Patents

Literature

56results about How to "Satisfy the requirement of coaxiality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

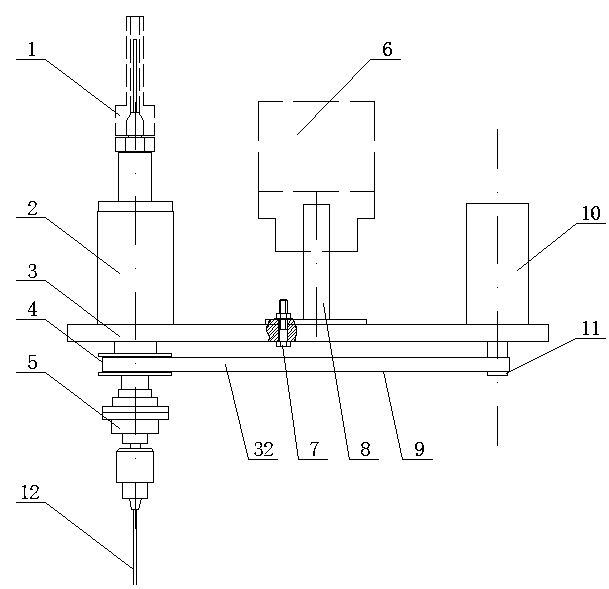

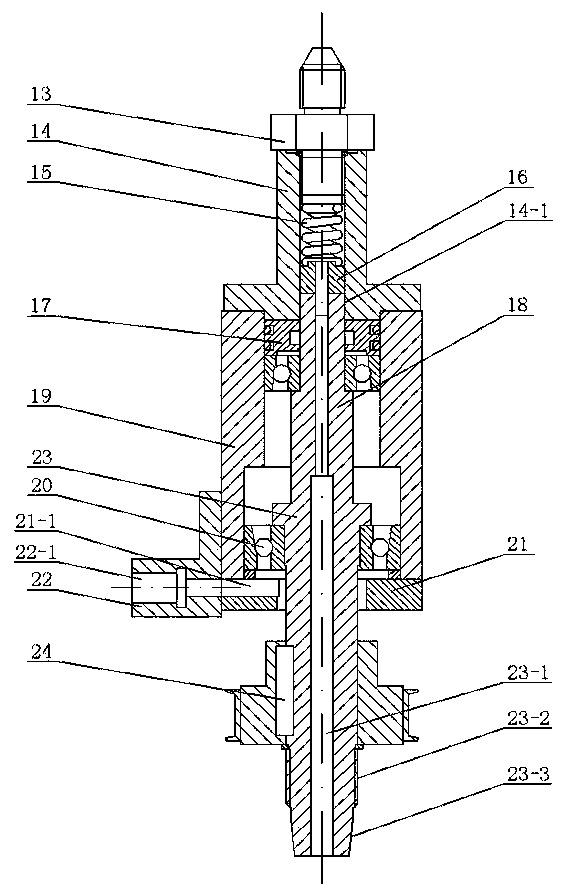

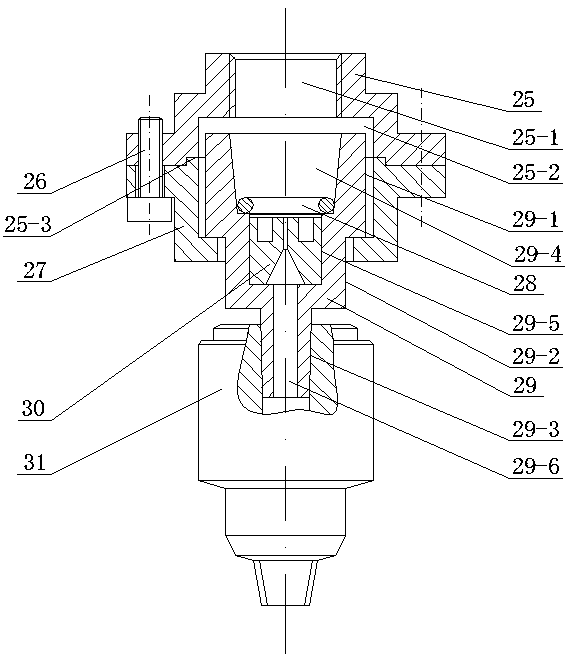

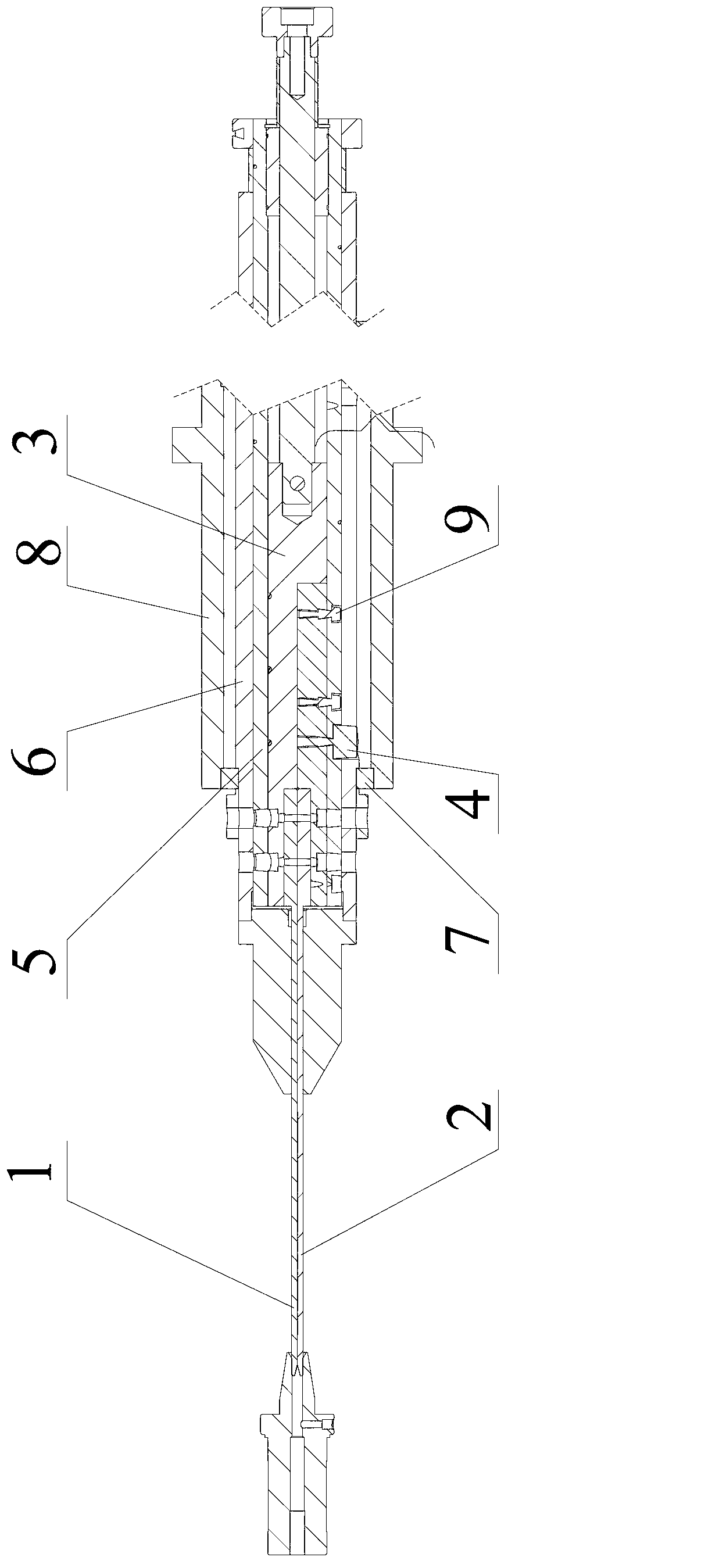

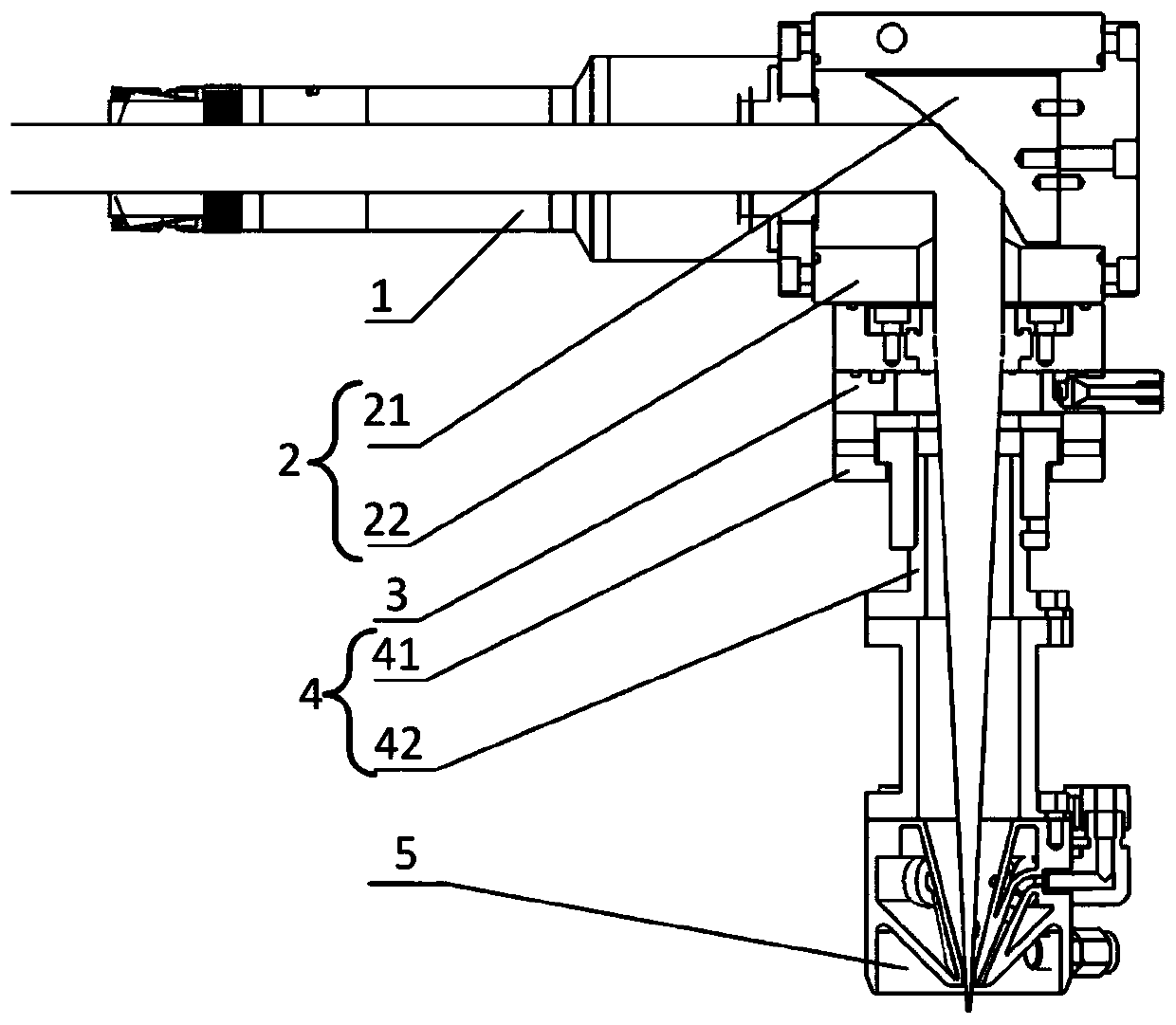

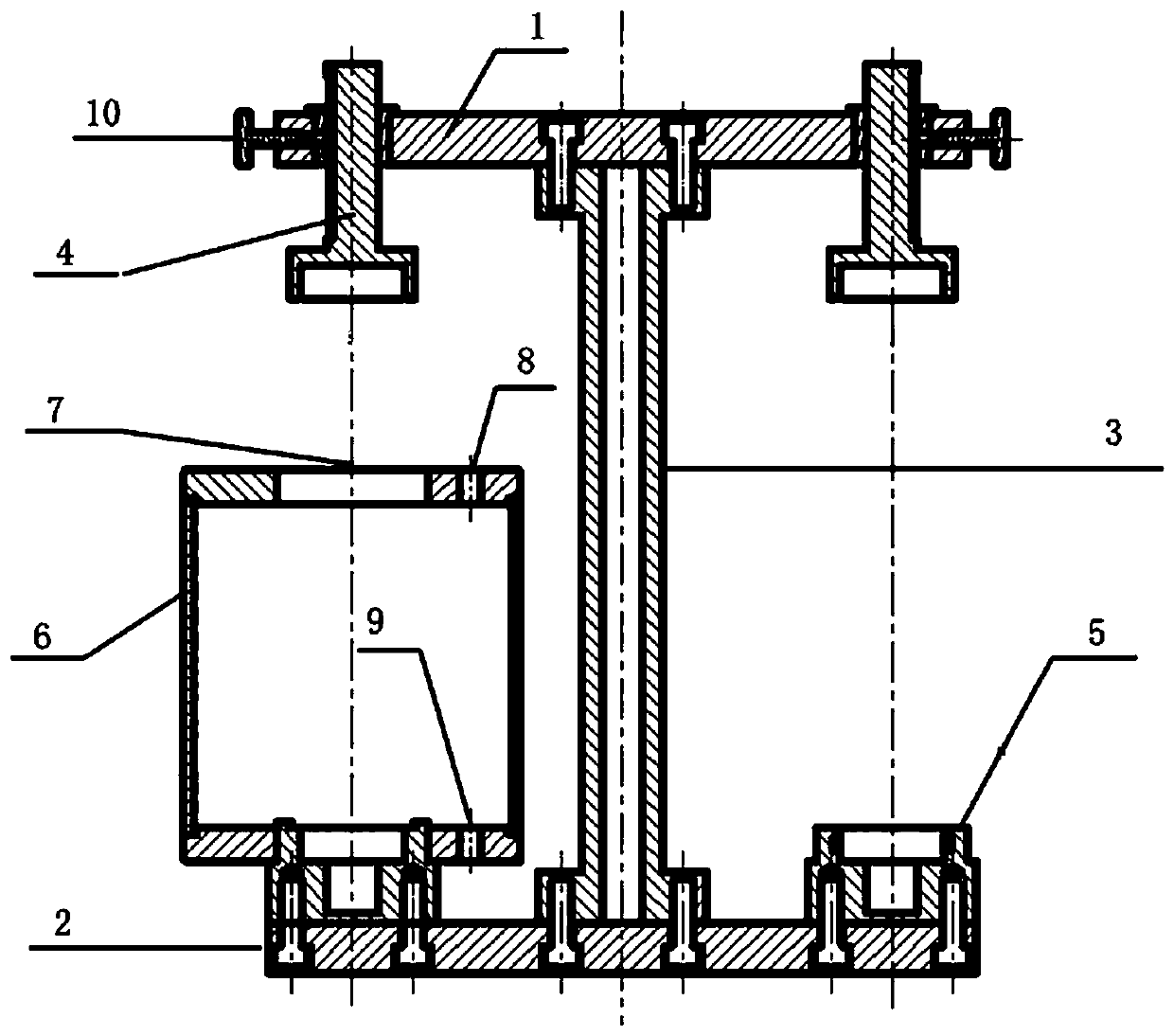

Electrode rotating and clamping device for electrosparking of insulating ceramic coated metal

The invention discloses an electrode rotating and clamping device for electrosparking of insulating ceramic coated metal, belongs to the field of electrosparking and forming technique, and solves the problem that the electrode rotating and clamping device on an EDM machine tool can not be used in an oil base working solution in the present electrosparking of the insulating ceramic coated metal. The working solution is the oil base working solution; a synchronous belt drive mechanism is connected with a DC gear motor and an electrode slewer; the positioning section of the hollow shaft of the electrode slewer is mounted in the circular truncated conical hole of the taper connecting shaft of an electrode clamping device in a matched manner; the electrode clamping device clamps an electrode and drives the electrode to rotate; the high-pressure working solution provided by an oil supply pipeline is erupted from the lower end of the electrode through the electrode; an insulation baseplate is connected with a fixed block; the fixed block is connected with the main shaft of the EDM machine tool; the main shaft of the EDM machine tool enables the whole electrode rotating and clamping device to move in the vertical direction. The electrode rotating and clamping device for electrosparking of the insulating ceramic coated metal can realize rotation of the tubular electrode and inner solution flushing of the oil base working solution during the electrosparking of the insulating ceramic coated metal.

