering power mechanism, and the transition connecting rod is connected with a terminal antenna bottom plate through a turning mechanism,a self-locking mechanism is also arranged inside the cavity mounting column, the turning mechanism comprises four inclined rods, the four inclined rods are mounted on a load-bearing three-dimensionalblocks at the upper end of the transition connecting rod, and pushing cylinders are arranged on the inclined rods, the terminal antenna bottom plate is also provided with a hollow barrel column, andthe outside of the hollow barrel column is provided with a tightening nut, the load-bearing three-dimensional blocks are provided with a limiting column matched with the hollow barrel column, and theupper end of the limiting column is provided with a rotating ball. The position of the terminal antenna can be accurately adjusted, so that the terminal antenna can transmit or receive signals accurately, the working quality of the terminal antenna is improved, the stability when the antenna works is improved, and the circumstance of insensitive signal reception caused by severe weather is reduced.

Owner:SHANDONG TIANYUAN INFORMATION TECHNOLOGY CO LTD

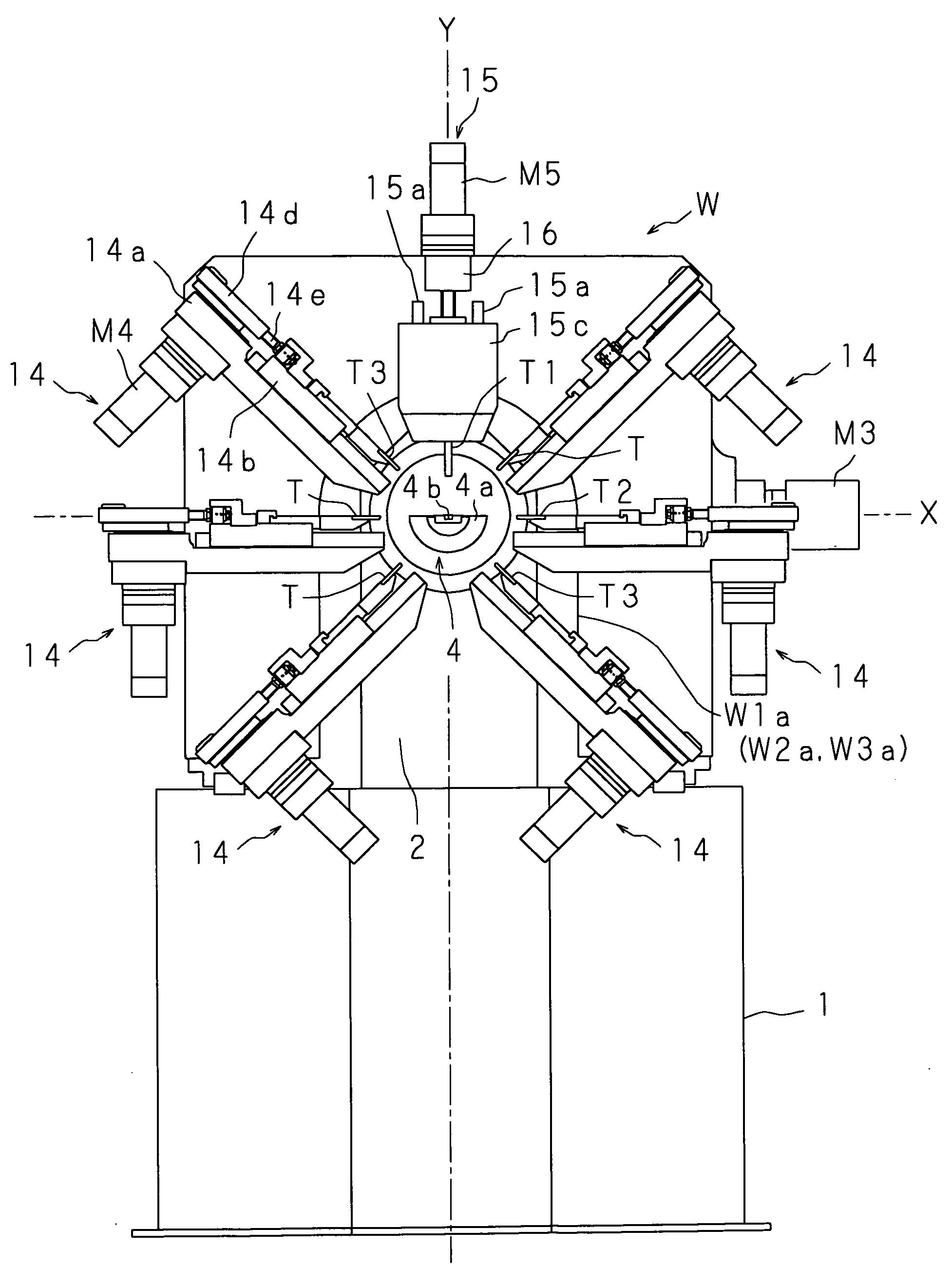

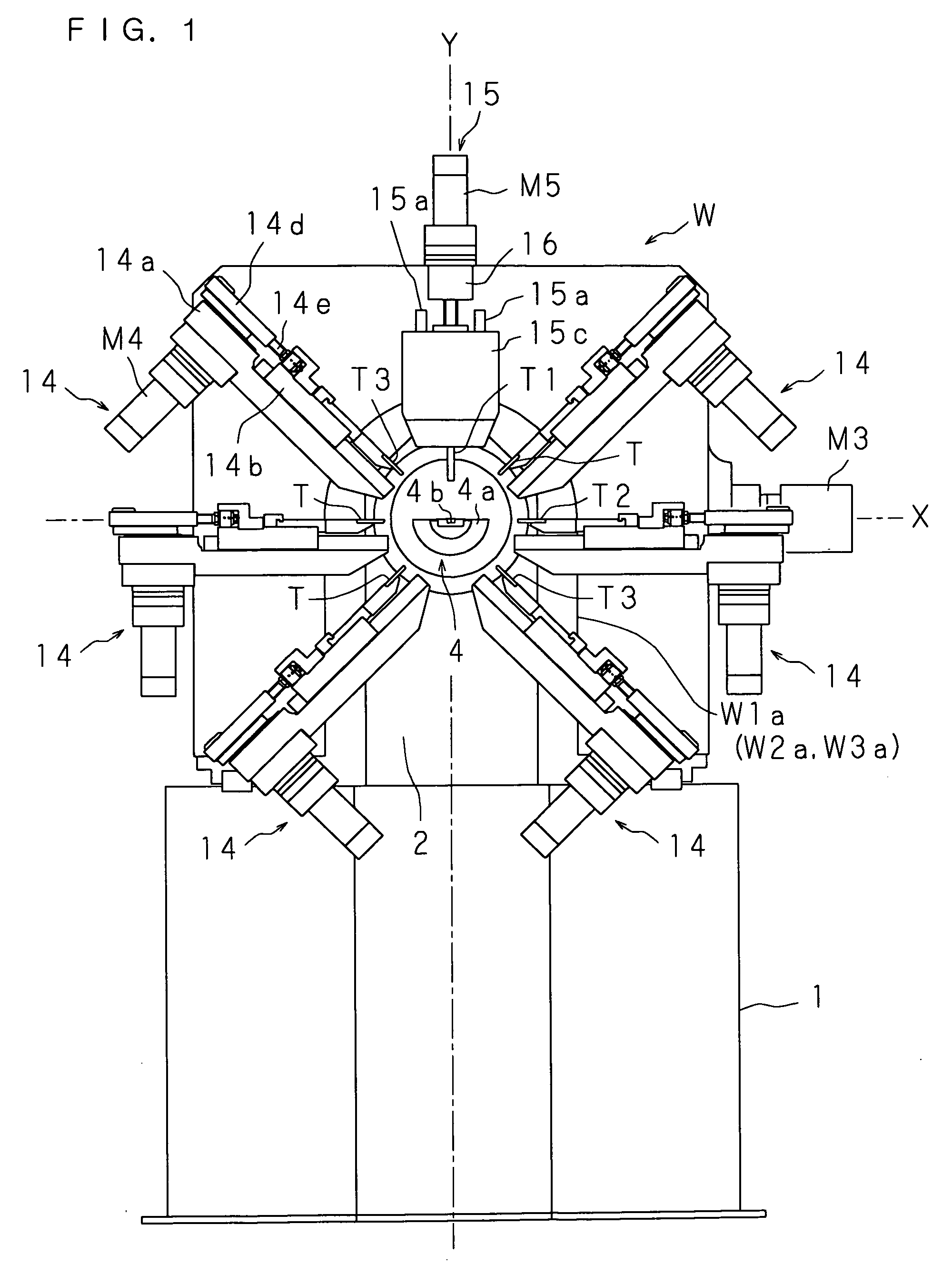

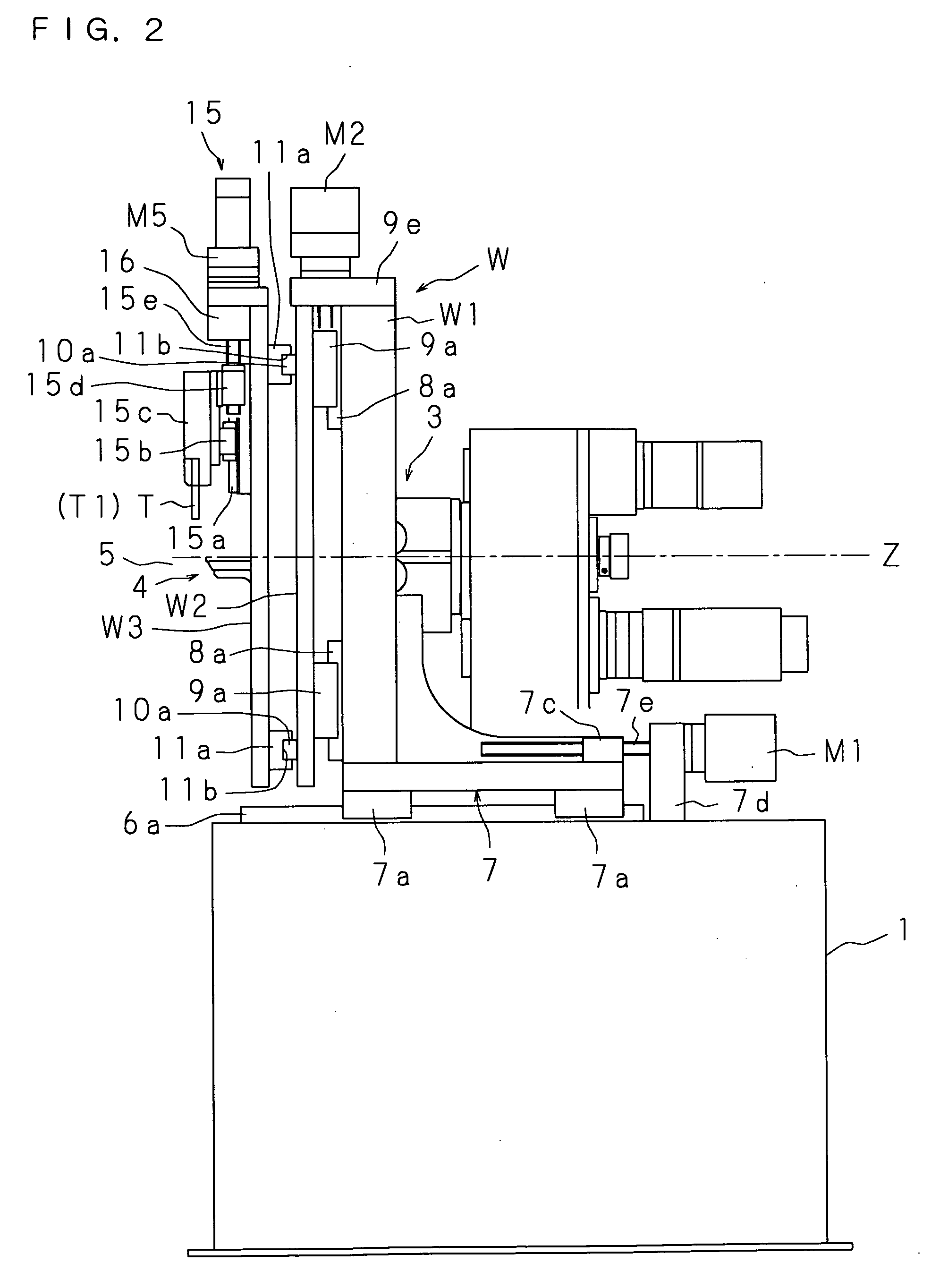

Spring manufacturing apparatus

ActiveUS20080314110A1Good precisionIncreased durabilityWire springsForging/hammering/pressing machinesWire rodOrthogonal coordinates

A spring manufacturing apparatus includes a supporting body which moves in X, Y, and Z-axes directions of a XYZ orthogonal coordinate system representing a moving direction of a wire rod fed from a wire rod feeding unit as a Z-axis. The supporting body is formed with an opening in which the quill is arranged. The supporting body further includes a tool holder for holding a processing tool for processing the wire rod to a spring. The supporting body arranged at the vicinity of the quill is moved to accurately adjust the relative position of the quill and the processing tool, thereby manufacturing a desired spring.

Owner:SHINKOU KIKAI INDS

Multifunction target mark

InactiveCN1620112AAccurate adjustment effectAccurate detectionTelevision system detailsElectrical testingGraphicsCcd camera

The invention discloses a multifunctional target, which includes one or more basic group figures, and the multifunctional target is attached to a plane or cylindrical surface carrier, and the multifunctional target of the present invention can be conveniently, quickly and accurately Adjust and detect the position and performance parameters of each CCD camera.

Owner:CHINA BANKNOTE PRINTING & MINTING

Construction method for rapid hole alignment and posture adjustment of prefabricated stand column

ActiveCN110387825AAccurate adjustment positionShorten the timeBridge erection/assemblyAgricultural engineeringRebar

