Double-track online automatic dispensing machine and control method thereof

A dispensing machine and dispensing mechanism technology, applied in the field of dispensing machines, can solve problems such as low production efficiency, inability to adjust track width, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

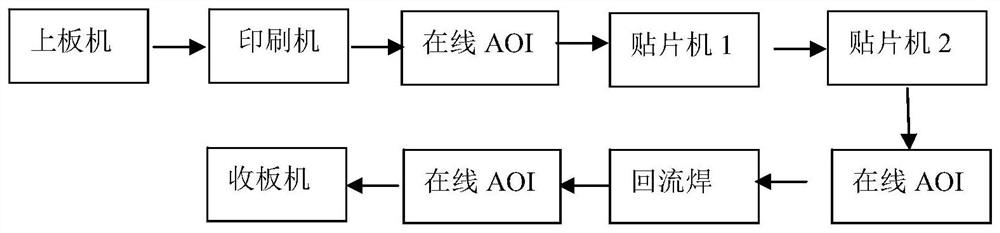

[0070] The equipment layout diagram of the PCB board online automatic production line is as follows figure 1 Shown: Including board loading machine, printing machine, online AOI, placement machine, reflow soldering, board receiving machine and other equipment. The dual-track online automatic dispensing machine of the present application can be arranged between the online AOI and the board receiving machine of the production line. The inlet of the dispensing machine is connected to the online AOI equipment, and the outlet is connected to the receiving board machine to realize online production.