Owner:HARBIN INST OF TECH

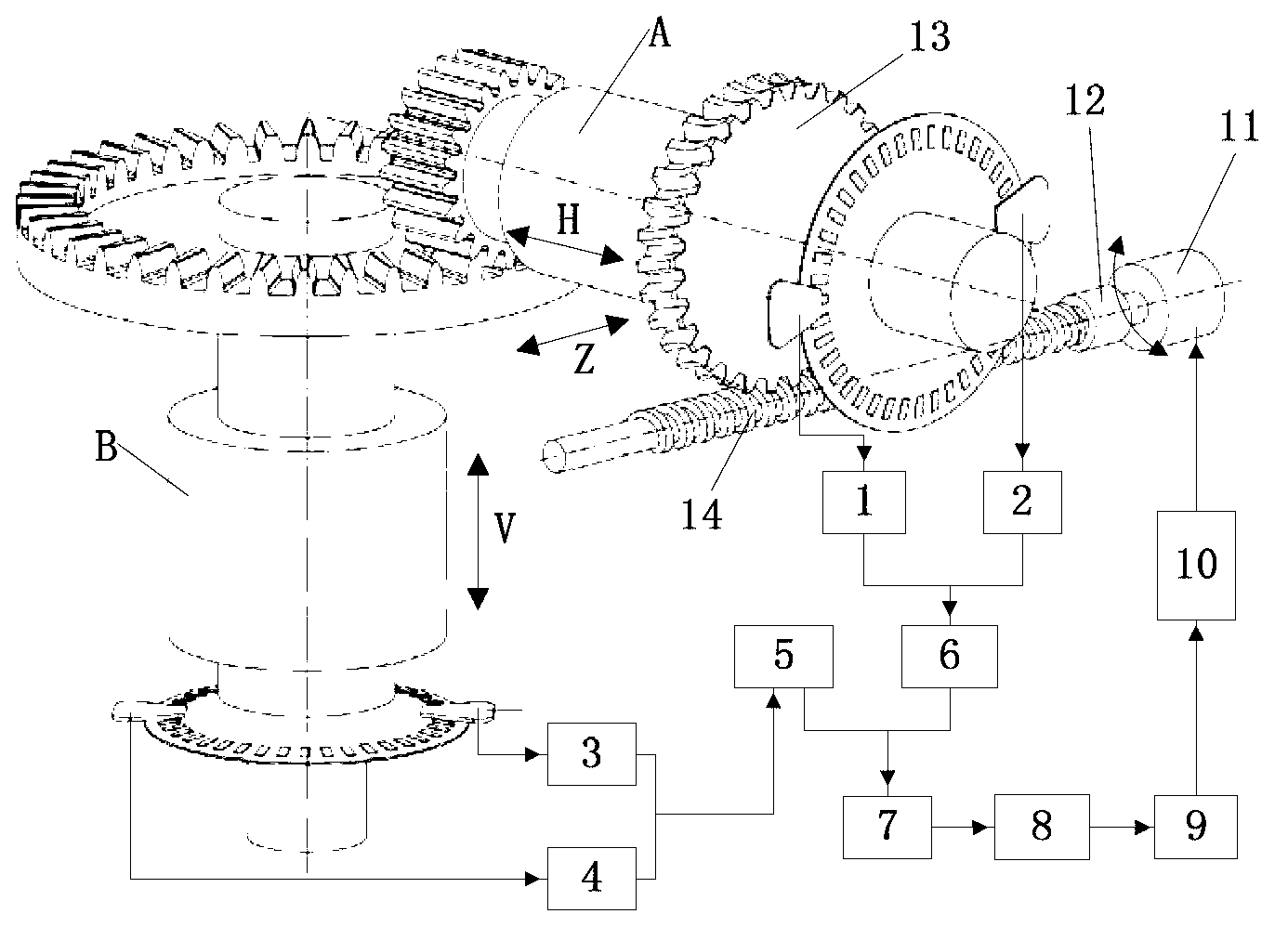

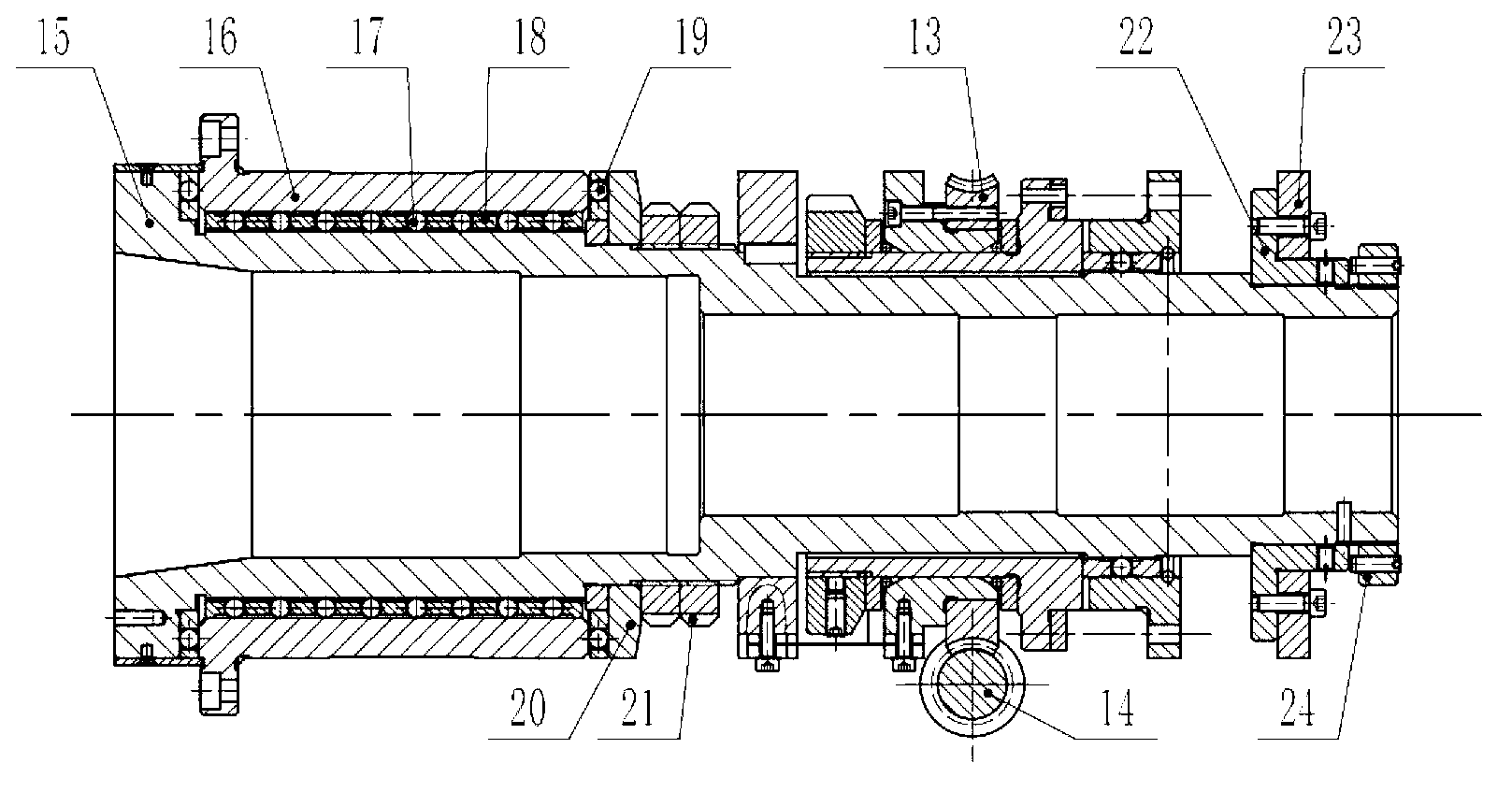