Owner:CHINA RAILWAY 24TH BUREAU GRP

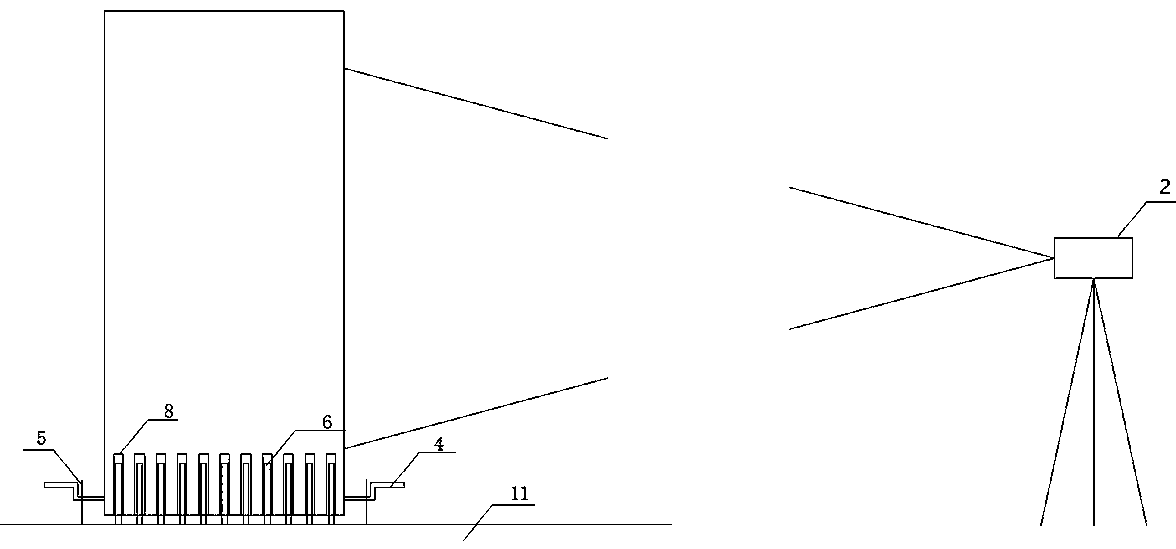

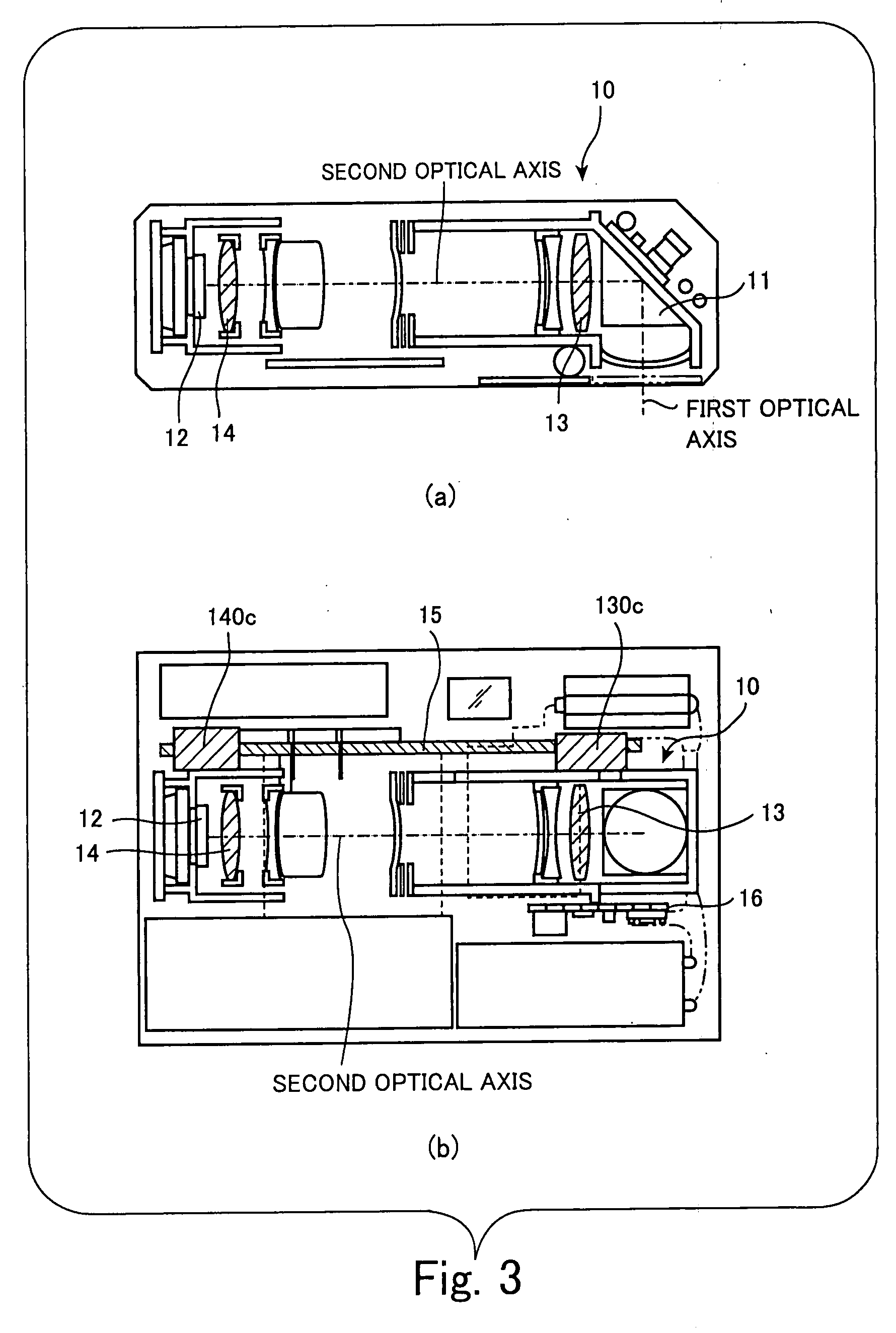

Image taking apparatus

InactiveUS20080007842A1Precisely adjust positioningAvoid complicated structureMountingsLinear motorEngineering

An image taking apparatus is provided with a lens driving unit that includes a magnetic shaft in which the S pole and the N pole are alternately aligned in a longitudinal direction of the shaft. The lens driving unit also includes a first lens holding frame that holds a first lens and has a first coil, and a second lens holding frame that holds a second lens and has a second coil. The magnetic shaft is inserted in the first and second coils, so that each of the first and second coils form a linear motor in cooperation with the magnetic shaft.

