Rock test piece manufacturing mold capable of adjusting joint angle and position and using method

A technology of rock specimen and angle adjustment device, which is applied in the preparation of test samples and other directions, can solve the problems of mold usage limitation, inability to achieve cross-joint specimens, etc., and achieves convenient assembly and mold disassembly, ingenious design and device novel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

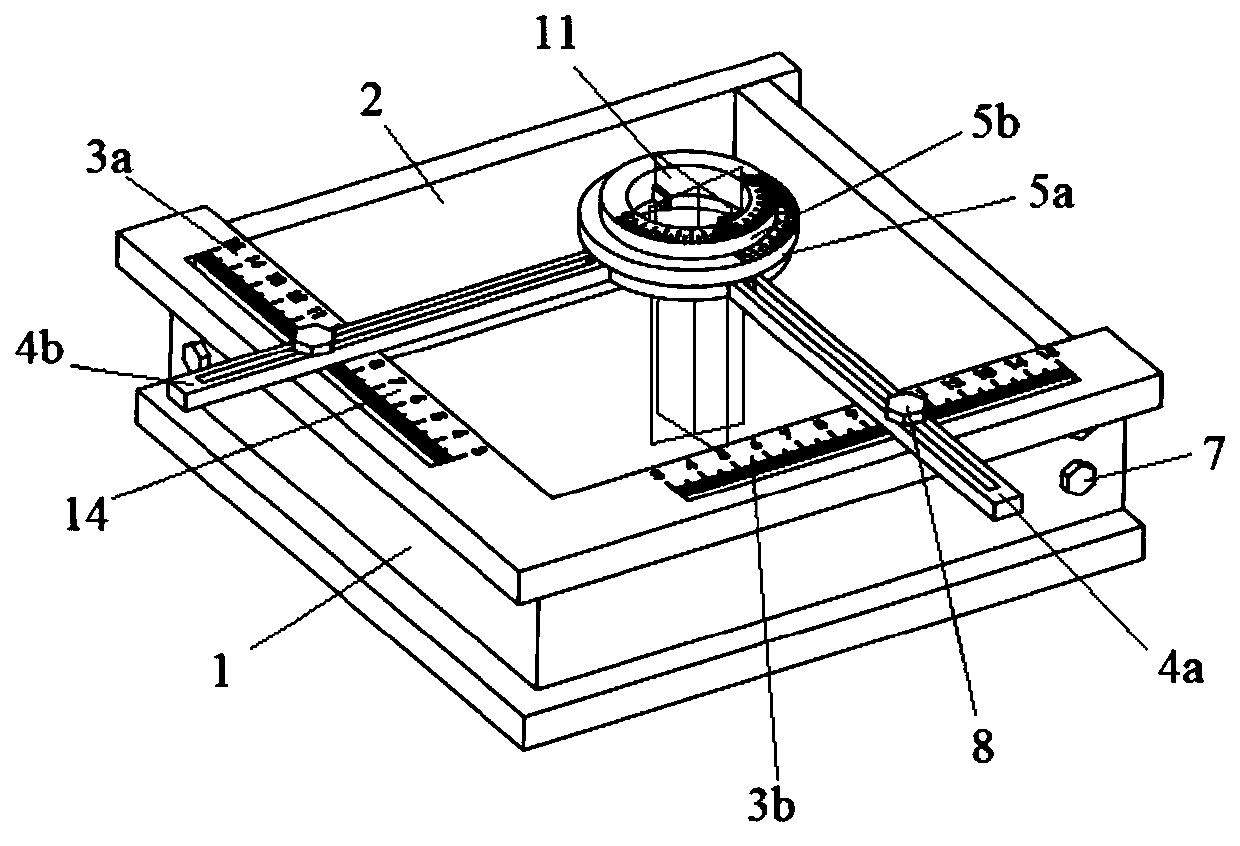

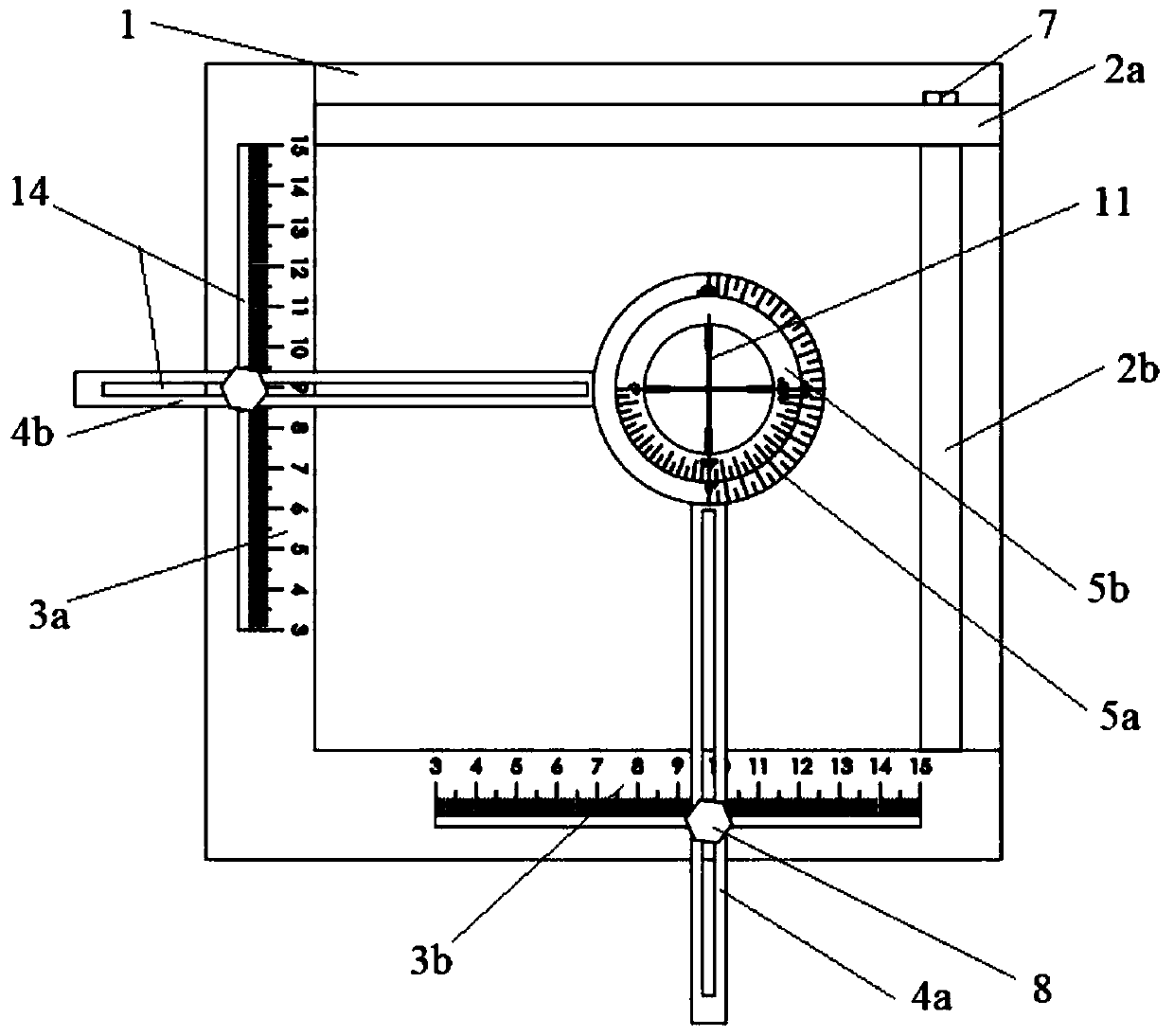

[0039] refer to figure 1As shown, the rock specimen production mold for adjusting the joint angle and position of the present invention includes a rectangular mold groove with an upper opening, which is composed of a fixed template 1 and a movable side plate 2, and a position adjustment device with adjustable horizontal and vertical axes. Composed of steel ruler plate 3 and sliding positioning straight rod 4, the angle adjustment device 5 of two prefabricated mold splints 6 on the inner wall, the above-mentioned components are connected and fixed by self-tightening bolts 7, long rod bolts 8, self-tightening nuts 9 and prefabricated grooves , The "X" shaped die material 11 with a crossing angle is polypropylene material.

[0040] figure 2 for figure 1 top view.

