Patents

Literature

222results about How to "Precise position adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

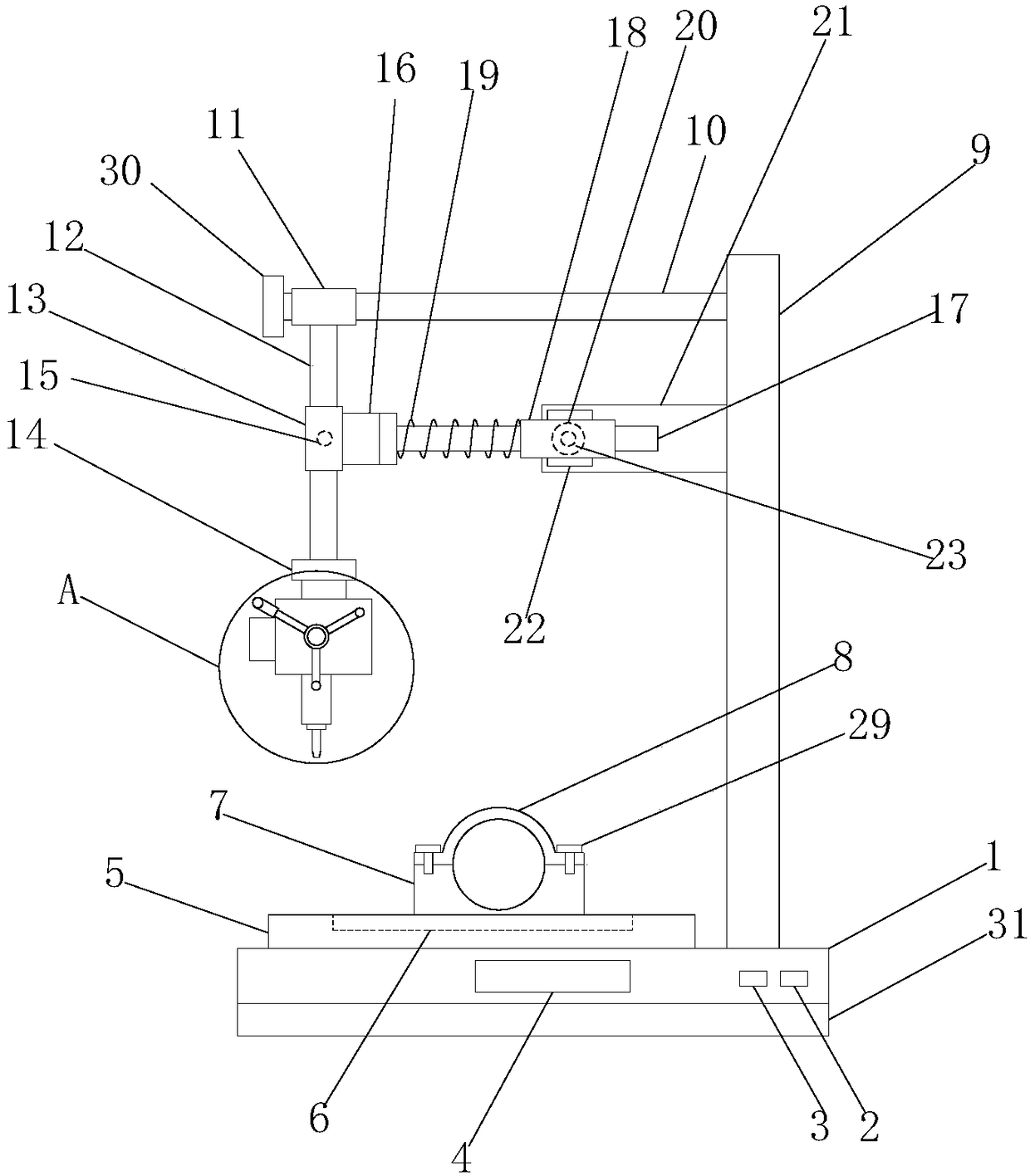

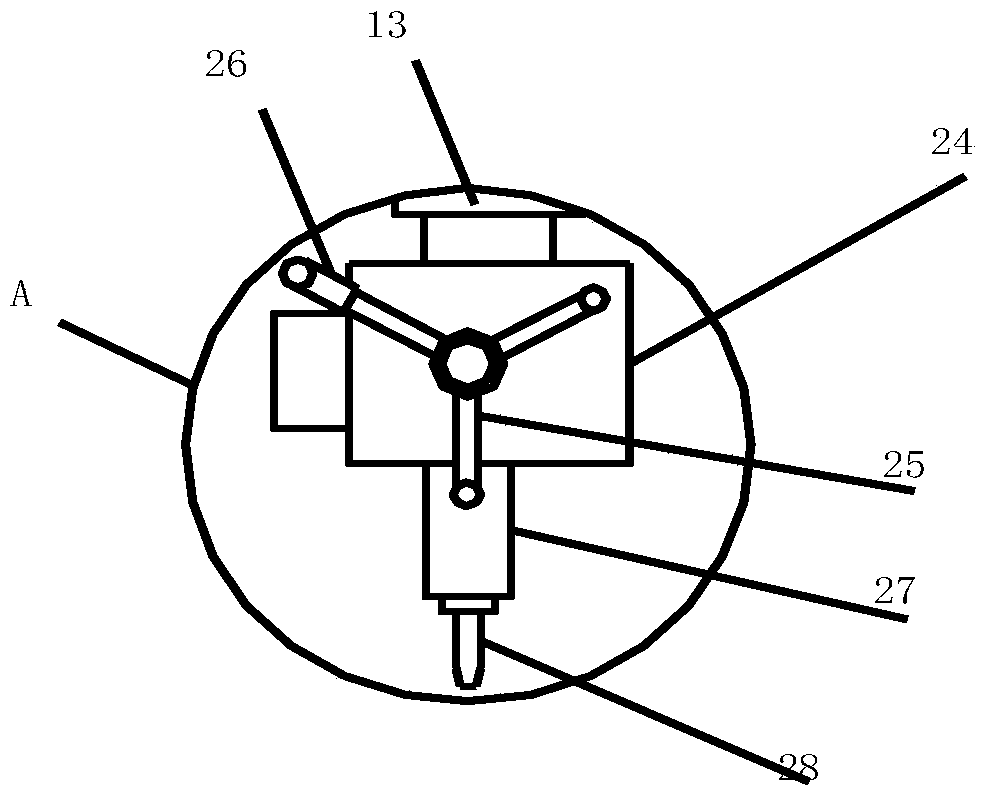

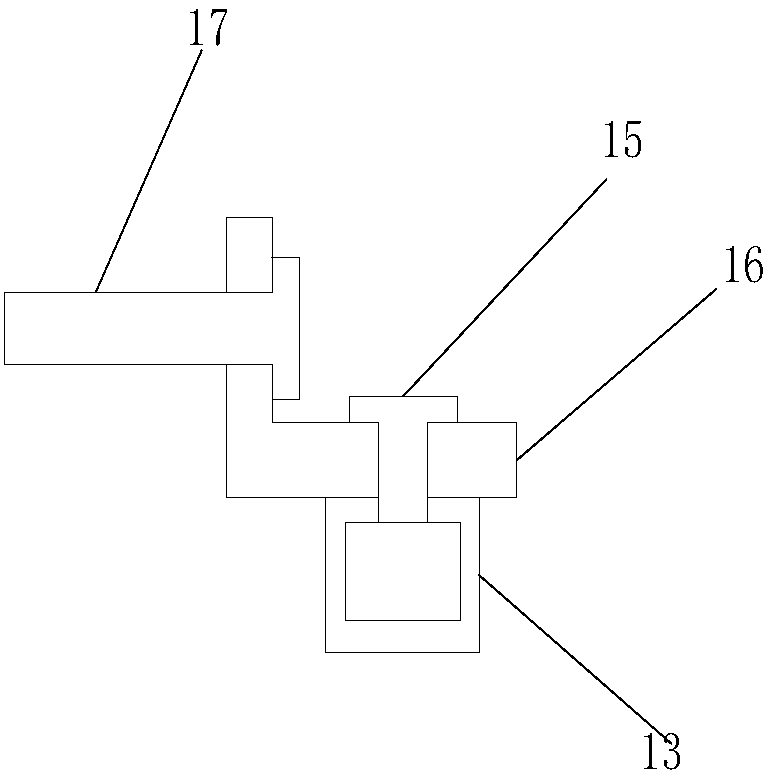

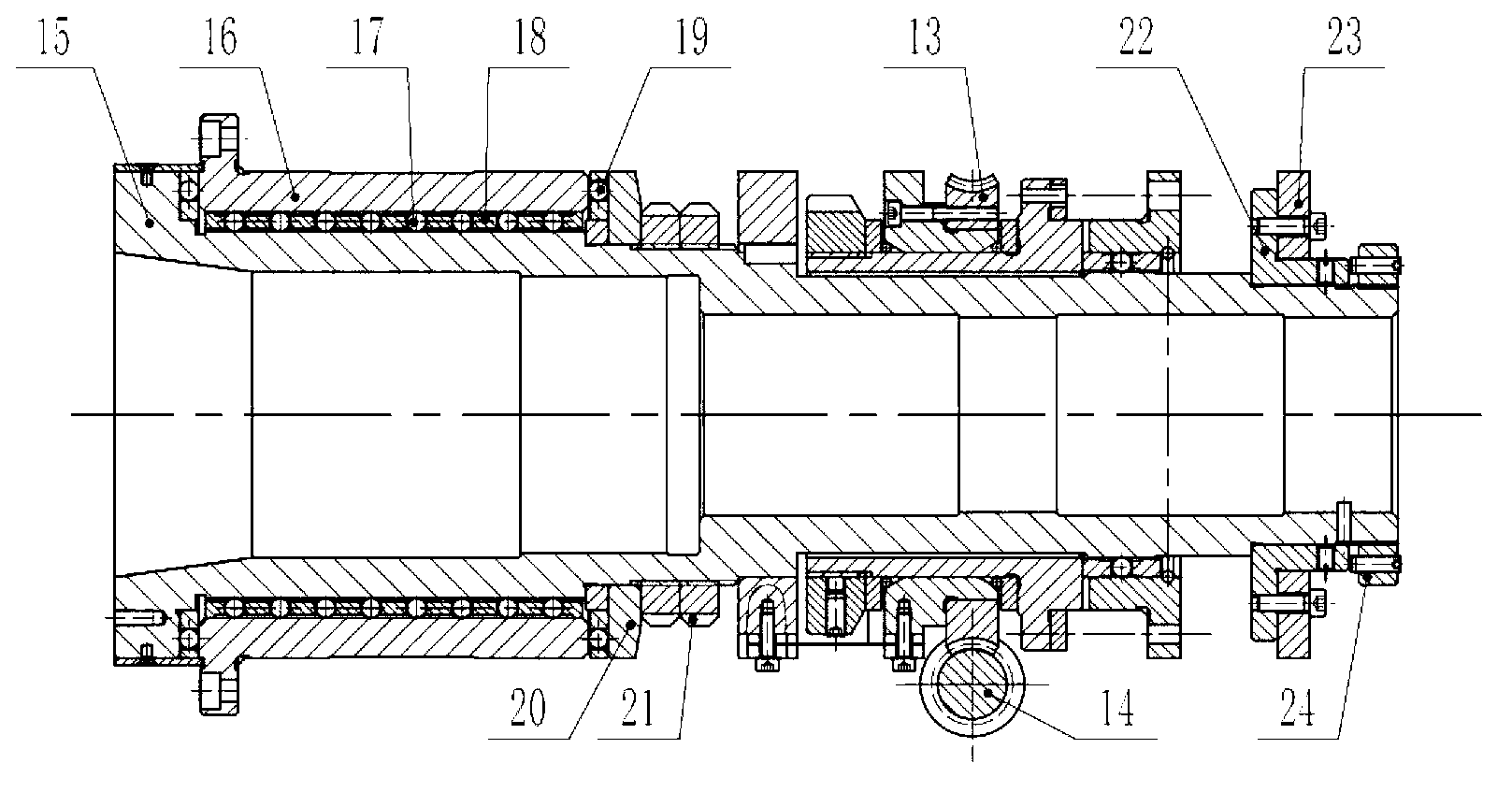

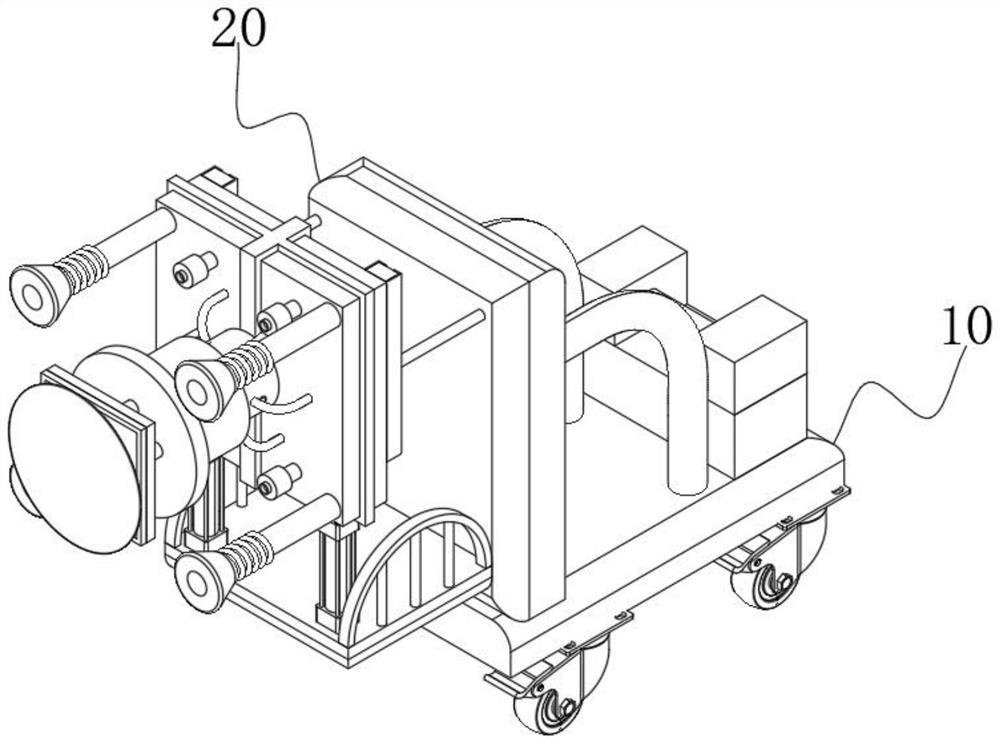

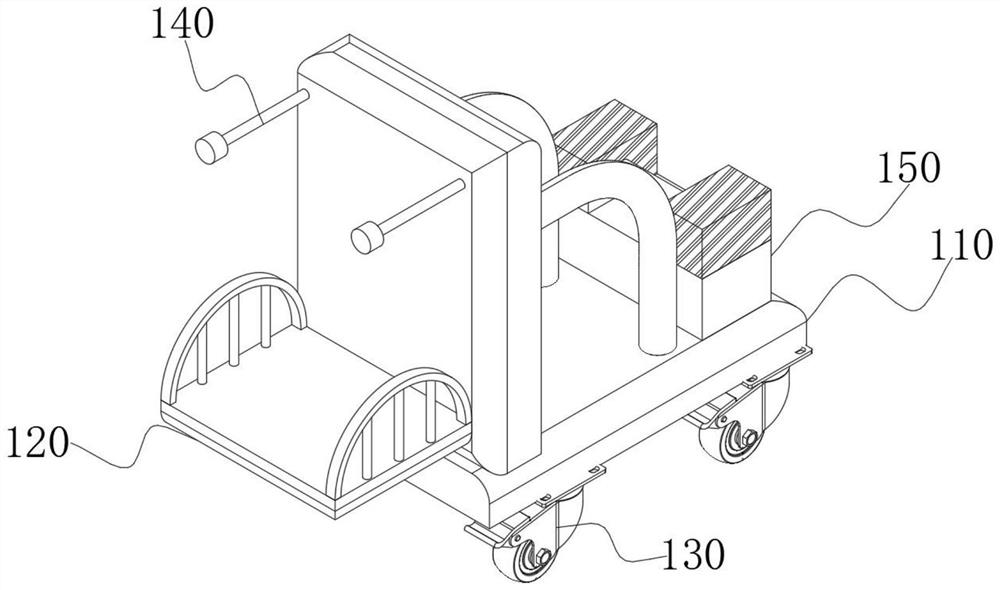

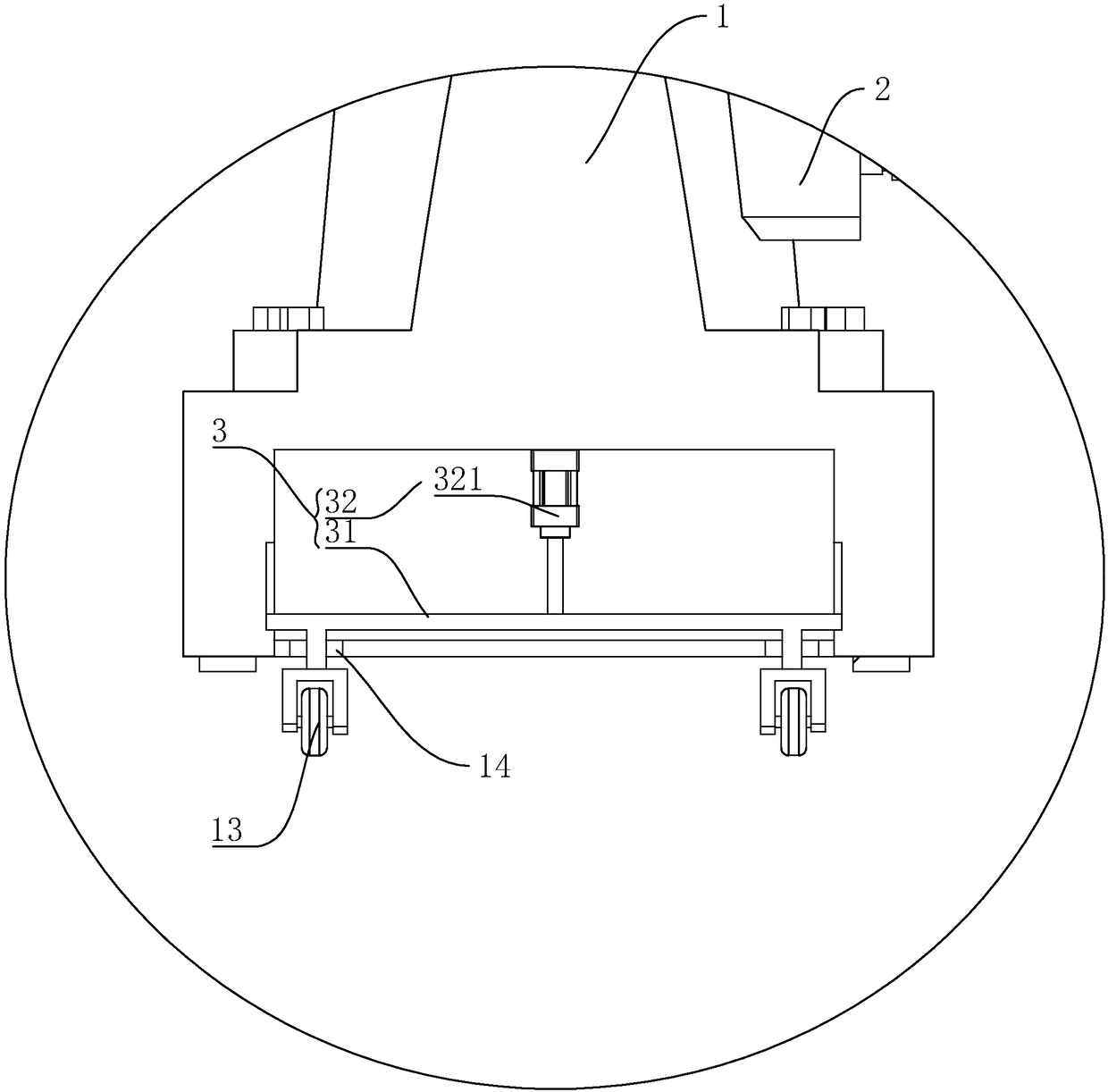

Multifunctional vacuum friction and wear testing machine

ActiveCN102759489APrecise position adjustmentAvoid time costInvestigating abrasion/wear resistanceDrivetrainEngineering