Owner:FUJIFILM CORP

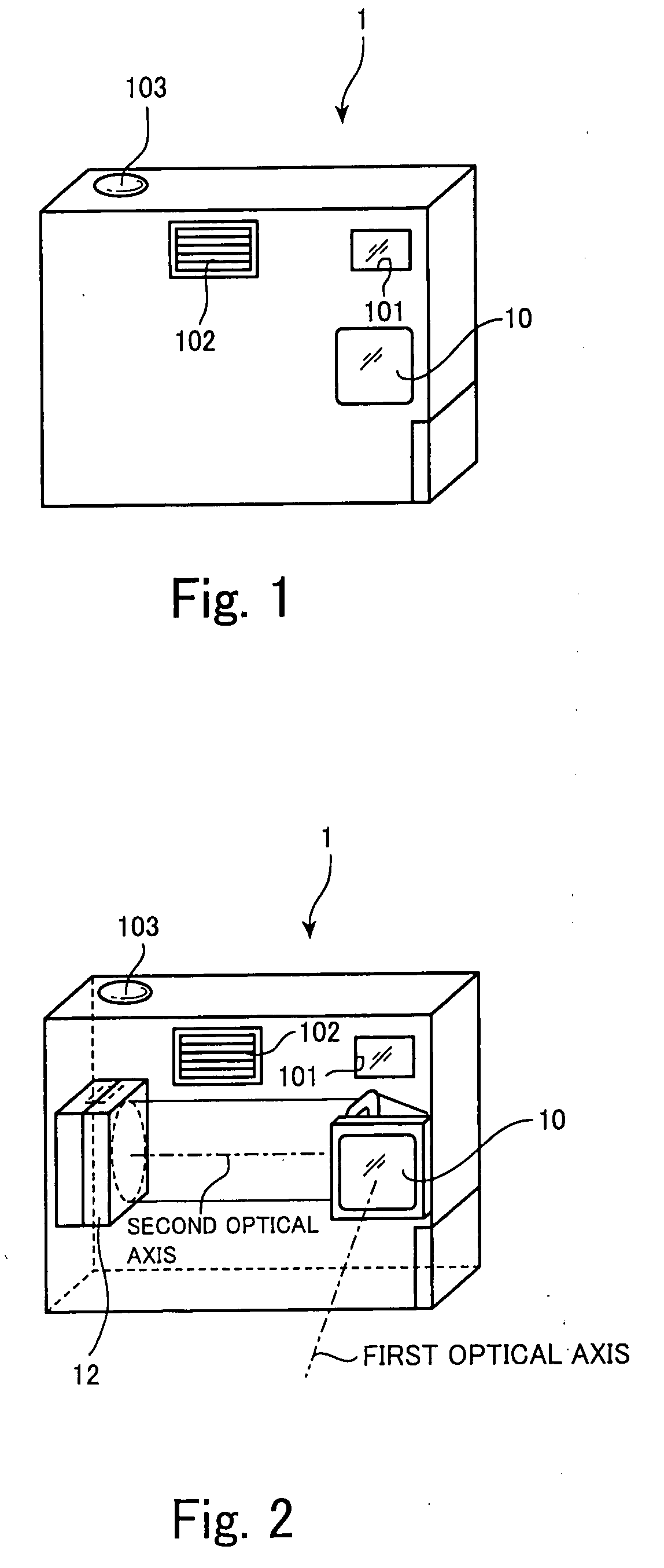

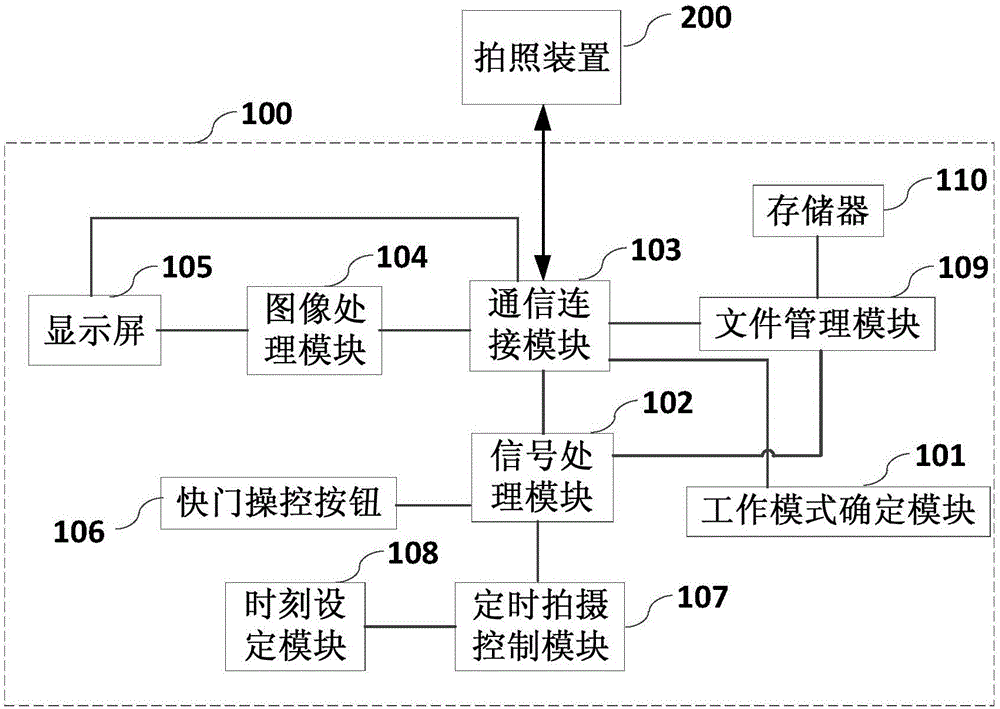

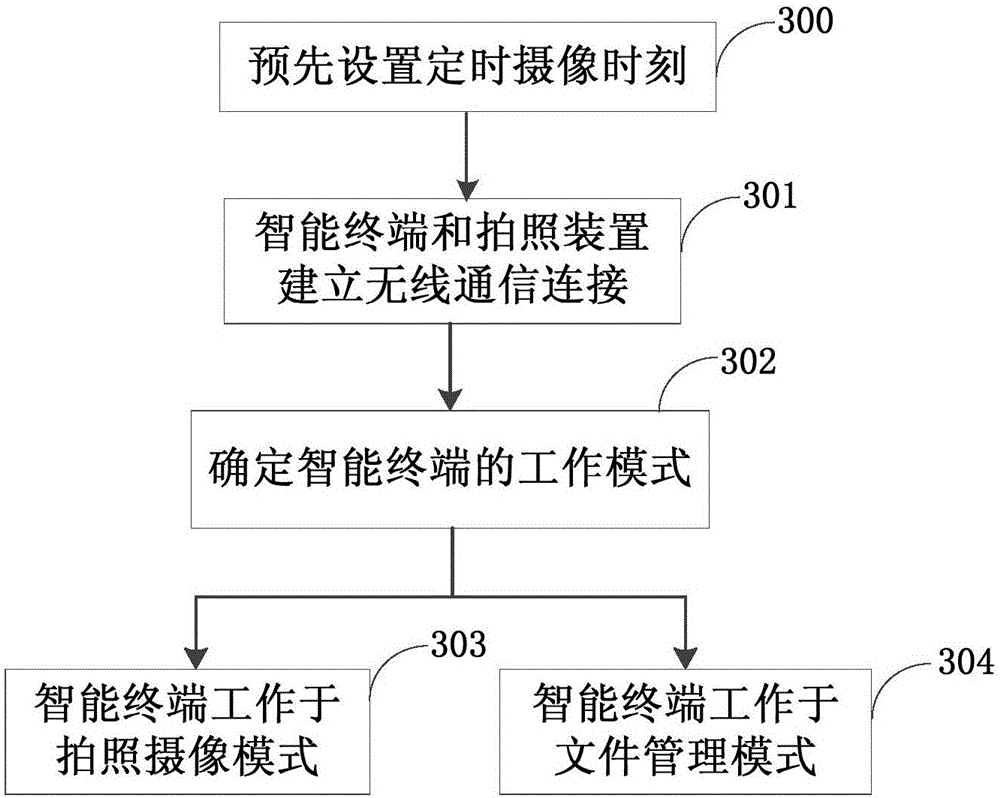

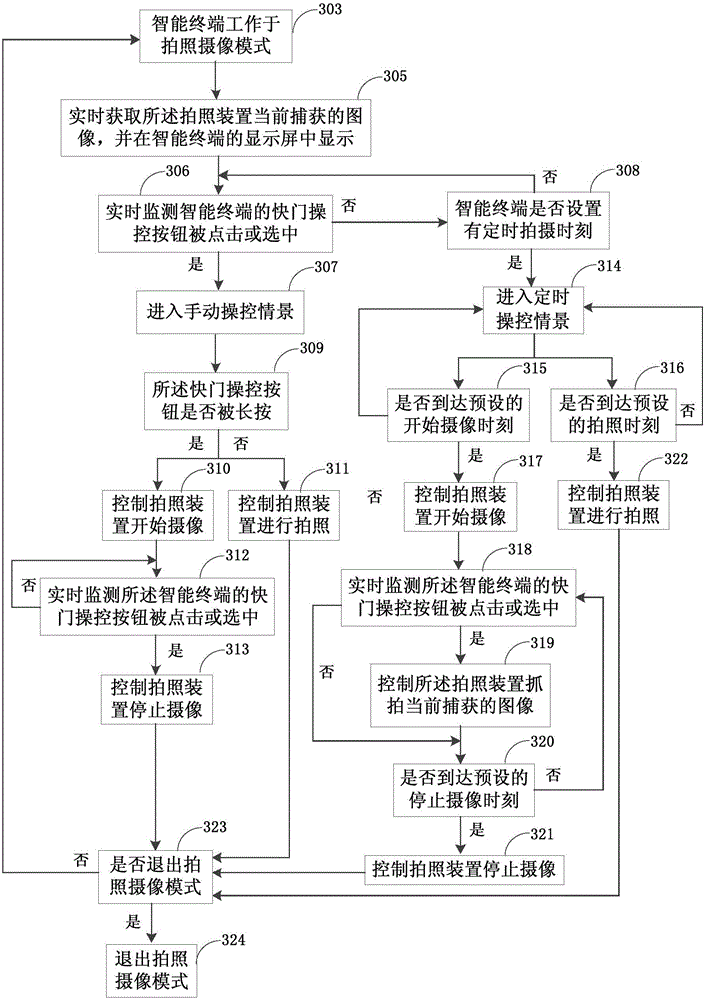

Photographing and camera shooting method and system

InactiveCN105933614AAccurate adjustment positionTelevision system detailsColor television detailsComputer graphics (images)Shooting method

The invention discloses a photographing and camera shooting method and system, for enabling users to better carry out photographing or camera shooting. The method provided by the invention comprises the steps that an intelligent terminal establishes a wireless communication connection with a photographing device, obtains an image currently captured by the photographing device in real time in a photographing and camera shooting mode, displays the image in a display screen of the intelligent terminal, and sends a control instruction of starting camera shooting to the photographing device at a preset camera shooting start moment to control the photographing device to start camera shooting. According to the invention, a photographing or camera shooting function is realized by the cooperative use of the intelligent terminal and the photographing device, the intelligent terminal displays the image currently captured by the photographing device in real time, so that people can accurately adjust the position of the photographing device, in addition, the system is further provided with a timing photographing function, so the photographing can be started or stopped according to a preset moment of people, thereby being very convenient.