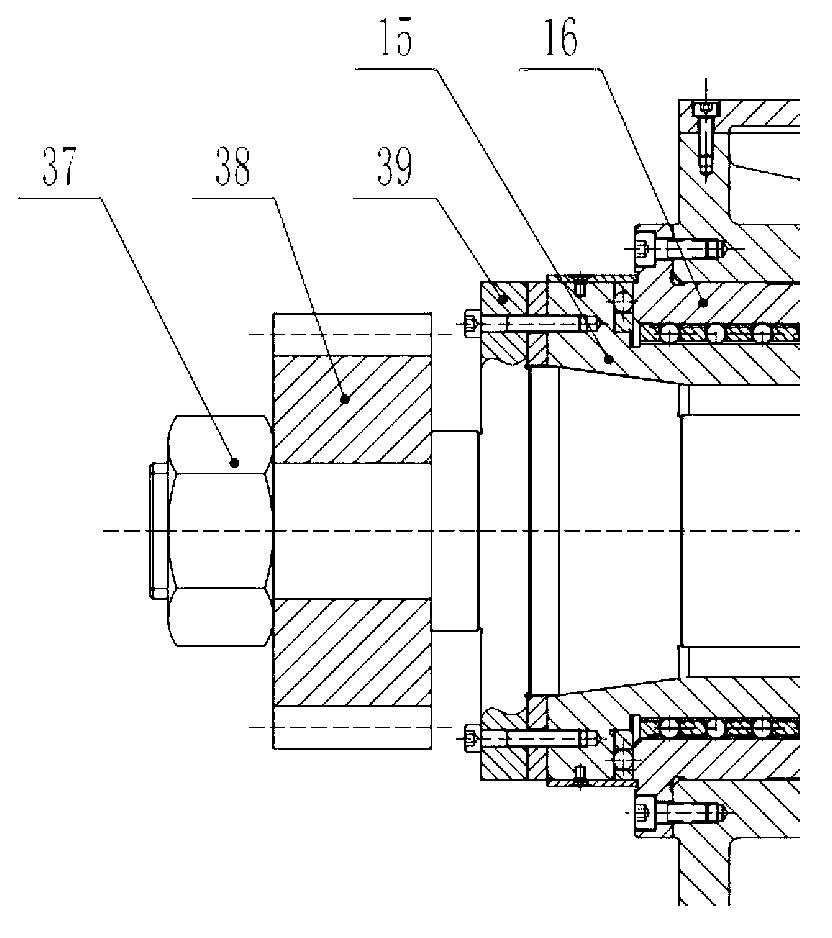

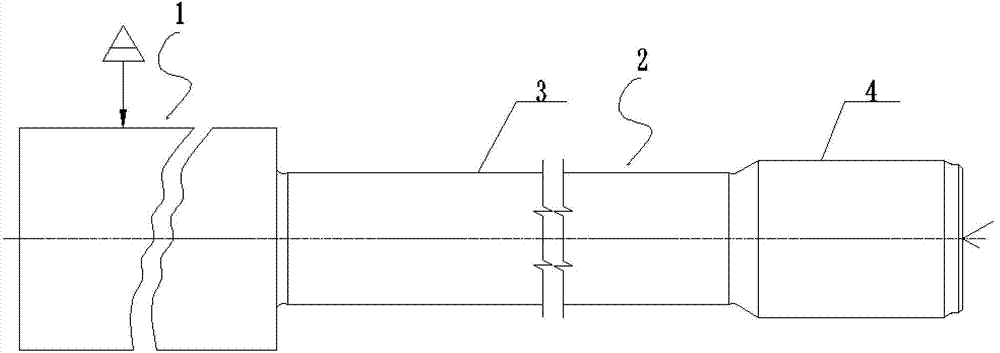