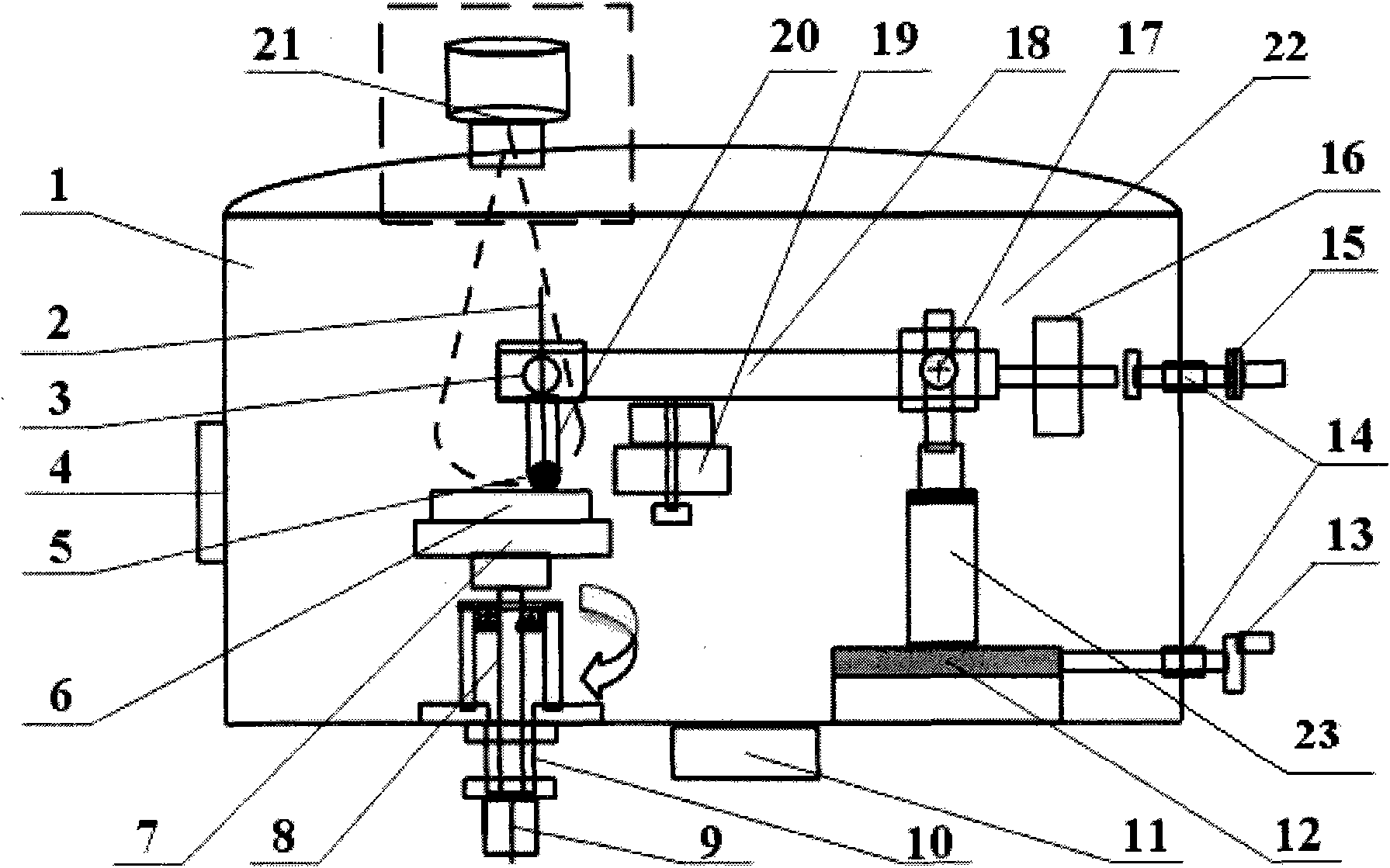

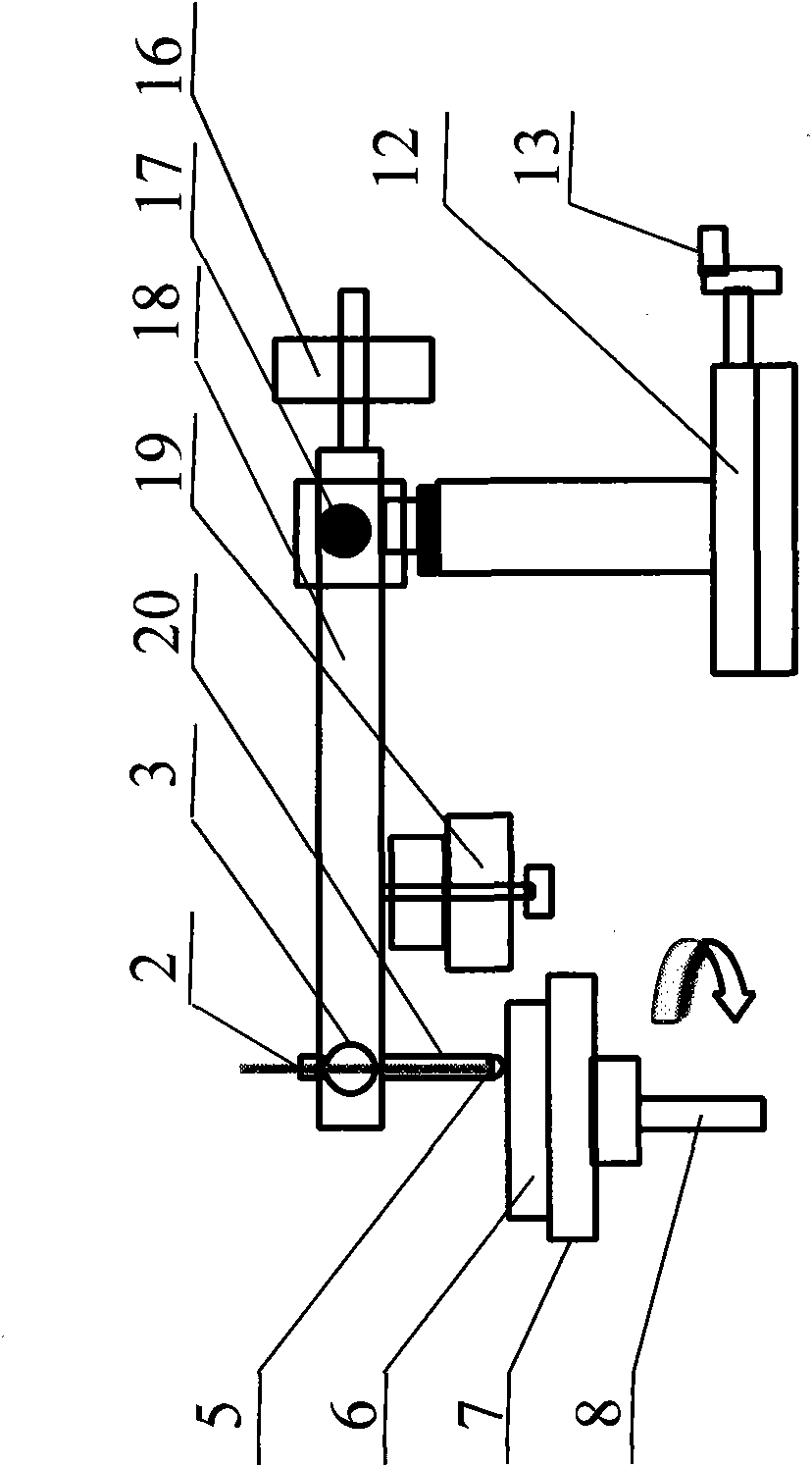

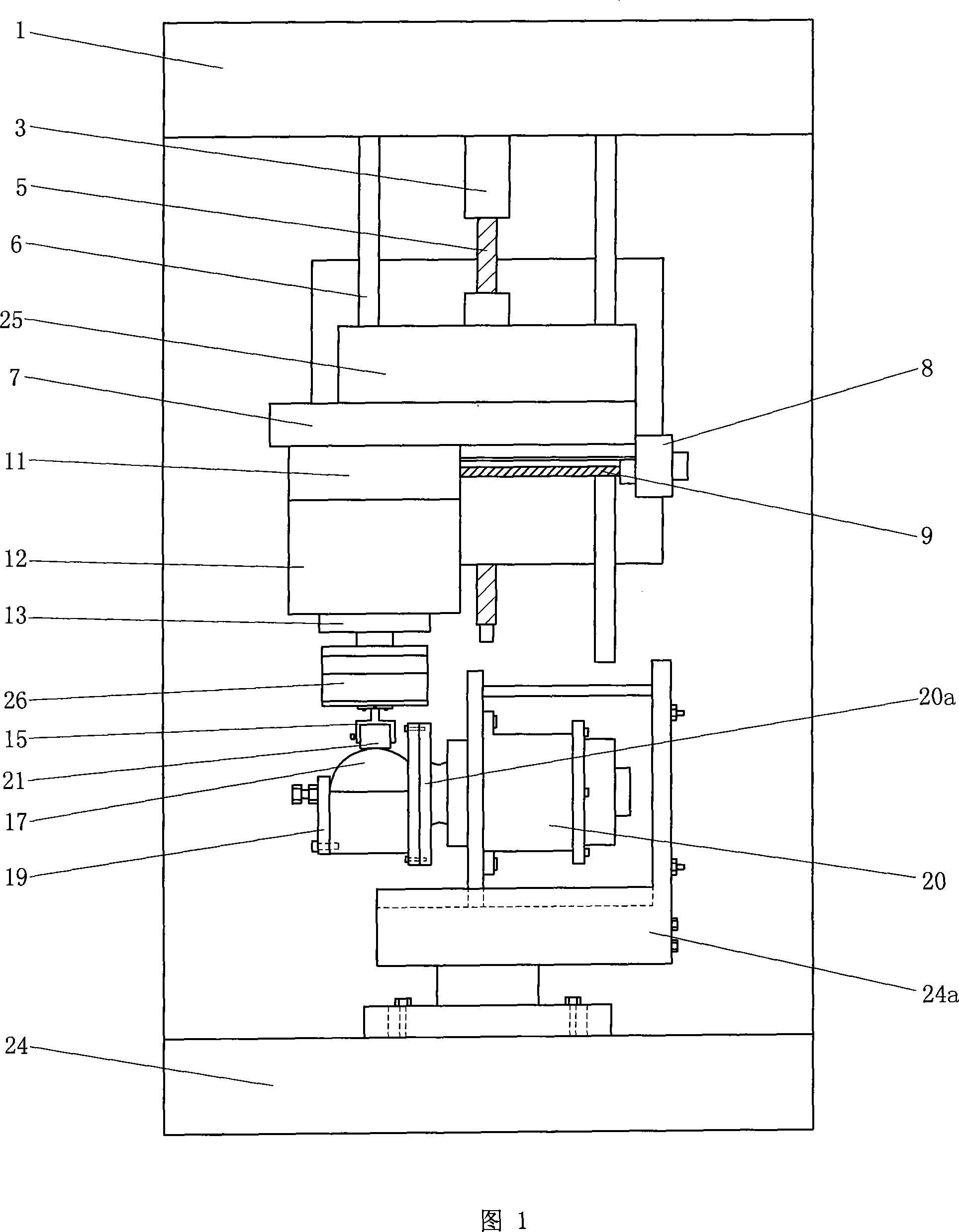

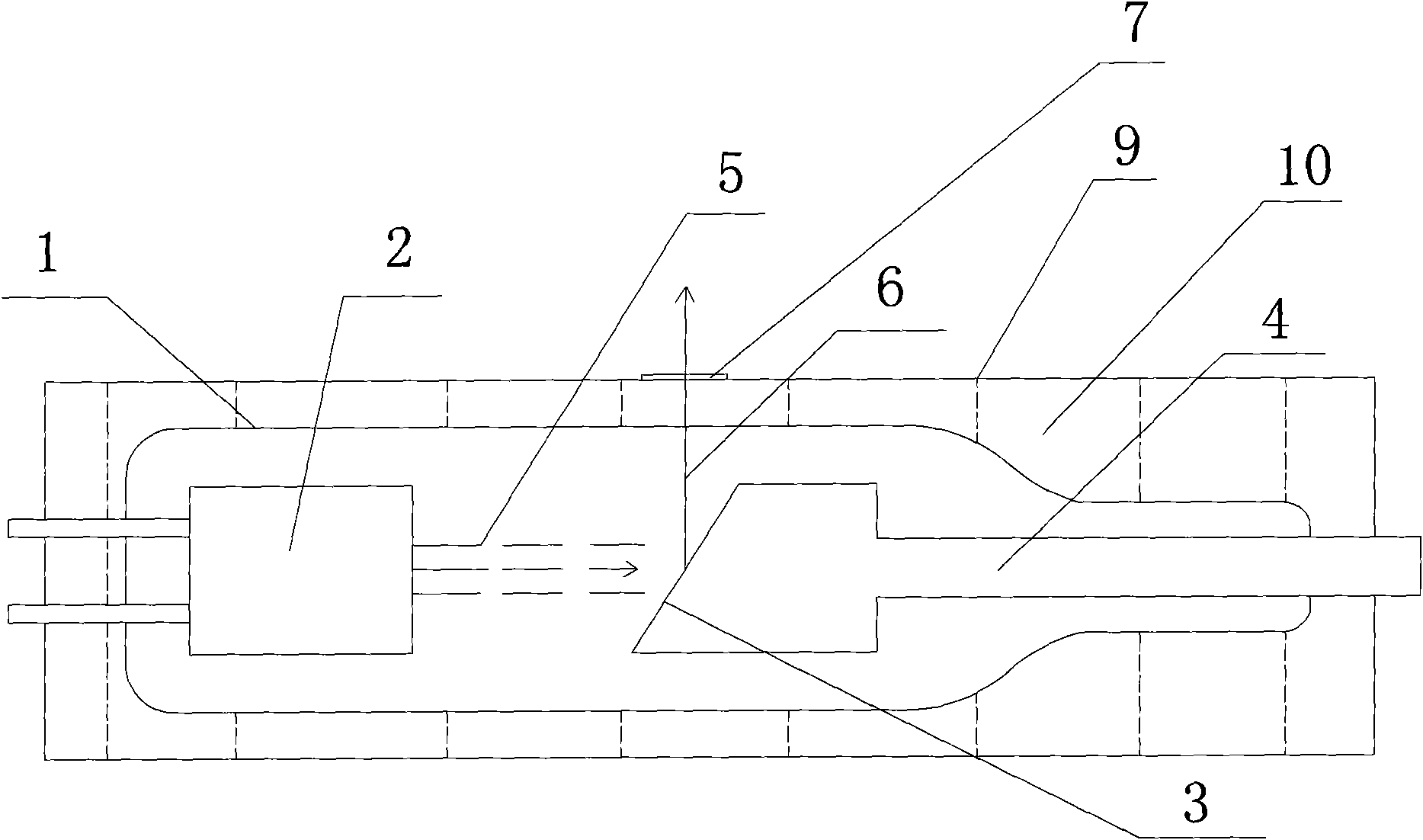

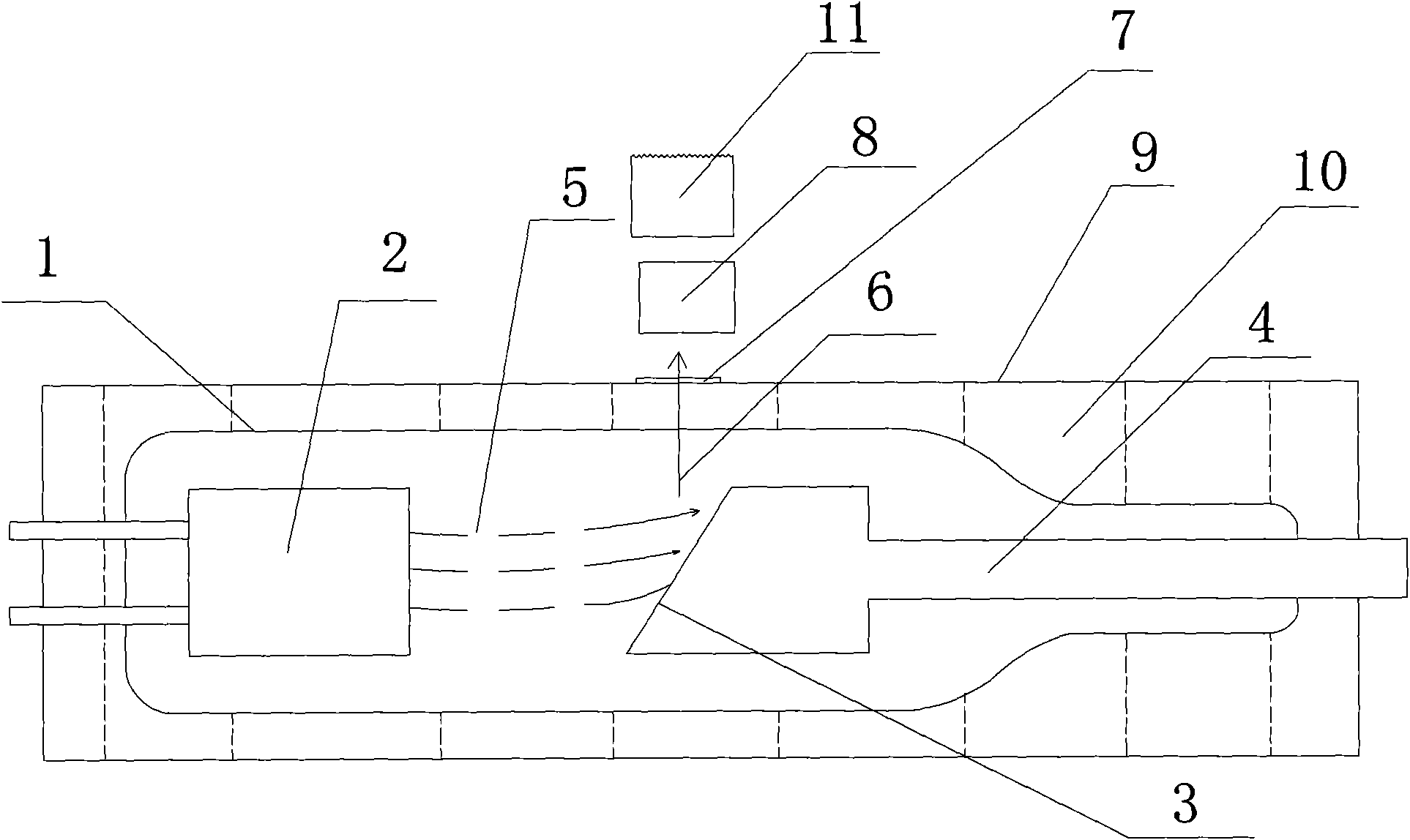

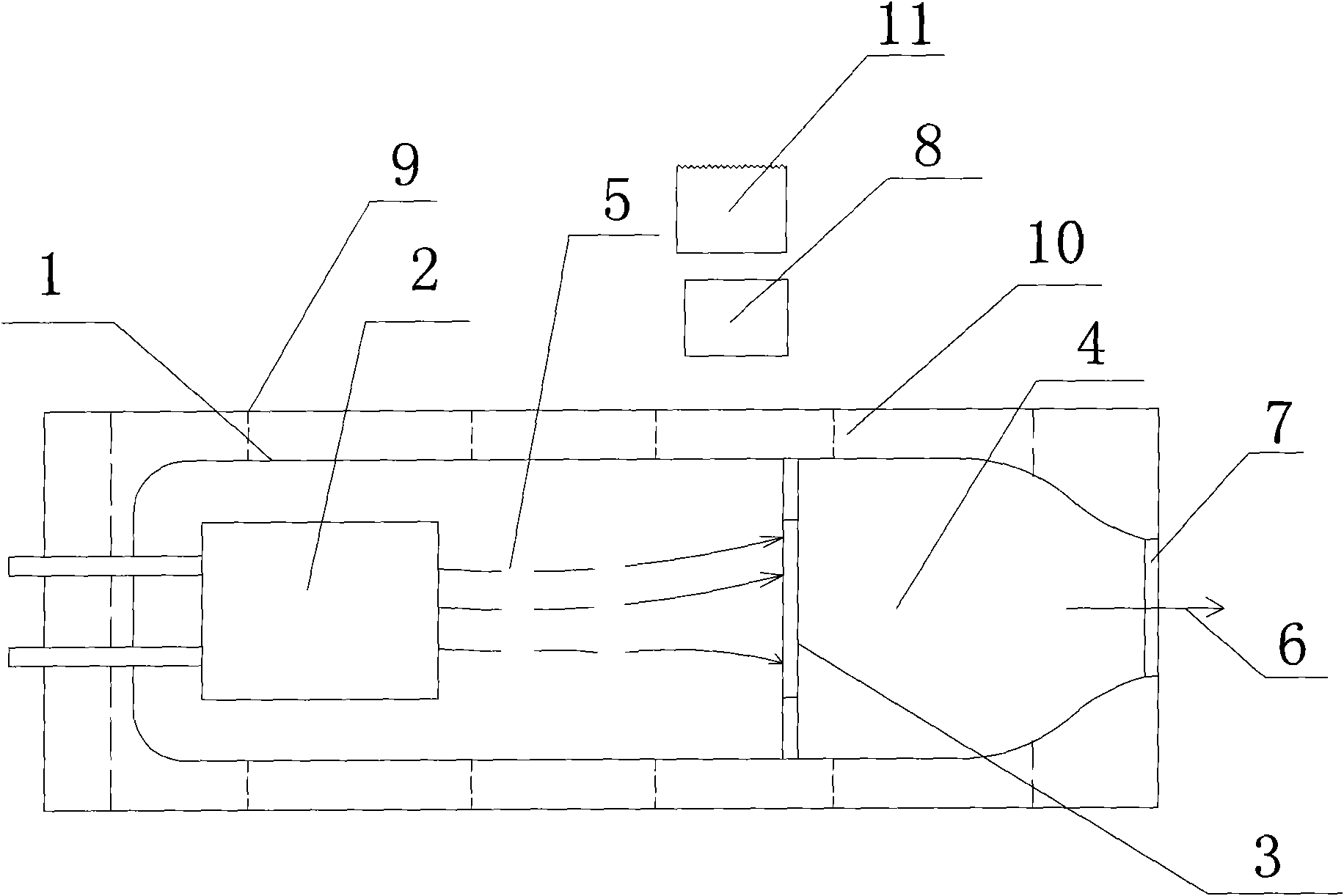

The invention provides a multifunctional vacuum friction and wear testing machine, which not only can simulate special environmental atmospheres such as vacuum, radiation and corrosion, but also can conduct tribology tests in a relatively wide speed and load range by using various contact manners (ball-disc and pin-disc). The multifunctional vacuum friction and wear testing machine mainly comprises a vacuum system, a friction and wear system, a power transmission system, a control system, and the like, wherein the friction and wear system comprises a lever structure (22) used for fixing a test sample fixture (20) and capable of freely rotating in a horizontal direction and a vertical direction; the lever structure (22) comprises a cantilever beam (18) and a vertical arm (23) which are arranged in a perpendicular manner; the cantilever beam (18) is connected with the vertical arm (23) through a two degree of freedom bearing structure (17); positions of the cantilever beam (18) and the vertical arm (23) can be adjusted in the horizontal direction and the vertical direction through the control of a manipulator (15) and a hand wheel structure (13), so that the test sample fixture (20) can accurately move within two degrees of freedom; and a temperature sensor (2) and a pressure sensor (3) are mounted on the test sample fixture (20), so as to detect / monitor friction coefficients and temperature variations during the tribology tests.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

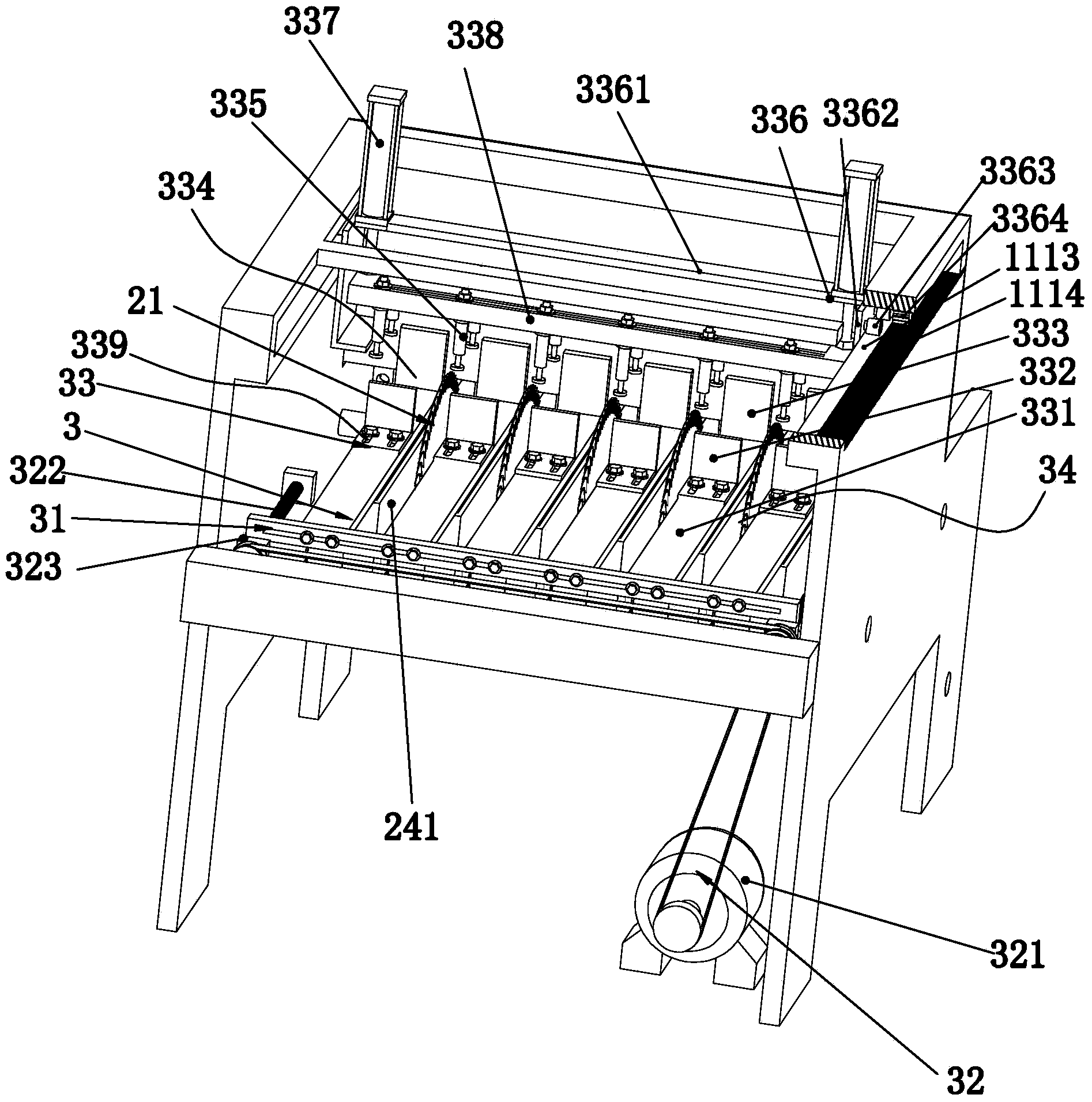

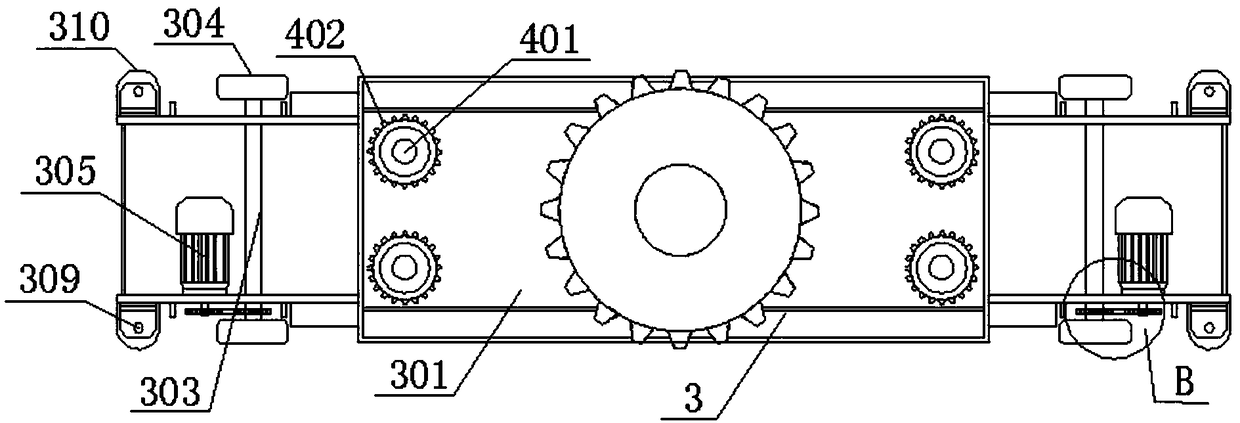

Safe type timber cutting machine with multiple cutting saw blades

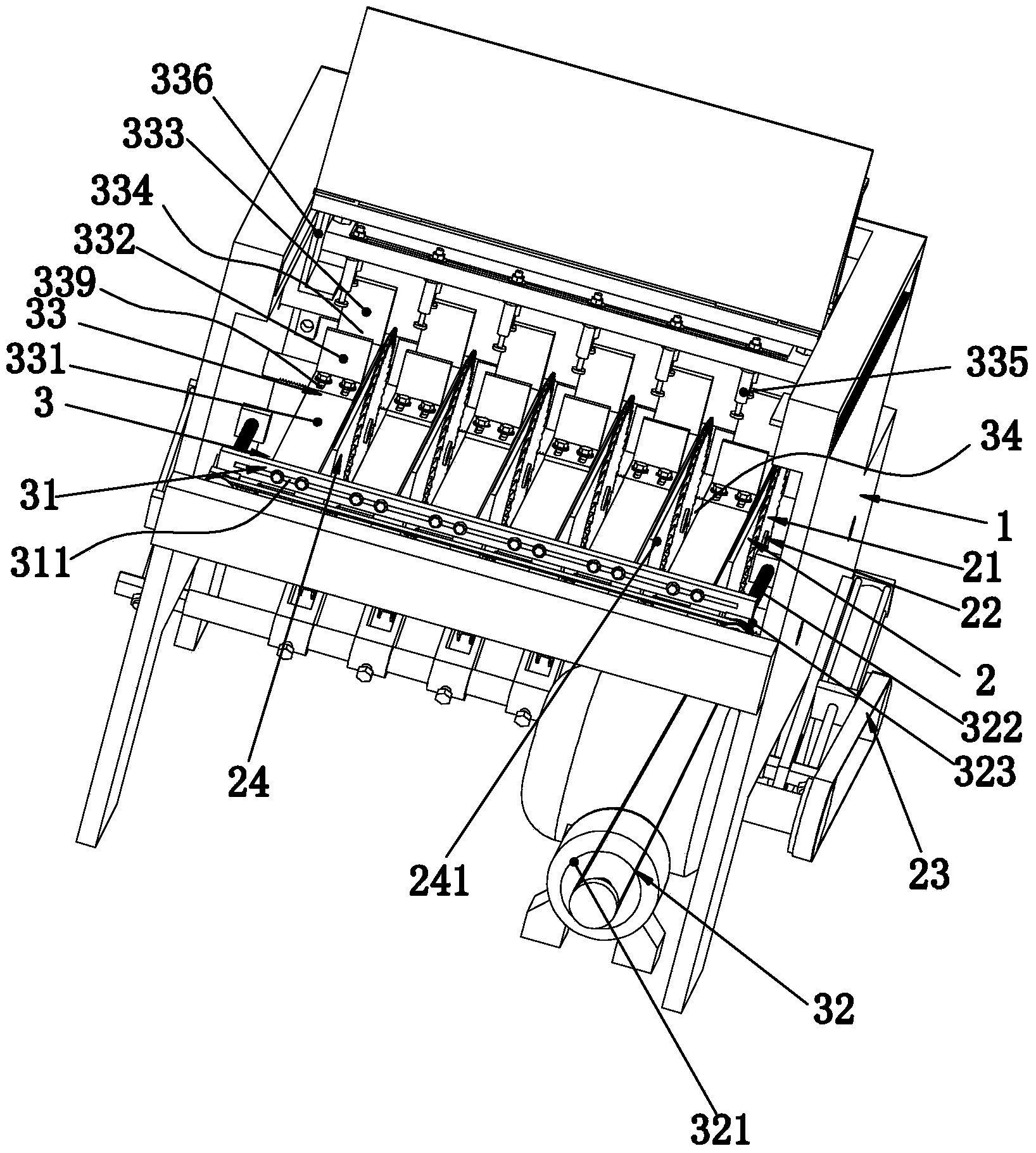

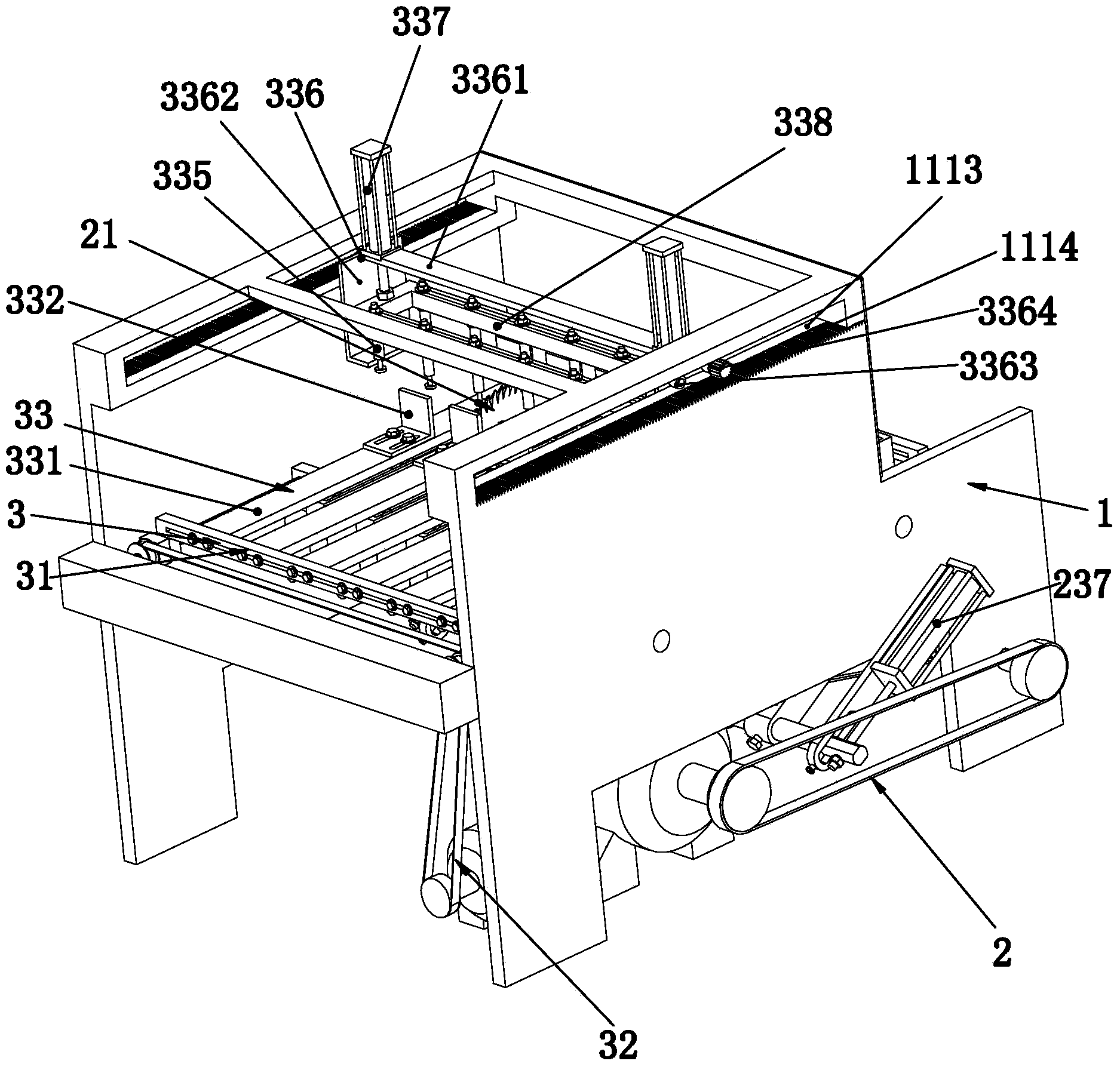

The invention relates to a safe type timber cutting machine with multiple cutting saw blades. The safe type timber cutting machine comprises a machine base and a cutting device arranged on the machine base. The cutting device comprises a plurality of cutting saw blades, a saw blade mounting rotary shaft and saw blade driving mechanisms, wherein the cutting saw blades are coaxially assembled, and the spacing between the cutting saw blades can be adjusted, the saw blade mounting rotary shaft is used for allowing the cutting saw blades to be installed on, and the saw blade driving mechanisms drive the cutting saw blades to rotate and are in drive connection with the saw blade mounting rotary shaft. The machine base is further provided with an automatic feeding device. The automatic feeding device comprises a feeding rack and a feeding driving mechanism, wherein the feeding rack is arranged in a moving and sliding mode in the rotating and cutting direction of the cutting saw blades, and the feeding driving mechanism drives the feeding rack. A plurality of timber fixing platforms are arranged on the feeding rack, the number and the positions of the timber fixing platforms correspond to those of the cutting saw blades. The timber fixing platforms are coaxially arranged. Timber cutting passages for allowing the cutting saw blades to enter and cut timbers are formed between the adjacent timber fixing platforms in a spaced mode. The spacing between the adjacent timber fixing platforms can be adjusted. Compared with the prior art, the safe type timber cutting machine with the multiple cutting saw blades can automatically feed the timbers and is more convenient and safer to operate.