Owner:GRAND IPEARL ELECTRONICS & TECH

Position adjustable lower die

The invention discloses a position adjustable lower die. The position adjustable lower die comprises a bottom plate, a first fixing base, a second fixing base, a die base, a lower die body, a transverse fine adjustment mechanism, a first support, a first micrometer rotary knob, a second support, a longitudinal adjusting screw and a longitudinal adjusting mechanism. During longitudinal adjustment,a limiting head and a clamping head are matched so that the second fixing base can be pulled back or pushed far. After the second fixing base is adjusted to the rough position, the first micrometer rotary knob is manually adjusted, the second fixing base is adjusted to the accurate position, and then an installing bolt of the second fixing base is tightly screwed. During transverse adjustment, a bolt for die base fixation is unscrewed, then, a transverse adjusting screw is unscrewed, a second micrometer rotary knob is manually adjusted, and accordingly the position of the die base can be accurately adjusted. The device is simple in structure, the transverse position and the longitudinal position of the die base fixedly connected with the lower die body can be accurately adjusted, positionprecision is effectively improved, and accordingly punching precision is improved.

Owner:SUZHOU SPARK AUTOMATION

Paper diaper pull-up water cooling coating component and method

InactiveCN105232233AWith cooling functionImprove cooling effectAbsorbent padsBandagesDisplay deviceEngineering

The invention relates to a paper diaper pull-up water cooling coating component and a method. The paper diaper pull-up water cooling coating component can adapt to products in different specifications and dimensions, can fast cool a coating pull-up, and can accelerate the bonding between a rubber band and pull-up non-woven fabrics. A first water cooling support plate moves along a guide rail through being regulated by a long regulating screw rod; a second water cooling support plate moves along the guide rail through being regulated by a short regulating screw rod; the upper end of the first water cooling support plate is provided with an inner side covering plate; and the upper end of the second water cooling support plate is provided with an outer side covering plate. The paper diaper pull-up water cooling coating component and the method have the advantages that 1, the space and the covering width of the covering plates can be regulated so as to realize the compatibility with the products in different specifications and dimensions, the goal of adapting to the products with different coating widths and different specifications and dimensions can be achieved, and the cooling function is realized, so that the pull-up rubber band is fast cooled in the coating process, and the rubber band is fast bonded with the pull-up non-woven fabrics; and 2, by installing a digital position display, the position regulation is precise, and the fast regulation to the required position after the specification change is facilitated.

Owner:ZHEJIANG YONGCHUANG MACHINERY

Bonding machine lead mechanism and working method

InactiveCN111048447AAvoid welding failureAccurate adjustment positionSemiconductor/solid-state device manufacturingElectric machineStructural engineering

The invention discloses a bonding machine lead mechanism which is fixedly installed on a bonding machine base. The mechanism comprises an installation frame fixedly installed on the base, a lead clampfixedly connected to the installation frame and a wire feeding mechanism arranged on the base. The lead clamp comprises a displacement amplifier fixedly installed on the lead clamp, a driving motor connected with the displacement amplifier, a pair of connecting bridge plates in transmission connection with the driving motor, a left clamping jaw and a right clamping jaw, wherein the left clampingjaw and the right clamping jaw are connected to the other ends of the pair of connecting bridge plates. In the invention, a servo motor and a first stroke cylinder drive the lead clamp to adjust a metal wire output by a wire feeding part; the metal wire is welded on a chip metal layer; a tension generated by the metal wire in an adjusting process is fed back according to a tension measurement andcontrol unit; and adjusting positions of a second bonding point and the lead clamp are accurate, and welding failure caused by over-high tension of the metal wire is avoided.