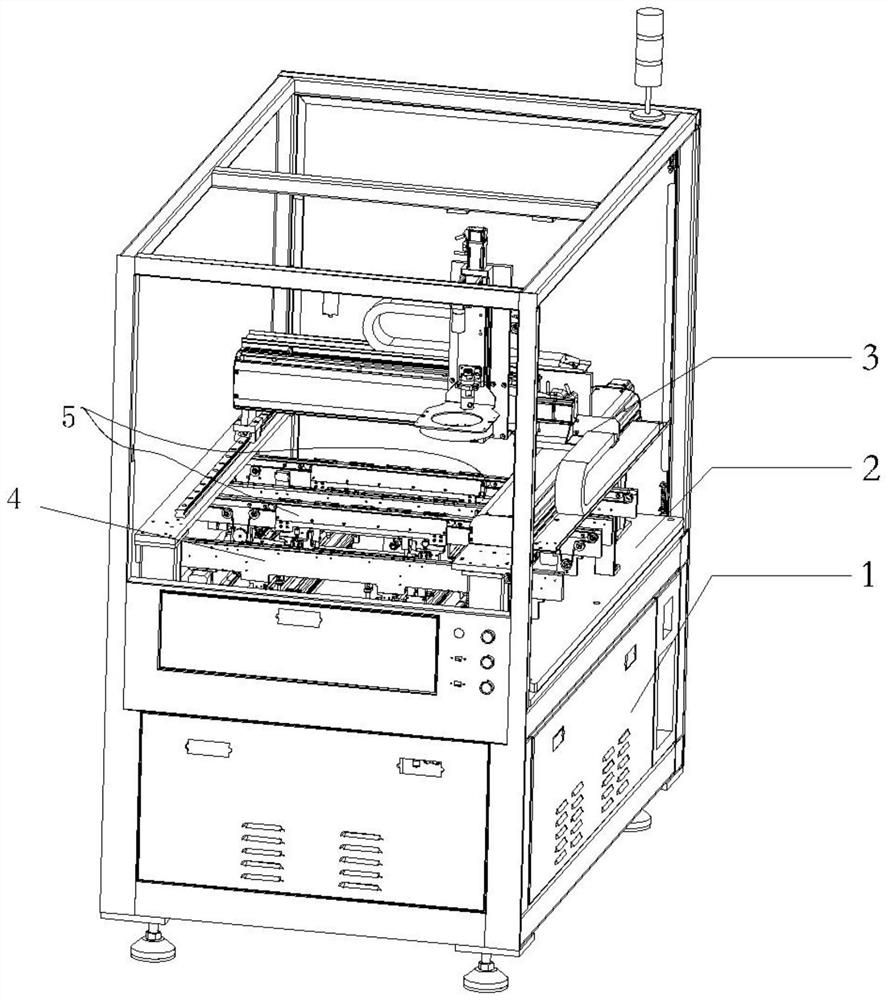

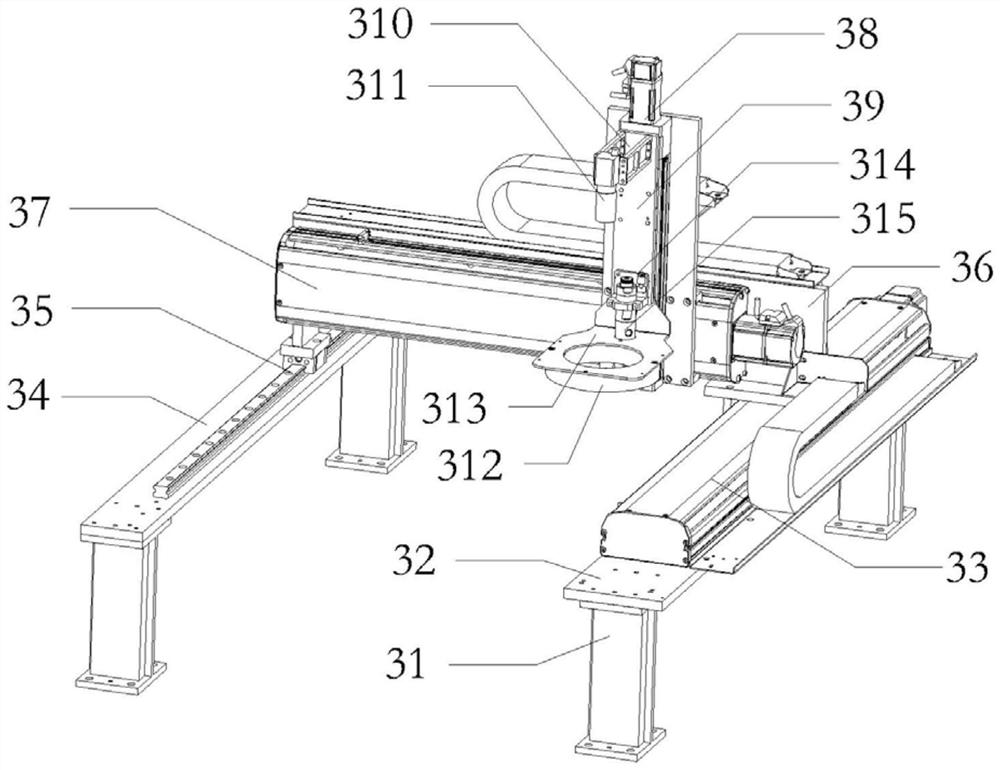

[0071] see figure 2 , the dual-track online automatic dispensing machine includes a frame 1 and a three-axis visual dispensing mechanism 3 located on the frame 1, a multi-track conveying mechanism and a PCB positioning mechanism 5, wherein the frame 1 includes a platen 2 and an appearance plate Gold, control buttons and electronic control components, three-axis visual glue dispensing...

Embodiment 2

[0093] see Figure 9 , in order to control the dispensing machine more conveniently, a dual-track online automatic dispensing machine control method dedicated to the dispensing machine is provided, including the following steps:

[0094] S100, receiving the PCB board information to be processed flowing out from the online AOI;

[0095] In this step, the size information of the PCB board is mainly received, so PCB boards of different sizes can be processed simultaneously on the two transmission tracks.

[0096] S200, the first transmission track and the second transmission track automatically adjust the track width to match the size of the PCB board to be processed;

[0097] In this step, the automatic width adjustment structure is actually used to realize the width adjustment.

[0098] S300. Simultaneously feeding two PCB boards to be processed through the first transmission track and the second transmission track;

[0099] In this step, the flat belts 456 running on the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com