Glue sealing structure for organic electroluminescent planar display device and production thereof

A flat-panel display and electroluminescence technology, applied in electroluminescent light sources, electric light sources, light sources, etc., can solve problems such as lamination, low moisture permeability, and unfavorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

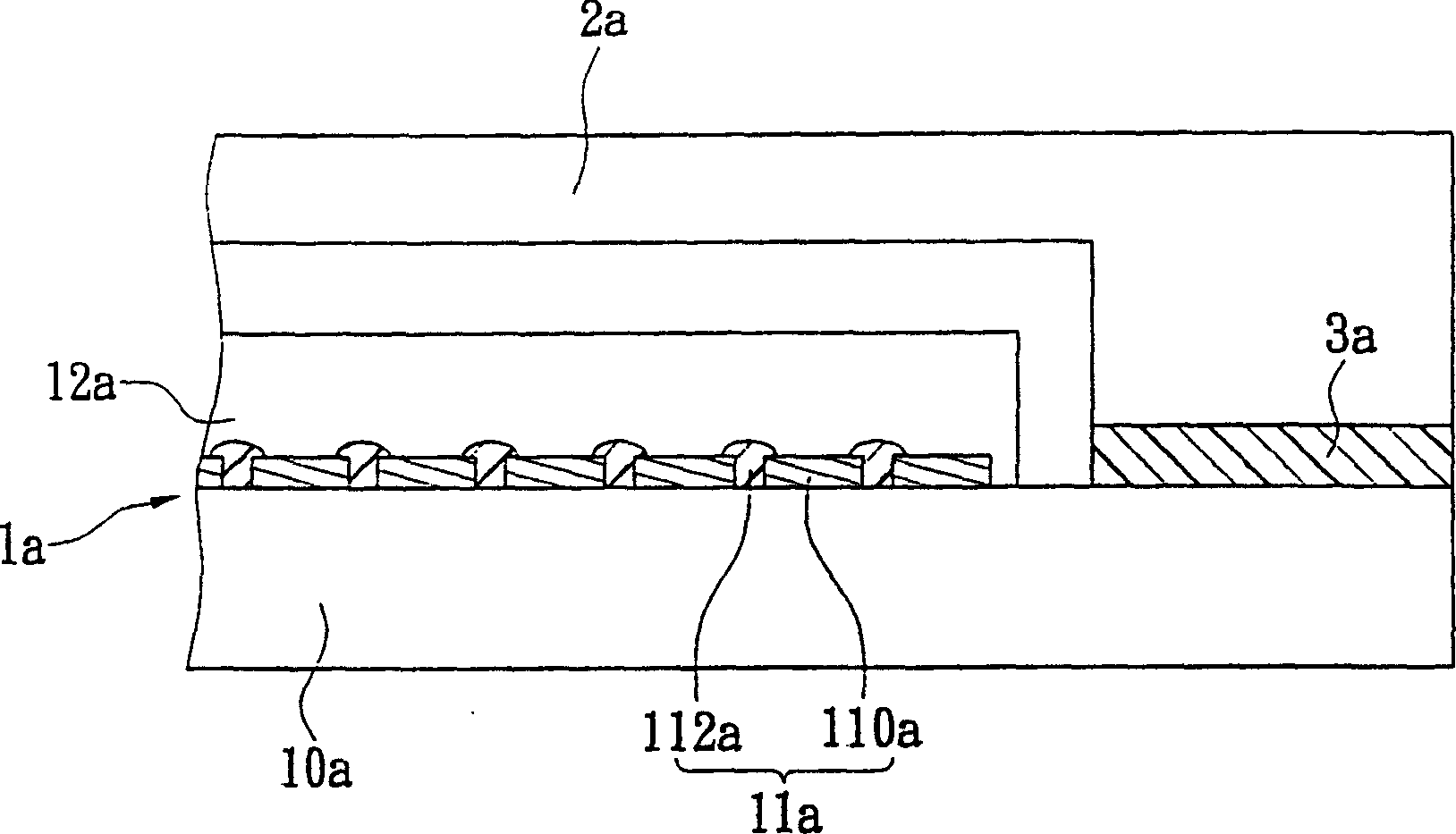

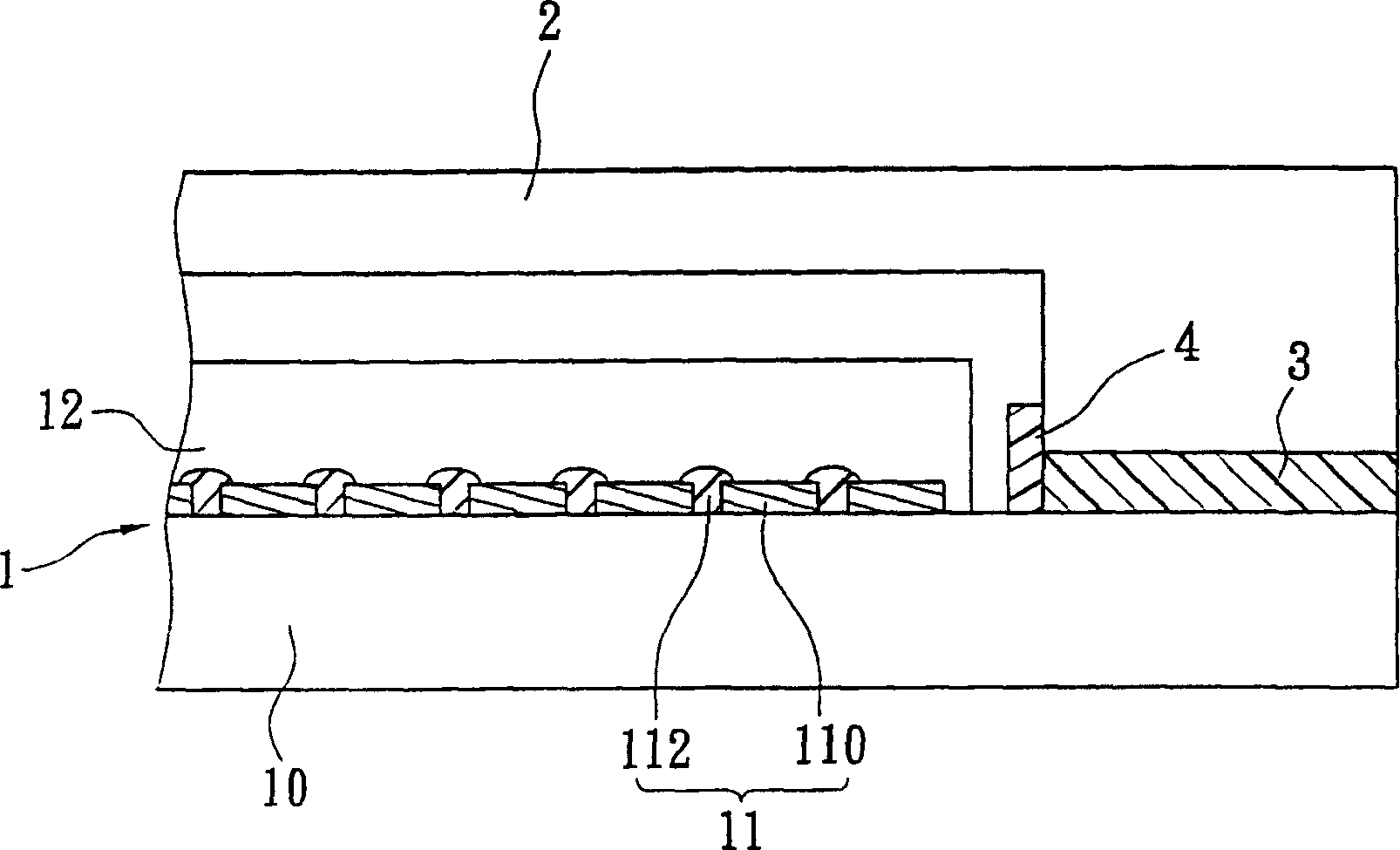

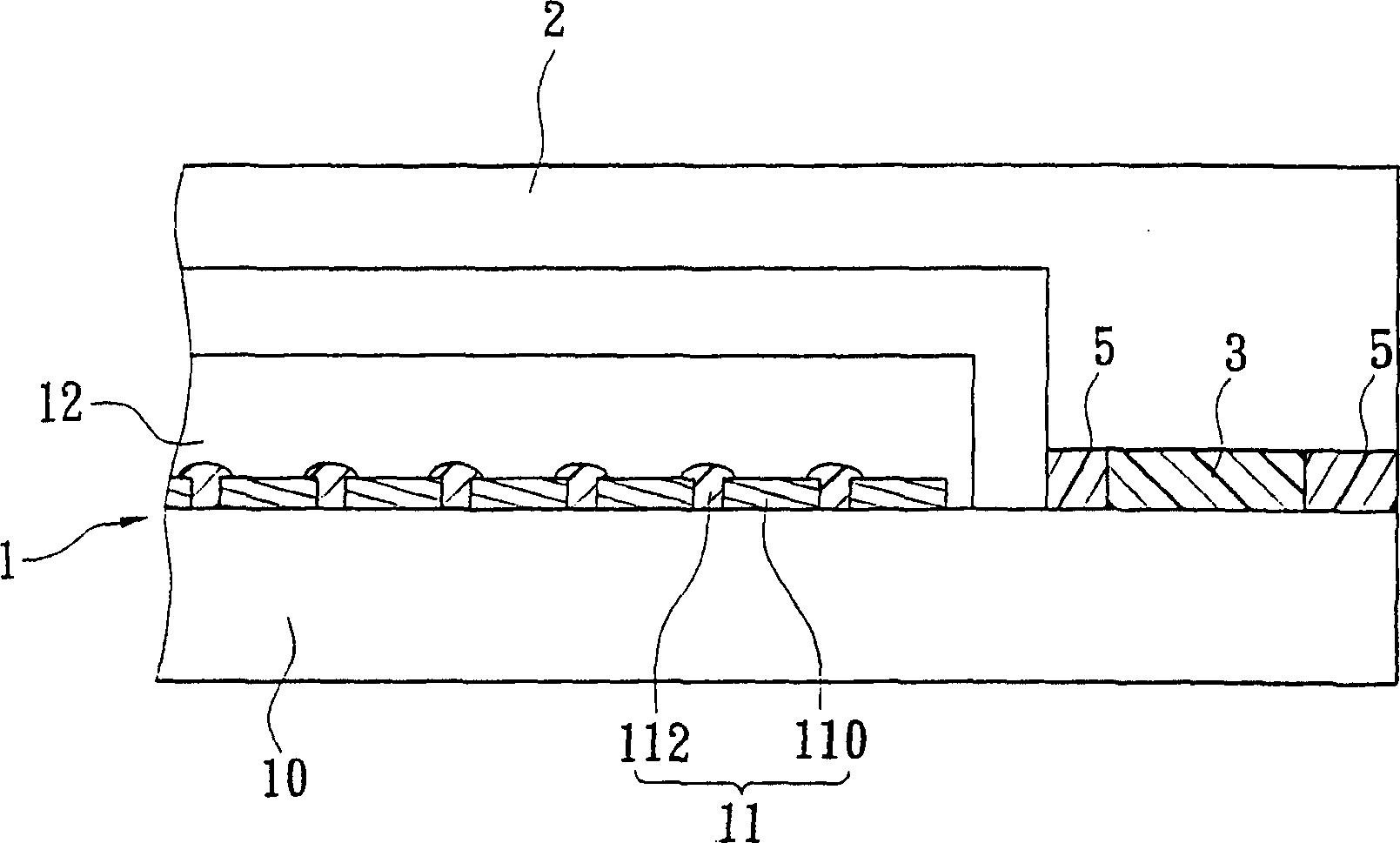

[0036] see figure 2 As shown, the organic electroluminescent flat panel display provided by the present invention includes a glass substrate 10, a light-emitting display structure 11 disposed on the glass substrate 10, an organic light-emitting structure 12 covering the light-emitting display structure 11, and covering the light-emitting display structure 11. The cover 2 of the organic light-emitting structure 12 . Wherein, the light emitting display structure 11 includes an ITO conductive layer 110 and an insulating region 112 in the ITO conductive layer as an isolation. The light-emitting display structure 11 and the organic light-emitting structure 12 are jointly combined into an internal structure 1 . The first embodiment of the sealant structure of the organic electroluminescent flat panel display provided by the present invention has an adhesive layer 3 tightly connected between the cover 2 and the glass substrate 10, and an adhesive layer 3 adjacent to the adhesive la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com