Owner:南京微毫科技有限公司

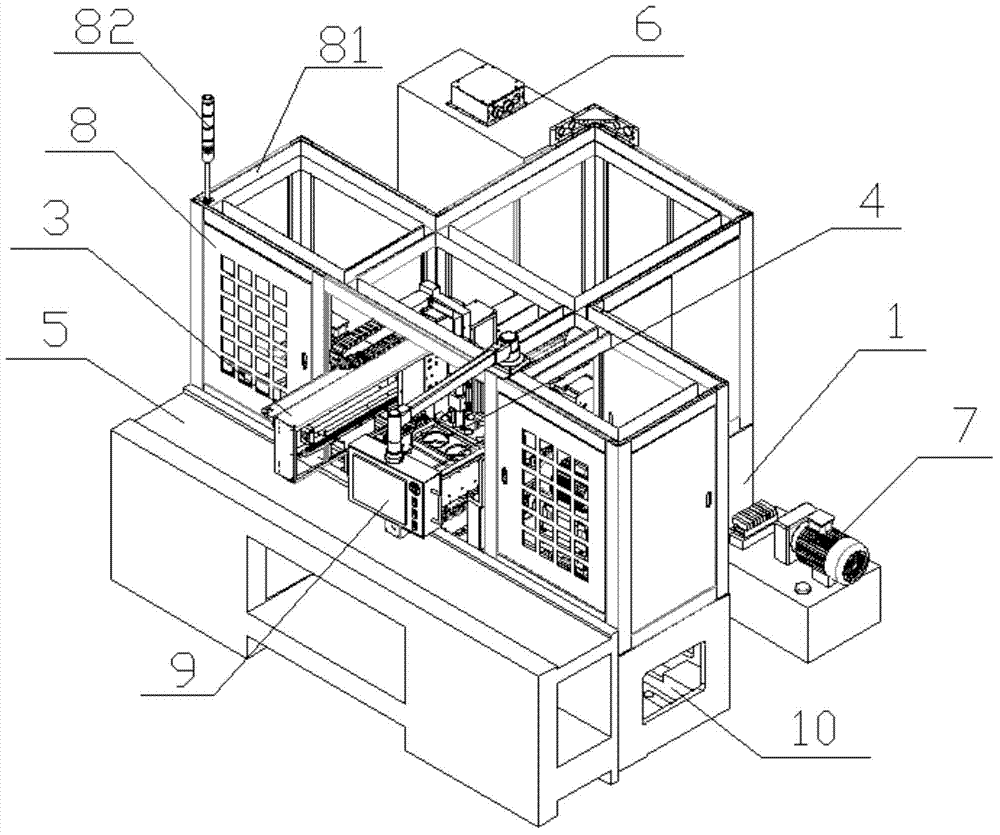

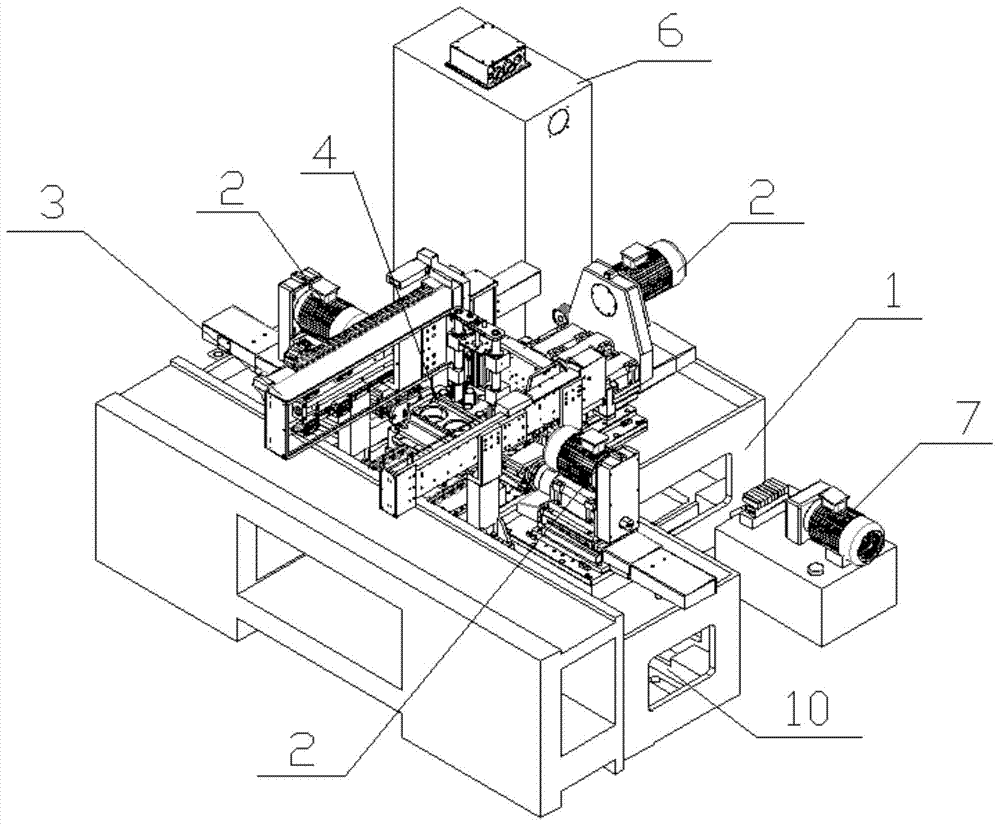

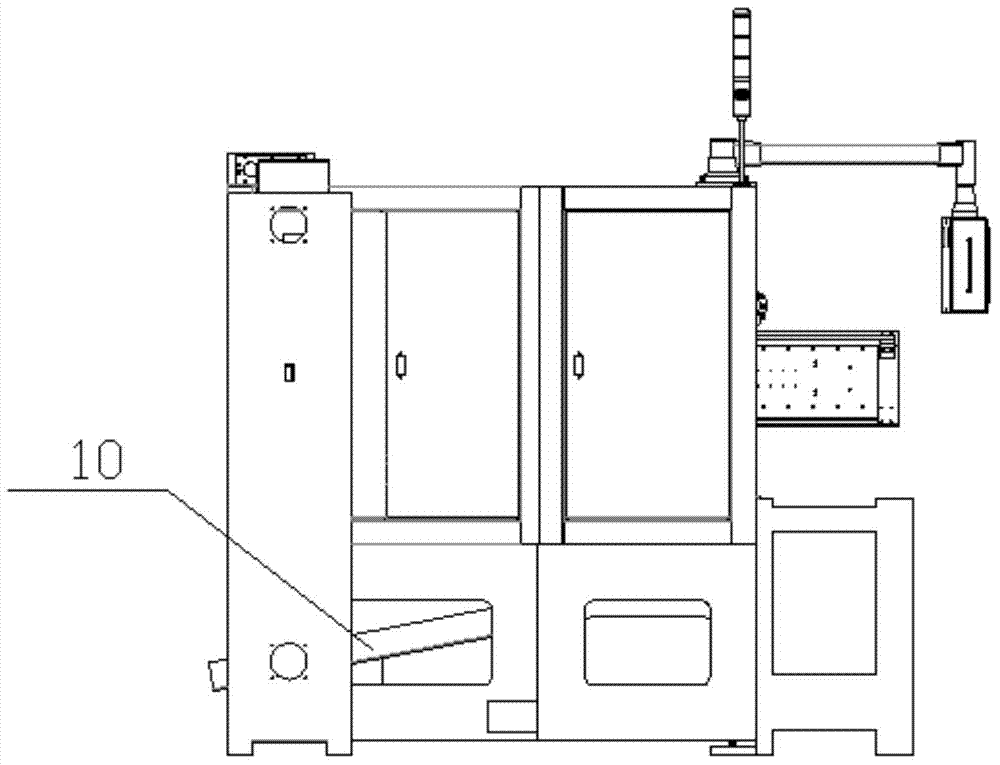

Yaw brake machine tool

ActiveCN104741932AReduce labor costsReduce manual labor intensityOther manufacturing equipments/toolsControl systemEngineering

The invention relates to a yaw brake machine tool. The yaw brake machine tool comprises a base which is of an inverted T-shaped structure, a cutting tool system, a manipulator system, a workpiece clamping auxiliary system, an assembly line workbench, an electric appliance control system and a hydraulic system; the cutting tool system is formed by a left cutting tool unit, a right cutting tool unit and a rear cutting tool unit which are arranged at the left position, the right position and the rear position of the base respectively; the manipulator system is located between the left cutting tool unit and the right cutting tool unit; the workpiece clamping auxiliary system is fixed on the base and located below the manipulator system; the assembly line workbench is fixed at the front end of the base; a position of the assembly line workbench, which is corresponding to a manipulator, is provided with a sensor and a jack-up cylinder; the electric appliance control system and the hydraulic system are arranged at two ends behind the base respectively; the hydraulic system is connected with the workpiece clamping auxiliary system. According to the yaw brake machine tool, the simultaneous machining can be performed on a plurality of machining surfaces, a fixture, a cutting tool and a milling machine do not need to be replaced, the machining accuracy is high, and the intelligent automation control is implemented.