Owner:邹建静

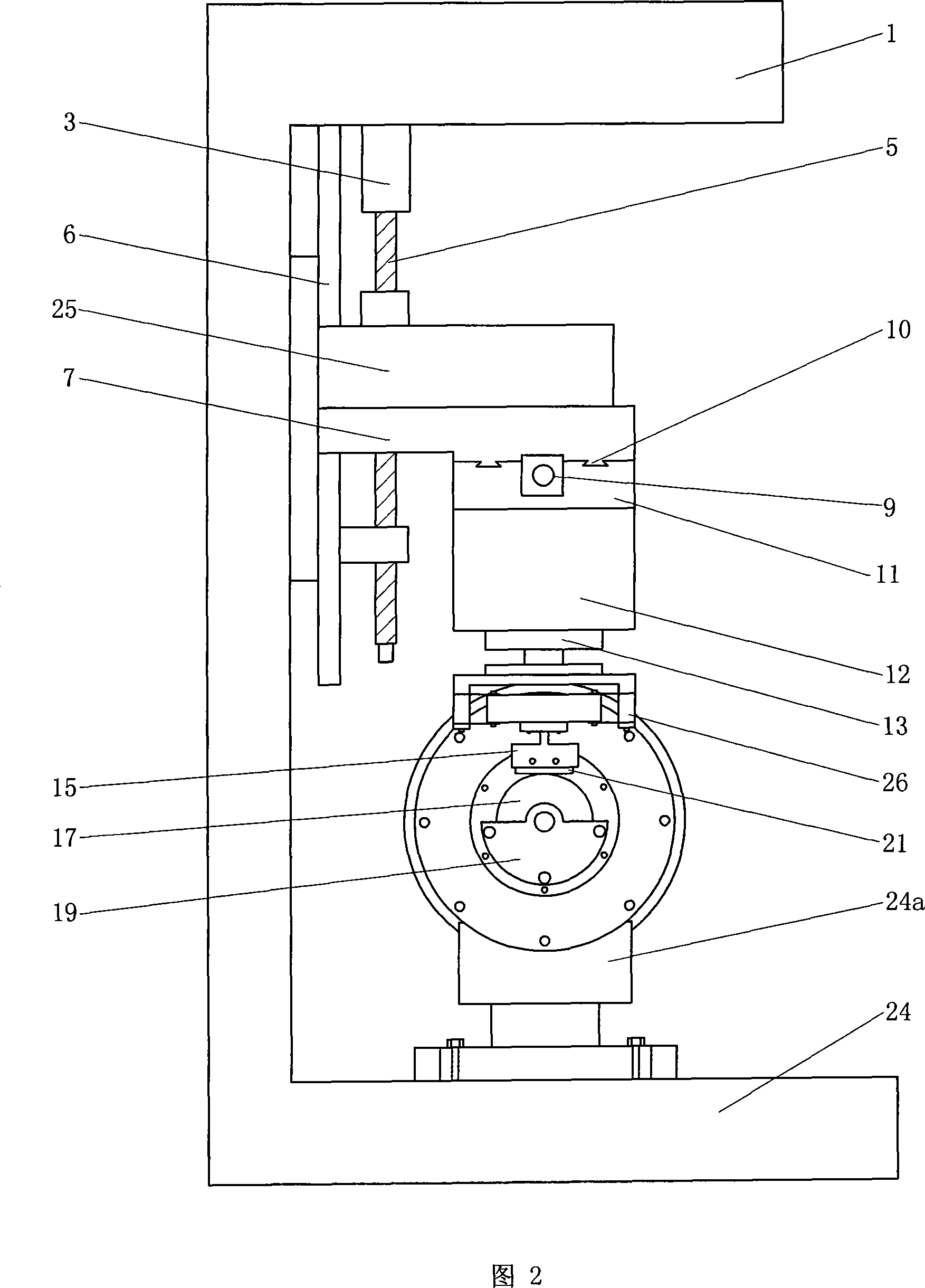

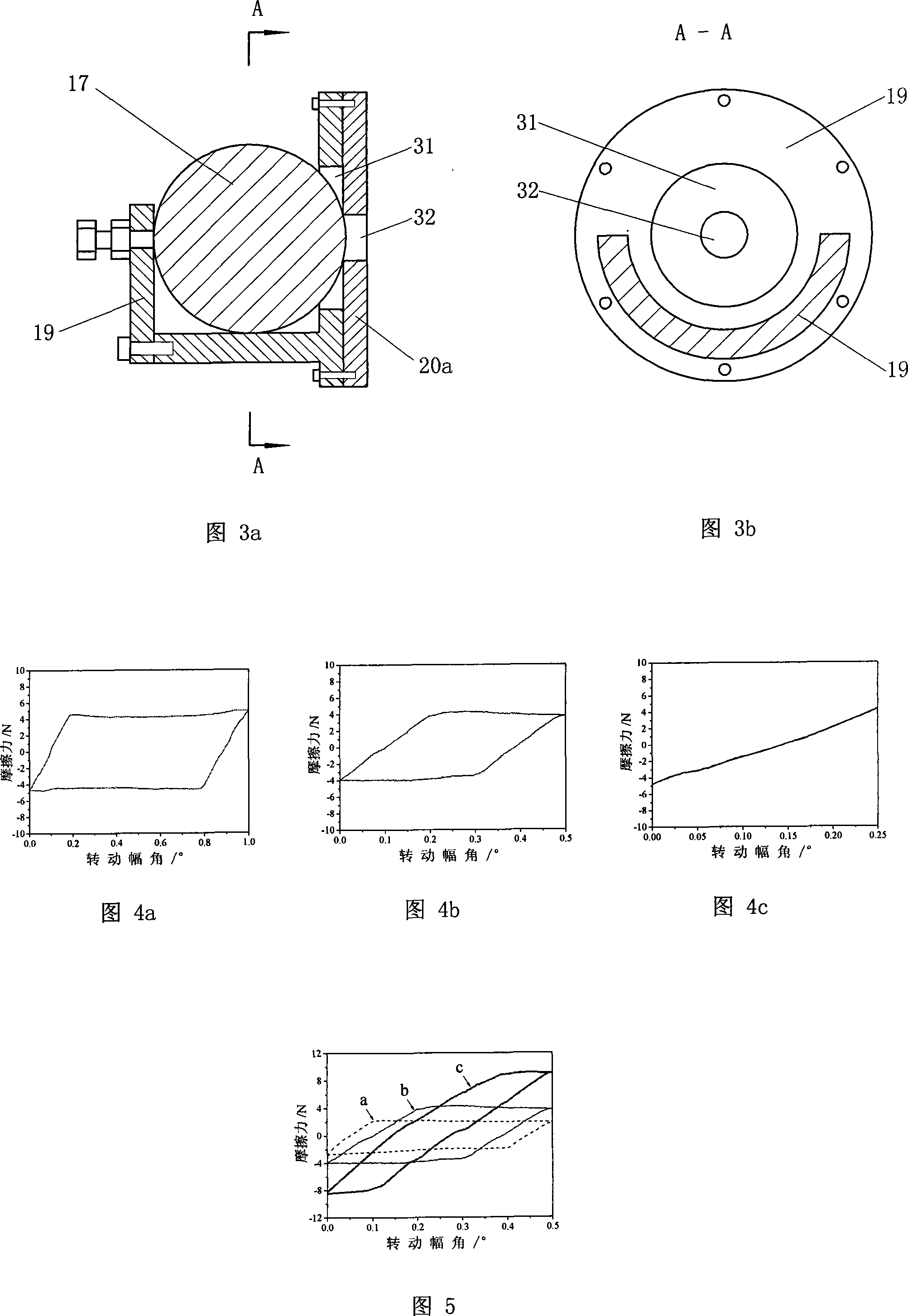

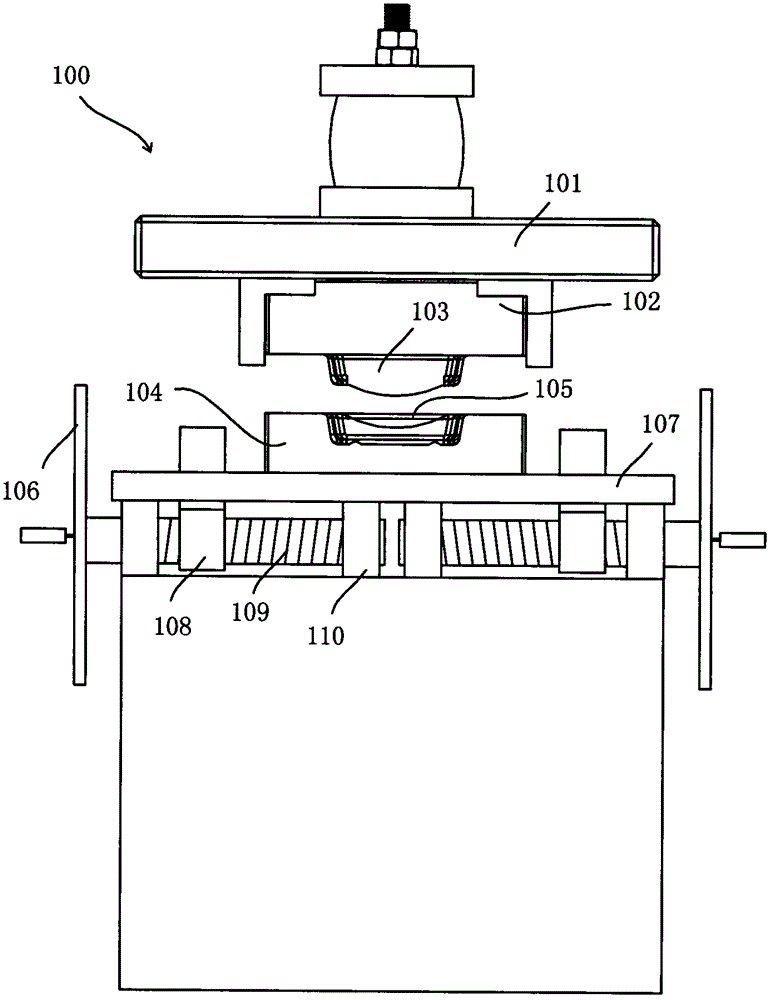

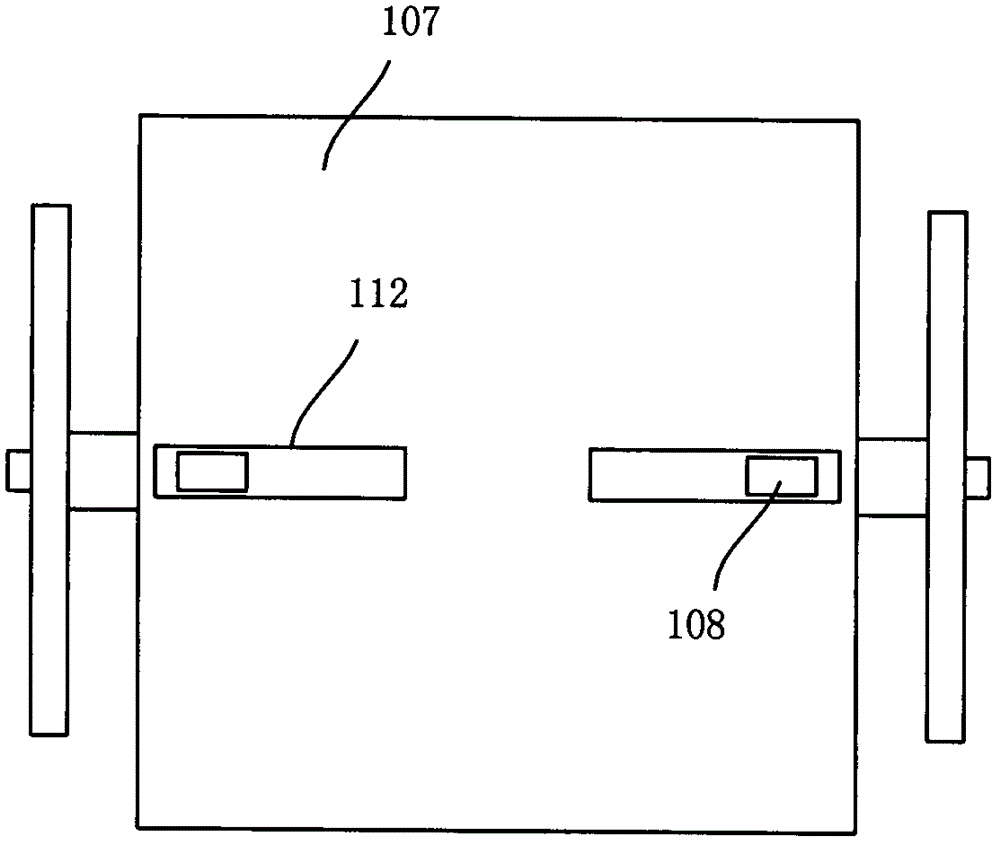

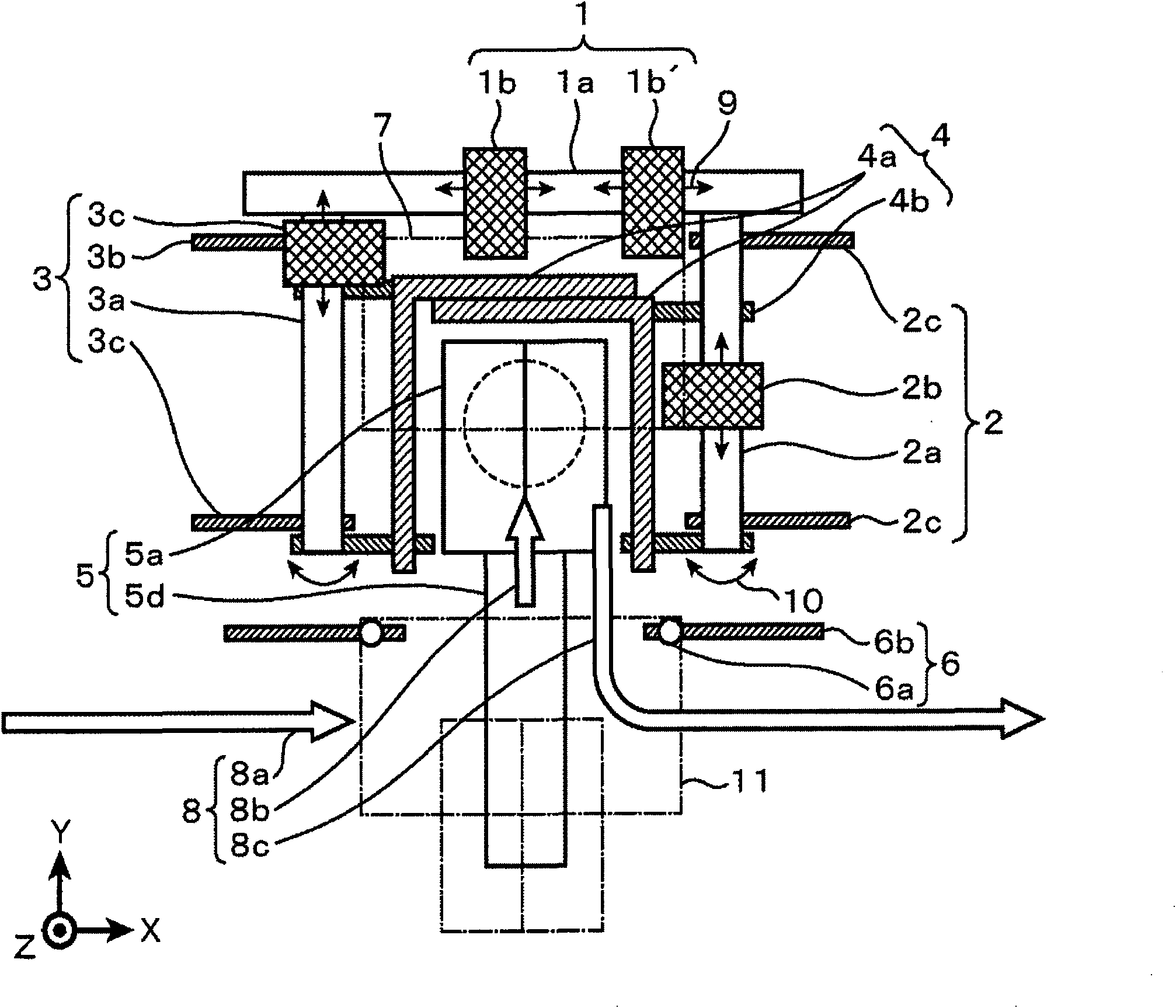

Rotary micromotion friction wear test method and device thereof

InactiveCN101226122AHigh degree of automationHigh precision of control and testingMachine part testingInvestigating abrasion/wear resistanceTorque sensorLow speed

The invention relates to a rotary inching friction abrasion test method and a relative device, wherein the method comprises clamping a plane upper sample on an upper clamp, fixing a lower clamp on the horizontal rotation shaft of a high-precision ultra-low speed rotation motor, clamping a spherical lower sample via a lower clamp, aligning the horizontal central line of the lower sample with the rotation shaft of the rotation motor, using a data acquisition and control system to control the up-and-down and left-and-right motions of the upper clamp to contact the upper and lower samples and apply a preset normal load, at the same time, using the data acquisition and control system to control the rotation motor to reciprocally rotate the lower clamp and lower sample at preset rotation argument, rotation speed and times, to realize the rotary inching friction between the upper and lower samples, using a six-dimension force / torque sensor to test and feed the friction force to the data acquisition and control system to be analyzed to obtain a friction force-angle displacement curvature. The inventive method can simply realize small angle rotary inching friction abrasion of material, with high automatic degree, high control and test accuracy and better test data reappearance.

Owner:SOUTHWEST JIAOTONG UNIV

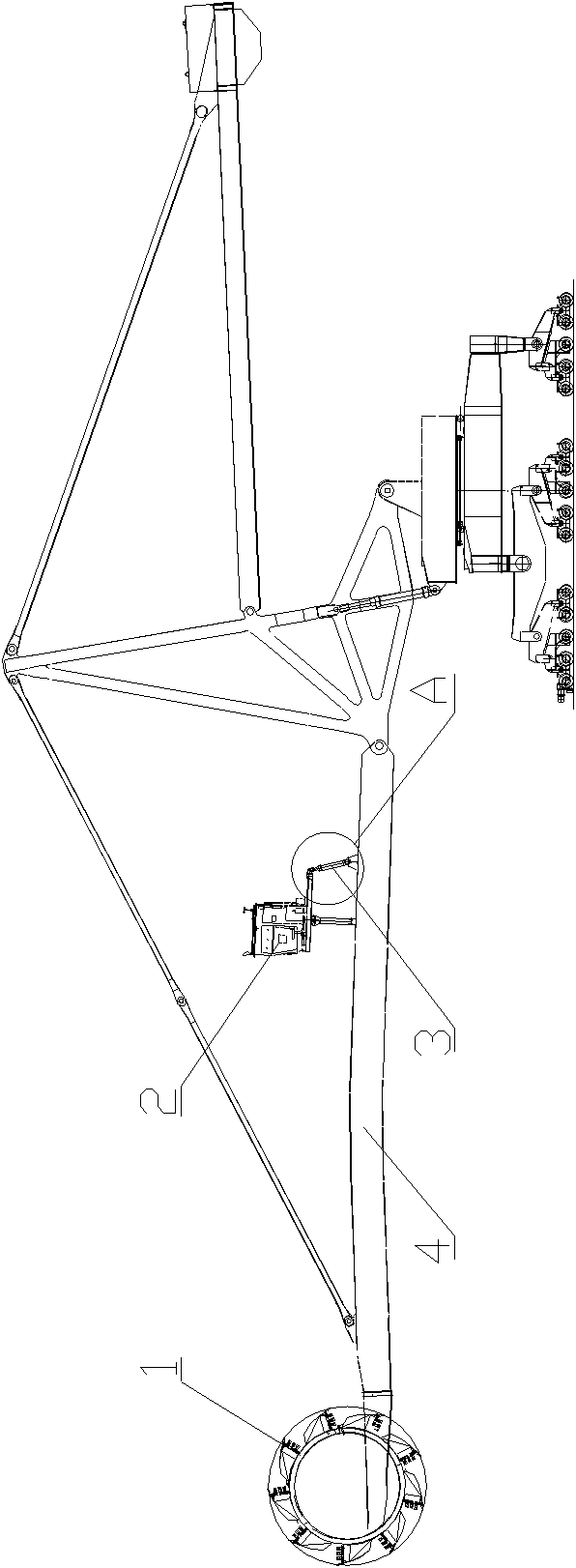

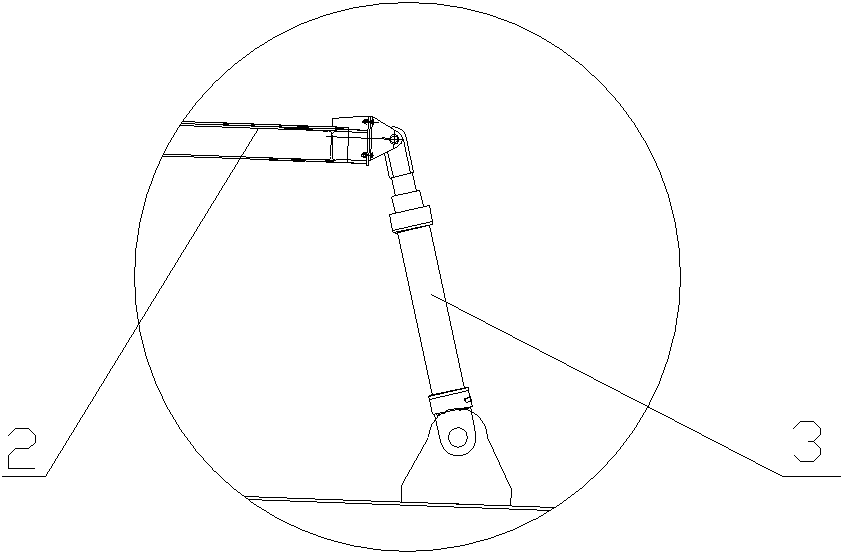

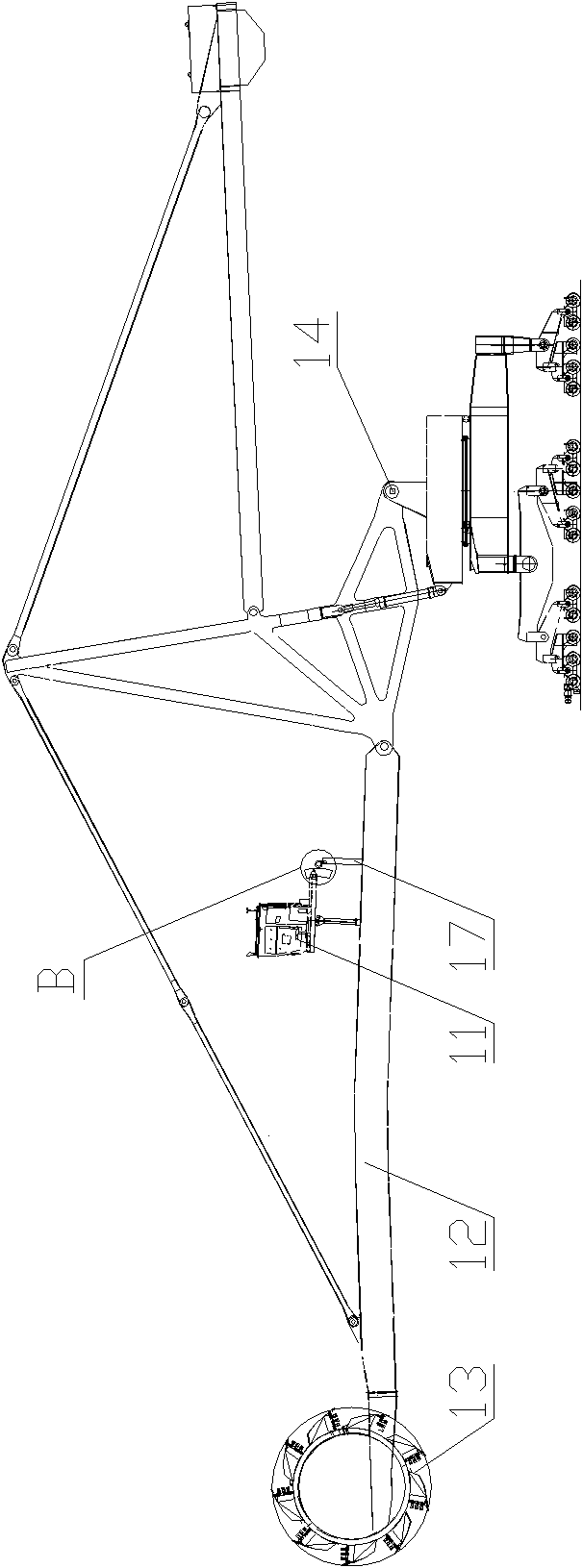

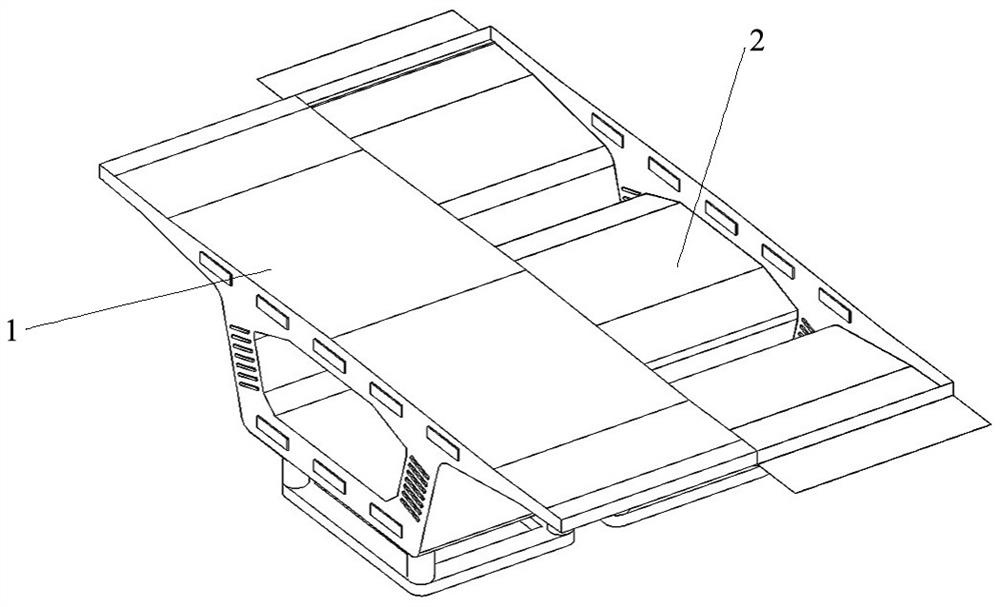

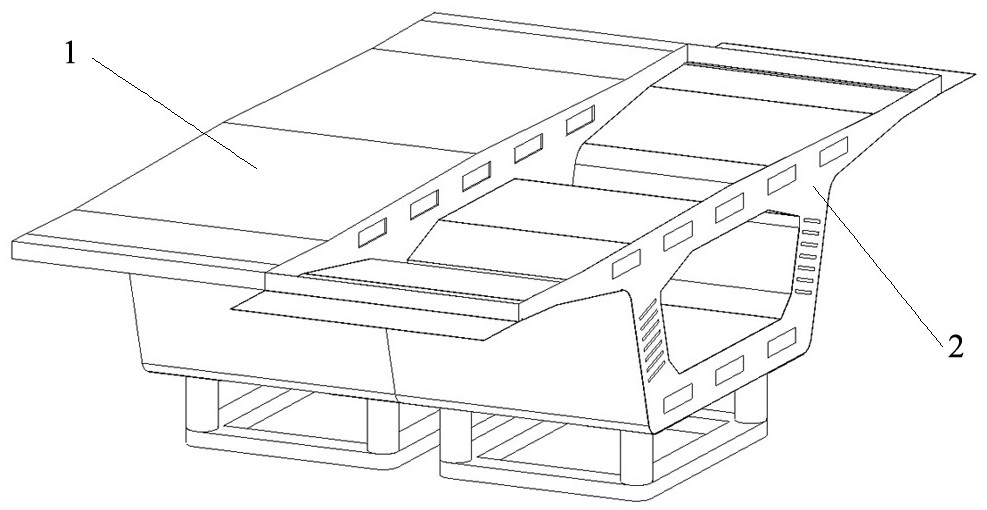

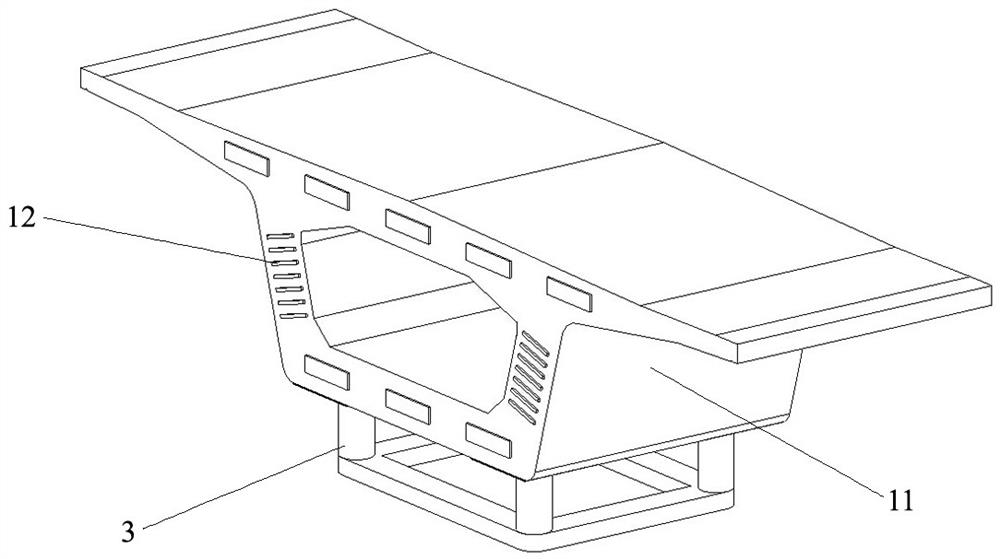

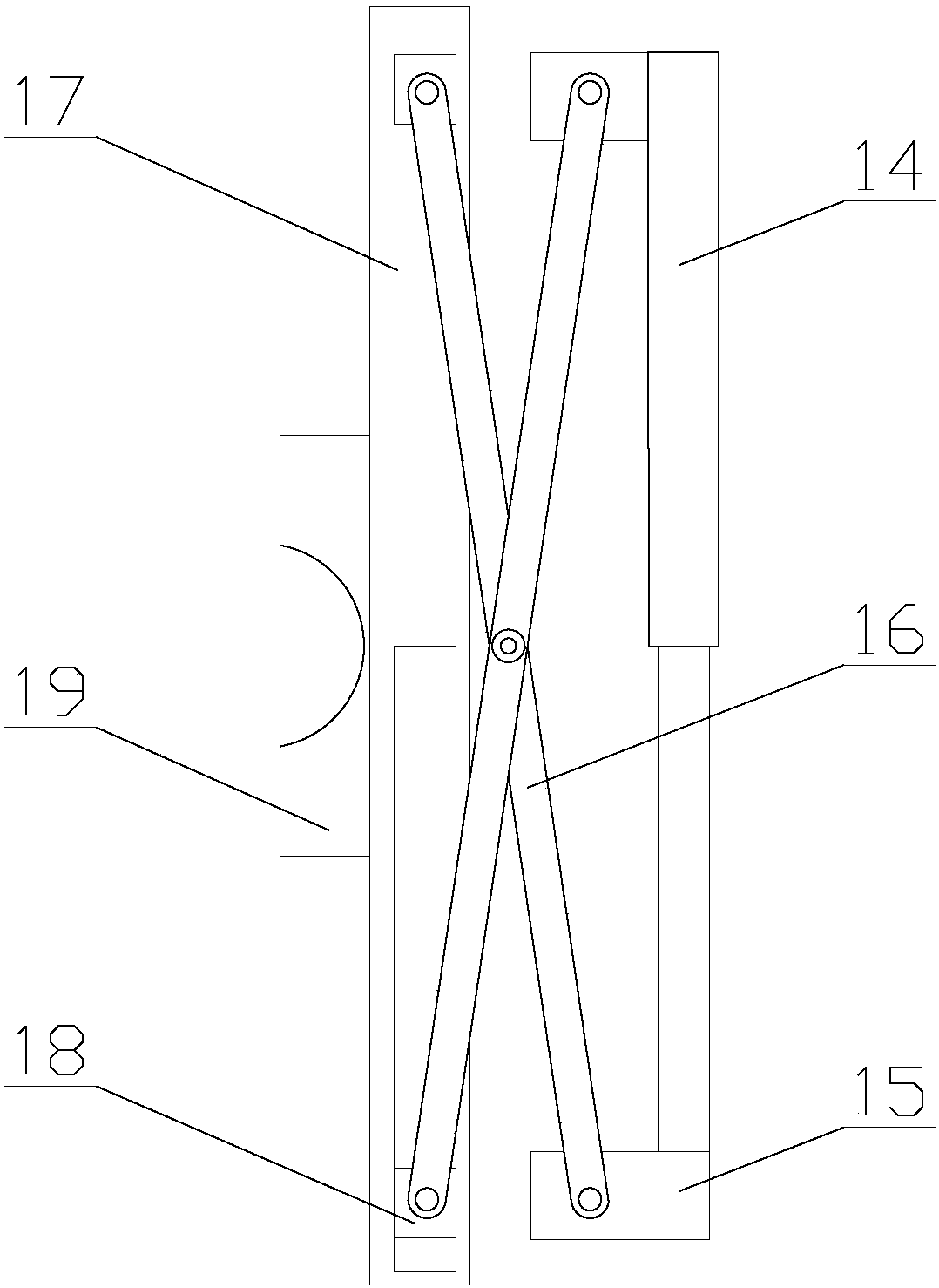

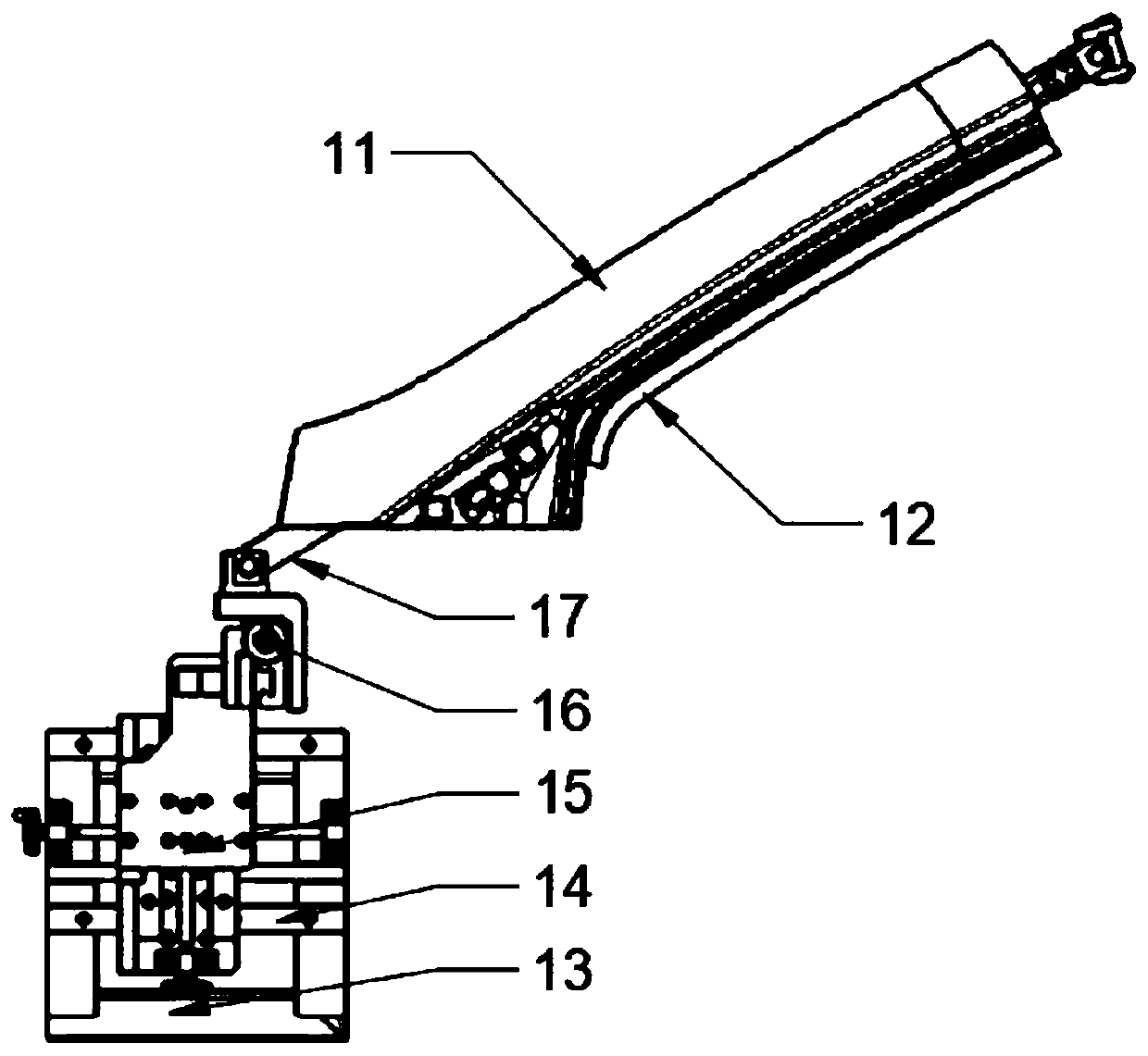

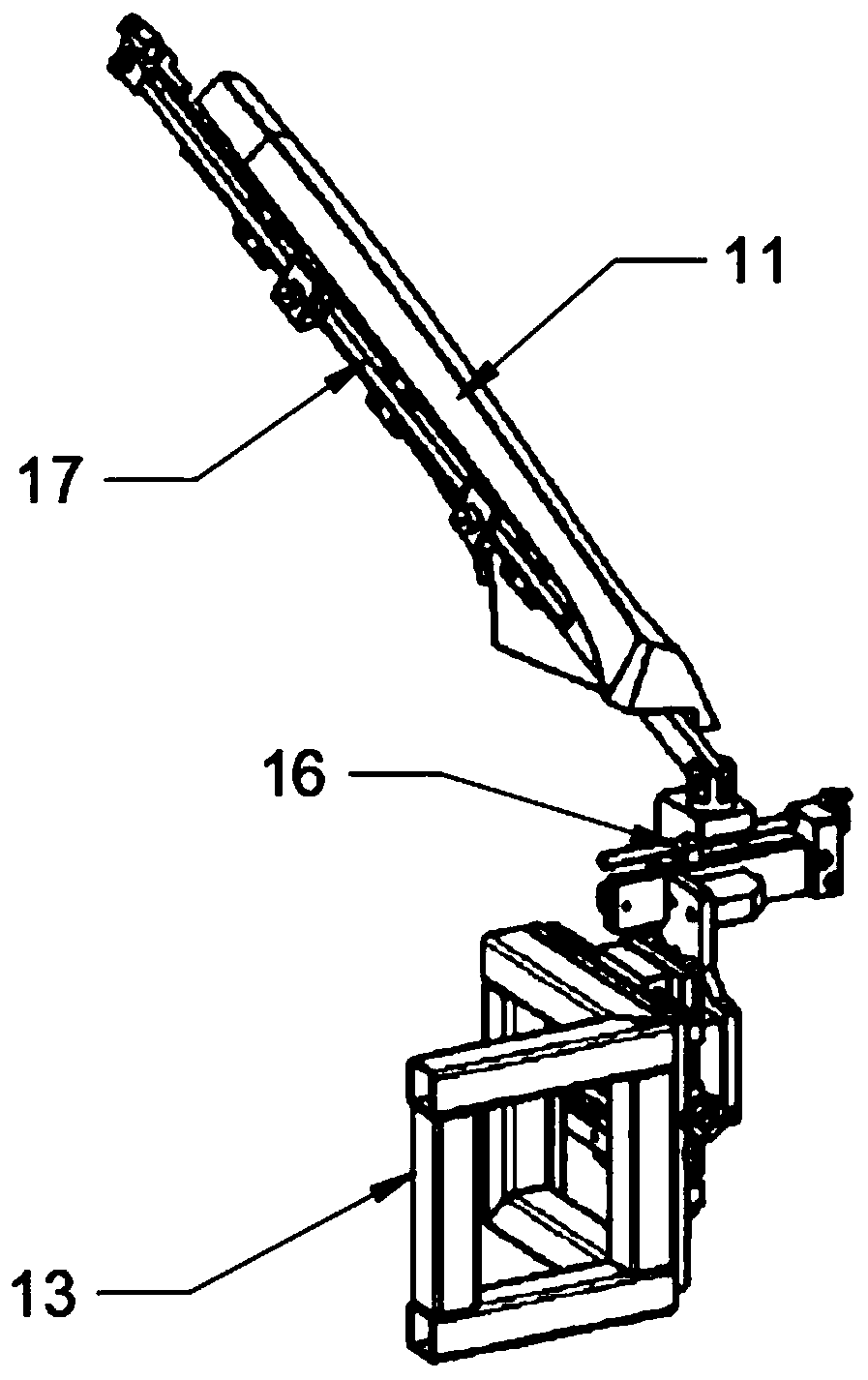

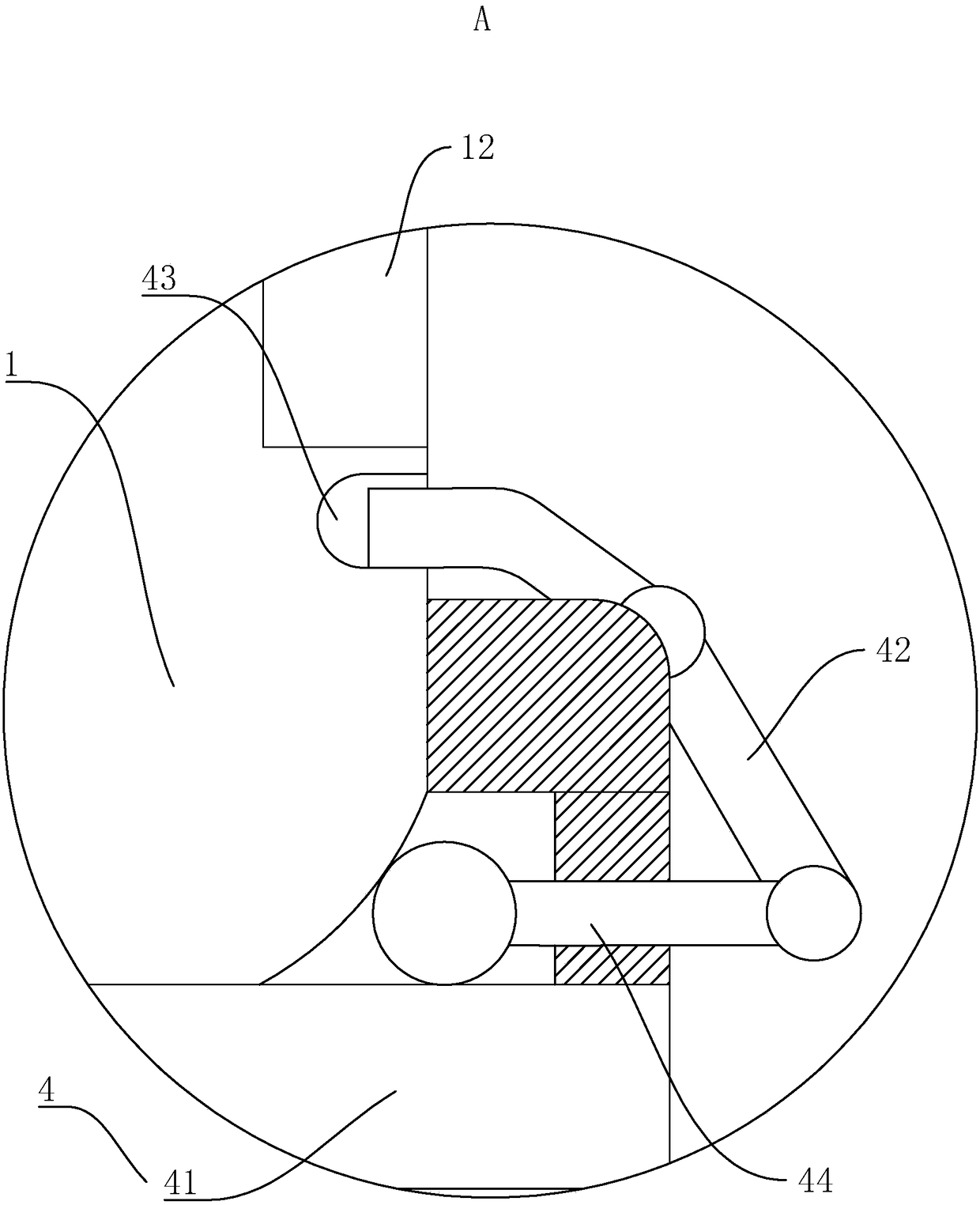

Cab pitching device and bucket wheel machine

InactiveCN102424280APrecise position adjustmentEasy to operateLoading/unloadingMechanical engineeringHinge point

The invention discloses a cab pitching device of a bucket wheel machine, which comprises a driving device used for driving a cab (11) of the bucket wheel machine to rotate around a hinge point between the cab (11) and an arm support (12), a detector used for detecting the pitch angle of the arm support (12), a controller used for receiving a detecting signal of the detector and transmitting an action instruction, and a locking device for locking or unlocking the position of the cab, wherein a signal output end of the controller is electrically connected with the driving device, so that the driving device correspondingly responds according to the action instruction. The position of the cab can be exactly adjusted by the cab pitching device, so that the ground surface of the cab is positioned at the horizontal position, and an operator in the cab can conveniently work. Furthermore, the invention further discloses thea bucket wheel machine comprising the cab pitching device.