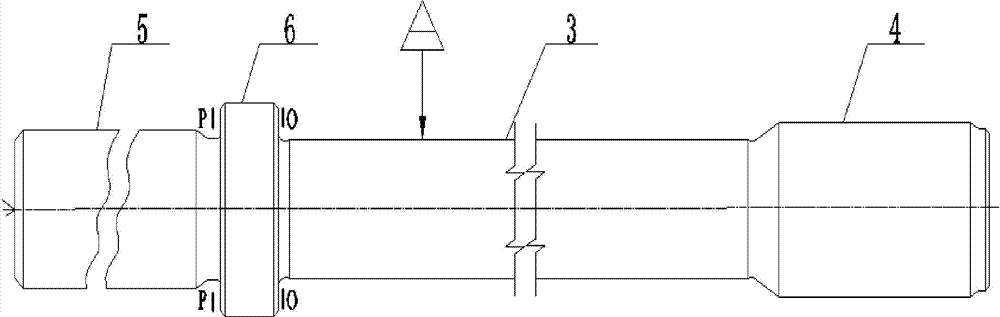

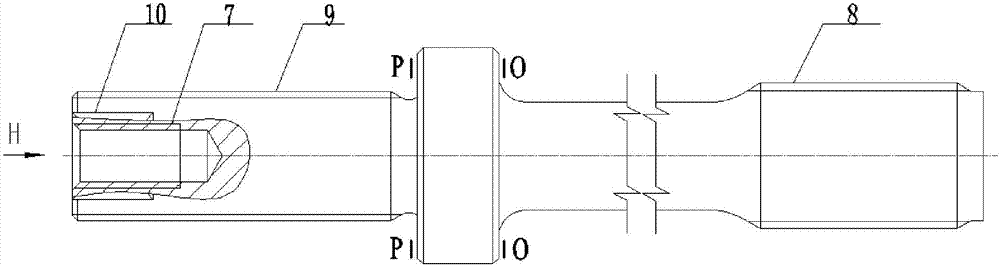

