Automatic sealing dispensing machine for small liquid crystal display screens

A liquid crystal display and automatic sealing technology, which is applied to the surface coating liquid device, optics, instruments, etc., can solve the problems of unstable dispensing quality, high labor intensity of employees, and low production efficiency, so as to avoid glue overflow Or the amount of glue is too small to improve the quality of dispensing and ensure the stability of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

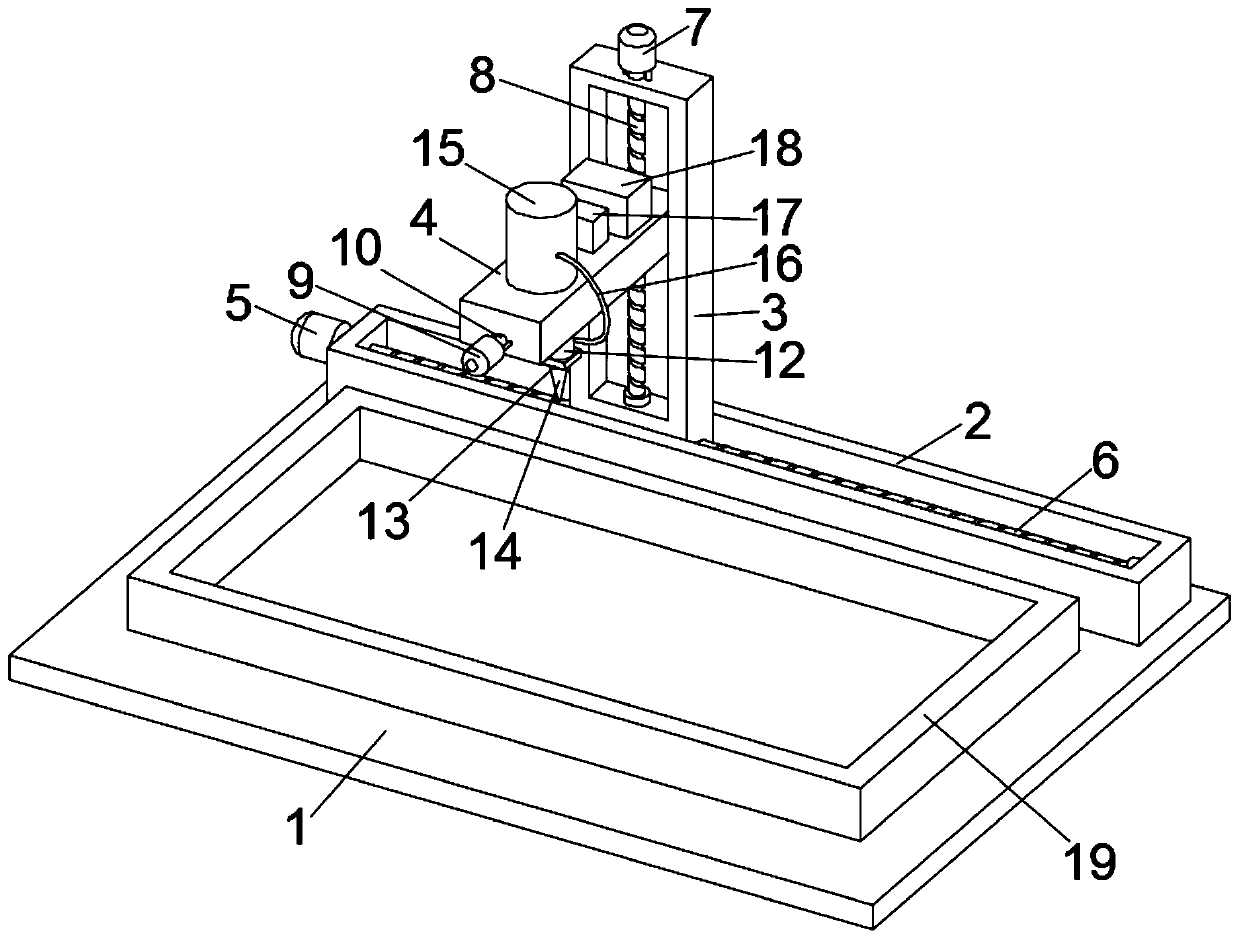