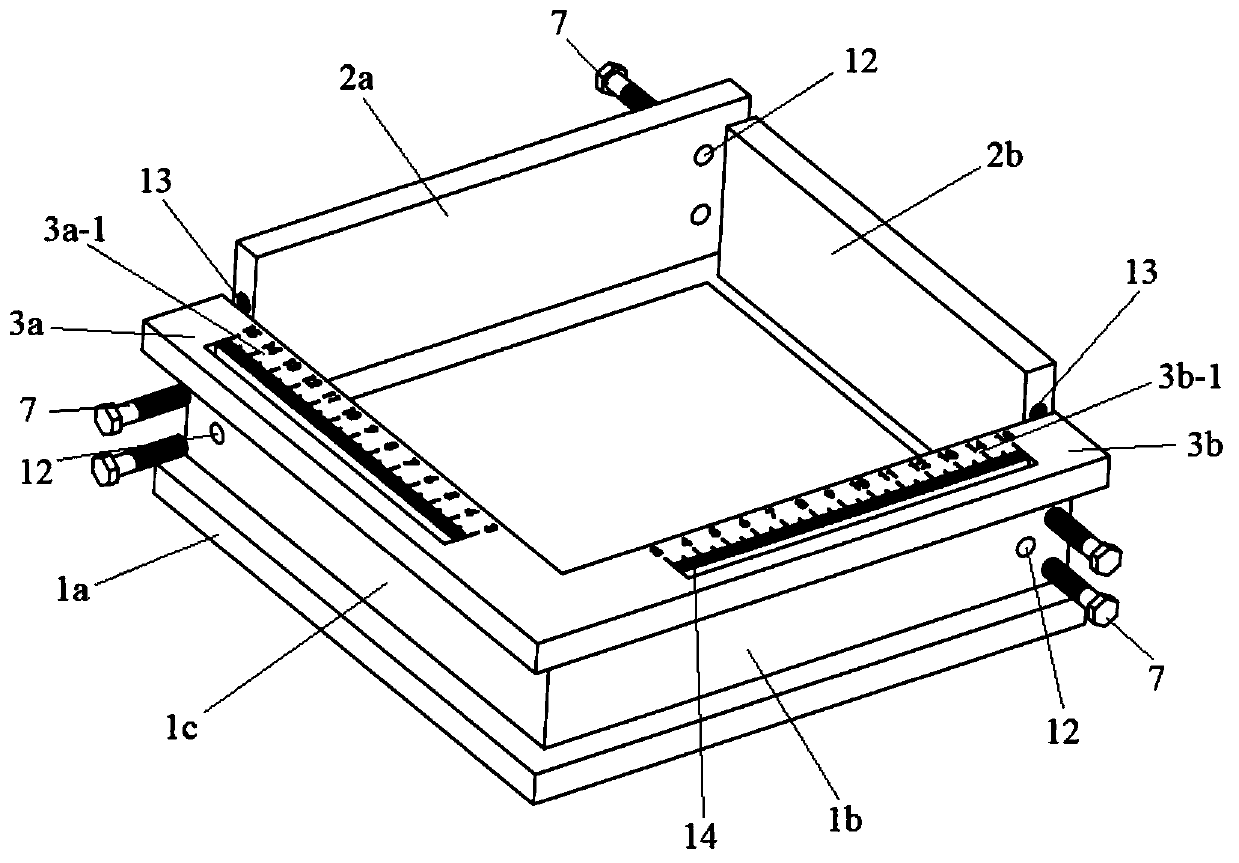

[0041] refer to image 3 As shown, the rectangular mold with upper opening is divided into fixed bottom plate 1a, fixed main side plate 1b, fixed secondary side plate 1c, movable main side plate 2a and movable sec...

Embodiment 2

[0053] Embodiment 2 is basically the same as Embodiment 1. It also assembles a rectangular groove first to make a rock-like sample, and then uses the position adjustment device and angle adjustment device to accurately determine the position and angle of the crack. The difference from Embodiment 1 is that this embodiment Example of prefabricated single-joint rock-like samples. refer to Figure 5 As shown, turn the second angle adjustment device 5b to a position that coincides with the size of the first angle adjustment device 5a, and at this time, the four groups of die splints are on the same plane. Only one piece of polypropylene mold piece 11 is needed, and its manufacture only considers the size of the cracks in the rock-like test piece, without slotting and assembling.

[0054] Using the mold described in this embodiment to make a rock-like specimen containing a single joint, the steps are basically the same as in Embodiment 1, the difference is that there is no need to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com