Owner:嘉兴德威高传动系统股份有限公司

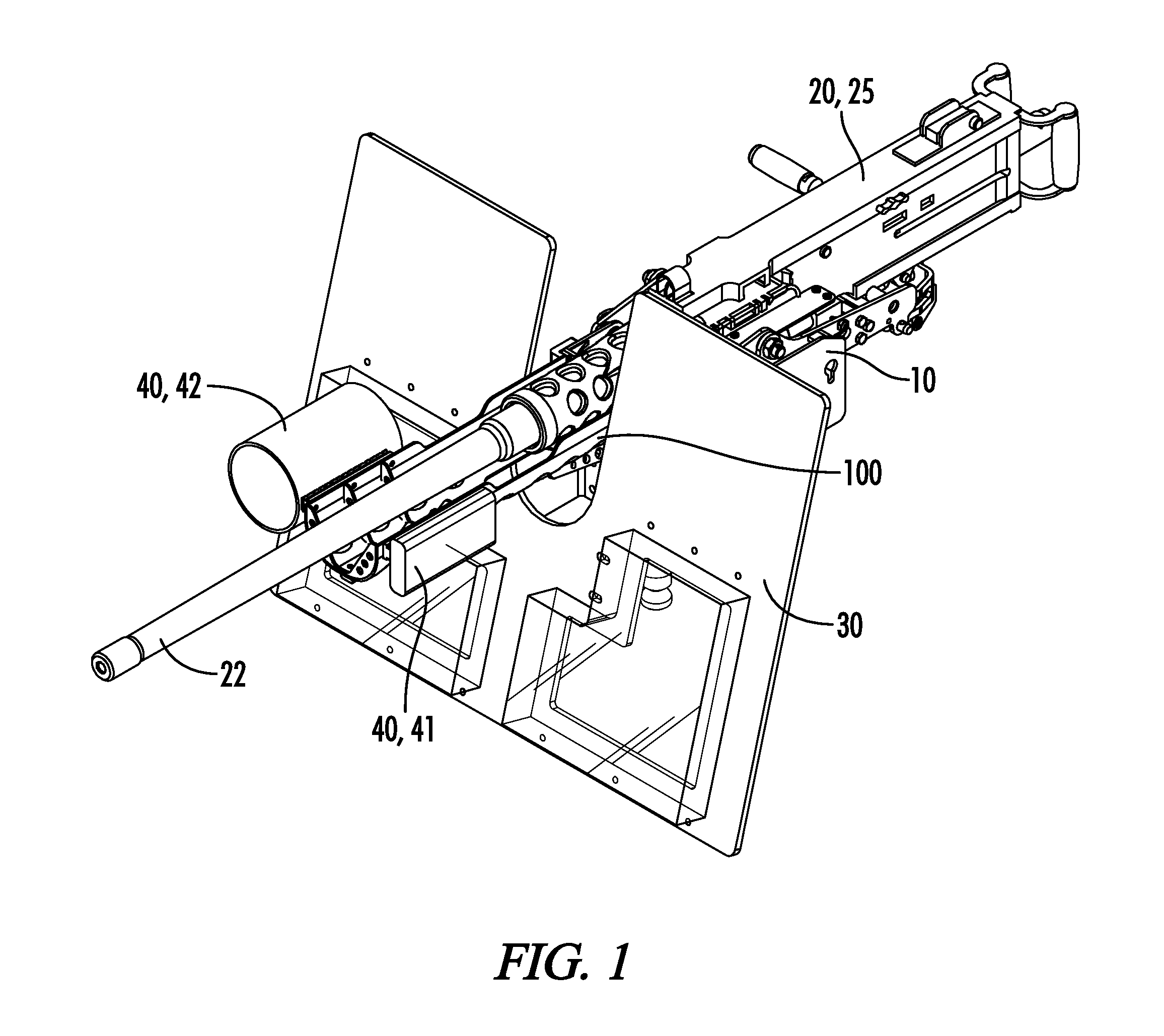

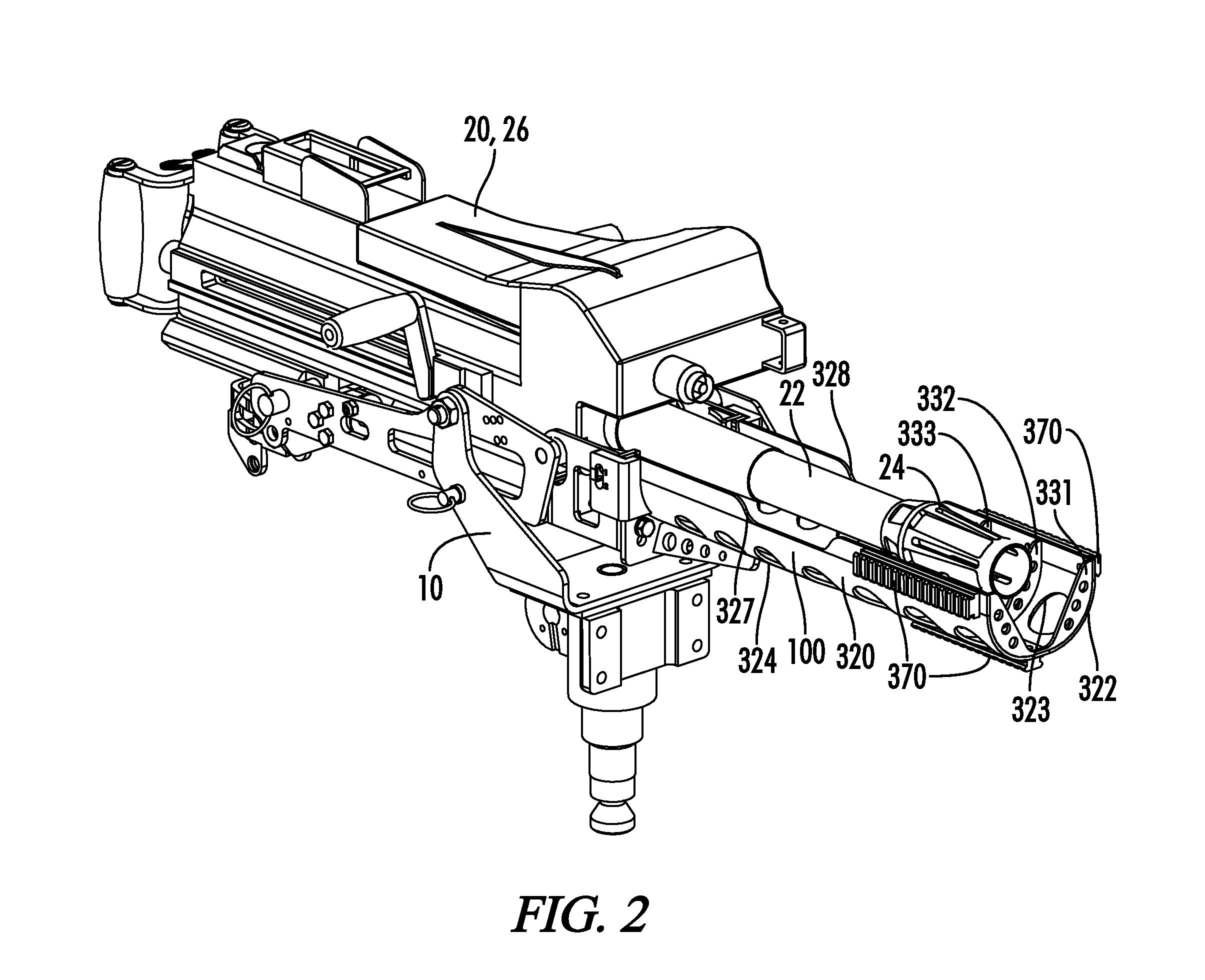

Accessory bracket for firearm mount

InactiveUS8584393B2Accurate adjustment positionSecure attachmentCartridge extractorsSighting devicesFull movementGun barrel