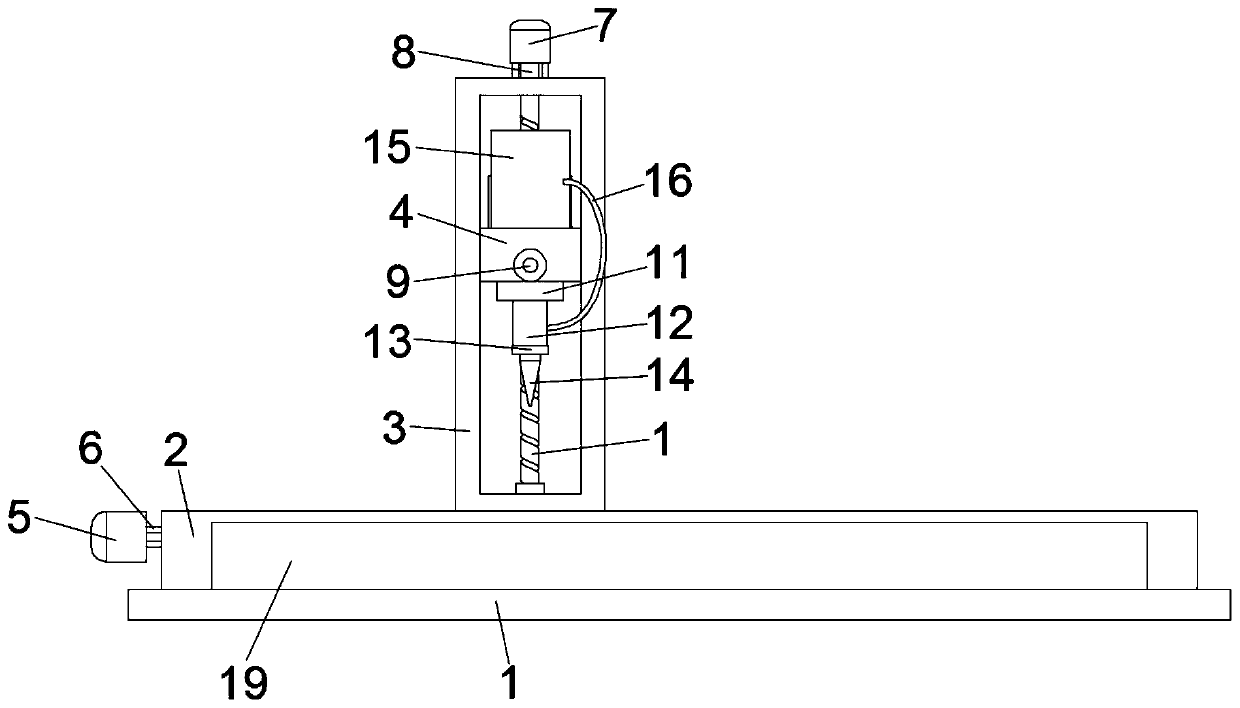

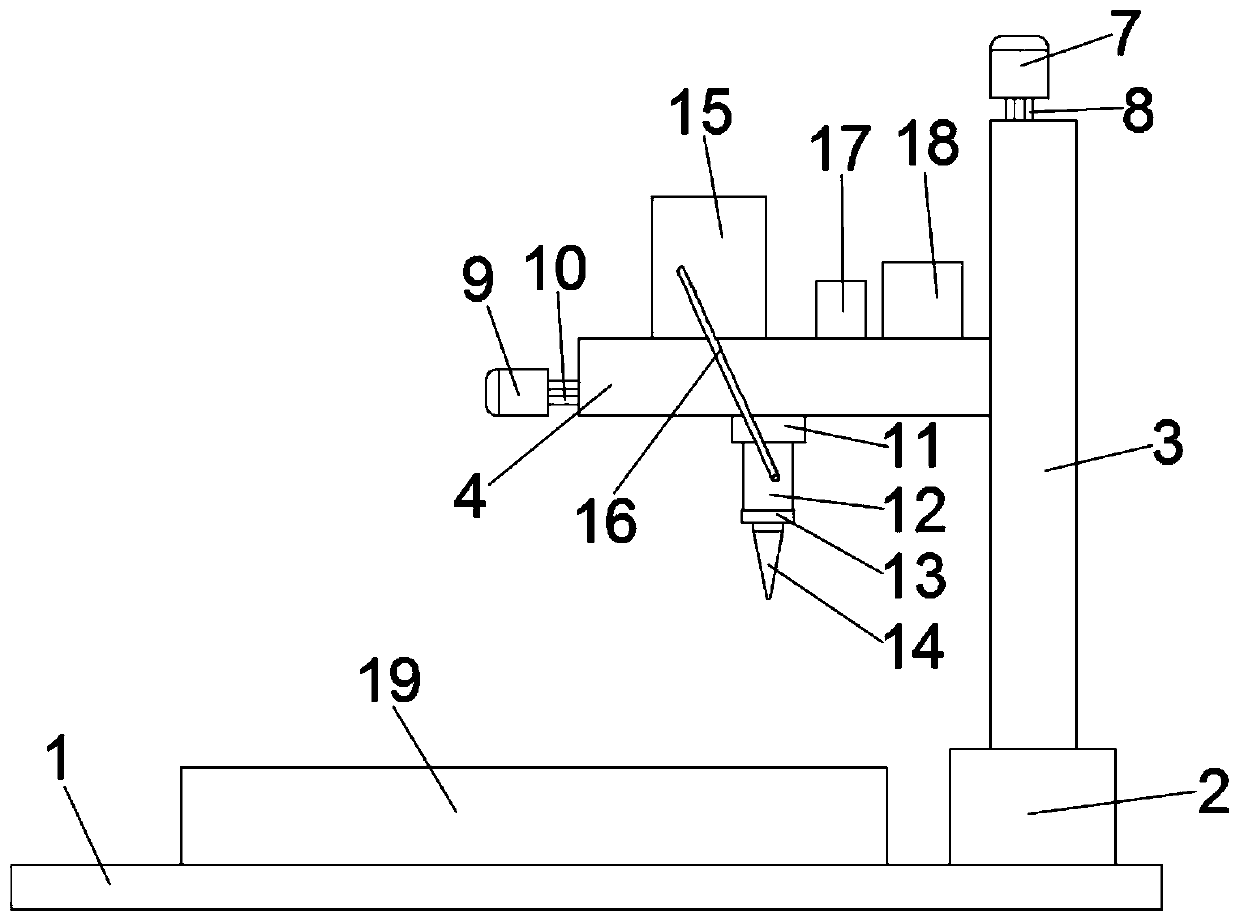

[0032] The present invention will be clearly and completely described below in conjunction with the accompanying drawings.

[0033] see Figure 1-4 , Small LCD automatic sealing dispenser, including base 1. A horizontal guide rail 2 is installed horizontally on the base 1 . The base 1 is provided with a liquid crystal display fixing plate 19 .

[0034] The horizontal guide rail 2 is vertically and movablely embedded with a lifting guide rail 3 .

[0035] A vertical guide rail 4 perpendicular to the different planes of the horizontal guide rail 2 is movably embedded in the lifting guide rail 3 .

[0036] A horizontal drive mechanism, a lift mechanism and a longitudinal drive mechanism are respectively installed on the transverse guide rail 2, the lifting guide rail 3 and the longitudinal guide rail 4.

[0037] A mounting seat 11 is movably embedded in the bottom of the longitudinal guide rail 4 . The dispensing device 12 is fixedly mounted on the bottom of the mounting bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com