Owner:SANY GRP

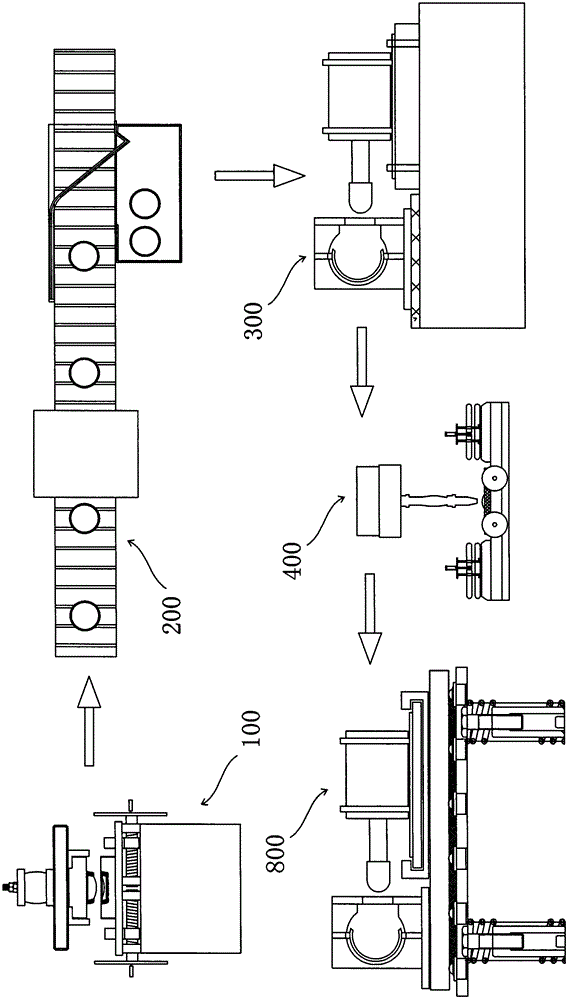

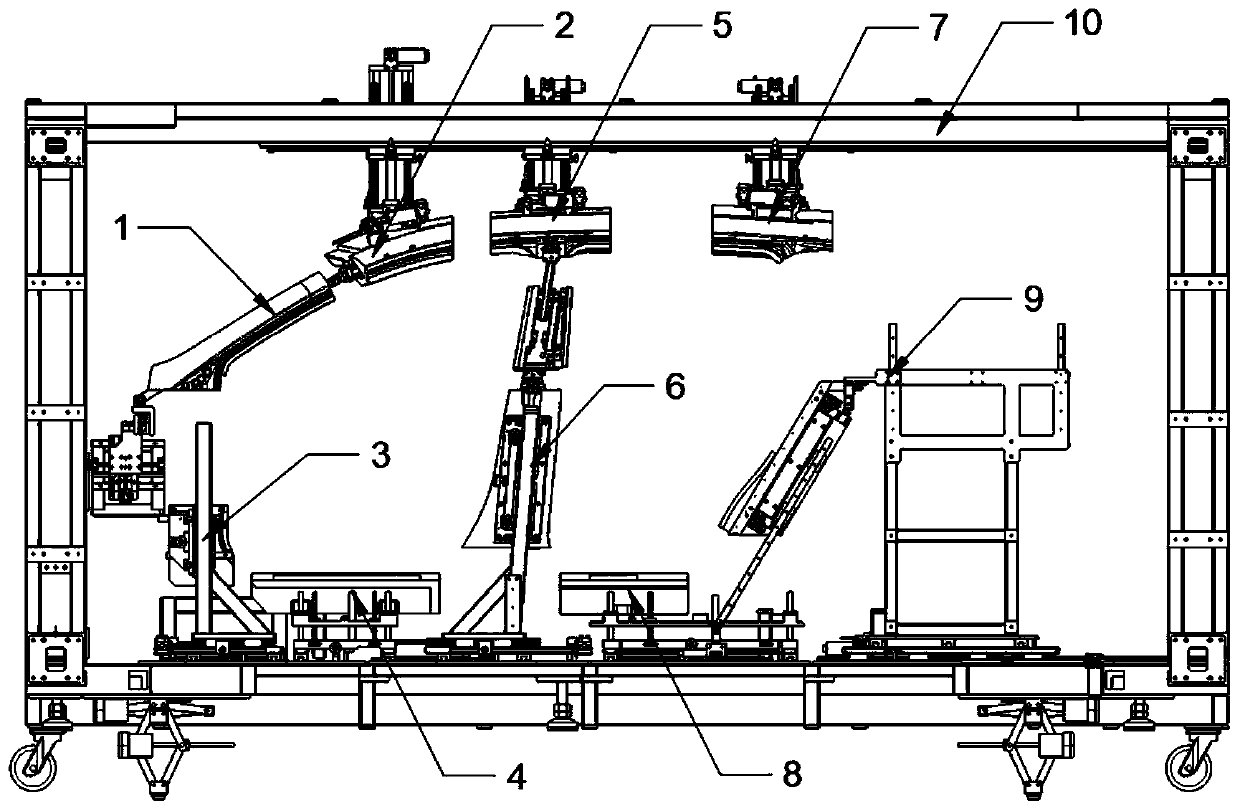

Automotive brake pad production line

ActiveCN104476200AHigh precisionImprove processing efficiencyOther manufacturing equipments/toolsProduction lineHeat transfer efficiency

The invention relates to an automotive brake pad production line which comprises a tabletting device, a thermal treatment device, a grinding device, a drilling device, a code spraying device and a conveying device connected among the former. Through the tabletting device, a concave die can be closely clamped, so that position of the concave die can be adjusted accurately; through the thermal treatment device, an automotive brake pad storage shelf after being subjected to thermal treatment can be automatically conveyed to a goods storage area, and heat transfer efficiency of a drum brake pad is improved; through the grinding device, an automotive brake pad is closely clamped, and position of an automotive brake pad clamp can be adjusted accurately, so that grinding accuracy is improved remarkably; through the drilling device, the automotive brake pad is closely clamped, the position of the automotive brake pad can be adjusted accurately, and a clamping clamp can be accurately positioned, so that drilling accuracy is improved remarkably; through the code spraying device, the brake pad is clamped closely, code spraying accuracy is improved, and one-step code spraying forming of multiple batches of brake pads is realized.

Owner:HUANGSHAN FEIYING AUTO PARTS

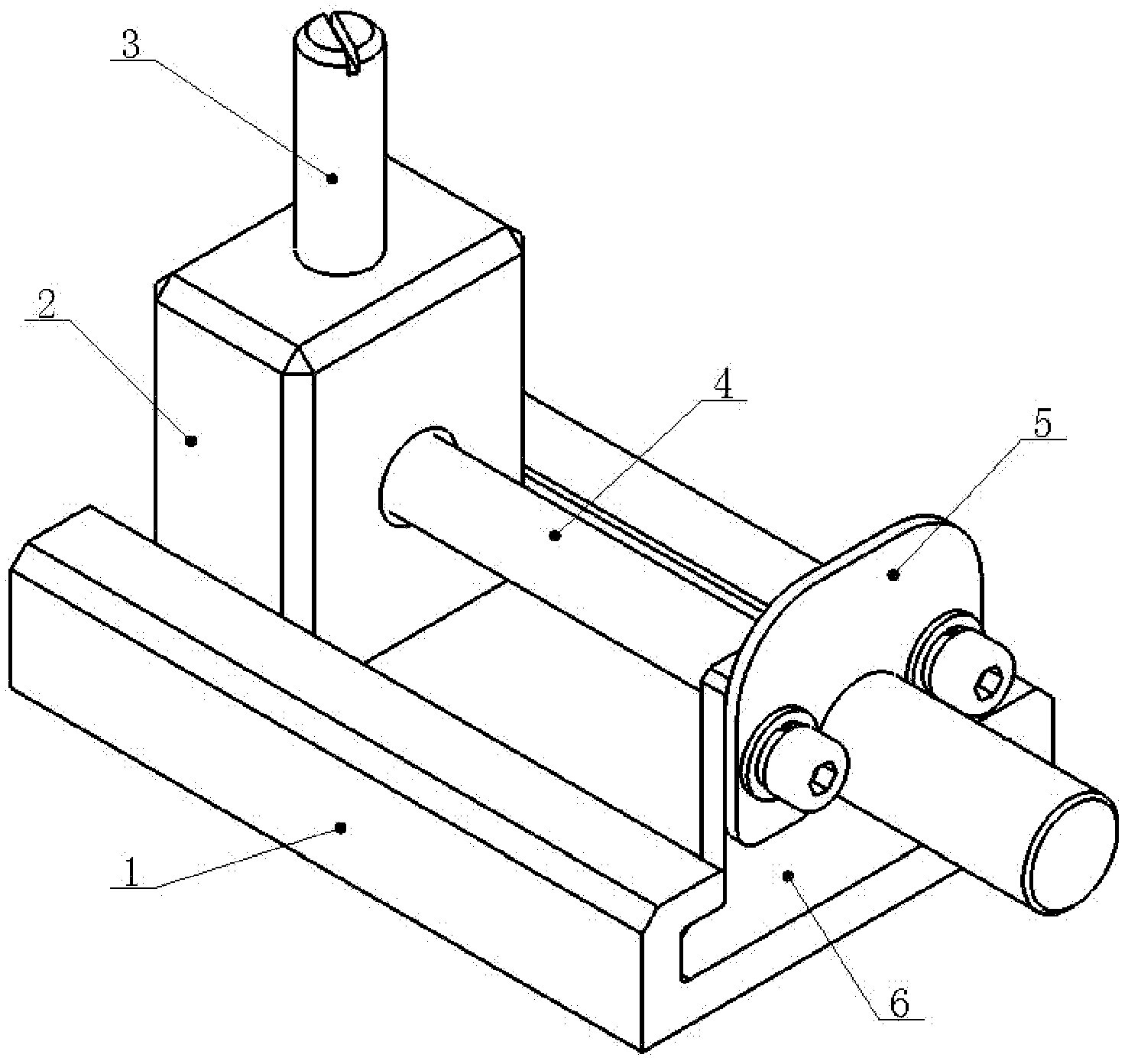

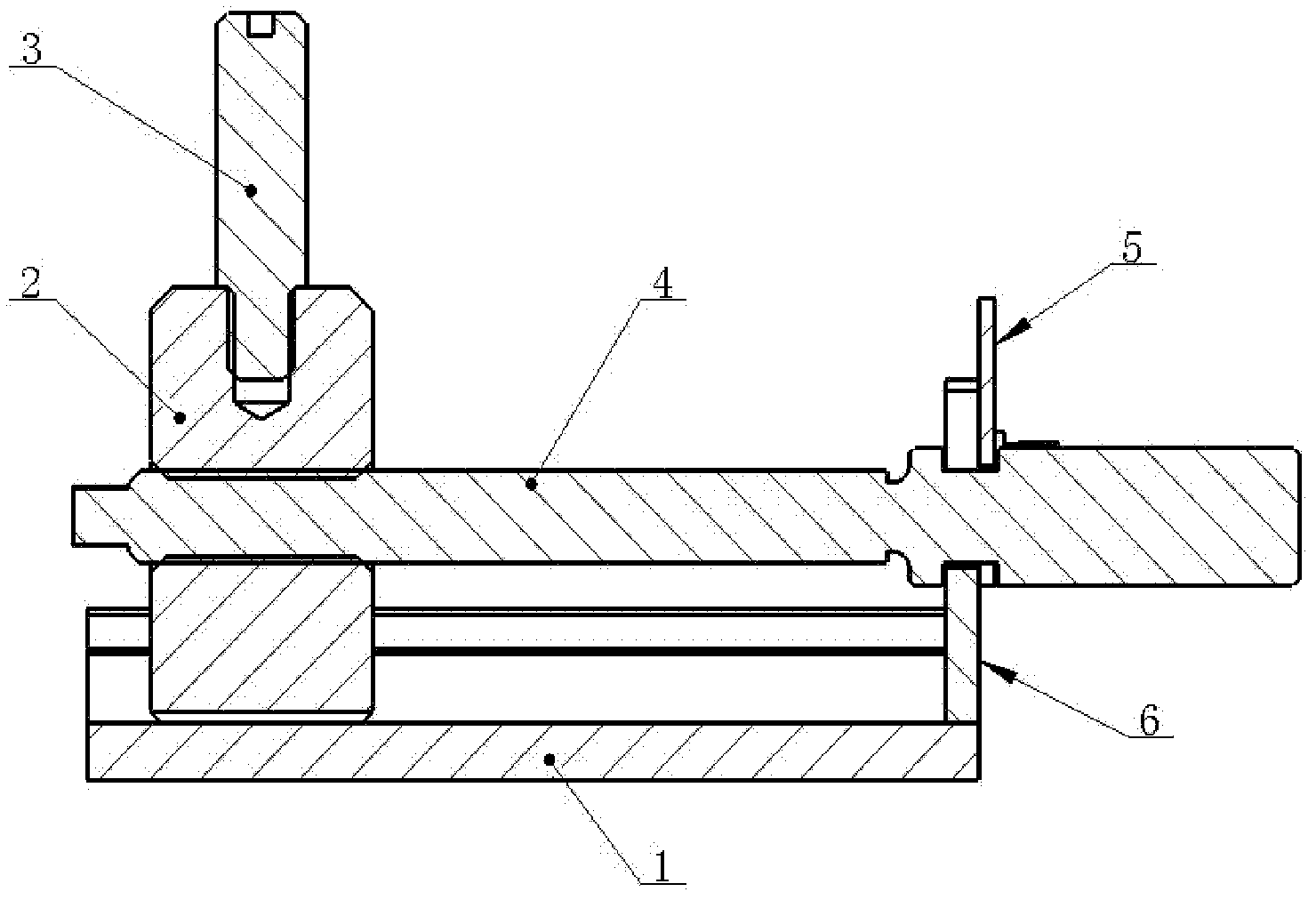

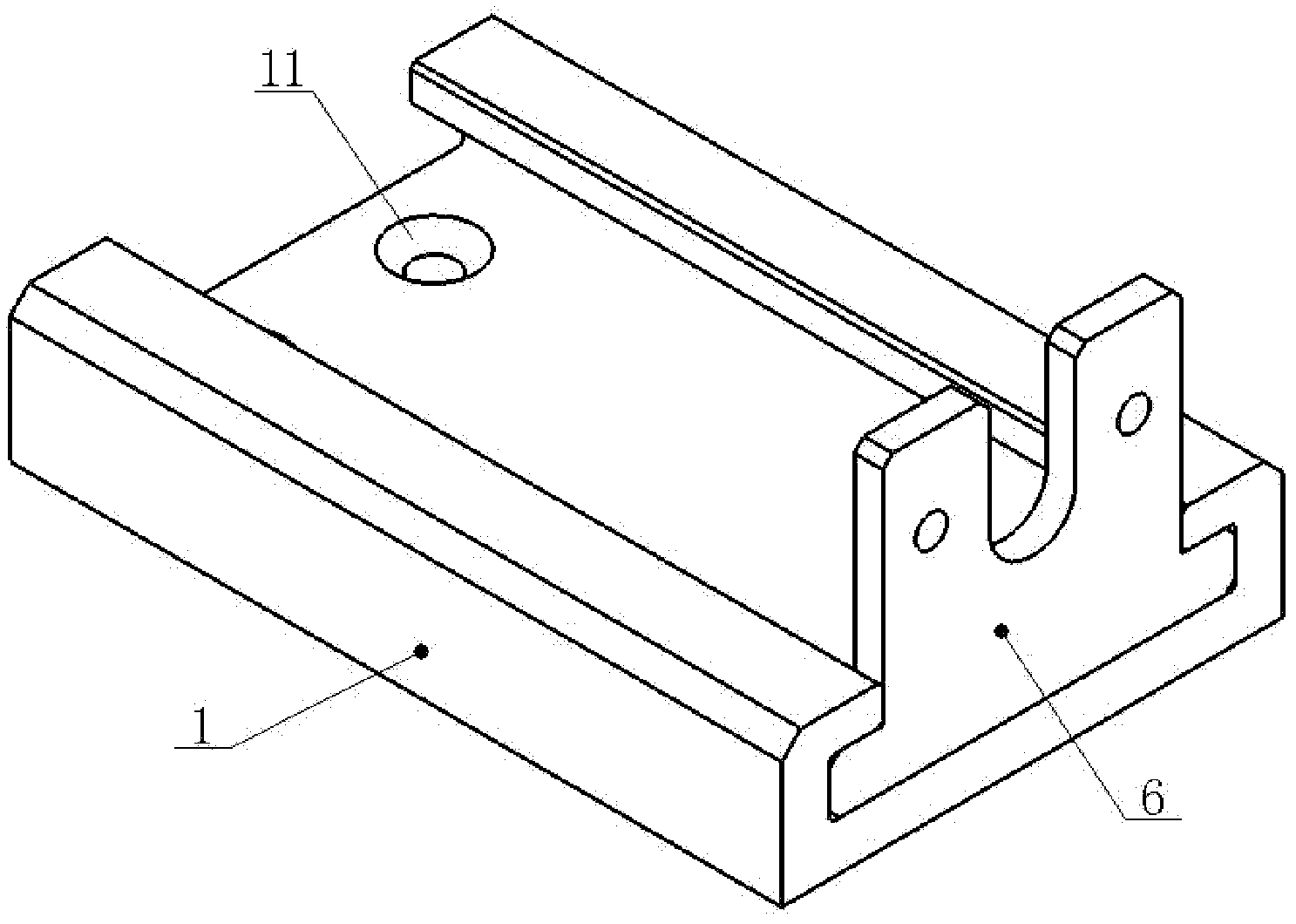

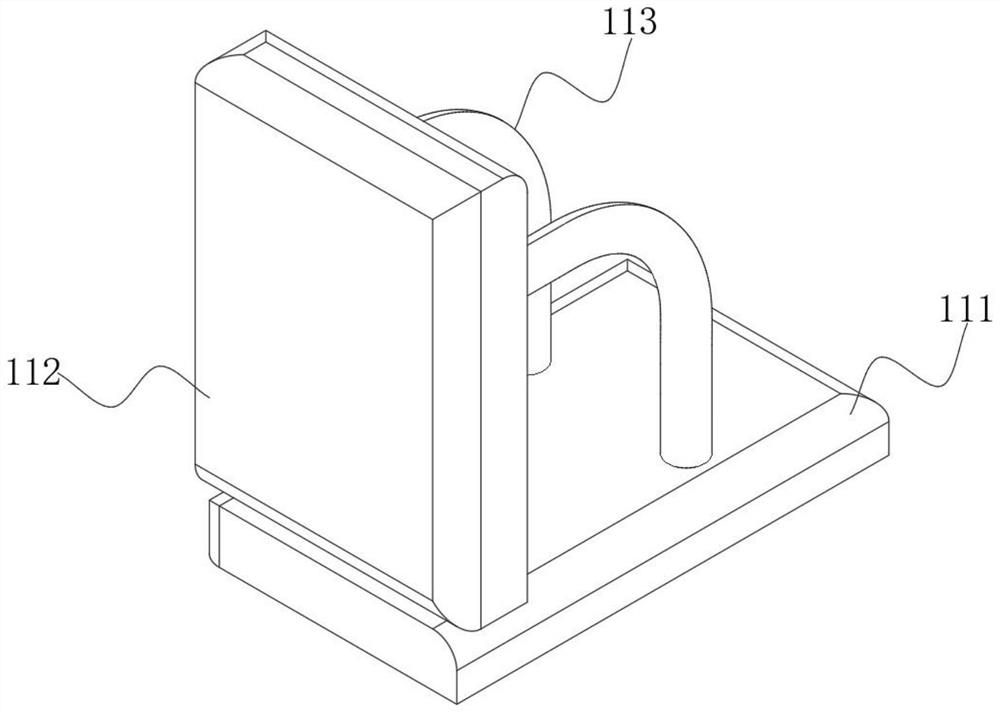

Positioning element and positioning mechanism thereof

InactiveCN102423877APrecise position adjustmentFlexible adjustmentWork holdersMetal-working hand toolsBiomedical engineering

The invention discloses a positioning element which comprises a guide seat, a slider, a positioning pin, a guide rod and a limiting structure, wherein the guide seat is provided with a guide slot; the limiting structure is arranged at one end of the guide slot; the slider is arranged on the guide seat and can slide in the guide slot; the guide rod penetrates between the limiting structure and the slider and is connected with the limiting structure through a head part and connected with the slider through a tail part; and the positioning pin is arranged at the upper part of the slider. Through the invention, flexible positioning is realized, the positioning structure is simple and compact, and the subsequent reconstruction and maintenance cost is low.

Owner:BEIJING SEVENSTAR ELECTRONICS CO LTD

Orthopedic perforating device capable of precisely positioning

InactiveCN108095796AImprove work efficiencyEasy to operateBone drill guidesEngineeringControl switch

The invention discloses an orthopedic perforating device capable of precisely positioning. The orthopedic perforating device comprises a base, a power interface, a control switch and an operation panel are successively arranged on the front face of the base from right to left, a working table is arranged at the upper end of the base, a movable device is arranged at the middle of the upper end of the working table, a fixed base is arranged at the upper end of the movable device, a fixed sleeve matched with the fixed base is arranged at the upper end of the fixed base, a vertical column is arranged at the upper end of the base and disposed at one side of the working table, a crossbar is arranged at one side of the upper end of the vertical column, the crossbar is sleeved with a first slidingsleeve, the lower end of the first sliding sleeve is fixedly connected with the upper end of a vertical rod, the vertical rod is sleeved with a second sliding sleeve, a fixed base is arranged at thelower end of the vertical rod, a first rotating shaft is arranged at one side of the second sliding sleeve, and one end, away from the second sliding sleeve, of the first rotating shaft is movably connected with one end of a connection plate. The orthopedic perforating device has the advantages of being high in work efficiency, simple in operation, accurate in positioning, and safe and high-efficiency in perforation assisted treatment recovery of orthopedic patients, the degree of work difficulty of medical staffs is reduced, and the comfort of the patients is fully guaranteed.

Owner:WUXI NO 2 PEOPLES HOSPITAL

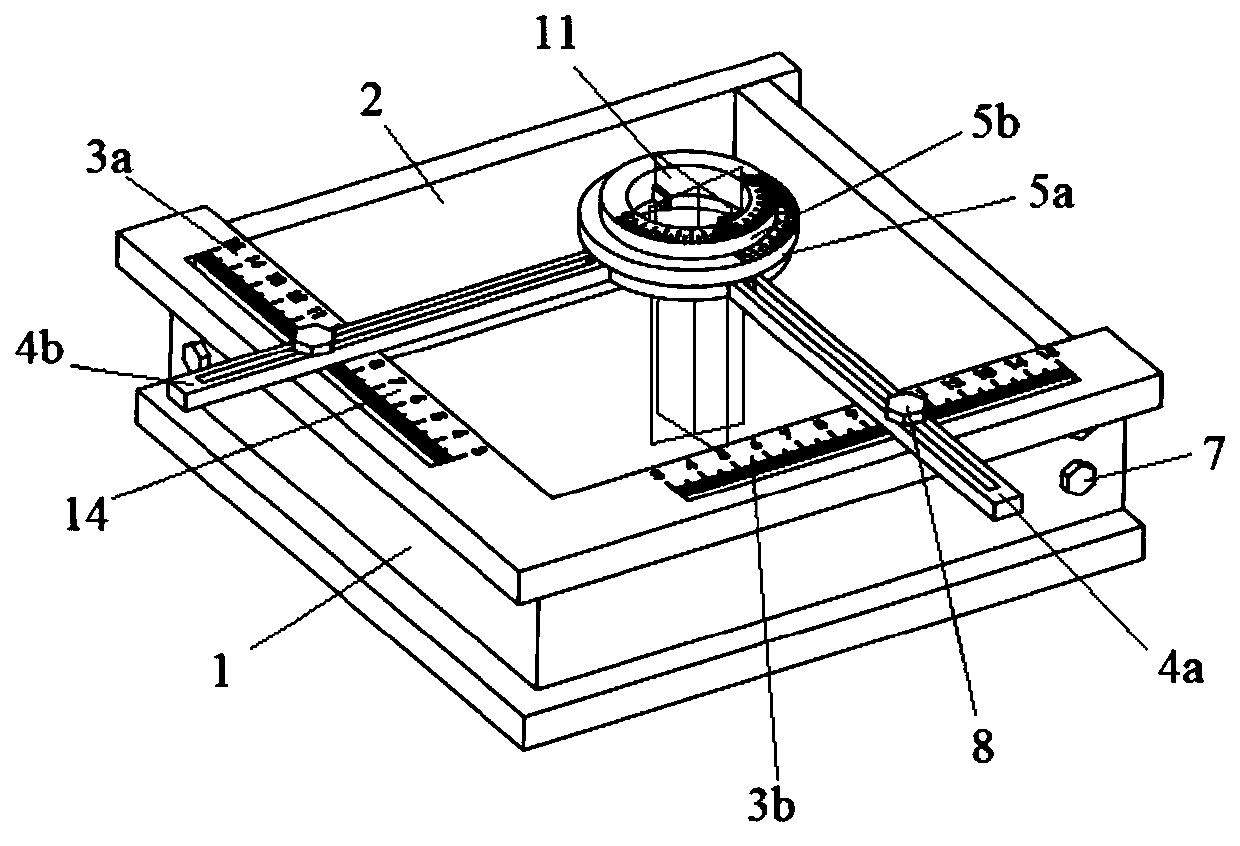

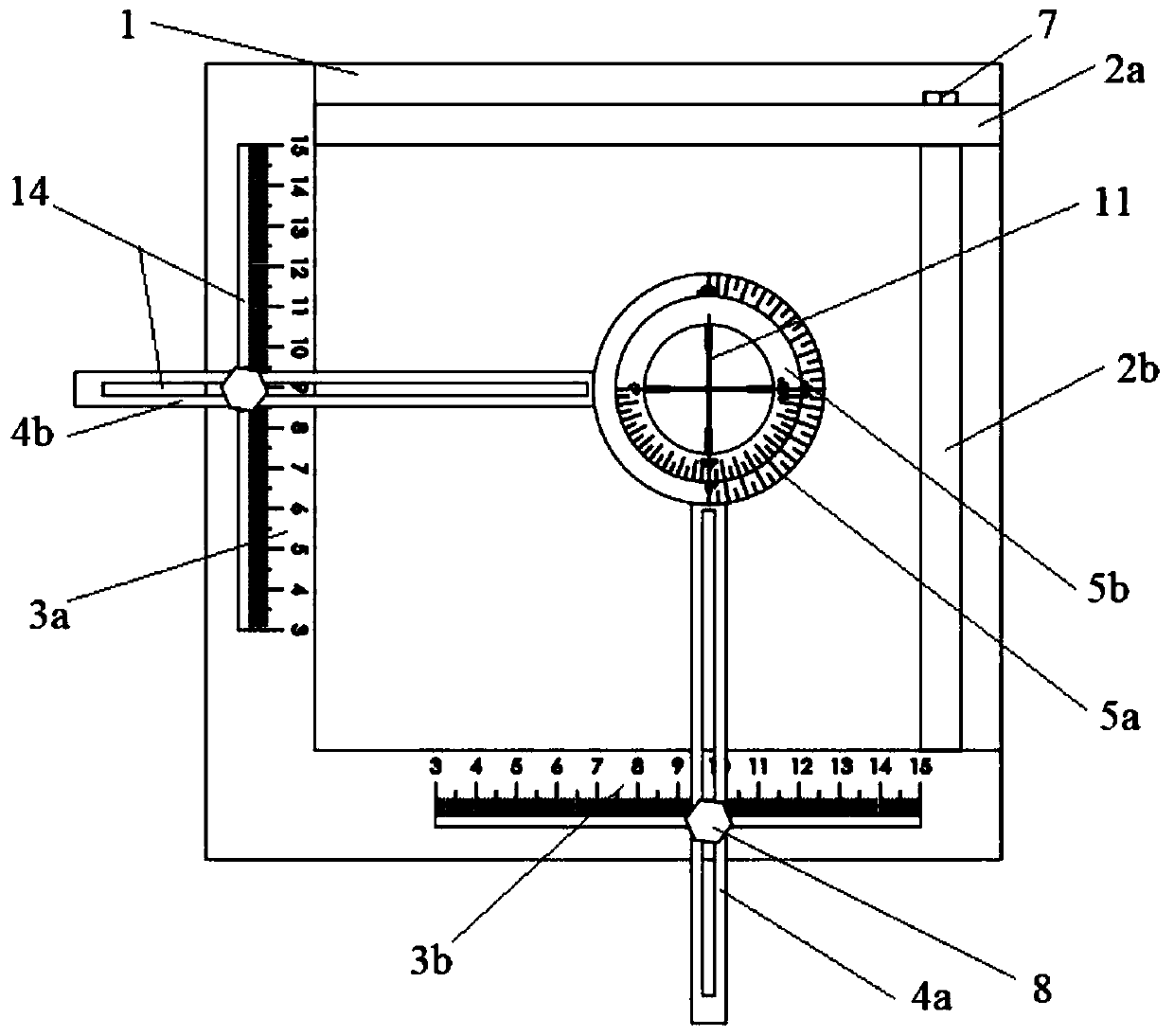

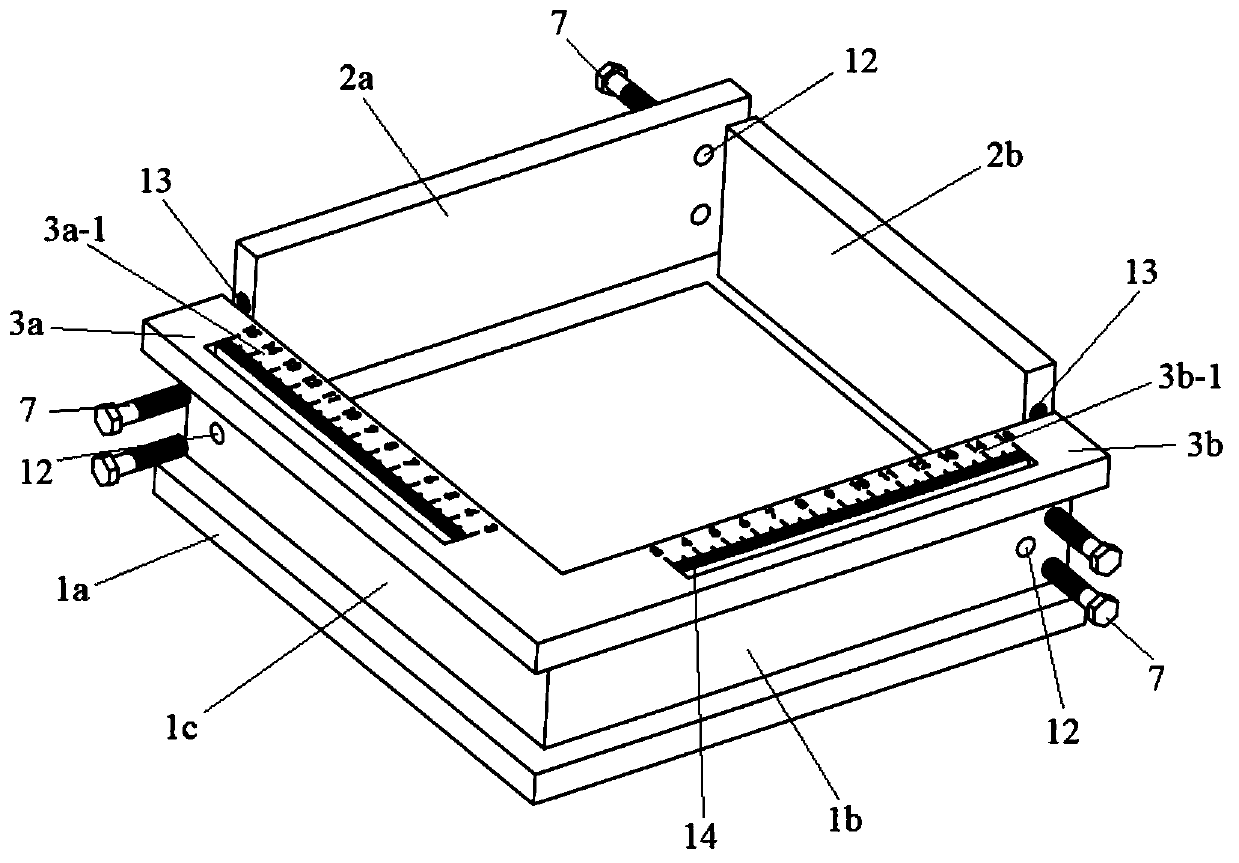

Rock test piece manufacturing mold capable of adjusting joint angle and position and using method

ActiveCN111207972AEasy to makeEasy to processPreparing sample for investigationPolystyreneMechanical engineering

The invention discloses a rock test piece manufacturing mold capable of adjusting the joint angle and position and a using method. The manufacturing mold comprises a detachable rectangular mold groove, a position adjusting device composed of a steel plate ruler and a positioning sliding straight rod, an angle adjusting device internally provided with a mold piece fixing plate, and a mold piece made of polystyrene, wherein all the components are connected and fixed through self-tightening bolts, nuts and other parts, mold dismounting is convenient, and manufacturing of rock-like test pieces isfacilitated. The manufacturing mold is advantaged in that a rock-like sample of a prefabricated cross joint can be manufactured, the included angle and the position of the cross joint can be accurately controlled, research on diversified joint forms of the rock-like sample is facilitated, the obtained result is accurate in size data, and the manufacturing mold is simple in manufacturing mode, capable of being repeatedly used and beneficial to popularization.

