Omnibearing peep-proof film with antireflection function and manufacturing process thereof

A production process and all-round technology, applied in the field of optical polarization, can solve the problems of low light transmittance, uneven light, and inability to realize all-round anti-peeping, etc., and achieve the effects of high processing efficiency, simple structure, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

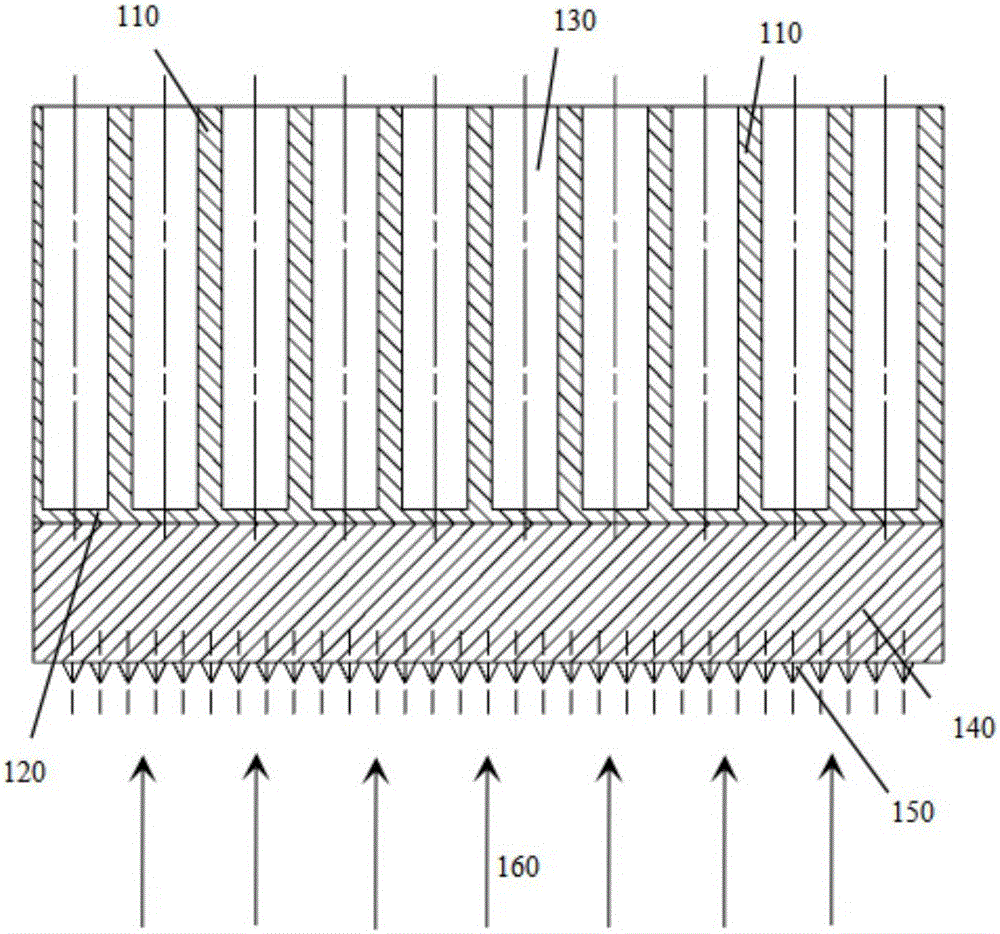

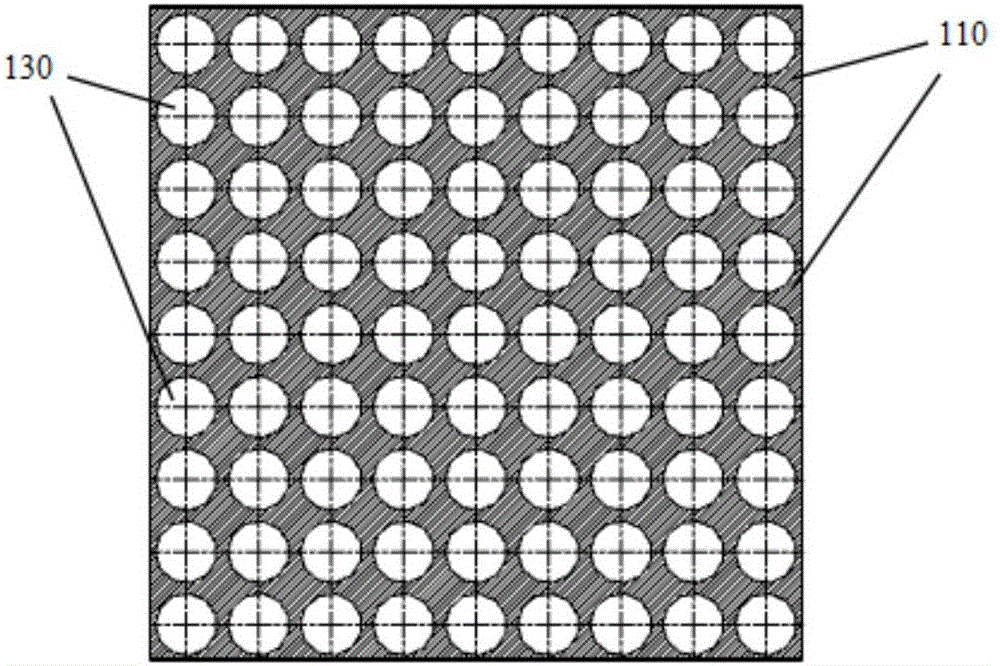

[0032] An all-round anti-peeping film with anti-reflection function, its structure is as follows Figure 1-2 As shown, it includes a PET layer 140, a peep-proof structure layer arranged on one side surface of the PET layer 140, the peep-proof structure layer includes a resin bottom layer 120 and a UV photocurable resin layer 110, and a peep-proof structure layer arranged on the other side surface of the PET layer 140 Moth-eye AR structure layer 150 . Wherein the resin bottom layer 120 is also made of UV photocurable resin. The UV photocurable resin layer 110 is formed with a penetrating structure 130 that penetrates the upper and lower surfaces. In this embodiment, the penetrating structure 130 is a cylindrical cavity structure, and all cylindrical cavities are arranged in a rectangular array. The maximum diameter is 5-100 microns, the distance between two adjacent cavities is 5-100 microns, and the height of each cavity is 5-200 microns. In this embodiment, the cavity adopts...

