Single-sided meshing measurement device for face gear errors

A single-sided meshing and measuring device technology, which is applied to measuring devices, optical devices, instruments, etc., can solve the problems of measuring instruments without face gear transmission error detection, and achieve high measurement accuracy and high measurement efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

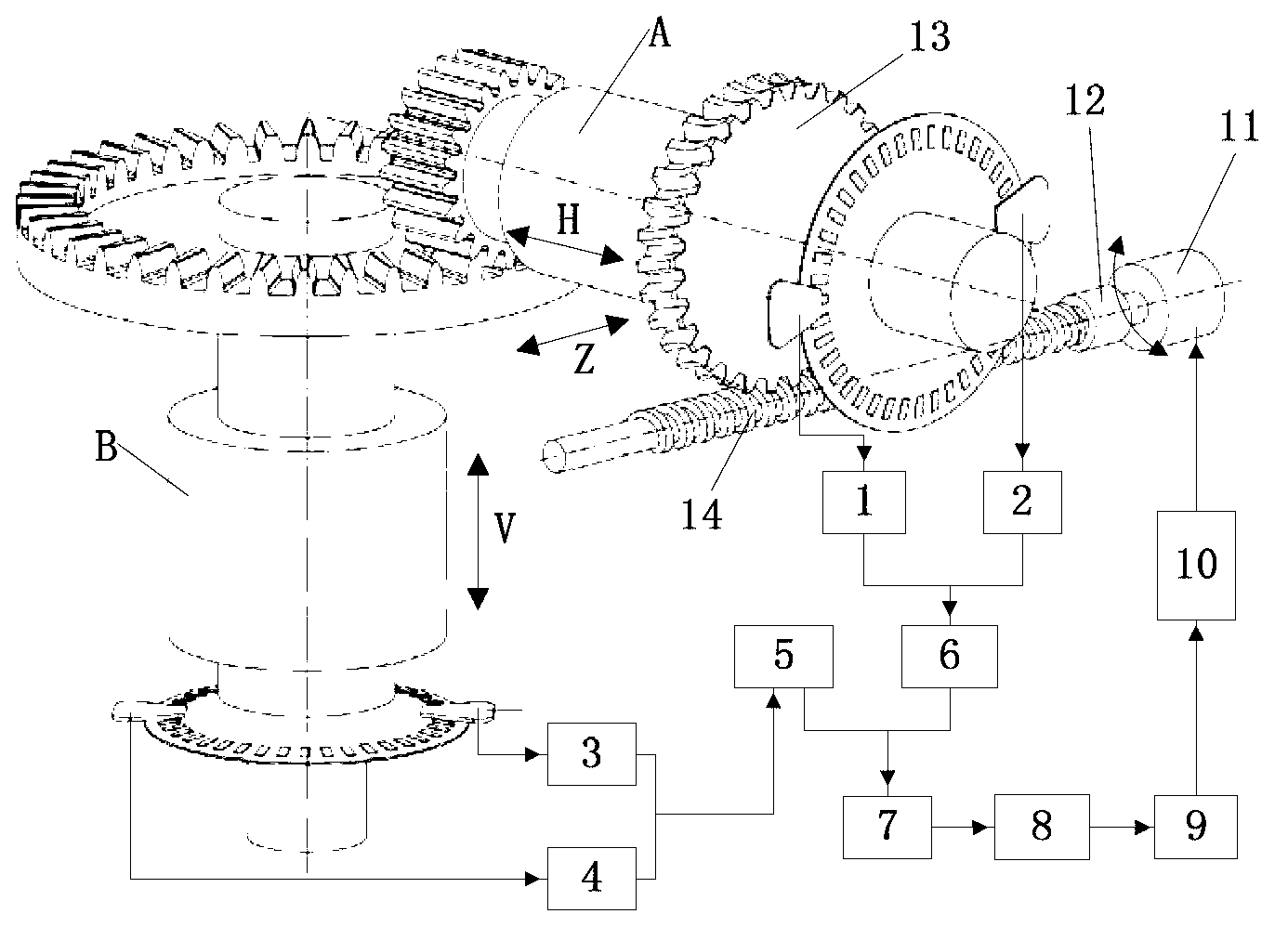

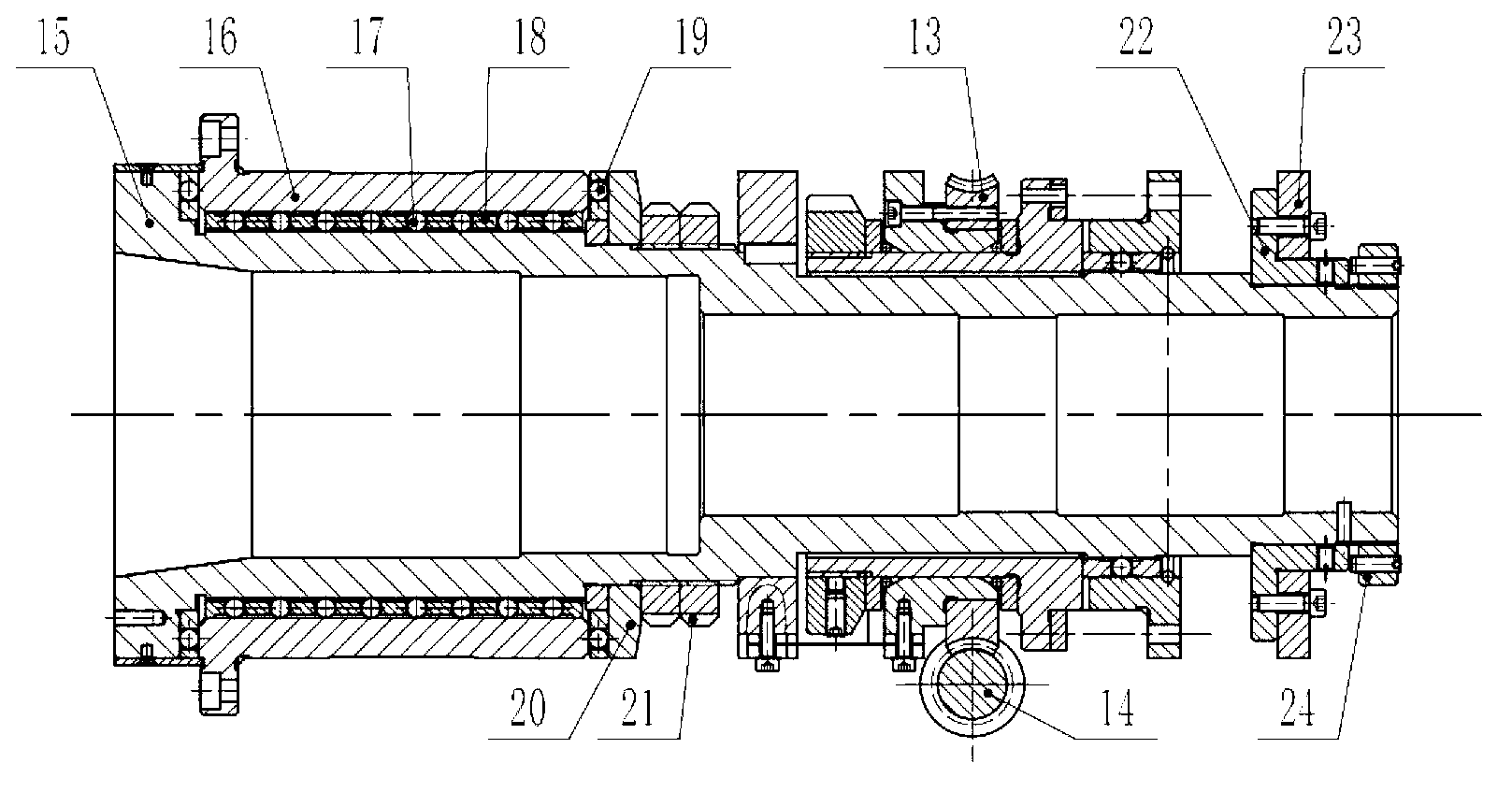

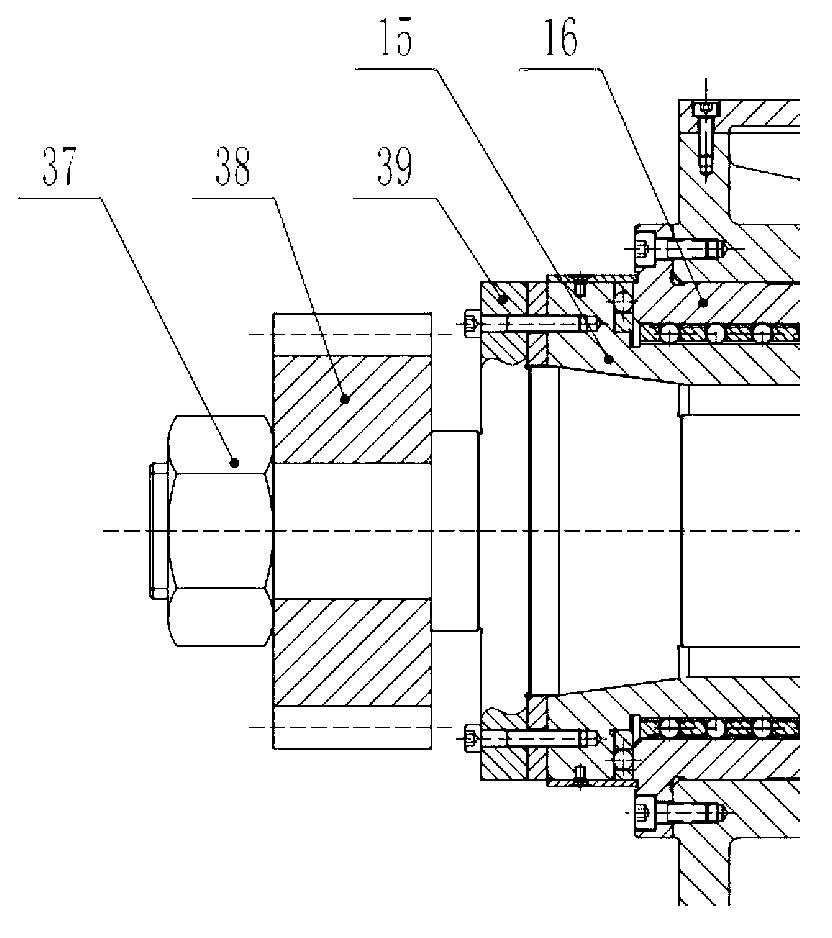

[0026] The working principle of the present invention is as figure 1 As shown, each structural member Figure 2-6 As shown; the cylindrical gear (38) and the face gear (40) are installed on the cylindrical gear shafting (A) and the face gear shafting (B) respectively. The cylindrical gear shafting (A) can move along the H / Z two directions on the horizontal plane, and the movement in these two directions is realized by the H-direction moving platform (49) and the Z-direction moving platform (48). The face gear shafting can move along the V direction in the vertical plane, and this movement is realized by the V-direction moving platform. The relative position of the gear pair is detected by the long grating system (47) in the H / V / Z direction to achieve precise positioning. Adjust the relative position of the cylindrical gear and the face gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com