Owner:SHANDONG JIANZHU UNIV

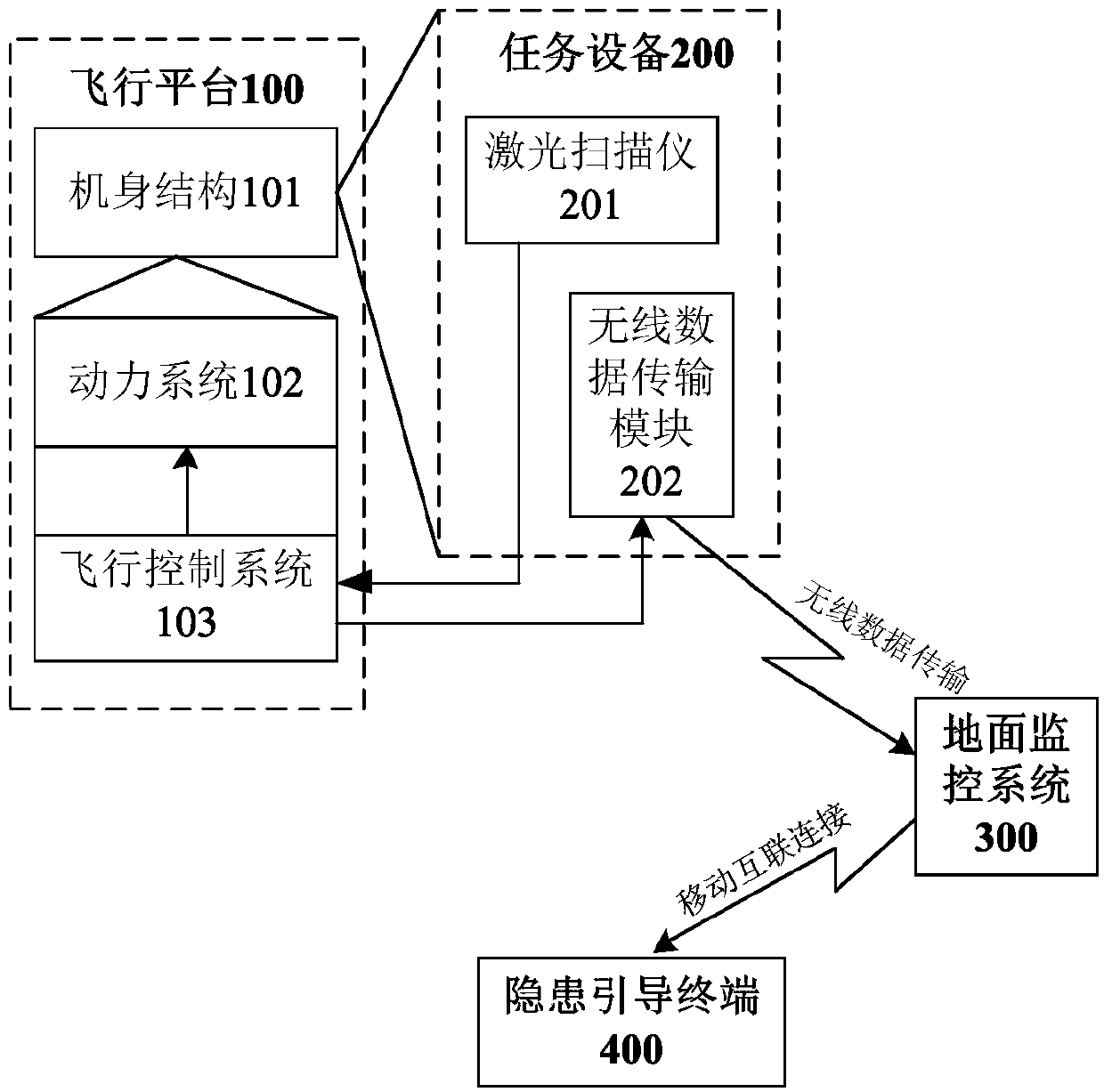

Rapid inspection system and method for power line corridor based on laser scanning guidance

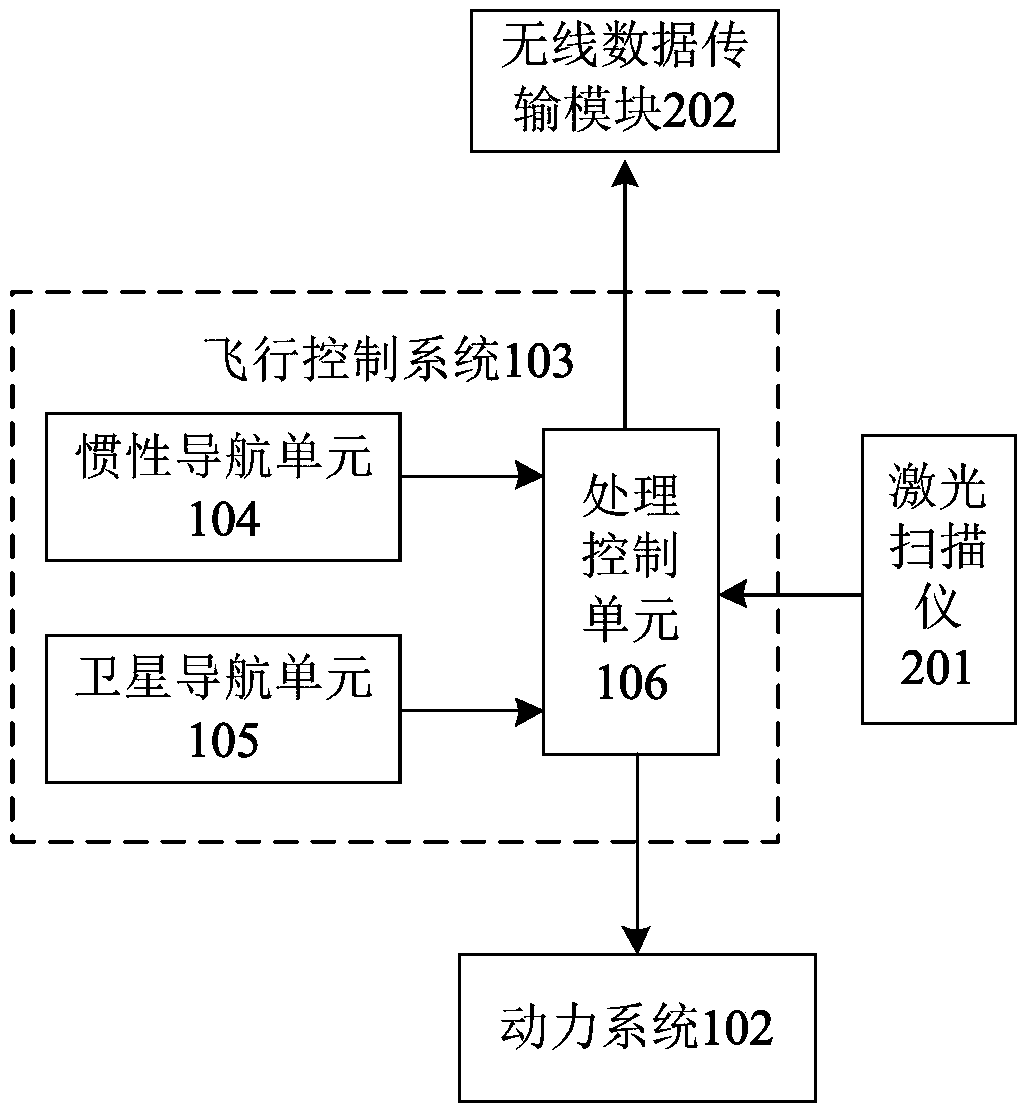

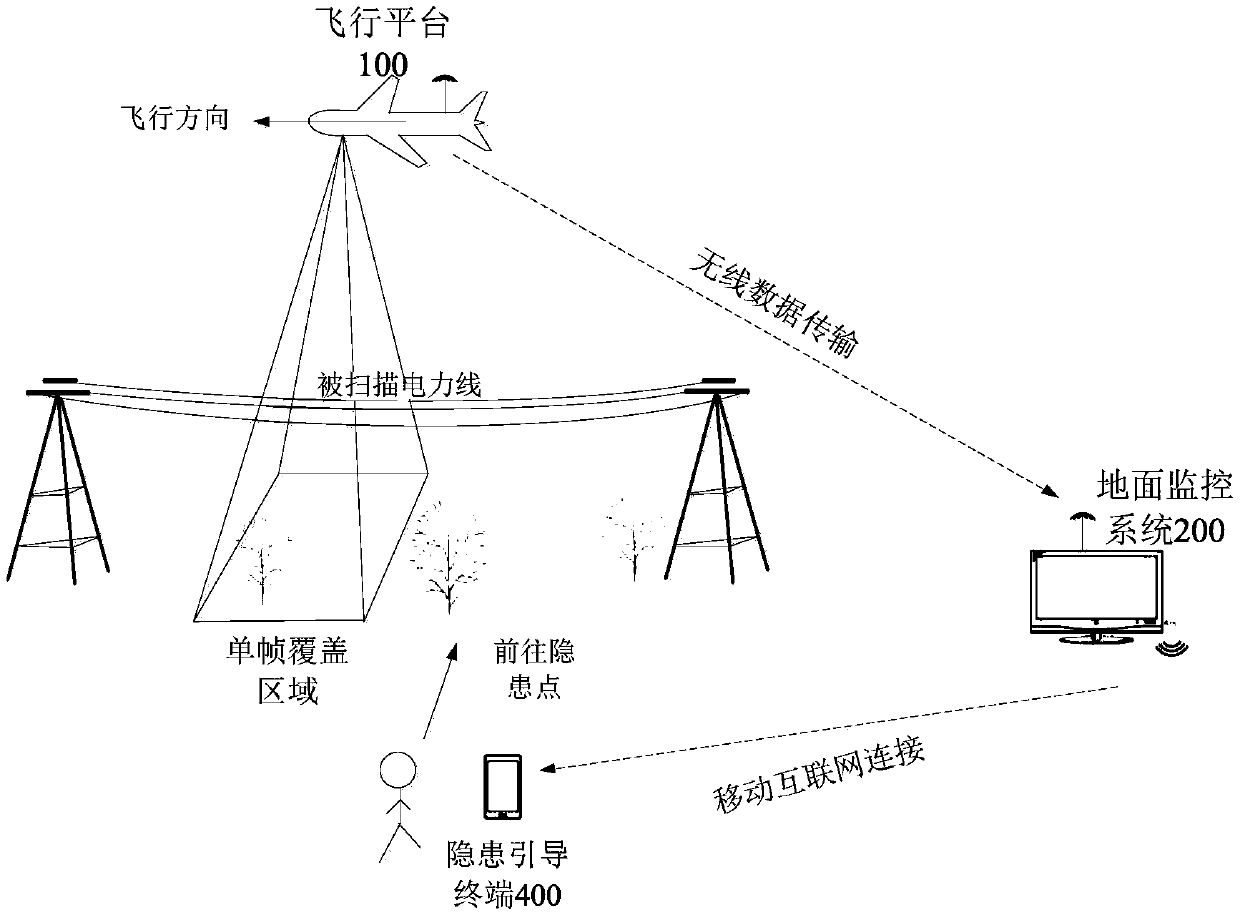

ActiveCN109254303ALower requirementReduced precision requirementsImage enhancementImage analysisLaser scanningEngineering

A rapid inspection system for a power line corridor based on laser scanning guidance comprises a flight platform and a ground monitoring system. The flight platform comprises a fuselage structure, a power system and a flight control system. The fuselage structure further carries a laser scanner and a wireless data transmission module. The flight control system comprises a processing control unit and further comprises an inertial navigation unit and a satellite navigation unit which are connected with the processing control unit. A rapid inspection system for the power line corridor based on laser scanning guidance comprises the steps that three-dimensional point cloud resolving is conducted according to laser scanning data, position data and attitude data, three-dimensional point cloud ofthe power line corridor is obtained, and the relative position relation is obtained through extracting of the power line point cloud; adjusting information of the next flight path is planned, the adjusting information is compared with a set clearance threshold value, and clearance hidden danger points are judged; hidden danger point data are sent back to the ground monitoring system in real time;the hidden danger point data are sent to a hidden danger guiding terminal; and the hidden danger guiding terminal displays the hidden danger point data, and a navigation track for advancing for hiddendanger trouble shooting is formed.

Owner:绵阳紫蝶科技有限公司

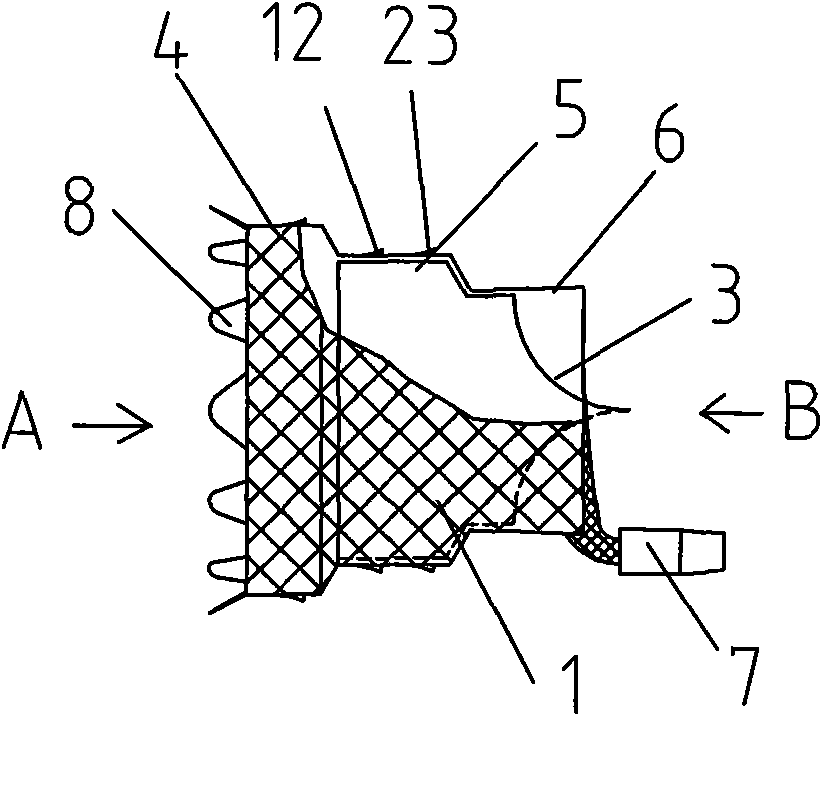

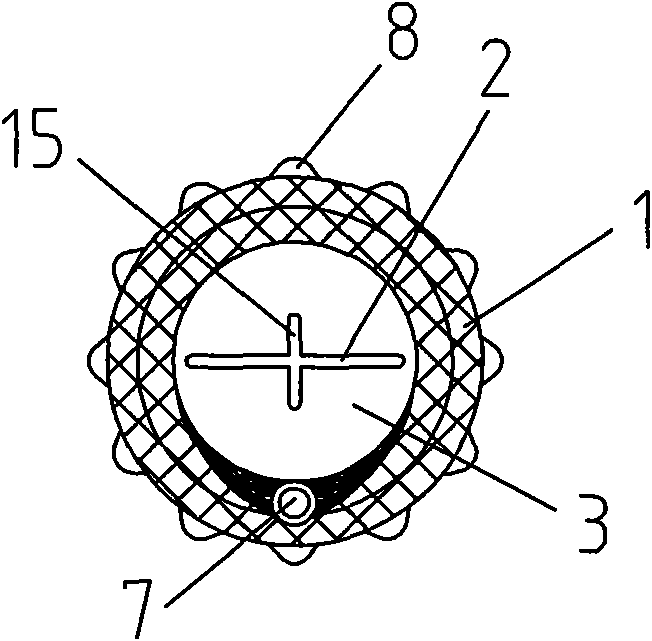

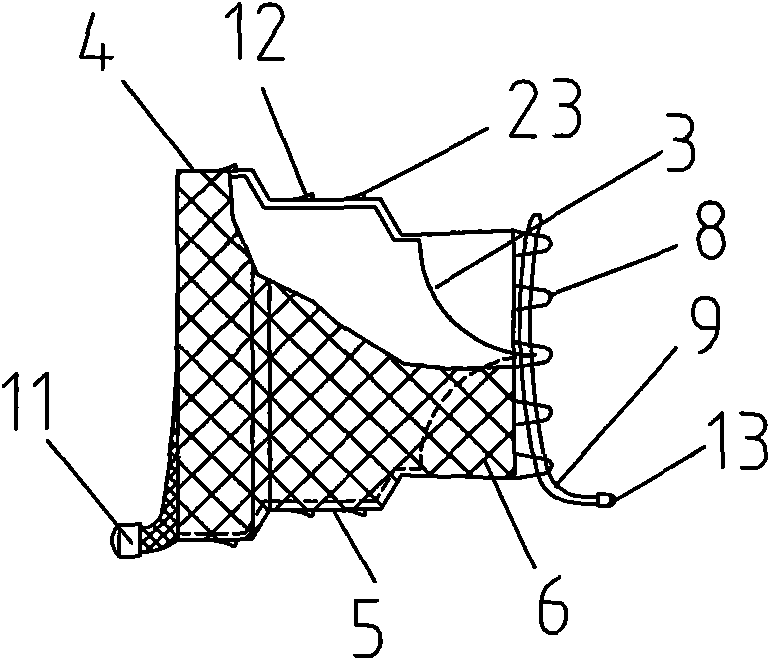

Recyclable unidirectional valve covered stent

The invention discloses a recyclable unidirectional valve covered stent which comprises a mesh stent (1) and a membrane (3) with a horizontal-strip shaped opening (2), wherein the mesh stent is formed by weaving a plurality of memory alloy wires; the key point is that the mesh stent (1) is integrally formed by at least two sections with different diameters, i.e. a section (4) with the big diameter (4) and a section (6) with the small diameter; the cross sections of the two sections are step-shaped; the membrane (3) is arranged in the section (6) with the small diameter; the edge of at least one end of the mesh stent (1) is provided with an end part device which can collect the mesh stent (1). The sent can realize the bi-directional imbedding or recovery, and is safe and reliable; the membrane has reasonable structure and strong anti-backflow capability, and is reliable and durable; and the covered stent can be used for lung diseases, bile ducts, blood artery, venous valves and preventing heterodromous circulating of human body lumens.

Owner:BEIJING PUYI MEDICAL TECH CO LTD

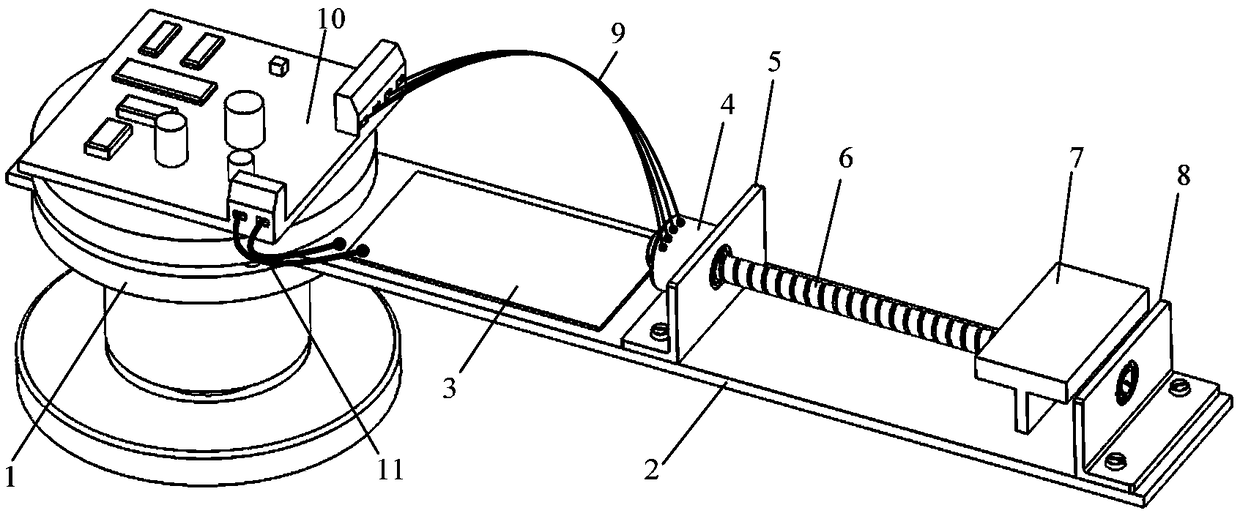

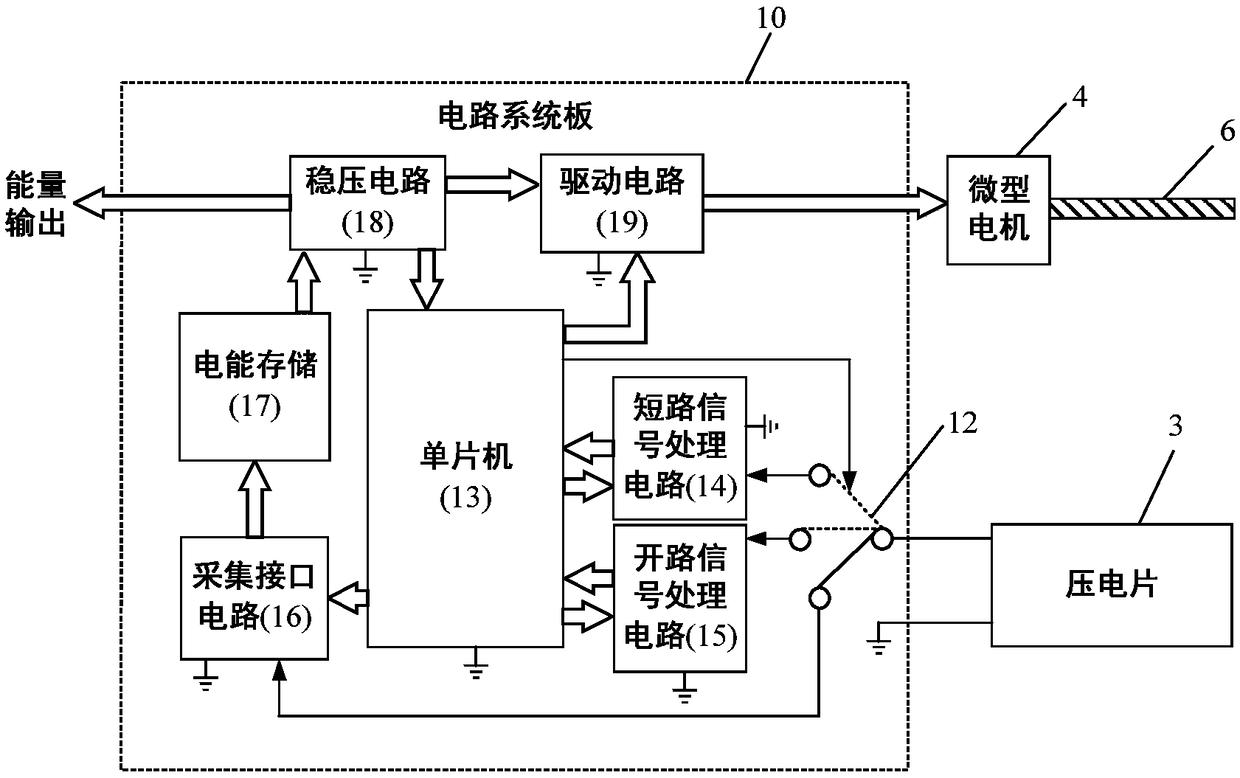

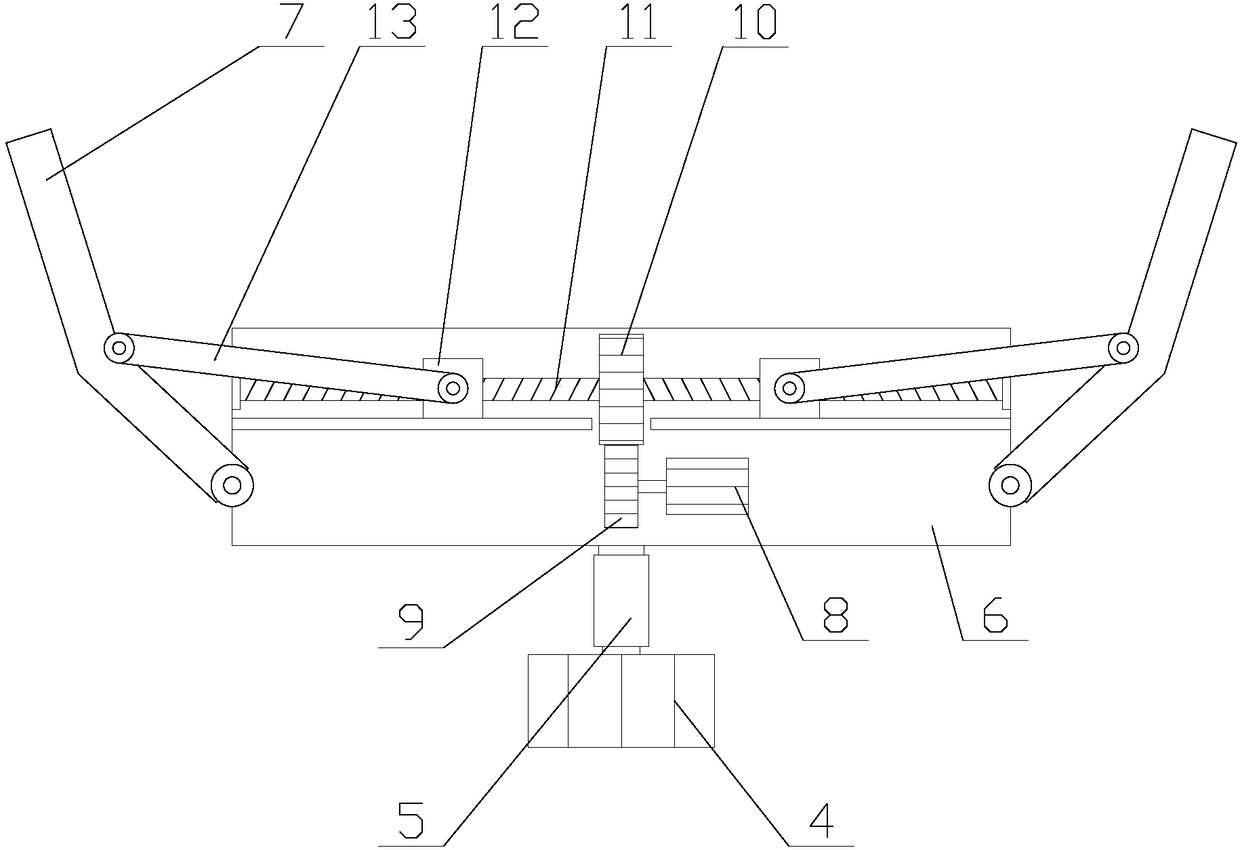

A piezoelectric energy harvesting device and method capable of automatically adjusting resonant frequency and bandwidth

PendingCN109274289ARealize fully automatic controlRealize automatic adjustmentBatteries circuit arrangementsPiezoelectric/electrostriction/magnetostriction machinesElectricityCantilevered beam

The invention discloses a piezoelectric energy harvesting device and method for automatically adjusting resonant frequency and bandwidth, characterized in that the piezoelectric plate is arranged on the cantilever beam, A cantilever beam is mounted on a fixed base, The micro motor is mounted on the cantilever beam through a motor bracket, the shaft of the micro motor is connected with the screw rod and can drive the screw rod to rotate, the other end of the screw rod is also fixed on the cantilever beam through the screw rod bracket, the mass block is mounted on the screw rod through threads corresponding to the screw rod, and when the screw rod rotates, the mass block can move along the screw rod direction. Circuit system plate are connected with piezoelectric plate for vibration energy capture, and judging whether the environmental vibration frequency matches the natural frequency of the piezoelectric energy harvesting device from the output signal of the piezoelectric piece, By controlling the forward and backward rotation of the micro-motor, the position of the end mass of the cantilever beam can be adjusted, and the distance between the mass and the motor can be adjusted, so that the first-order resonant frequency point of the piezoelectric energy harvesting device and the band width of the first-order and second-order superposition can be adjusted automatically.

Owner:CHINA JILIANG UNIV

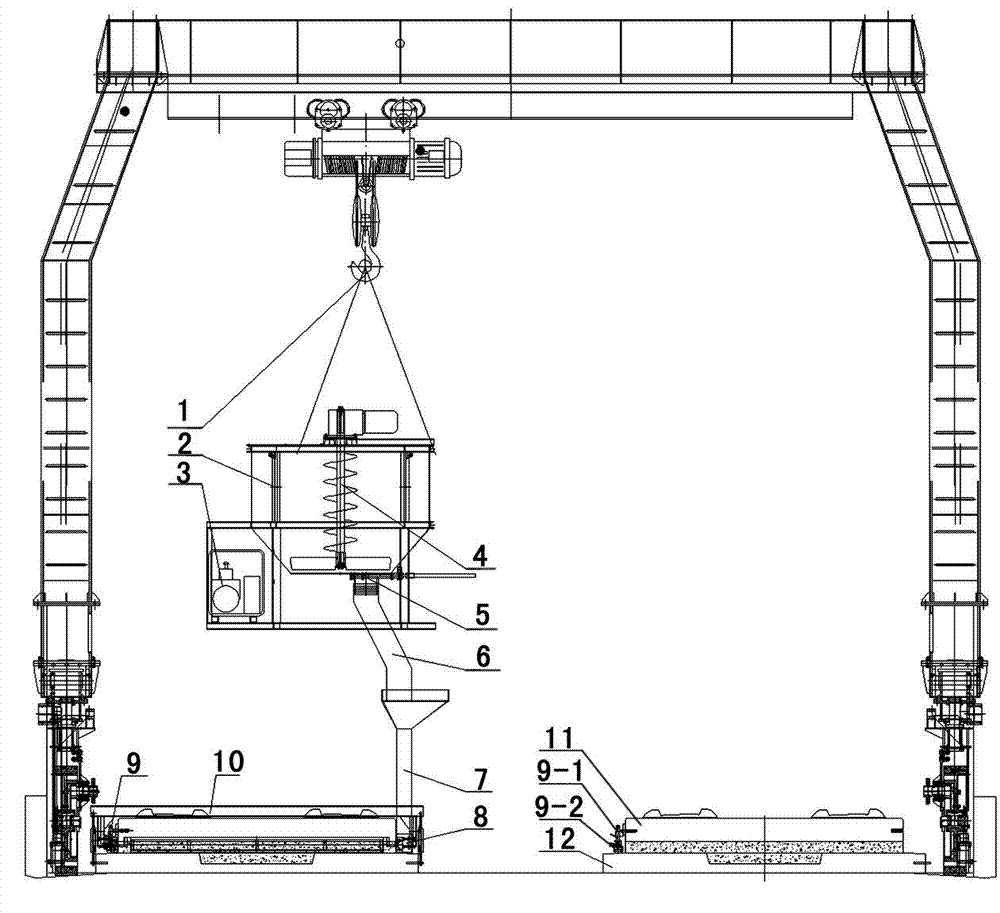

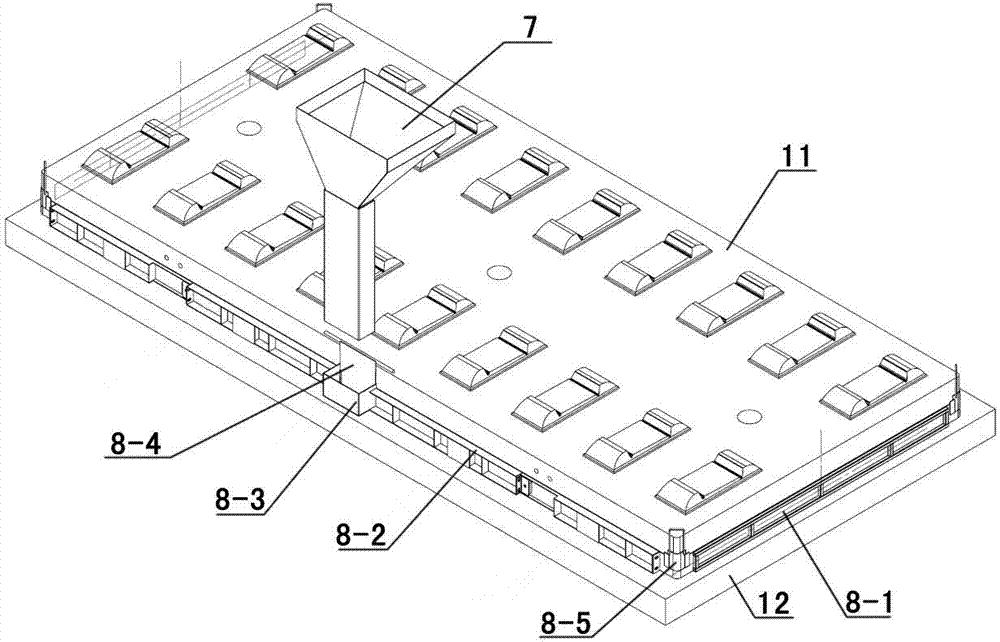

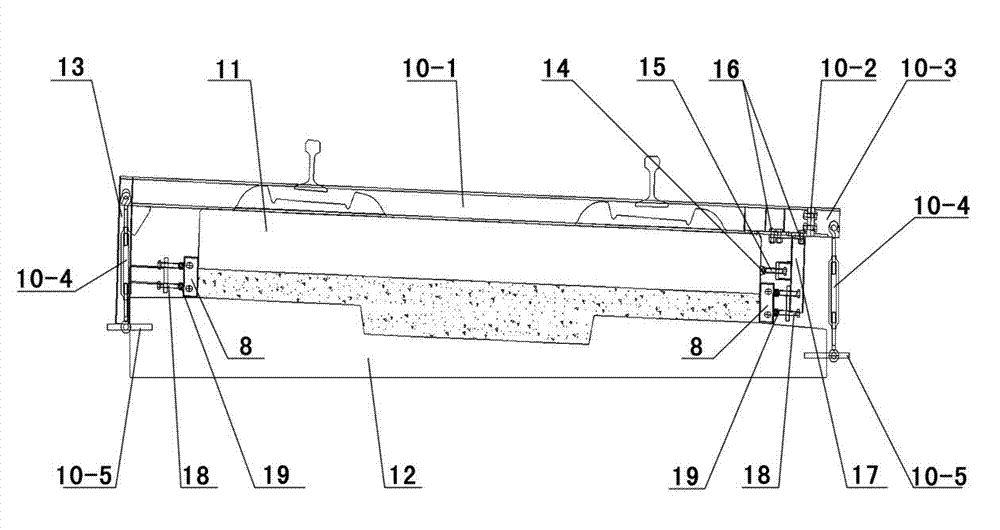

CRTS III type slab ballastless track self-compacting concrete casting tooling and method

The invention provides a CRTS III type slab ballastless track self-compacting concrete casting tooling and method. The casting tooling comprises a base slab, a track slab, a transferring hopper, a casting funnel, a slurry blocking template, a three-dimensional fine regulator, a track slab pressing device, a track slab lateral sliding preventing device and a slurry blocking template pressing device. The middle casting mode is changed into the lateral surface casting, and the problems of casting efficiency and air exhaust in the CRTS III type slab ballastless track construction are solved. The track slab lateral sliding preventing device, the track slab pressing device and the slurry blocking template pressing device effectively solve the problems of upward floating, lateral sliding and slurry leakage of the track slab in the casting process, so the fine regulation and the casting construction of the CRTS III type slab ballastless track are more convenient and fast, and the casting quality is better. The construction process has the advantages that in the use process, the weight is light, the rigidity is high, the efficiency is high, the operation is simple and convenient, the work intensity is low, and the construction process can adapt to the construction of road segments such as bridges, tunnels and roadbeds.