Embodiment 2

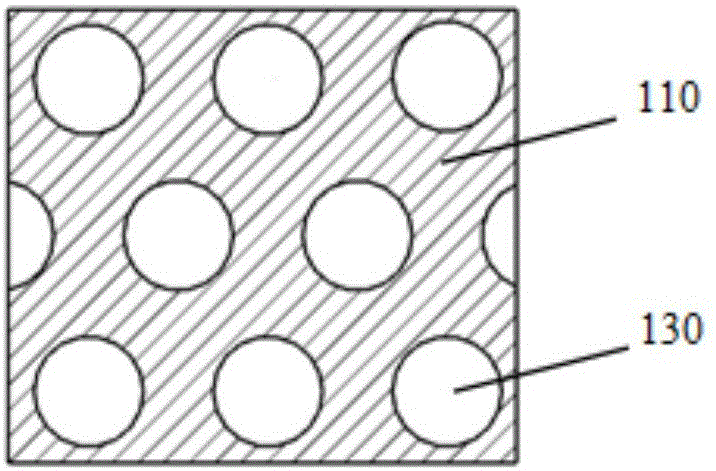

[0035] An all-round anti-peeping film with anti-reflection function, its structure is as follows image 3 As shown, it is roughly the same as the embodiment 1, except that in this embodiment, the through structures 130 are distributed in the UV curable resin layer 110 in the form of a hexagonal array. The moth-eye anti-reflection structure layer is a cone arranged in an array, and the diameter of the bottom of the cone is less than one-half of the incident light wavelength. In this embodiment, the ratio of the depth of the cone to the bottom diameter is 0.5, and the distance between the center and the diameter of the bottom of the cone is 0.5. The ratio is 1.

Embodiment 3

[0037] An all-round anti-peeping film with anti-reflection function, its structure is as follows Figure 4 As shown, it is substantially the same as the embodiment 1, except that in this embodiment, the through structures 130 are distributed in the UV curable resin layer 110 in the form of a circular array. The moth-eye anti-reflection structure layer is a cone arranged in an array, and the diameter of the bottom of the cone is less than one-half of the incident light wavelength. In this embodiment, the ratio of the depth of the cone to the bottom diameter is 20, and the distance between the centers and the diameter of the bottom of the cone The ratio is 20.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com