Dispensing jig

A technology of dispensing and jig, applied in the direction of coating, the device for coating liquid on the surface, etc., can solve the problems such as the position of the dispensing device is not adjustable, it is difficult to meet the production of large-scale button assembly, and the adaptability is not strong. Improves dispensing efficiency, versatility and dispensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

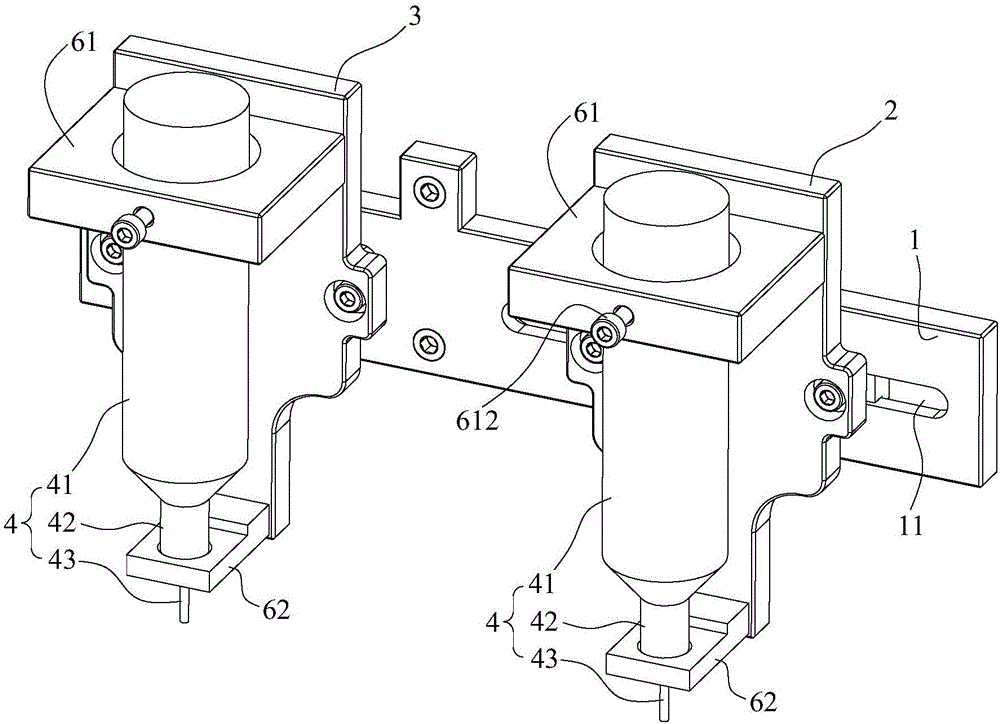

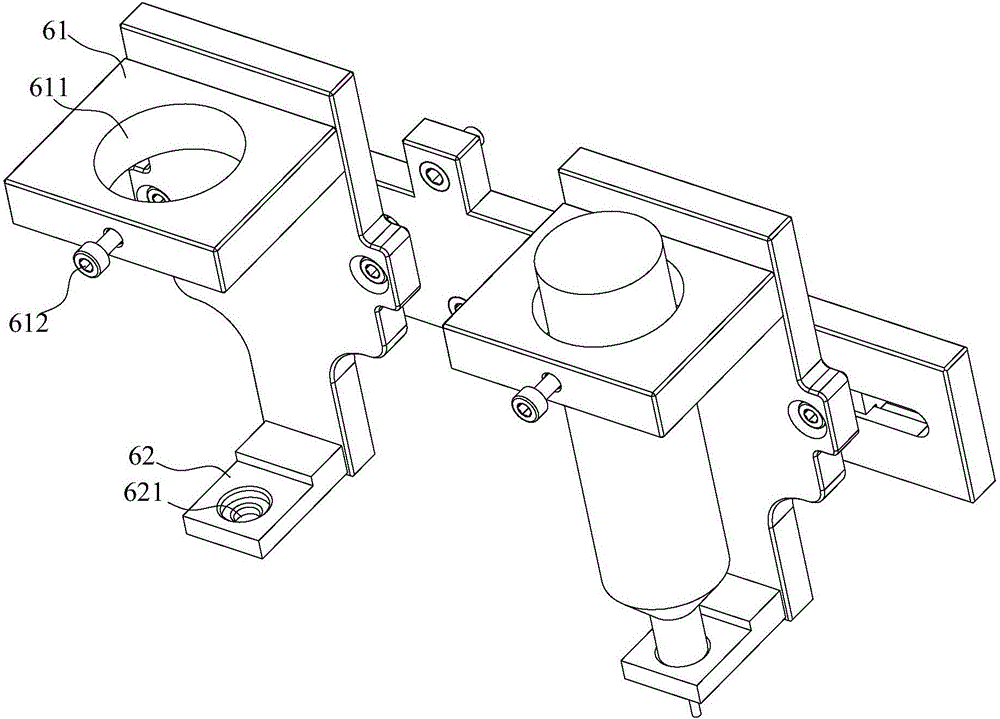

[0024] refer to Figure 1-Figure 4 , the present embodiment provides a dispensing fixture, including a fixture support 1, a first dispensing support 2 and a second dispensing support 3, the first dispensing support 2 and the second dispensing support 3 are used for fixing The dispensing syringe 4 and the jig bracket 1 are fixed on the dispensing machine. The first dispensing bracket 2 can slide along the surface of the jig bracket 1 in the transverse direction, and the second dispensing bracket 3 can slide along the surface of the jig bracket 1 in the longitudinal direction. Direction slide. The two dispensing syringes 4 can dispens glue to two parts at the same time, which improves the dispensing efficiency, and the first glue dispensing bracket 2 and the second glue dispensing bracket 3 can slide horizontally and vertically along the surface of the jig bracket 1 respectively, The position between the first glue dispensing bracket 2 and the second glue dispensing bracket 3 c...

Embodiment 2

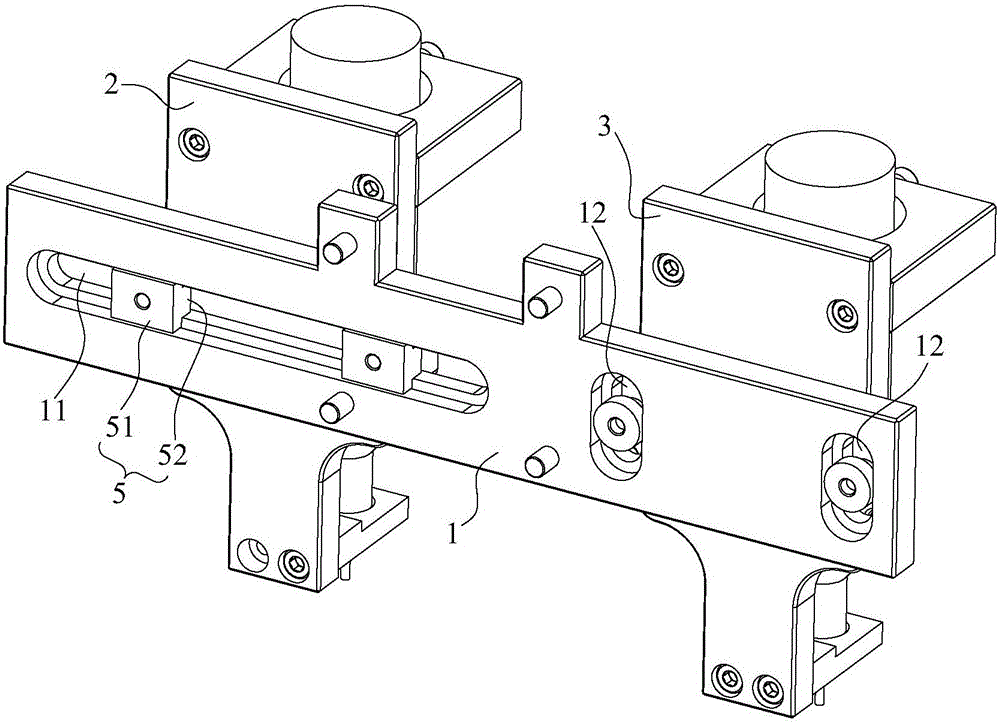

