Method for shaping patch type LED optical lens model

An optical lens and chip-type technology, which is applied in the field of chip-type LED optical lens molding, can solve the problems of easy falling off of optical lenses, slow production speed, and many operating procedures, so as to prevent glue overflow, fast production speed, and easy operation. The effect of fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings.

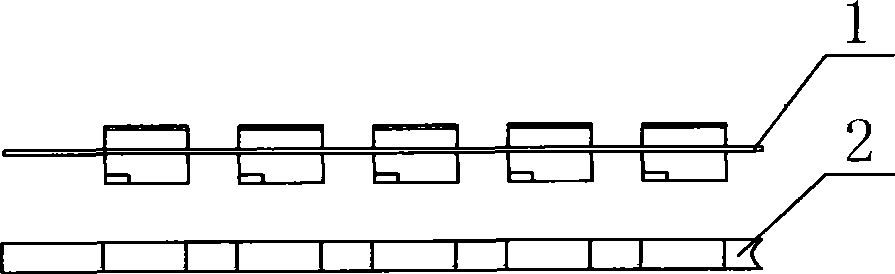

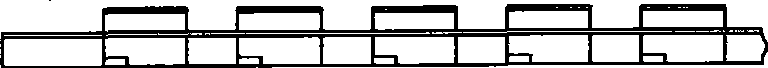

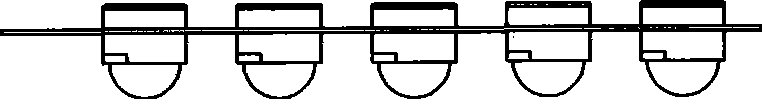

[0029] figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, make a piece of steel sheet 2 with the same thickness as the light-transmitting shell on the patch-type LED plastic bracket 1, and then use the steel sheet to match the plastic bracket. The light-transmitting shell and the steel sheet are fully matched, so the transparent resin can be prevented Or stick transparent silicone on the light-transmitting shell.

[0030] SMD LED plastic bracket semi-finished products are dehumidified and baked in an oven to remove hidden moisture in the bracket to prevent air bubbles, and then use plasma cleaning to remove dust in the bracket to ensure the smoothness of the bracket and improve the transparent resin or transparent silicone and plastic bracket. The bonding performance of the light-transmitting shell, replace the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com