Transformer iron core adhesive tape-adhering and dispensing equipment

A technology of transformer iron core and adhesive tape, which is used in inductor/transformer/magnet manufacturing, magnetic core manufacturing, conveyor objects, etc., can solve the problems of low degree of automation, complex equipment structure and complex process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

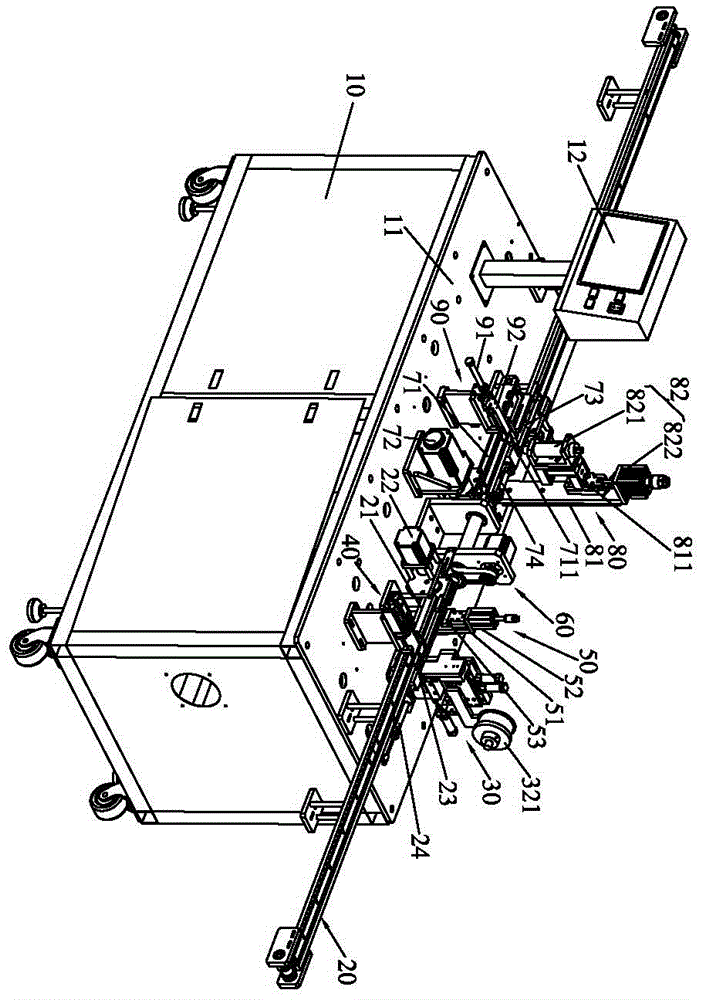

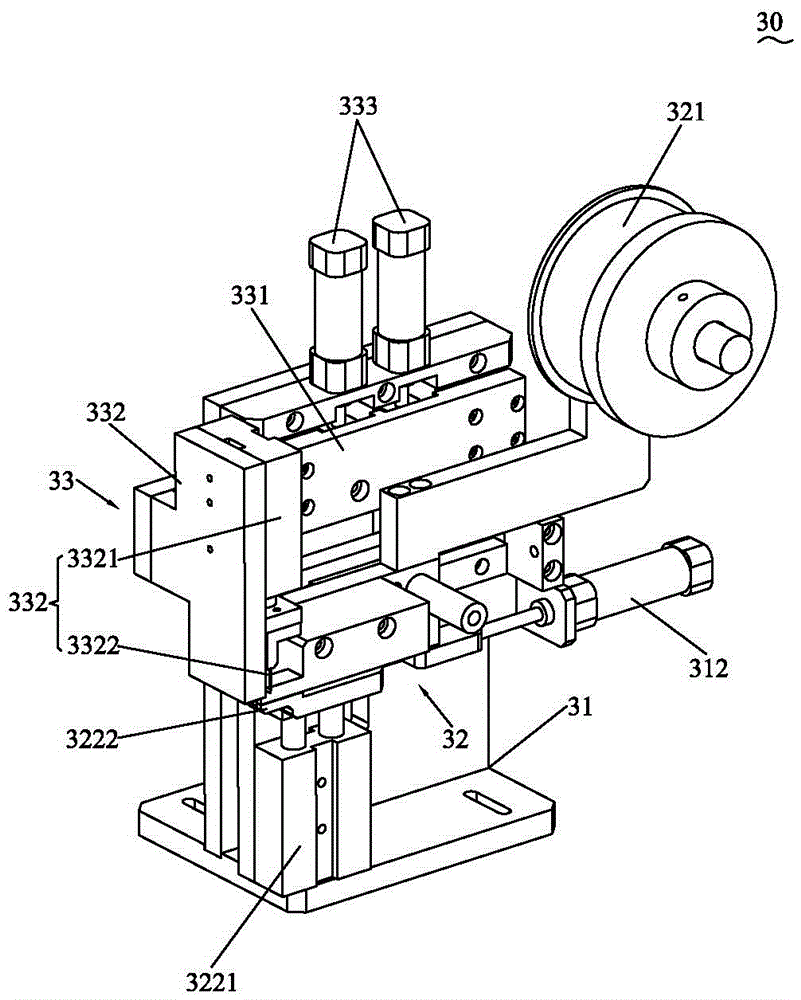

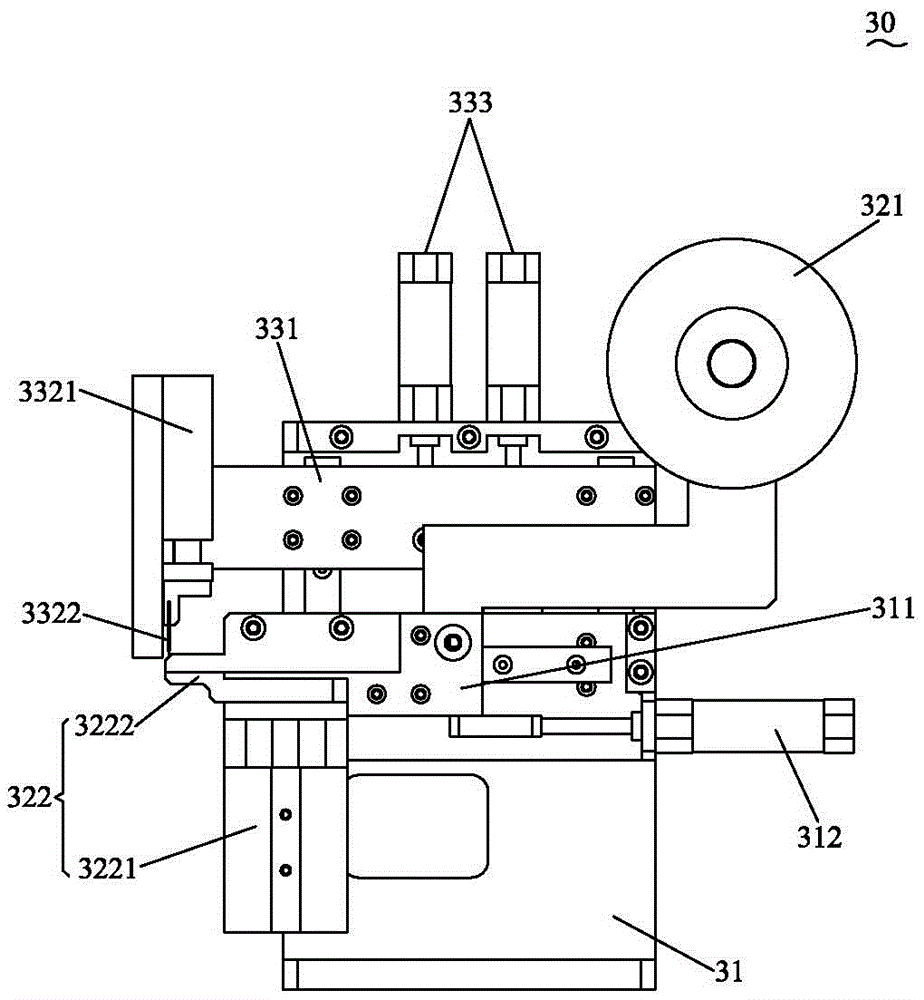

[0051] The present invention as Figure 1 to Figure 6 As shown, a transformer iron core adhesive tape and dispensing equipment includes a frame 10, a first feeding mechanism 20, an adhesive tape mechanism 30, a first pushing mechanism 40, a pressing device 50, a turning mechanism 60, The second feeding mechanism 70, the dispensing mechanism 80 and the second pushing mechanism 90, wherein:

[0052] A workbench 11 is arranged on the frame 10 , and a control panel 12 for controlling the equipment is arranged on the workbench 11 .

[0053]The first feeding mechanism 20, the turning mechanism 60 and the second feeding mechanism 70 are sequentially connected and horizontally arranged on the workbench 11, and the adhesive tape mechanism 30 and the first pushing mechanism 40 are respectively arranged on both sides of the first feeding mechanism 20, and Link to each other with the first feeding mechanism 20 respectively; The pressing device 50 is arranged on the side of the end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com