[0030] Different from Embodiment 1, a plurality of horizontal strip-shaped holes 11 parallel to each other are arranged horizontally on the fixture bracket 1, and the horizontal strip-shaped holes 11 are all stepped holes, and the T-shaped block 5 passes through the horizontal strip-shaped holes 11 and is fixed on the The first dispensing support 2, the rib 51 of the T-shaped block 5 abuts against the stepped portion of the transverse strip hole 11, the T-shaped block 5 and the first dispensing support 2 are fixed by bolts, and the T-shaped block 5 and the first dispensing support 2 are fixed by bolts. The tightness between the first glue dispensing bracket 2, loosen the bolt and slide the first glue dispensing bracket 2, and when it slides to the predetermined position, tighten the bolt to firmly clamp the T-shaped block 5 and the first glue dispensing bracket 2 to the stepped part To ensure that the position of the first glue dispensing bracket 2 does not change any longer, e...

Embodiment 3

[0032] The difference from Embodiment 1 is that a longitudinal strip hole 12 is longitudinally arranged on the fixture bracket 1, and the longitudinal strip hole 12 is a stepped hole, and a plurality of T-shaped blocks 5 pass through the longitudinal strip hole 12 and are fixed on the first Two dispensing brackets 3, to ensure that the second dispensing bracket 3 slides along the longitudinal strip hole 12, the rib 51 of the T-shaped block 5 abuts against the stepped portion of the longitudinal strip hole 12, the rib 51 and the second dispensing bracket 3. Clamp the stepped portion of the longitudinal strip hole 12 in the middle, fix the T-shaped block 5 and the second dispensing bracket 3 with bolts, adjust the tightness between the T-shaped block 5 and the second dispensing bracket 3 through the bolts, and turn Loosen the bolt and slide the second dispensing bracket 3, and tighten the bolt when sliding to the predetermined position to firmly clamp the T-shaped block 5 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com