Owner:LANGFANG HELI TIANYI MACHINERY & EQUIP

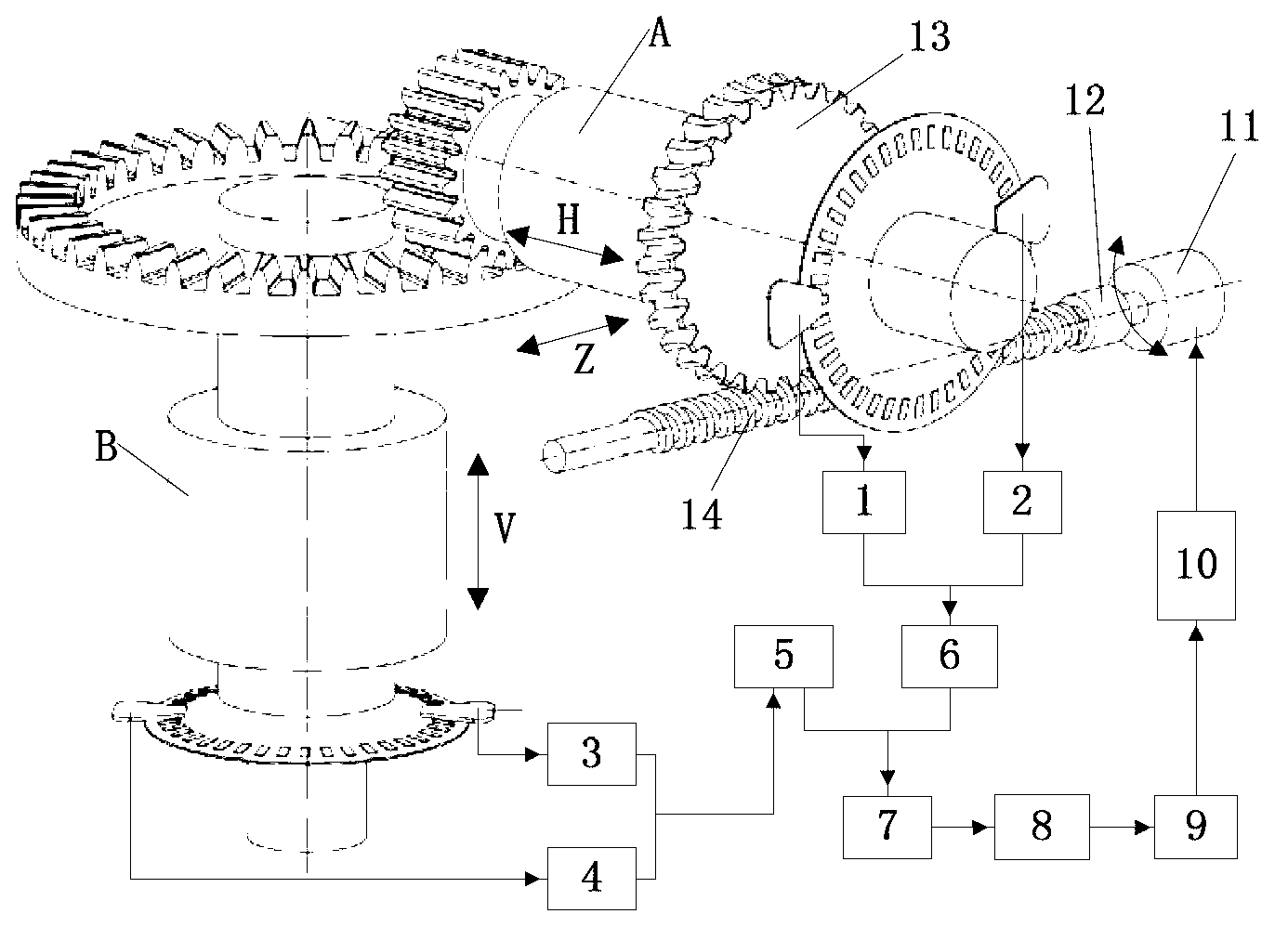

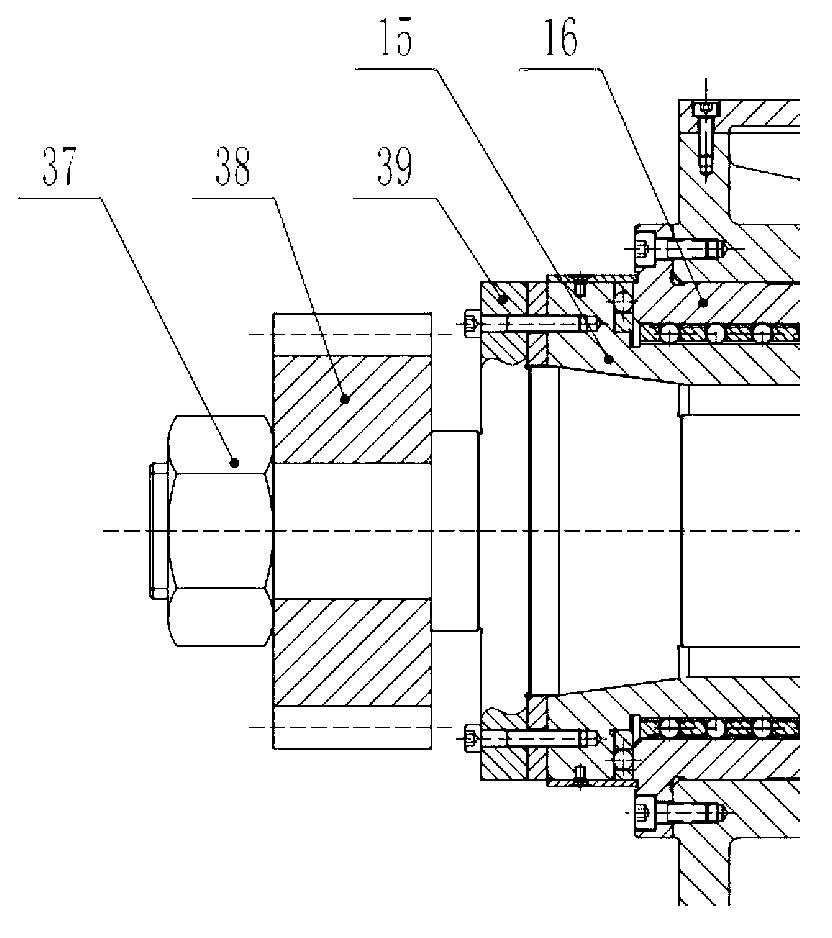

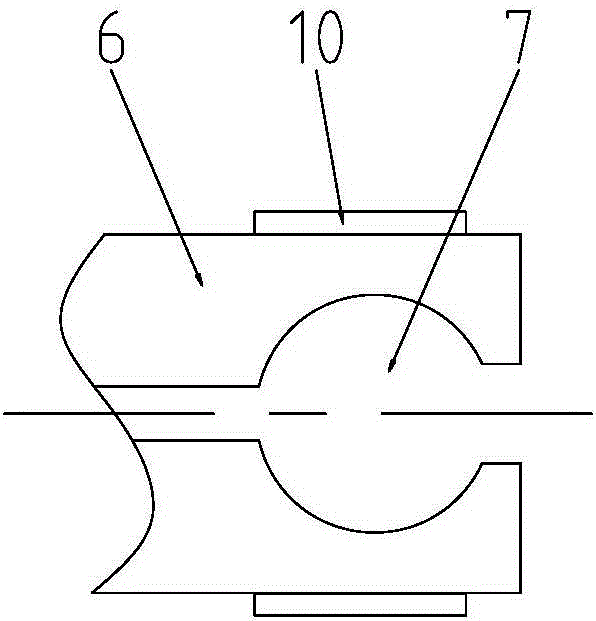

Single-sided meshing measurement device for face gear errors

ActiveCN103267480AImprove versatilityPrecise position adjustmentUsing optical meansGratingMeasurement device

The invention belongs to the field of a precision measurement technology, and provides a single-sided meshing measurement device for face gear errors. The single-sided meshing measurement device comprises a cylindrical gear shafting, a cylindrical gear installation mechanism, a face gear shafting, a face gear installation mechanism, a motor, a coupler, a worm, a controller, a drive unit, a circular grating system, a subdividing device, a DSI card, a data acquisition card and an industrial personal computer. The cylindrical gear shafting is an active shafting and is driven by a servo motor. The single-sided meshing measurement device reduces the quantity of parts of an instrument, and enhances stability of a system.

Owner:BEIJING UNIV OF TECH

Segmental box beam short line matching control and prefabrication construction method

ActiveCN112060307AEffective organizationEnsure construction efficiencyMouldsCeramic shaping plantsControl systemConstruction engineering

The invention discloses a segmental box beam short line matching control and prefabrication construction method. The method comprises the following steps that firstly, a beam field is divided into functional areas; secondly, end beams are manufactured in a beam manufacturing area; thirdly, a cast-in-place beam formwork is installed; fourthly, a tied steel reinforcement framework is put in, and theposition is controlled and checked; fifthly, concrete is poured into the cast-in-place beam formwork; sixthly, cast-in-place beams serve as matching beams to be prefabricated circularly, until pouring of adopted beam bodies is completed; and seventhly, the completed beam bodies are placed in a beam storing area to be maintained. According to the method, the beam field is divided into the functional areas, site construction flows can be organized effectively, and construction efficiency is ensured. By means of joint arrangement of a table base beam manufacturing system, a measuring control system and a supporting and adjusting platform, installing can be achieved, the position can be adjusted precisely, and real-time control can also be achieved. By means of design of a shear force key, line type butt joint of the later period can be ensured. By arranging different spraying facilities, maintaining of the later period can be carried out effectively.

Owner:中国建筑土木建设有限公司

Multi-target material X light tube

InactiveCN101644689AIncrease profitExtended service lifeMaterial analysis using wave/particle radiationX-ray tube electrodesFluorescenceLight spot

The invention discloses a multi-target material X light tube, relating to the technical field of X-ray light tubes in an X fluorescence analyzer. The multi-target material X light tube comprises a shell, high pressure oil, a glass tube, a cathode, an anode target, an anode, electron beam, X-ray and an X-ray window, wherein the cathode and the anode are respectively arranged at both ends of the glass tube in which vacuum is formed; the anode target is arranged at an end face of the anode which is close to the cathode; the electron beam ejected by the cathode ejects on the anode target to form X-ray which passes through the X-ray window; the anode target consists of a plurality of small target faces; and at least one magnet and an automatic light spot locating device are arranged around theperiphery of the X-ray window. The invention aims at providing a multi-target material X light tube of which the target face consists of multiple target materials, with high target face use ratio, increased analysis range and improved service life of the target face.

Owner:JIANGSU SKYRAY INSTR

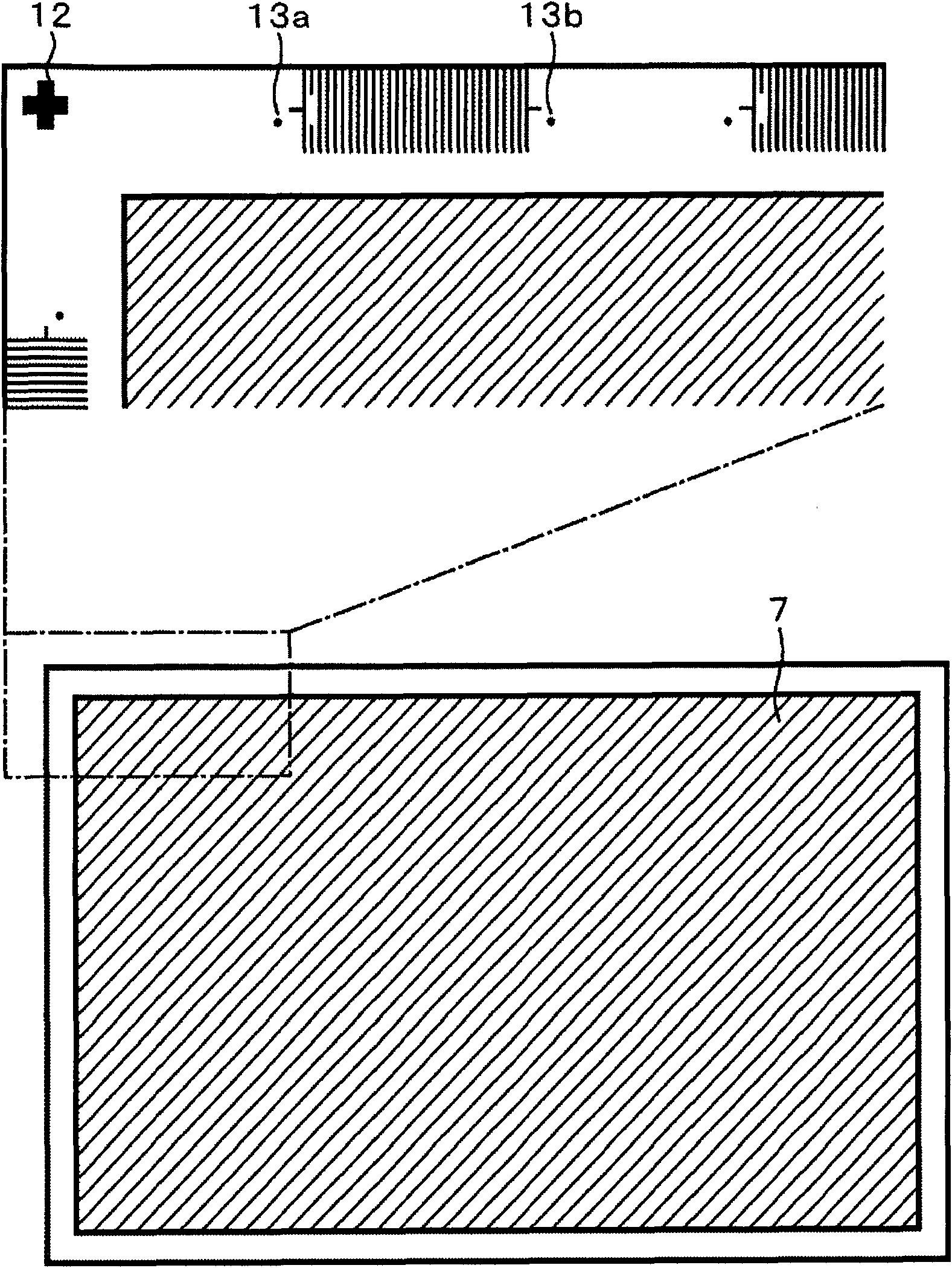

Display panel module assembly device

InactiveCN102263049APrecise position adjustmentAchieving drastic miniaturizationSemiconductor/solid-state device manufacturingCharge manipulationSurface plateComputer module

PURPOSE: A display panel module assembling device is provided to control a plurality of processing sides suitable for the size of each display panel substrate. CONSTITUTION: A processing panel maintenance unit(4) maintains a first display panel substrate and includes a processing unit. A first processing unit is arranged about the first processing side of the first display panel substrate. A second processing unit is arranged about the first processing unit. A third processing unit faces a second processing unit.

Owner:HITACHI HIGH-TECH CORP

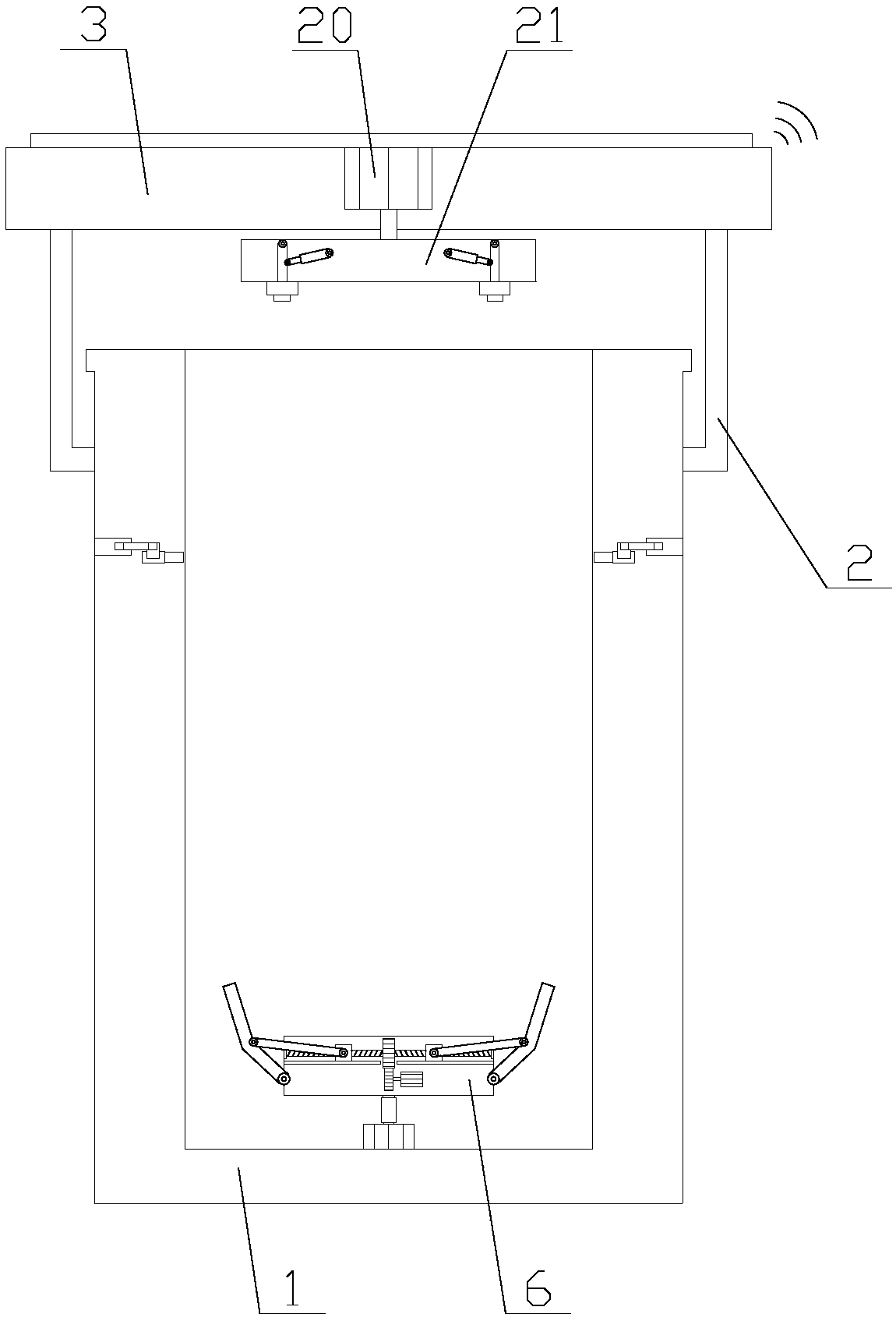

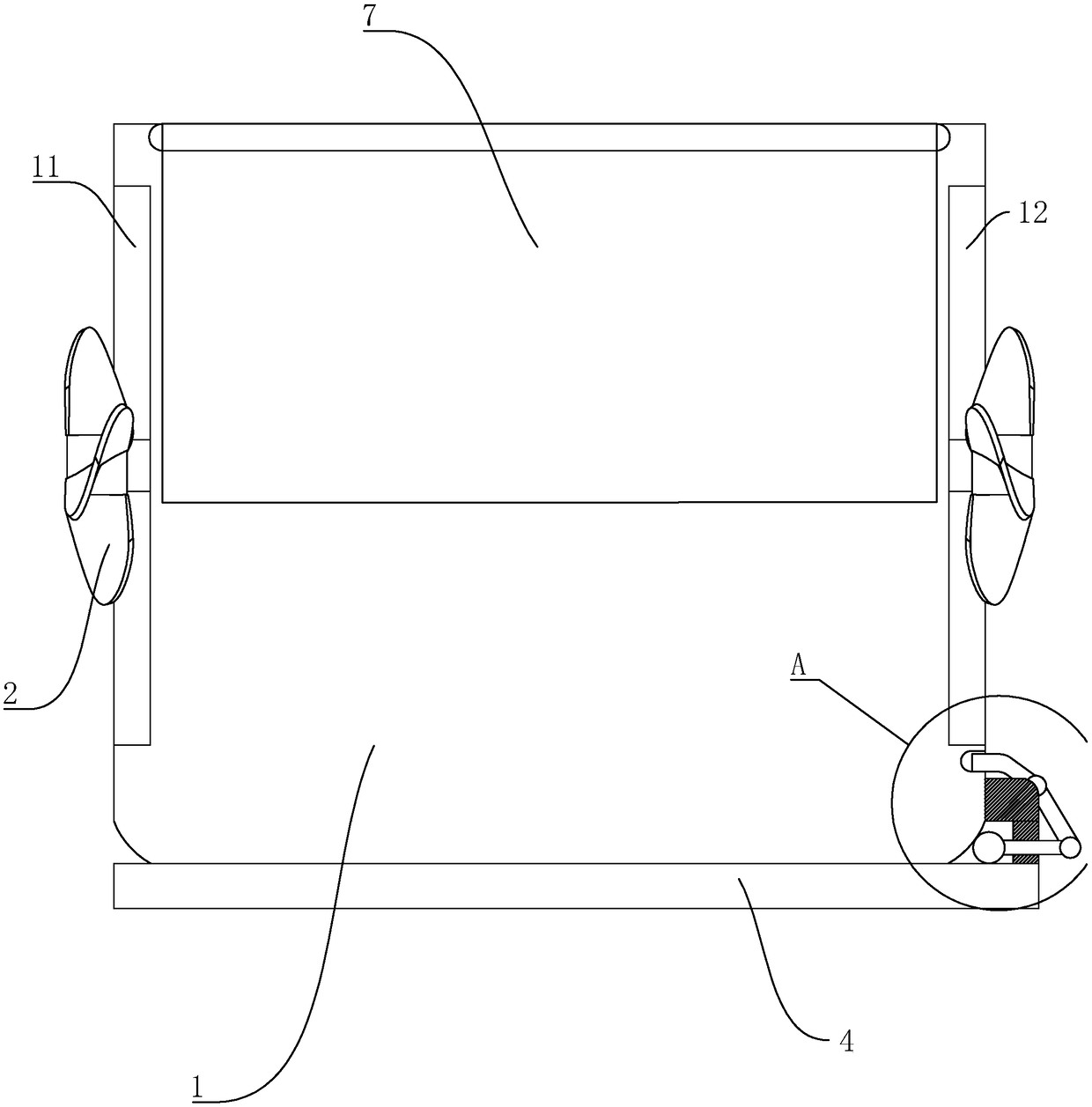

Intelligent equipment with garbage bag packaging function

InactiveCN108466782AEasy and reliable handlingImprove practicalityRefuse receptaclesFire - disastersIntelligent equipment

The invention relates to intelligent equipment with a garbage bag packaging function. The intelligent equipment comprises a main body, a support and a ceiling and further comprises a packaging mechanism and a fire-extinguishing mechanism. The packaging mechanism comprises a twisting assembly and two heating assemblies. The fire-extinguishing mechanism comprises a third motor, a rotary plate and two spraying assemblies. In the intelligent equipment with the garbage bag packaging function, through the packaging mechanism, garbage bags can be packaged and sealed to avoid diffusion of garbage foreign flavor, the situations that bag openings of the garbage bags are loosened and then opened, consequently accumulated garbage overflows, and the surrounding environment is influenced are prevented,the work amount of sanitation workers is reduced greatly, and garbage treatment is more convenient, rapider and more reliable; and through the fire-extinguishing mechanism, spray heads can be subjected to accurate position adjusting, then cigarette ends are extinguished through water spraying of the spray heads, the situation that fire disasters are caused by the cigarette ends, and consequently economic losses are caused is avoided, safety is better, and the practicability and reliability of the intelligent equipment are improved greatly.

Owner:惠安县冠威机械设备有限公司

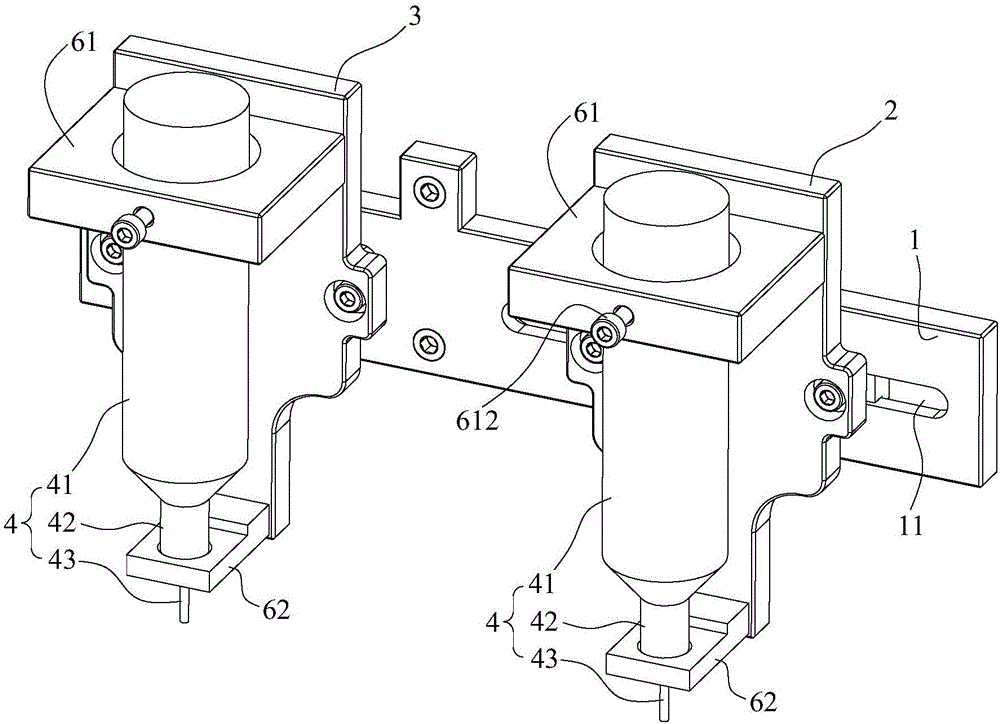

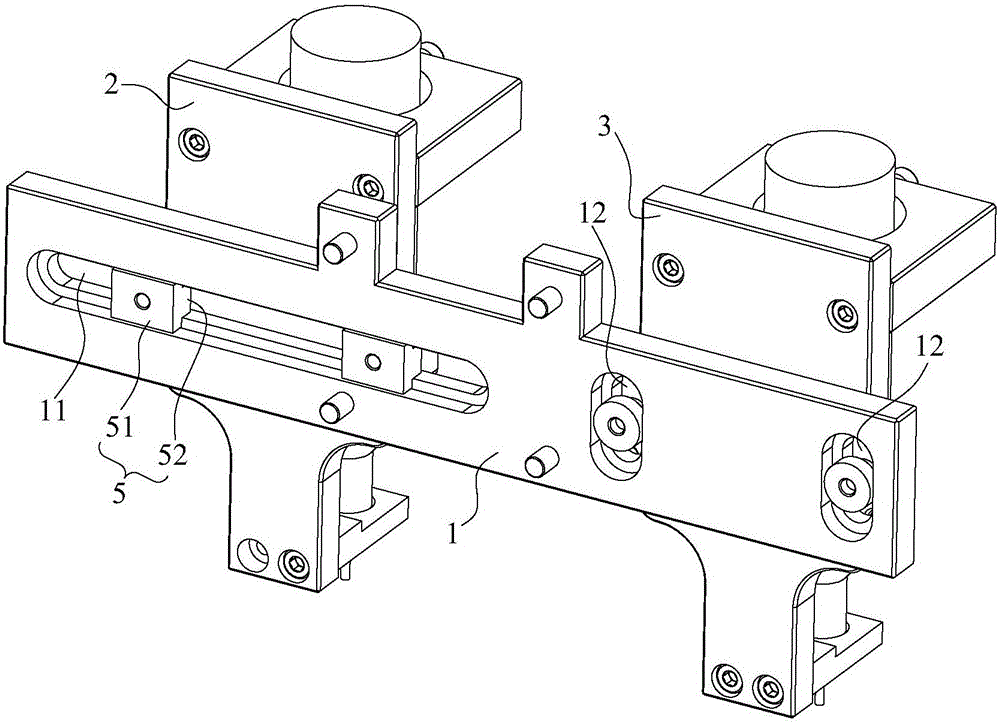

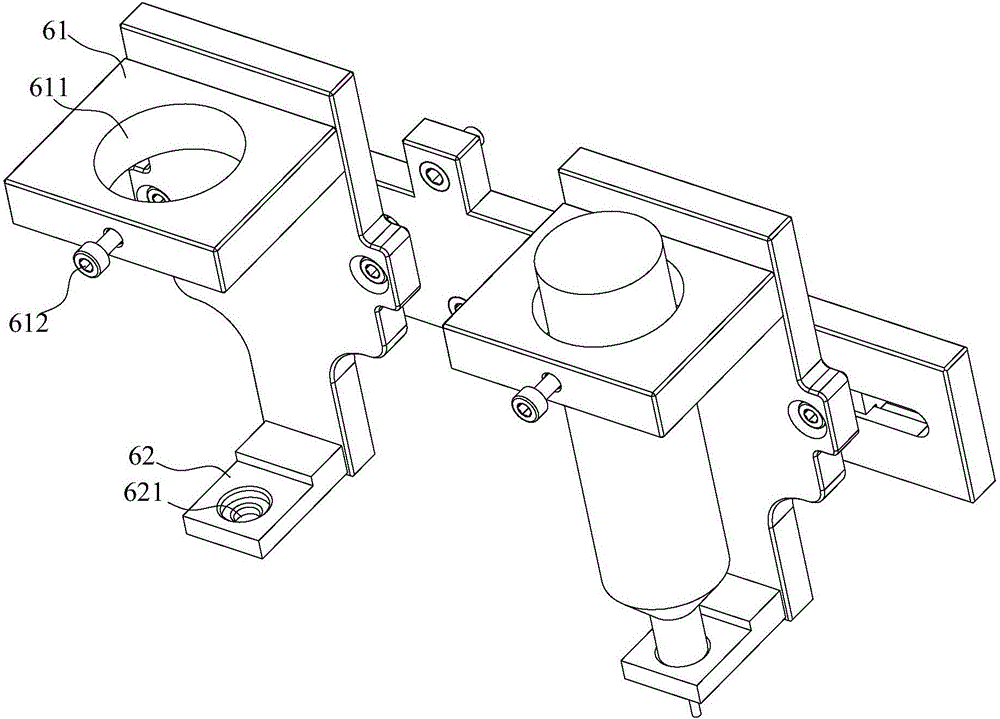

Dispensing jig

InactiveCN106111452AImprove dispensing efficiencyIncreased Versatility and Dispensing AccuracyLiquid surface applicatorsCoatingsInjectorBiomedical engineering

The invention discloses a dispensing jig. The dispensing jig comprises a jig support, a first dispensing support and a second dispensing support. The first dispensing support and the second dispensing support are used for fixing dispensing injectors. The jig support is fixed to a dispensing machine. The first dispensing support can slide along the surface of the jig support in the transverse direction. The second dispensing support can slide along the surface of the jig support in the longitudinal direction. The two dispensing injectors can conduct dispensing on two components at the same time, and the dispensing efficiency is improved. Due to the fact that the first dispensing support can slide along the surface of the jig support in the transverse direction, and the second dispensing support can slide along the surface of the jig support in the longitudinal direction, the position between the first dispensing support and the second dispensing support can be accurately adjusted, the two dispensing positions are accurately adjusted, and universality and the dispensing precision are improved.