Owner:STEINER EOPTICS INC

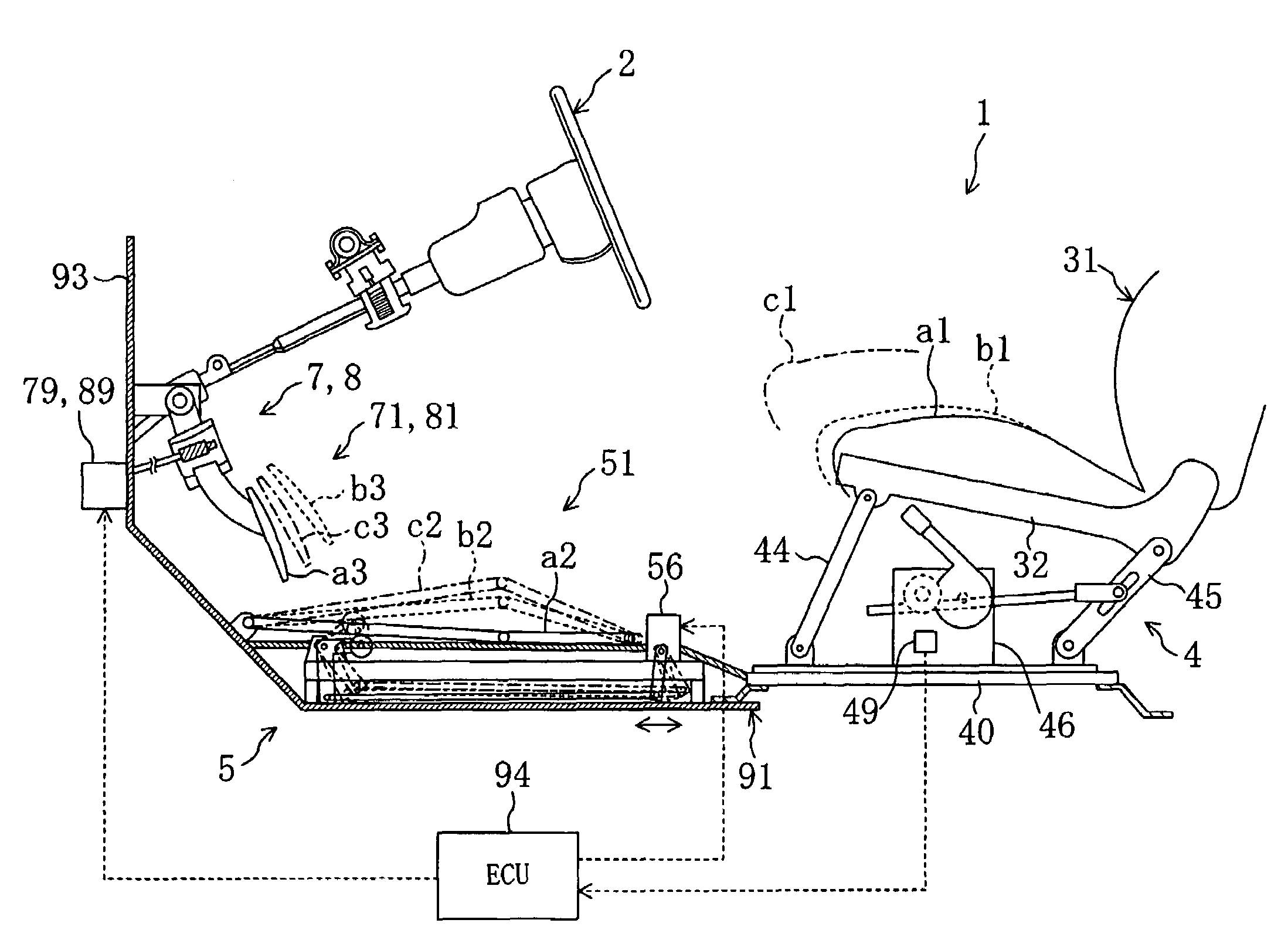

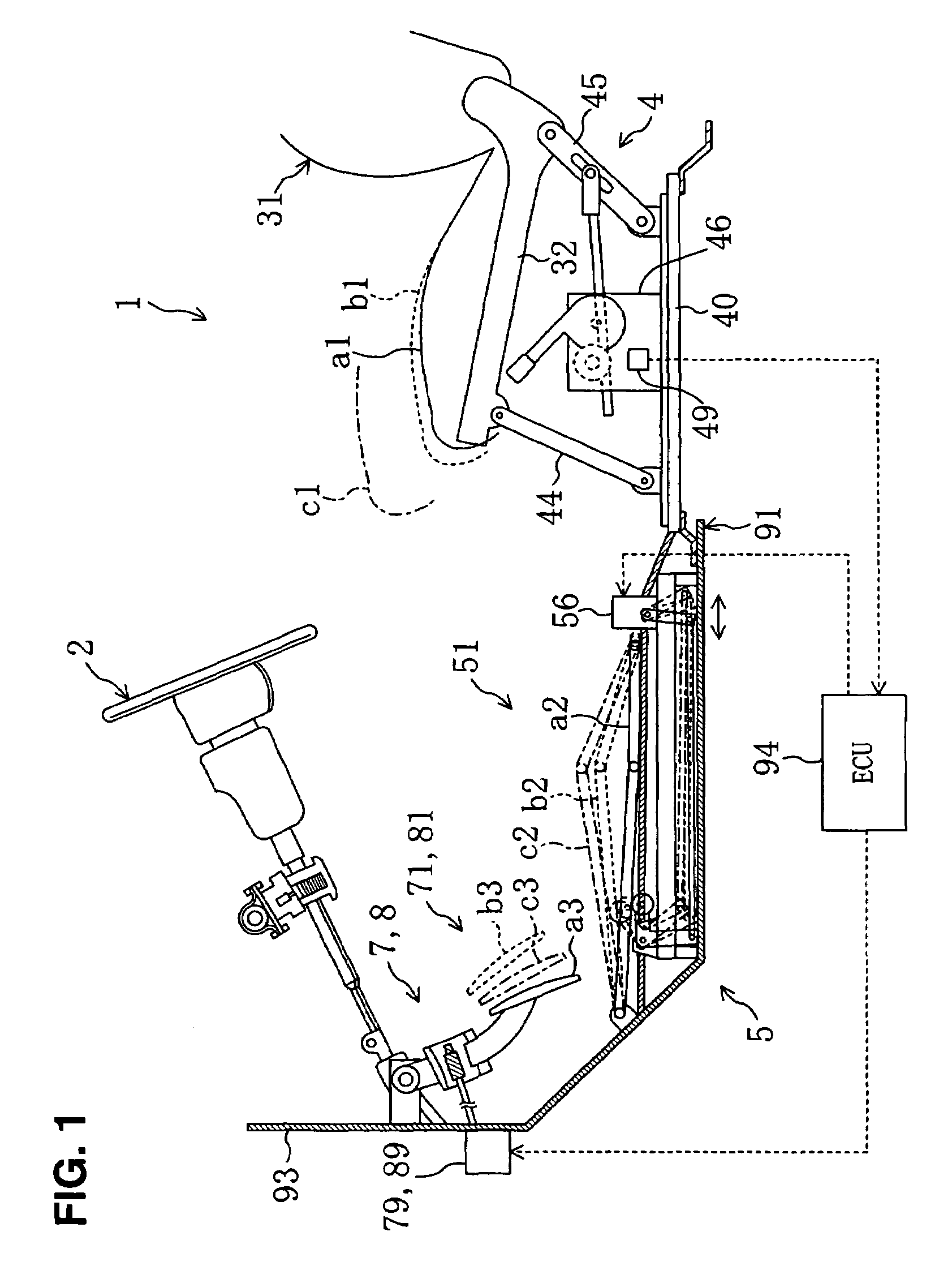

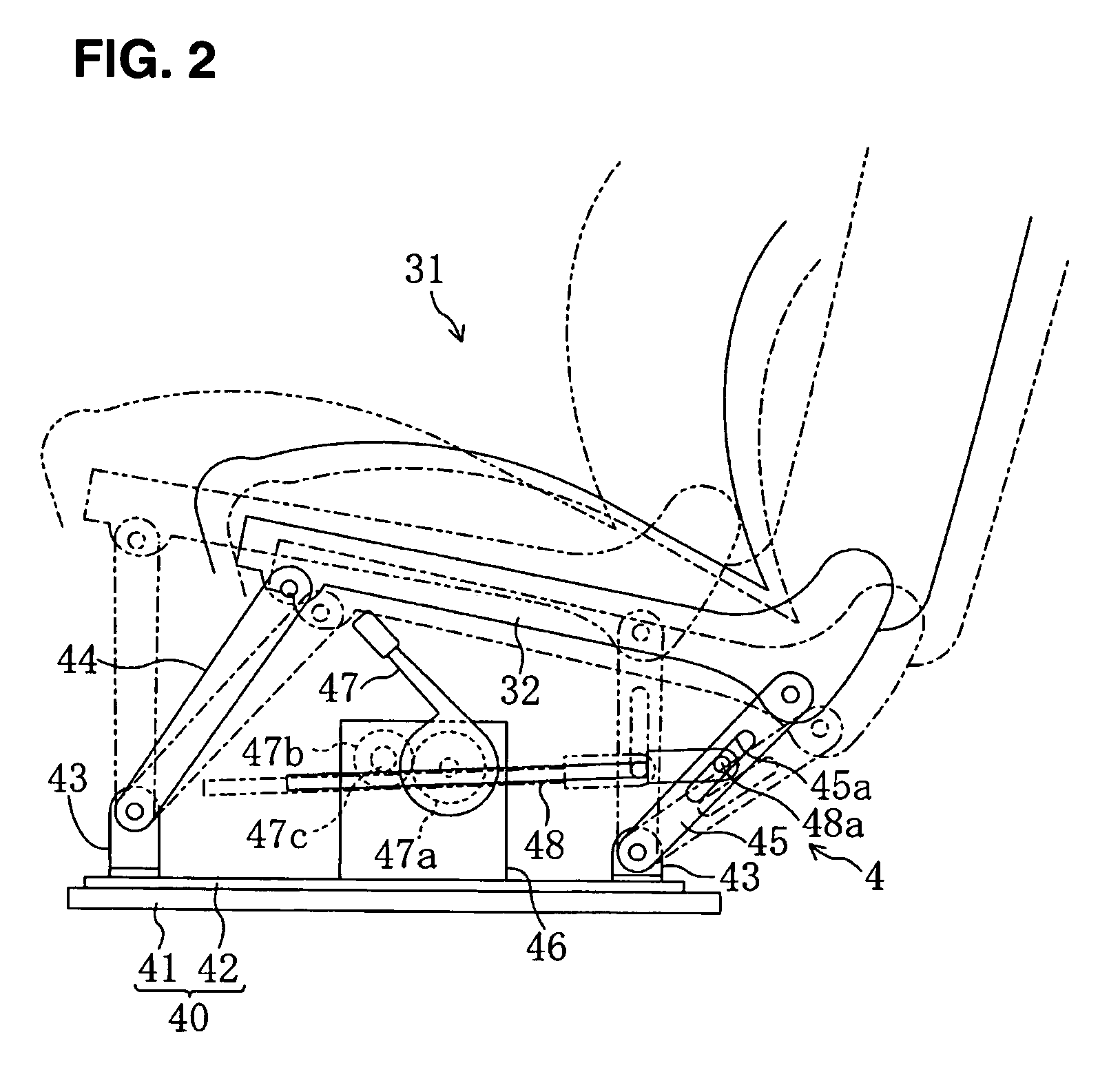

Driving position adjusting device for automotive vehicle

InactiveUS7437229B2Accurate adjustment positionControlling membersVehicle seatsDriver/operatorBody size

Owner:MAZDA MOTOR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com