Owner:KESEN SCI & TECH DONGTAI CO LTD

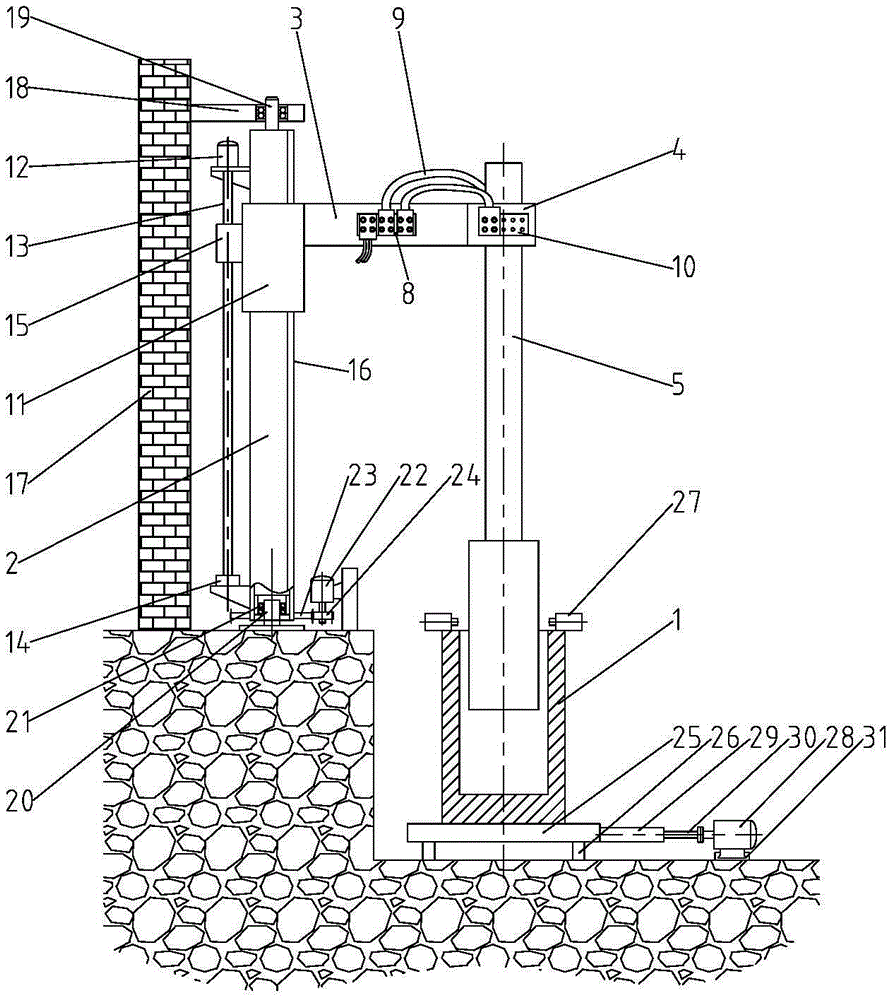

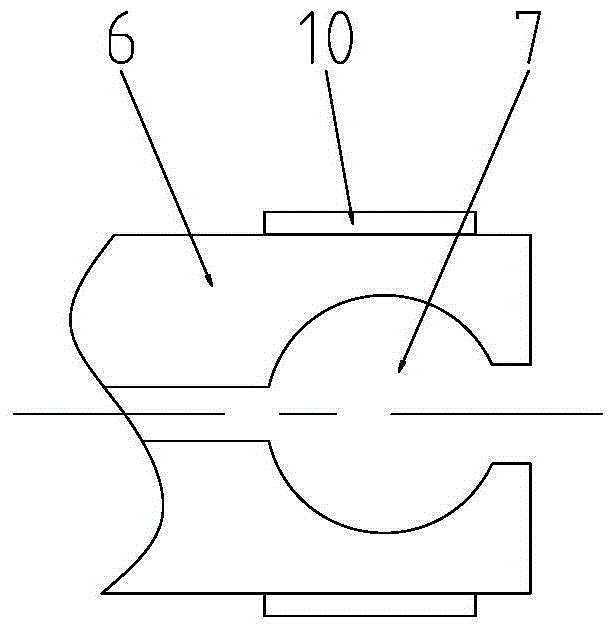

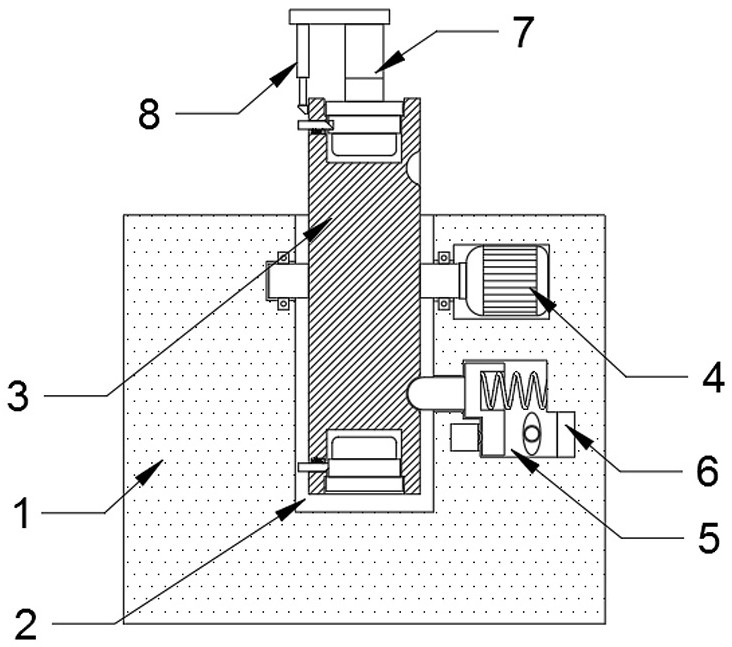

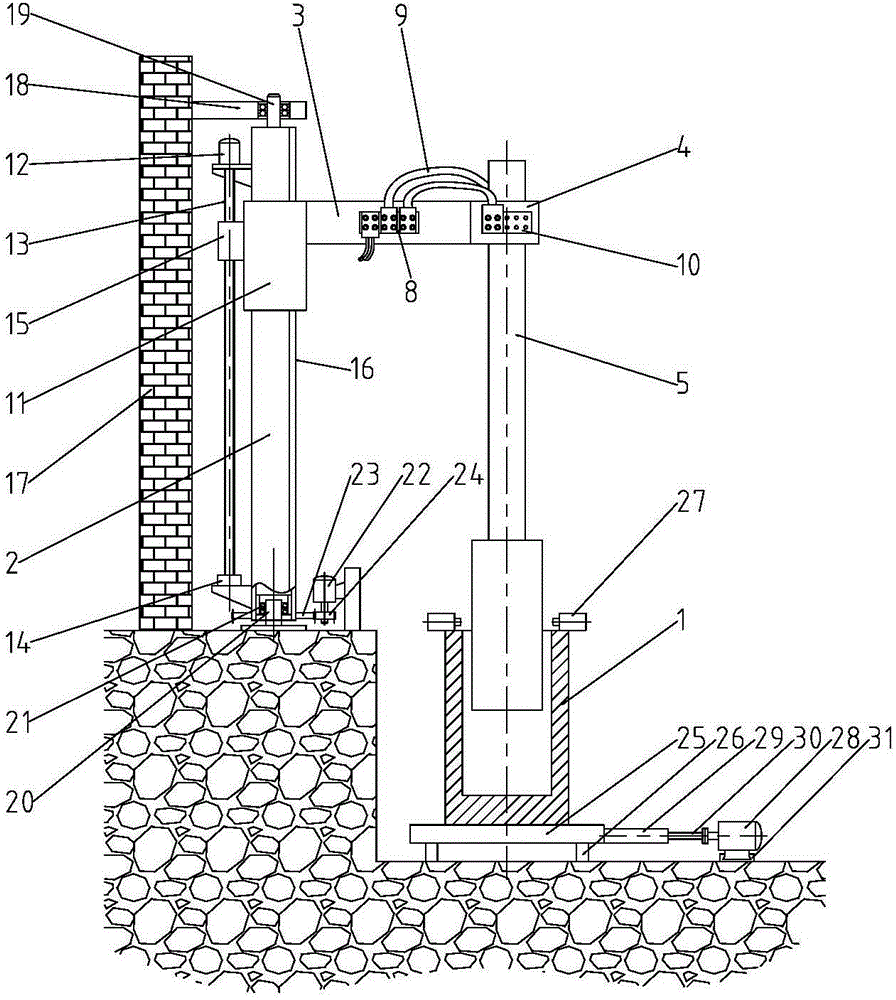

Electroslag remelting furnace with accurate positioning function

InactiveCN106544521APrecise control of lifting heightPrecise position adjustmentEngineeringElectro-slag remelting

The invention discloses an electroslag remelting furnace with the accurate positioning function. The electroslag remelting furnace with the accurate positioning function comprises a crystallizer and a vertical supporting column located on one side of the crystallizer; the vertical supporting column is provided with a transverse arm in sliding fit with the vertical supporting column; the end, away from the vertical supporting column, of the transverse arm is located above the crystallizer and provided with a holder; an electrode extending into the crystallizer is clamped and fixed to the holder; the electroslag remelting furnace with the accurate positioning function further comprises a transverse arm lifting mechanism used for controlling lifting of the transverse arm, a stand column rotation mechanism used for controlling the vertical supporting column to rotate, and an electrode centering mechanism used for centering and positioning of the crystallizer and the electrode; the electrode centering mechanism comprises a supporting seat fixedly arranged below the crystallizer and a position adjusting mechanism used for adjusting the position of the supporting seat; the crystallizer is fixedly installed on the supporting seat; universal idler wheels are arranged below the supporting seat; and photoelectric sensors used for detecting the position of the electrode are annularly and evenly arranged on the top face of the crystallizer.

Owner:RONGCHANG XINDA MACHINERY FORGING CO LTD

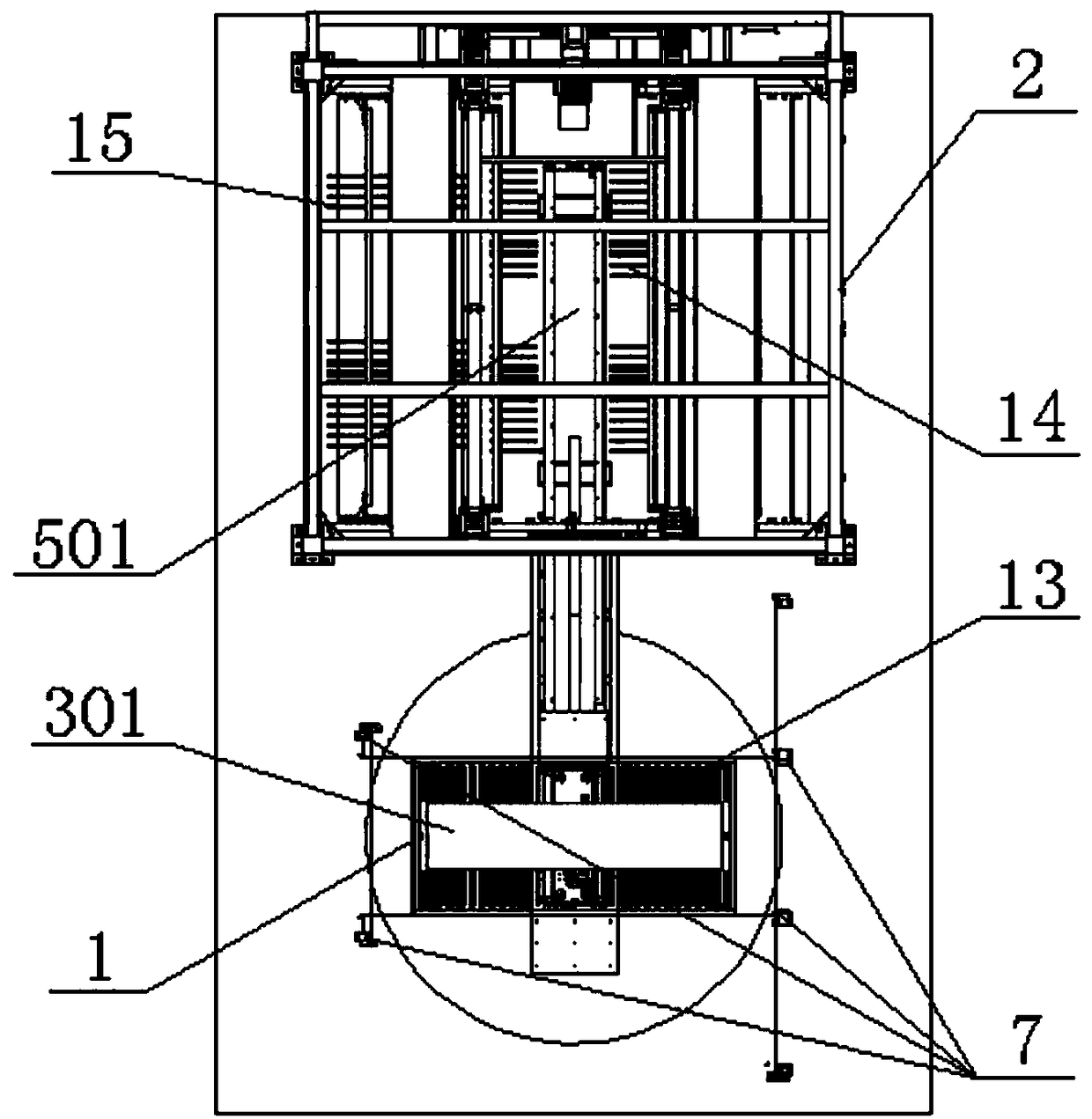

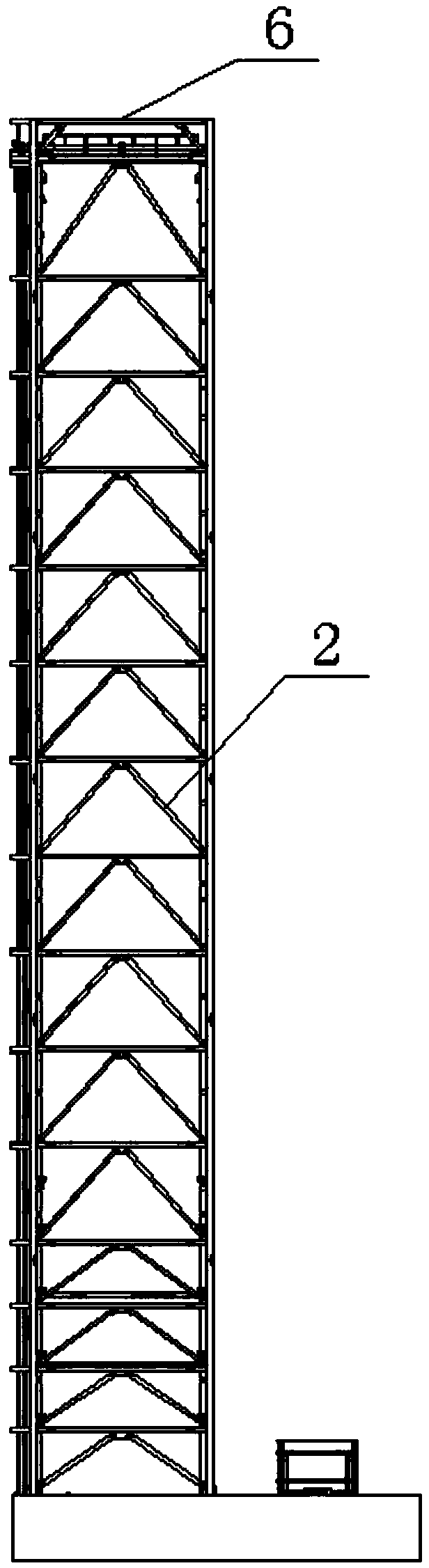

Lifting and horizontal-moving parking equipment with charging device

InactiveCN108222594ANot workingRealize autonomous chargingBatteries circuit arrangementsElectric powerParking spacePhotoelectric sensor

The invention discloses lifting and horizontal-moving parking equipment with a charging device. The lifting and horizontal-moving parking equipment comprises an intelligent rail guided vehicle and a three-dimensional frame, wherein photoelectric sensors are arranged at four corners of the intelligent rail guided vehicle, the top of the three-dimensional frame is provided with a solar panel, lifting comb teeth and parking space comb teeth are arranged in the three-dimensional frame, and the intelligent rail guided vehicle comprises a vehicle walking mechanism, a vehicle lifting mechanism and avehicle rotating mechanism. The vehicle walking mechanism comprises a lifting frame and walking frames, the walking frames are arranged at the two ends of the lifting frame, a rotating rod is arrangedon the walking frames in a penetrating mode, and walking wheels are arranged at the two ends of the rotating rod. A first driving motor is arranged on the inner side of one of the walking frames, anda first gear is arranged at the end part of an output shaft of the first driving motor. The functions of vehicle walking and carrying, rotating and U-turn and lifting exchange are integrated into a whole, so that the convenience of parking is greatly improved, and the problem of urban static traffic is relieved.

Owner:ANHUI LOCKU INTELLIGENT PARKING EQUIP

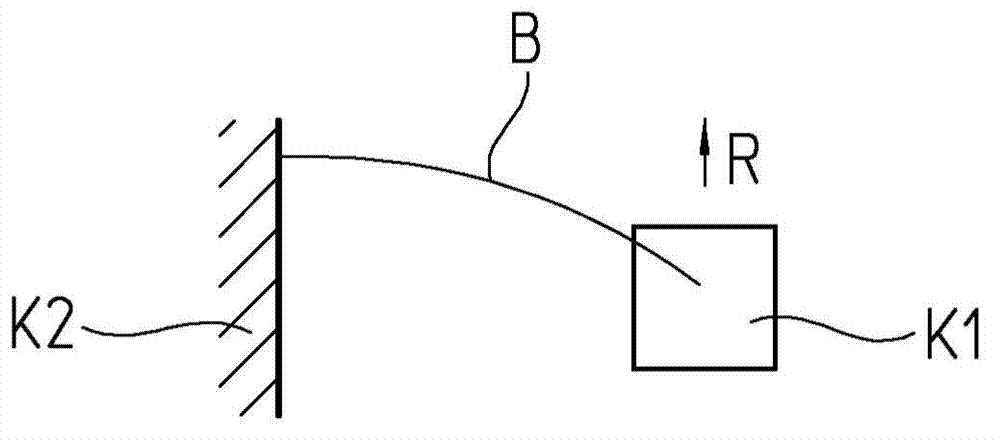

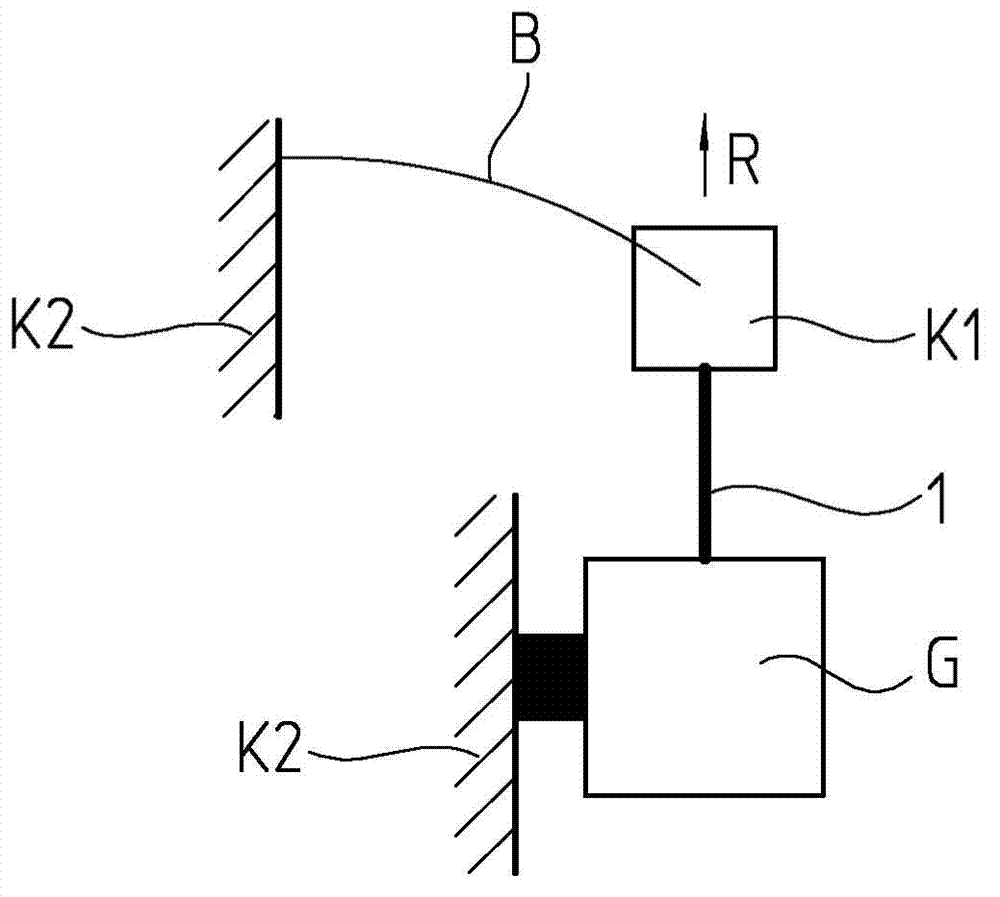

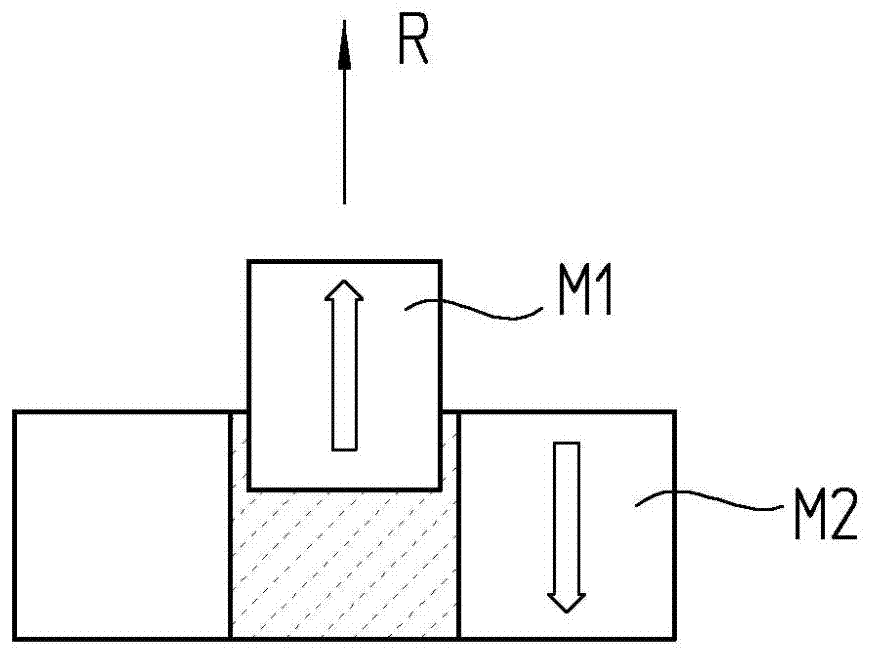

Guide having passive gravity compensation and vertically movably mounted platform

The invention relates to a guide having passive gravity compensation by means of a magnet assembly (M1, M2, M3, M4), for guiding a first body (K1) relative to a second body (K1) in a vertical direction (R), comprising a spring guide (B), which enables movements between the first and second bodies (K1, K2) in the vertical direction and which blocks movements in all other directions, wherein moreover the first body (K1) is connected to a first magnet (M1) and the second body (K2) is connected to a second magnet (M2), wherein the second magnet (M2) has an opening in which the first magnet (M1) is arranged at least partially such that a repellant force acts between the first and second magnets (M1, M2), which are magnetized parallel to the vertical direction (R), but are magnetized oppositely, said repellant force opposing the force of gravity of the first body, wherein the positive mechanical rigidity of the spring guide (B) is compensated for at least partially by a negative rigidity of the magnetic spring formed by the first and second magnets (M1, M2), and wherein the first and second magnets (M1, M2) are shaped such that a horizontal gap (d) between the first and second magnets (M1, M2) varies in the vertical direction (R) inside the opening of the second magnet (M2). A platform mounted by means of such guides is also described.

Owner:DR JOHANNES HEIDENHAIN GMBH

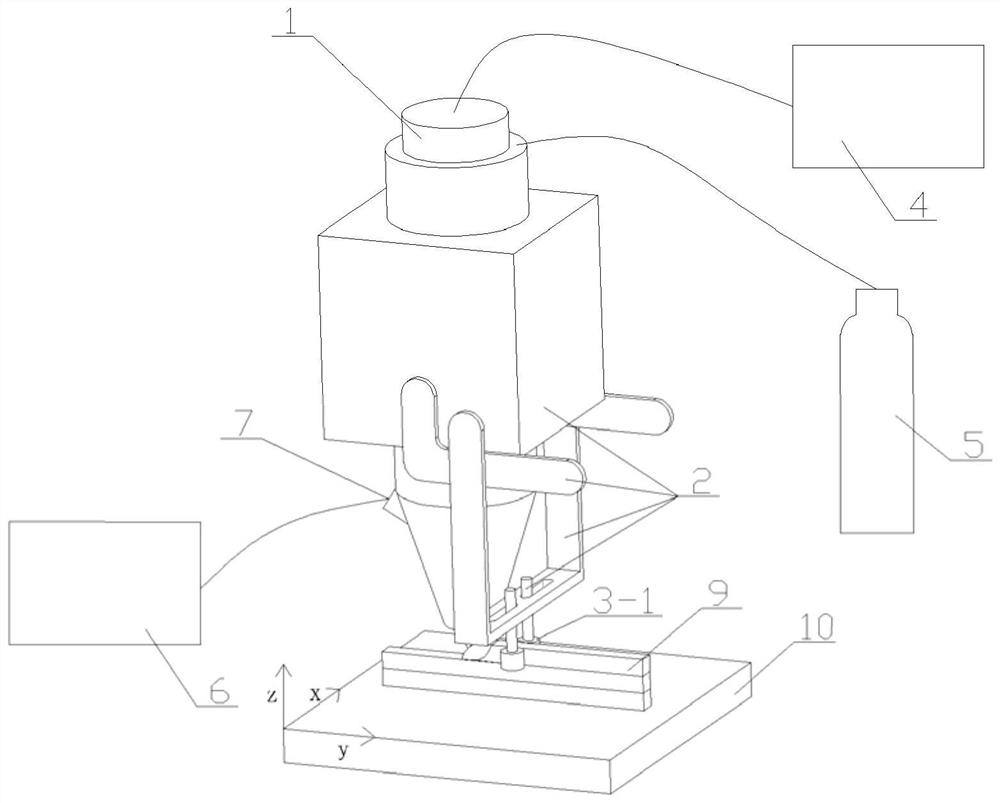

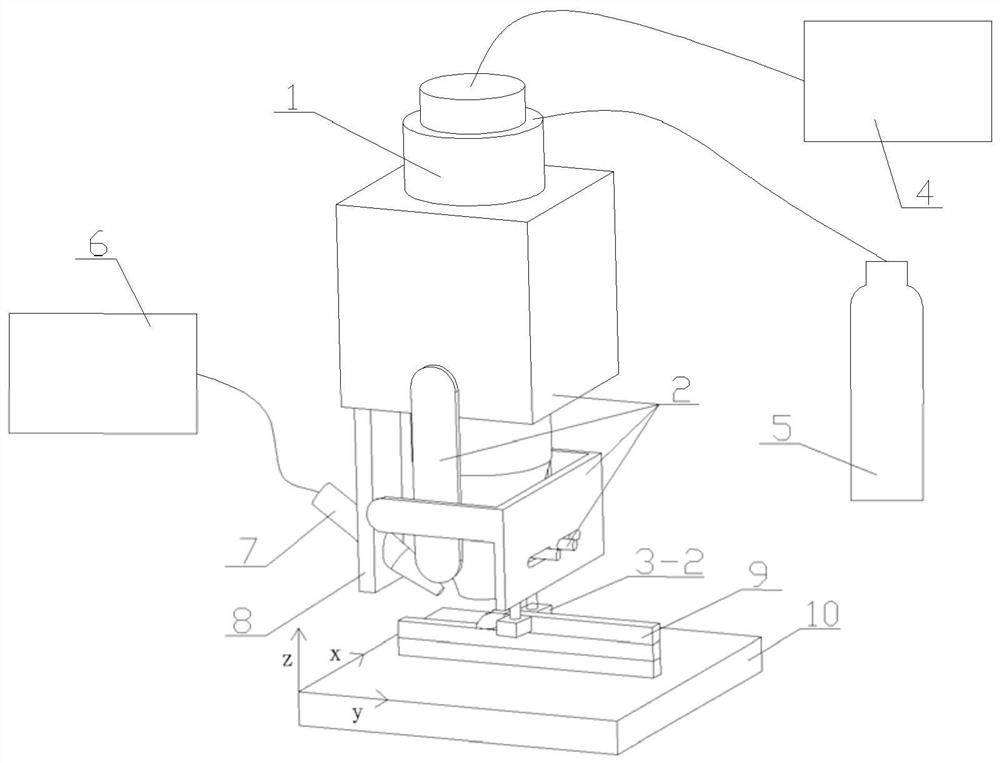

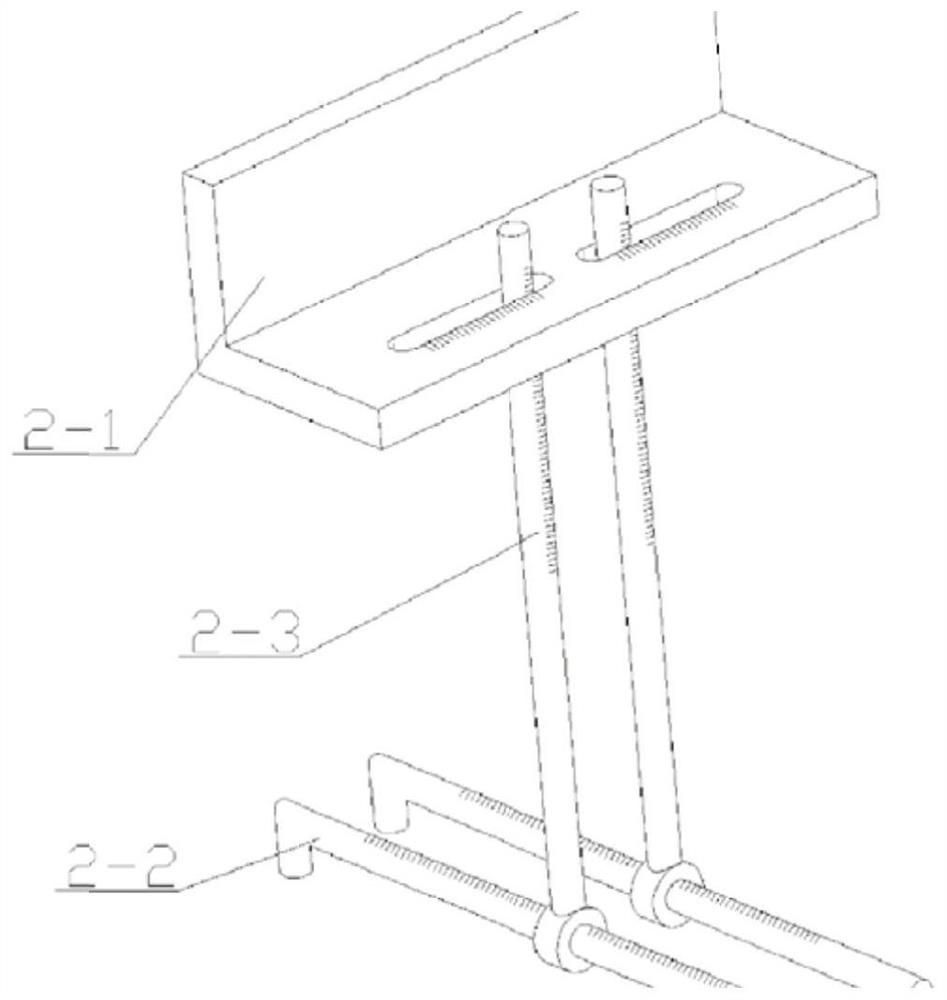

Clamping auxiliary forming device for two sides of molten pool in additive manufacturing process and method

PendingCN112916874AHigh dimensional accuracyPrecise position adjustmentAdditive manufacturing apparatusProcess engineeringMechanical engineering

The invention belongs to the technical field of additive manufacturing, and particularly relates to a clamping auxiliary forming device for two sides of a molten pool in an additive manufacturing process and a method. The device comprises additive manufacturing equipment, a connecting device and a clamping component; the connecting device is used for connecting the clamping component with the additive manufacturing equipment so as to adjust the relative position of the clamping component and an additive deposition head to ensure synchronous movement of the clamping component and the additive deposition head, the additive manufacturing equipment comprises the additive deposition head, an additive heat source, a gas cylinder, a feeding device, a feeding nozzle and a feeding nozzle connecting plate, and the feeding nozzle conveys additive manufacturing raw materials to a deposition position. According to the clamping auxiliary forming device for the two sides of the molten pool in the additive manufacturing process and the method, the device and method can be applied to the additive manufacturing processes of different deposition widths through the connecting device, and the surface flatness and the size precision in the width direction of the side wall of a deposition layer can be effectively improved through the clamping and restraining effect of the clamping component.

Owner:DALIAN UNIV OF TECH

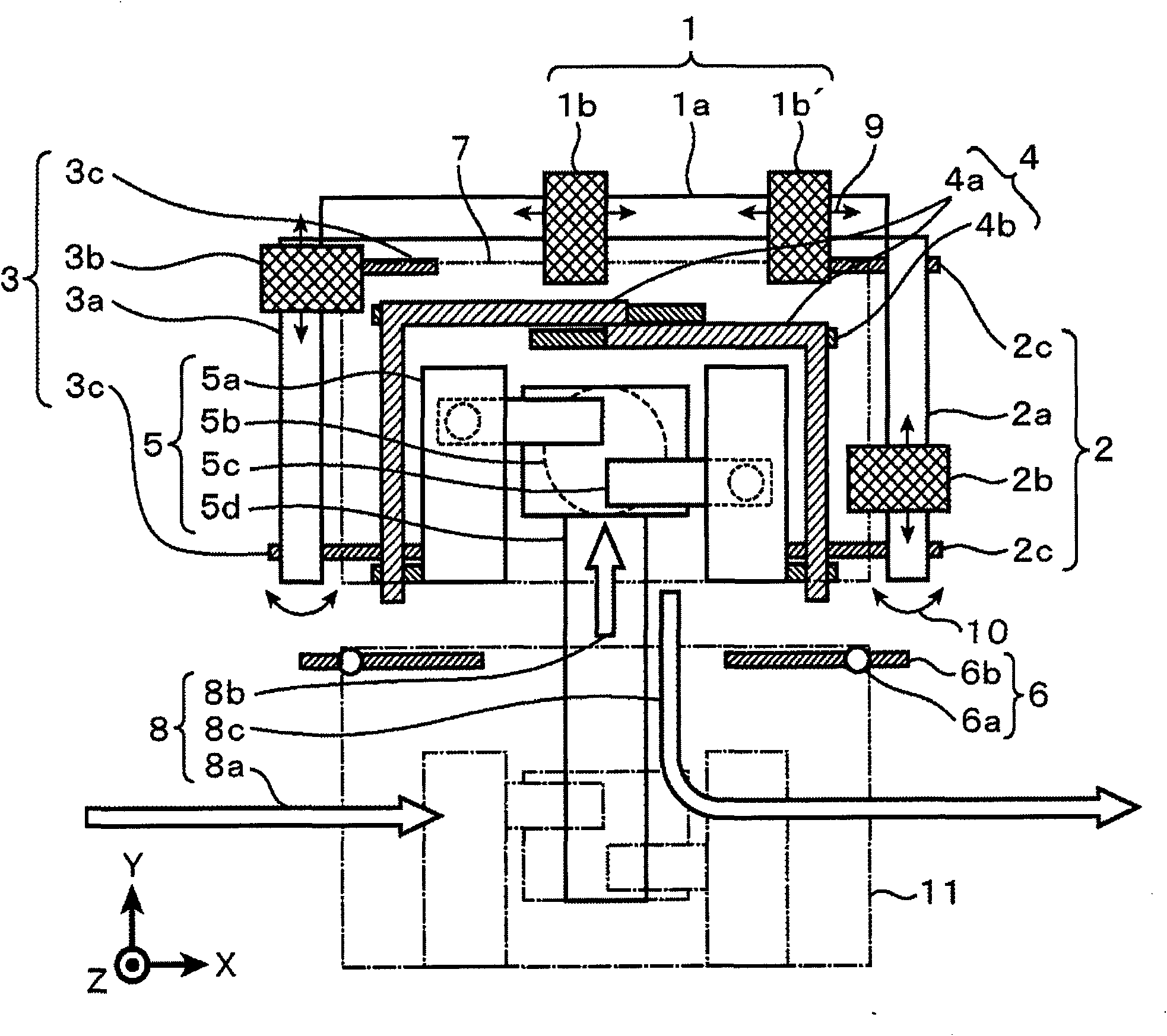

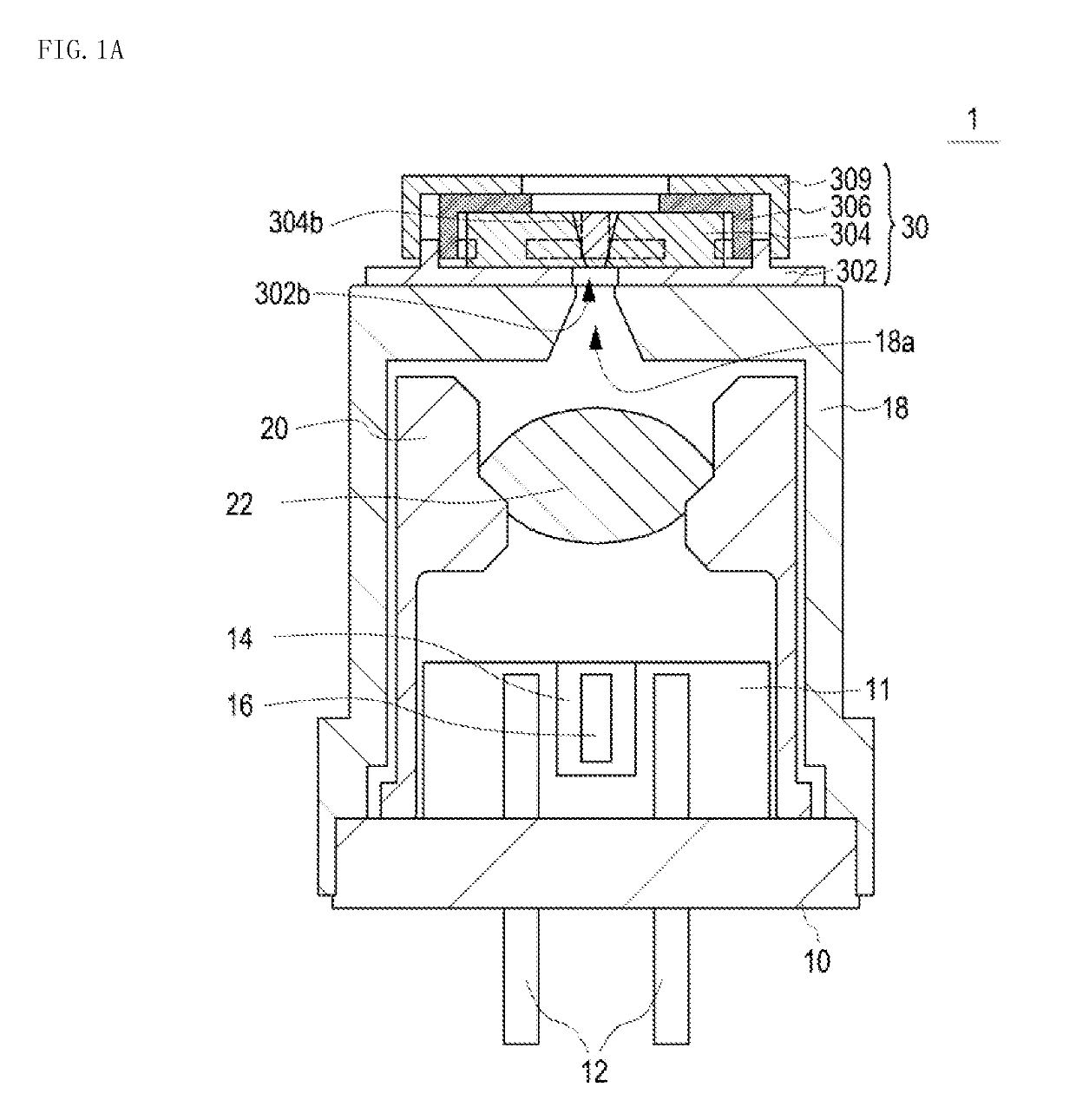

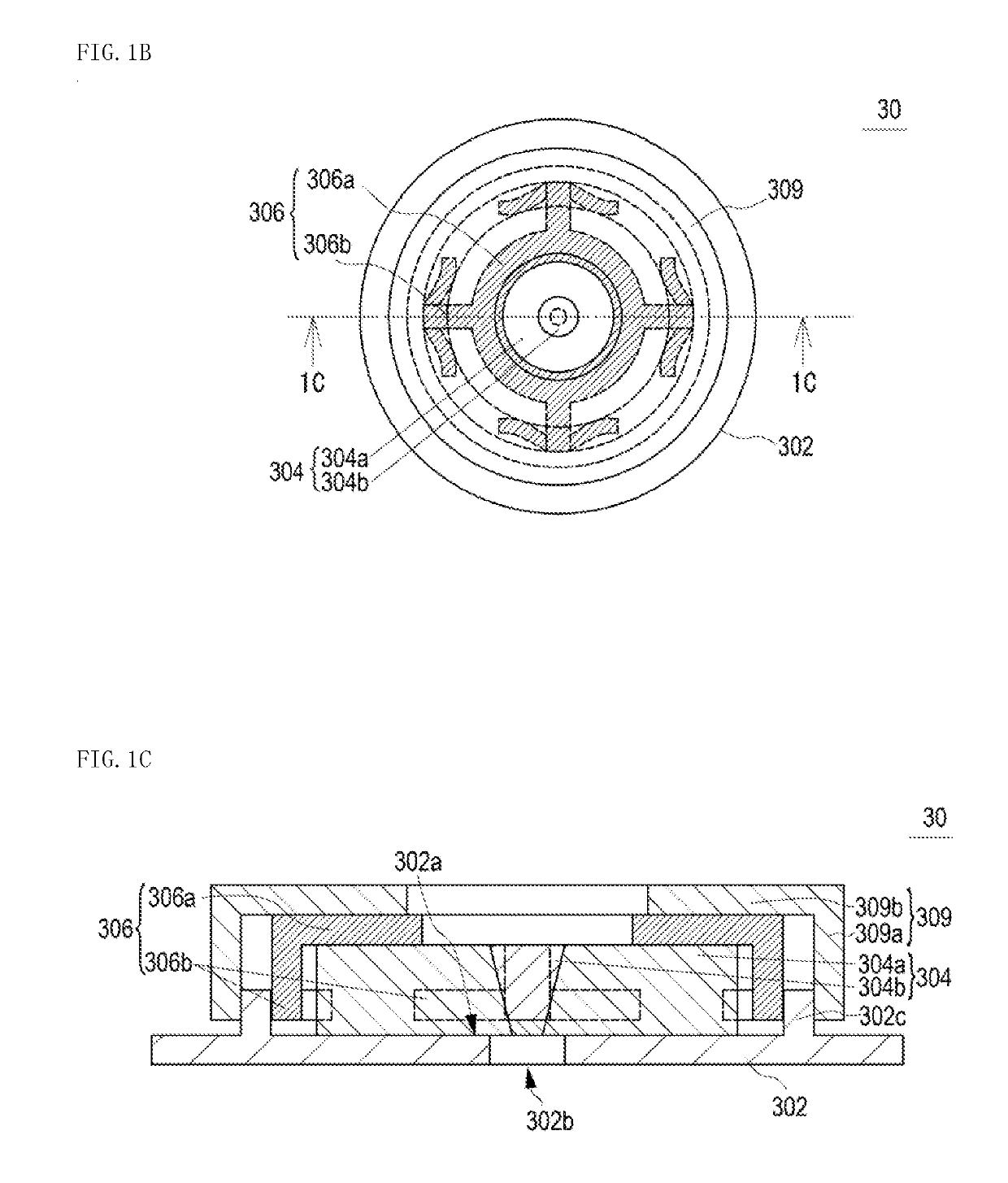

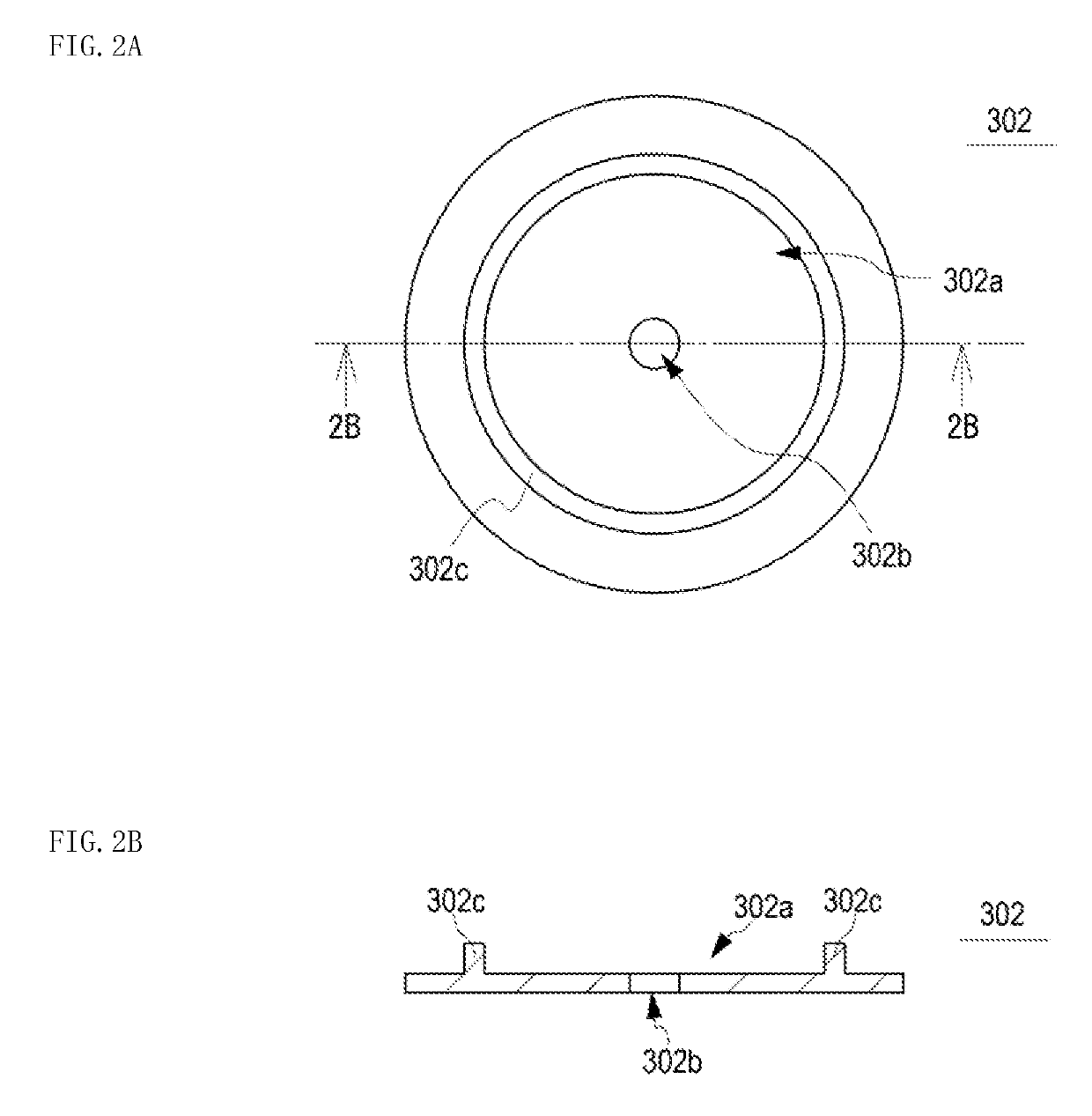

Optical member holding device, semiconductor laser device, method of manufacturing optical member holding device, and method of manufacturing semiconductor laser device

ActiveUS20190148909A1Improve reliabilityPrecise positioningLaser detailsSemiconductor laser optical deviceEngineeringInorganic materials

Owner:NICHIA CORP

Butt-joint installation device for building curtain wall

InactiveCN112695939AGuaranteed stabilityPrevent collapseWallsBuilding material handlingArchitectural engineeringCurtain wall

The invention provides a butt-joint installation device for a building curtain wall. The installation device comprises a pushing device and a splicing device installed on the side face of the pushing device, the splicing device comprises a side plate, a pair of hydraulic rods are installed at the bottom end of the side plate, and a telescopic device is installed on the side face of the side plate. According to the installation device, through the arranged hydraulic rods, when the building curtain wall is installed in a butt joint mode, the hydraulic rods drive the side plate to move up and down so that the installation height of the building curtain wall can be adjusted, meanwhile, the arranged telescopic device can conduct telescopic adjustment on the building curtain wall, installation is easy and convenient, adjustment is easy, and the installation efficiency of the building curtain wall is improved.

Owner:斑马找房(武汉)信息科技有限公司

Adjustable door opening seam allowance verification device and method

ActiveCN111351672APrecise position adjustmentMaterialize dataVehicle testingMechanical measuring arrangementsLinear motionCar manufacturing

The invention relates to an adjustable door opening seam allowance verification device and verification method, and belongs to the technical field of automobile manufacturing, the adjustable door opening seam allowance verification device comprises a mounting rack which is of a rectangular frame structure formed by splicing a plurality of rod pieces end to end; an A-column adjusting unit which isused for adjusting the A-column simulation piece to linearly move in the X-axis direction, the Y-axis direction and the Z-axis direction respectively; a threshold adjusting unit which is used for adjusting the threshold simulation piece to do linear motion in the Y-axis direction and the Z-axis direction respectively; a top cover adjusting unit which is used for adjusting the top cover simulationpiece to linearly move in the X-axis direction, the Y-axis direction and the Z-axis direction respectively; a B-column adjusting unit which is used for adjusting the B-column simulation part to linearly move in the X-axis direction and the Y-axis direction respectively; and a C-column adjusting unit which is used for adjusting the C-column simulation piece to do linear motion in the X-axis direction, the Y-axis direction and the Z-axis direction and do rotary motion around the axis of the Y-axis and the axis of the Z-axis. According to the verification device and the verification method, the research and development efficiency and the research and development quality are improved, trial-manufacture resource investment is reduced, the research and development cost is reduced, and the research and development period is shortened.

Owner:DONGFENG MOTOR CORP HUBEI

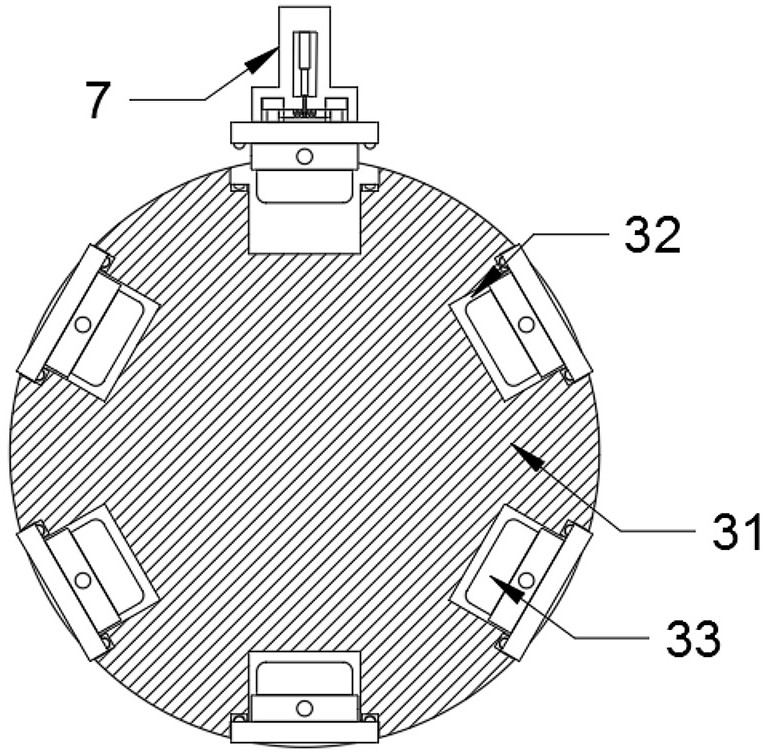

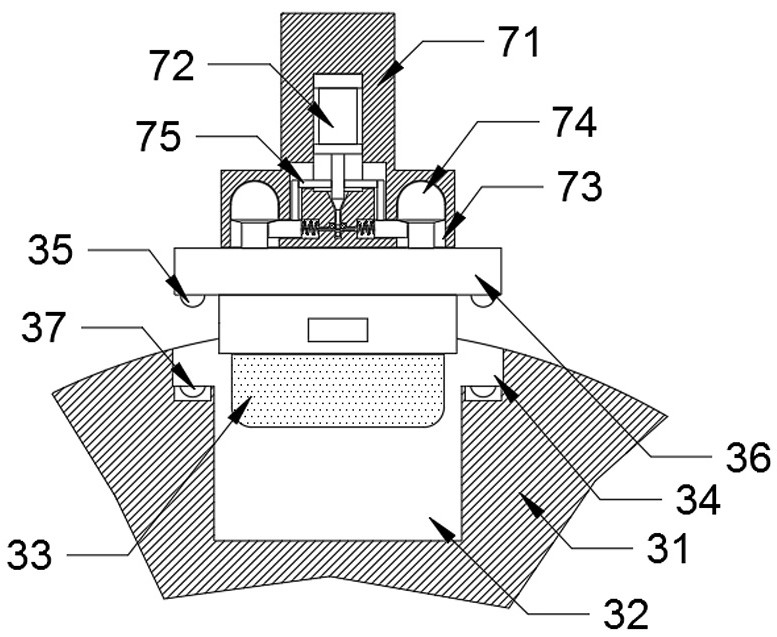

Automatic rubber head replacing mechanism of pad printing machine

ActiveCN112172328AReduce occupancyEliminates programming steps for moving positionsRotary pressesPad printingCircular disc

The invention provides an automatic rubber head replacing mechanism of a pad printing machine. The mechanism comprises a machining table, a mounting groove and a motor, the mounting groove is formed in the surface of the machining table, the motor is mounted in the machining table and located on the side edge of the mounting groove, a disc-shaped rotatable rubber head library assembly is mounted in the mounting groove, the output end of the motor is fixedly connected with a rotary shaft of the rubber head library assembly, and a positioning mechanism capable of accurately locking the angle ofthe rubber head library assembly is installed on the side wall of the mounting groove and below the motor. According to the automatic rubber head replacing device, automatic rubber head replacement isachieved, compared with traditional manual replacement, replacement by the automatic rubber head replacing device is more convenient and efficient, rubber heads are vertically placed and stored in adisc shape, compared with traditional automatic rubber head replacement equipment, more plane space occupation is saved, meanwhile, all rubber heads can be replaced by a printing head assembly only atone determined position, and compared with a traditional plane type rubber head storage device, the moving position programming step of the printing head assembly is omitted, operation is more convenient, and an automatic program is optimized.

Owner:深圳市久和丝印器材有限公司

Air cooler

PendingCN108131756AEasy to moveEasy to fixCondensate preventionLighting and heating apparatusEngineeringRefrigeration

The invention discloses an air cooler, and relates to the field of low-temperature refrigeration equipment. The air cooler comprises a machine body, an air inlet, an air outlet and an air cooling assembly disposed in the machine body, wherein the air inlet and the air outlet are formed in the machine body. A plurality of rolling wheels rotatably connected to the machine body are arranged on the side, facing the ground, of the machine body, and containing grooves for containing the rolling wheels are formed in the bottom of the machine body. The machine body is further provided with a lifting mechanism for pushing the rolling wheels to move toward or away from the containing grooves. The lifting mechanism comprises a lifting rod and a lifting component, wherein the lifting rod is slidinglyconnected in the machine body and connected with the rolling wheels, and the lifting component is used for pushing the lifting rod to slidingly move. A fixing mechanism for locking the machine body isarranged on the machine body and installed on the corresponding ground. When the air cooler needs to be assembled and disassembled, an operator can easily move the air cooler so that the operator cancarry and overhaul the air cooler conveniently, and therefore the air cooler can be more firmly fixed when installed at a designated position.

Owner:博维恩冷冻科技(苏州)有限公司

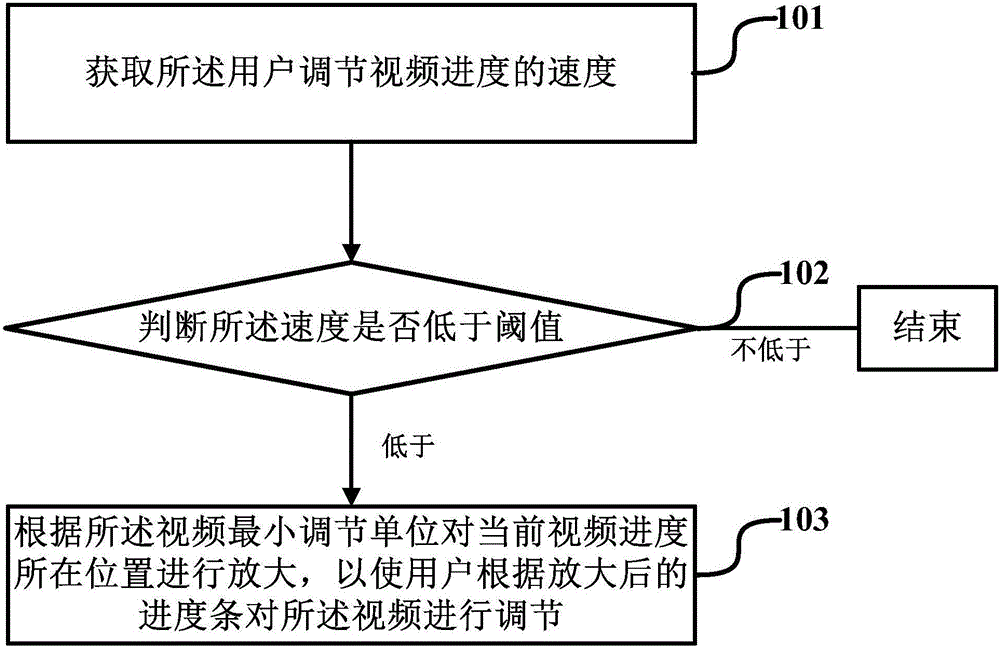

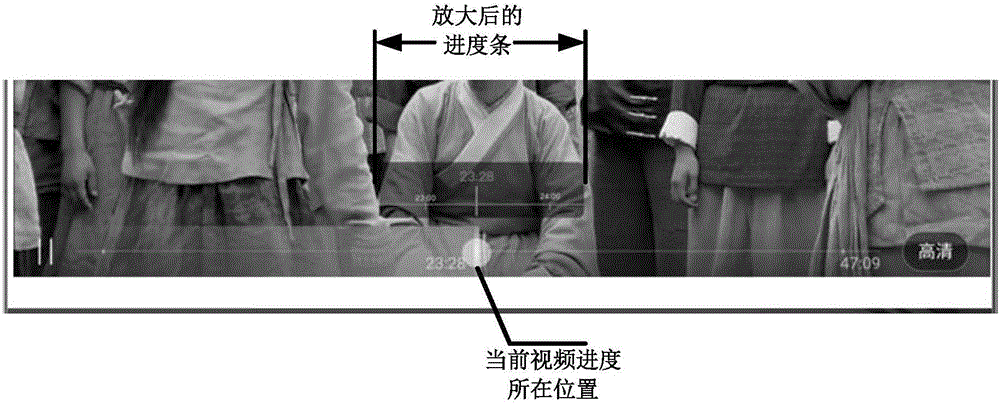

Video adjustment method and terminal

InactiveCN105916038AReduce adjustmentAchieve fine-tuningSelective content distributionProgress barSimulation

The embodiment of the invention provides a video adjustment method. When a user adjusts the progress of a video, the method comprises the steps: obtaining the speed that the user adjusts the progress of the video; judging whether the speed is less than a threshold value or not; carrying out the amplifying of the position of the current video progress according to the minimum adjustment unit of the video if the speed is less than the threshold value, so as to enable the user to adjust the video according to the amplified progress bar. According to the embodiment of the invention, the method carries out the amplification according to the minimum adjustment unit, and enables the video adjustment amount of the user to be less than the minimum adjustment unit of the video. Furthermore, the method can achieve the precise positioning and adjustment of the video because the method can achieve the fine tuning of the video.

Owner:LETV HLDG BEIJING CO LTD +1

Electroslag remelting furnace with uniform smelting function

InactiveCN106544522APrecise control of lifting heightPrecisely control the positional relationshipElectro-slag remeltingDistributor

The invention discloses an electroslag remelting furnace with the uniform smelting function. The electroslag remelting furnace with the uniform smelting function comprises a crystallizer and a vertical supporting column located on one side of the crystallizer; the vertical supporting column is provided with a transverse arm in sliding fit with the vertical supporting column; the end, away from the vertical supporting column, of the transverse arm is located above the crystallizer and provided with a holder; an electrode extending into the crystallizer is clamped and fixed to the holder; the holder comprises two oppositely-arranged clamping pieces; a clamping cavity used for clamping the electrode is formed between the two clamping pieces; a distributor plate connected with a power supply device is arranged on the lateral wall of one side of the transverse arm; a connection cable is arranged between the distributor plate and each clamping piece; the electroslag remelting furnace with the uniform smelting function further comprises a transverse arm lifting mechanism used for controlling lifting of the transverse arm, a stand column rotation mechanism used for controlling the vertical supporting column to rotate, and an electrode centering mechanism used for centering and positioning of the crystallizer and the electrode; and photoelectric sensors used for detecting the position of the electrode are annularly and evenly arranged on the top face of the crystallizer.

Owner:RONGCHANG XINDA MACHINERY FORGING CO LTD

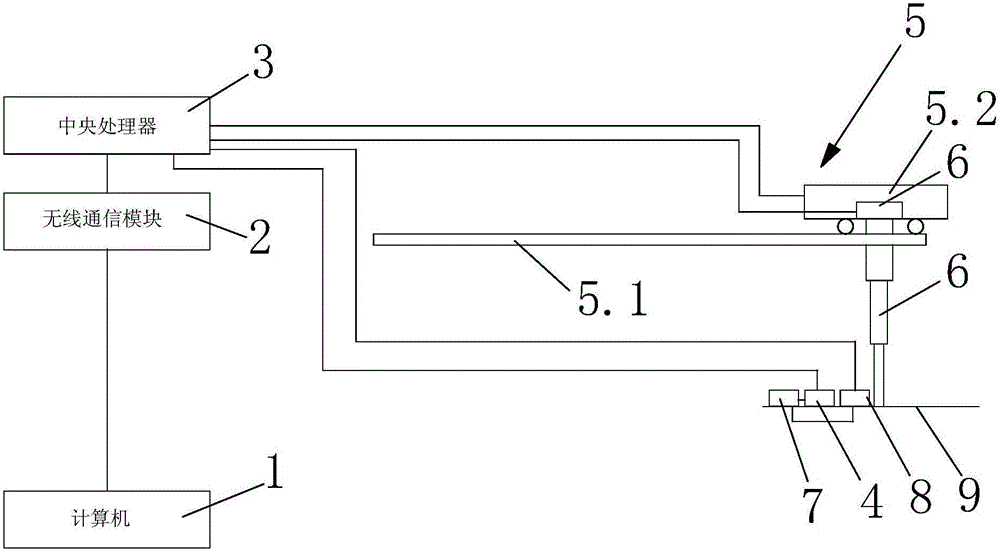

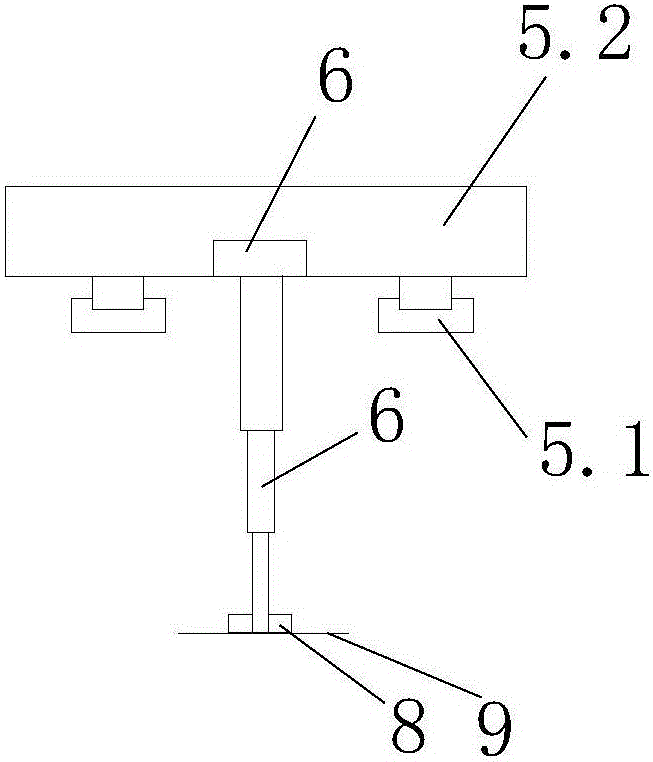

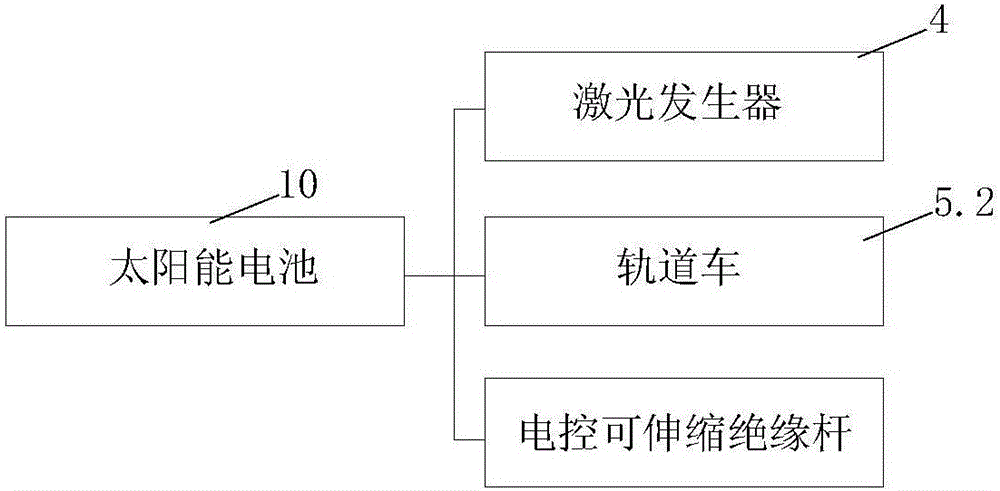

Insulator deterioration online detecting device and method thereof

InactiveCN105785172APrecise position adjustmentAvoid detection errorsElectrical testingElectrostatic field measurementsEngineeringCar controls

The invention discloses an insulator deterioration online detecting device. A horizontal movement positioning mechanism comprises a rail which is horizontally laid on a pole, and a railway car which is arranged on the rail and can operate on the rail. One end of an insulated rod is fixed on the railway car, and the other end is provided with an equipment rack fixedly. A laser generator, an optical electric field sensor and a photoelectric converter are fixed on the equipment rack. The laser signal output end of the laser generator is connected with the laser signal input end of the optical electric field sensor. The strong light feedback signal output end of the optical electric field sensor is connected with the feedback signal input end of a central processing unit through the photoelectric converter. The railway car control signal output end of the central processing unit is connected with the control signal input end of the railway car. The laser generator control signal output end of the central processing unit is connected with the control signal input end of the laser generator. A computer is connected with the central processing unit. The insulator deterioration online detecting device and a method thereof have advantages of relatively high detecting efficiency and relatively low detecting error.

Owner:STATE GRID EAST INNER MONGOLIA ELECTRIC POWER CO LTD MAINTENANCE BRANCH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com