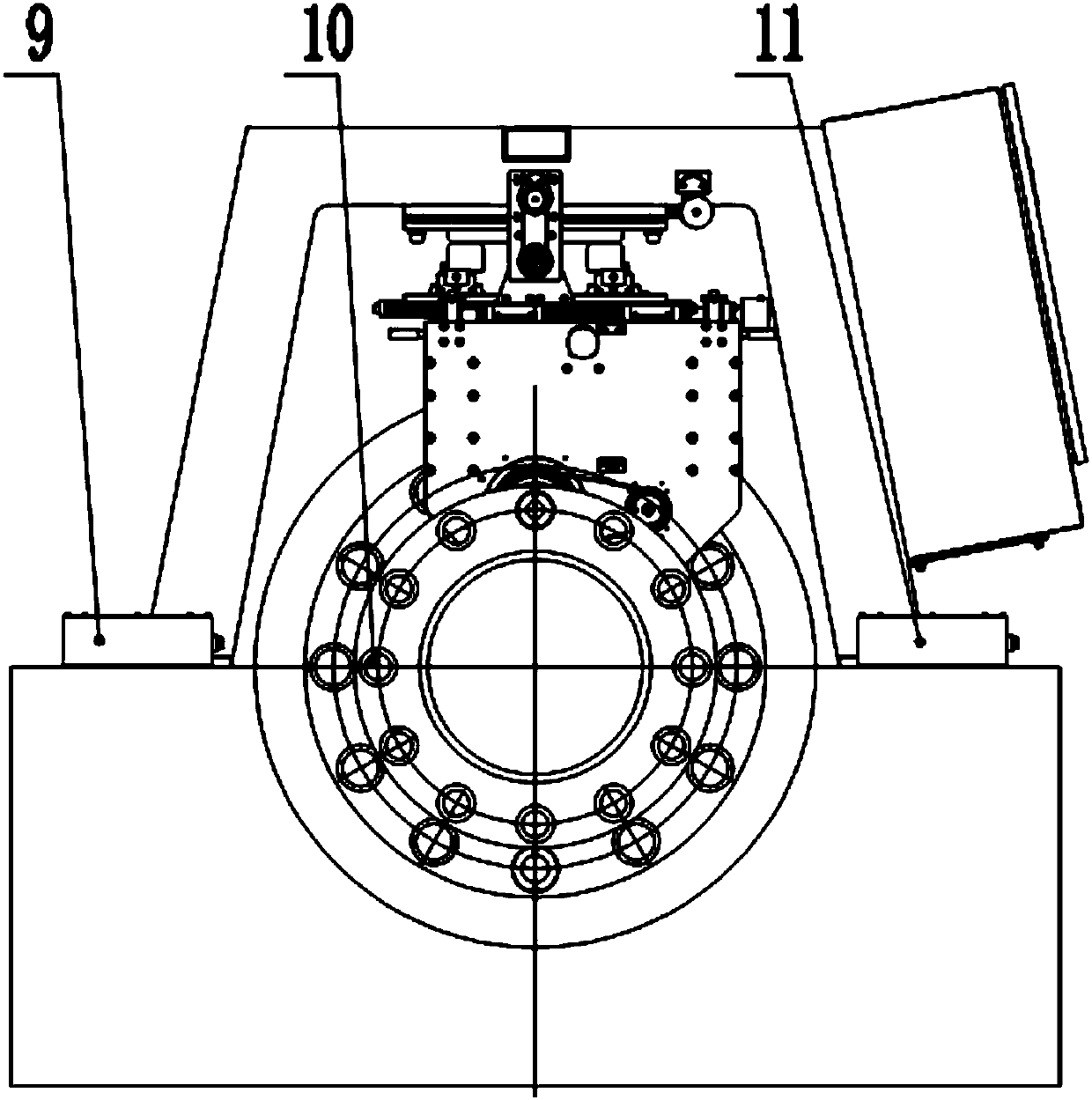

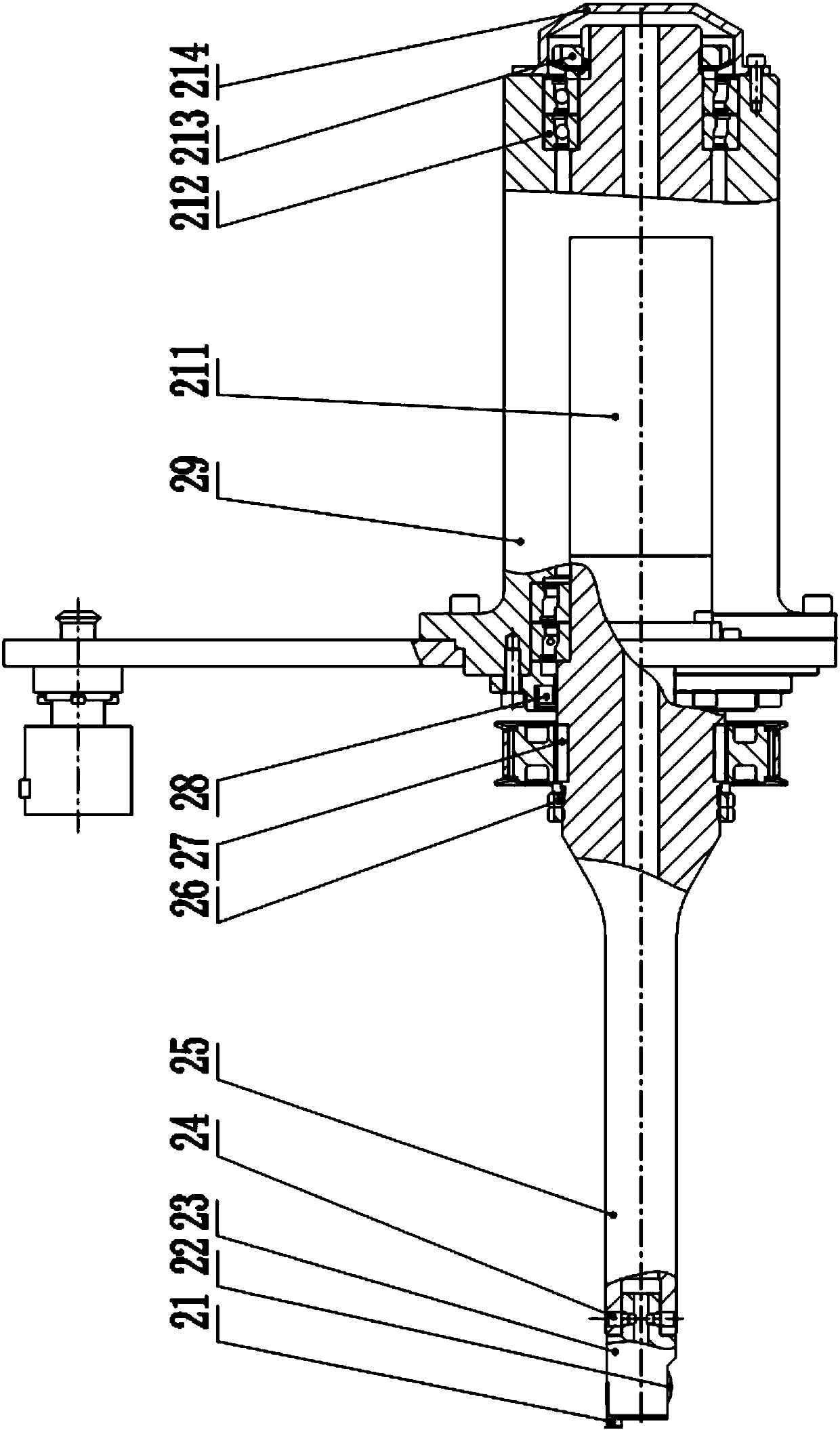

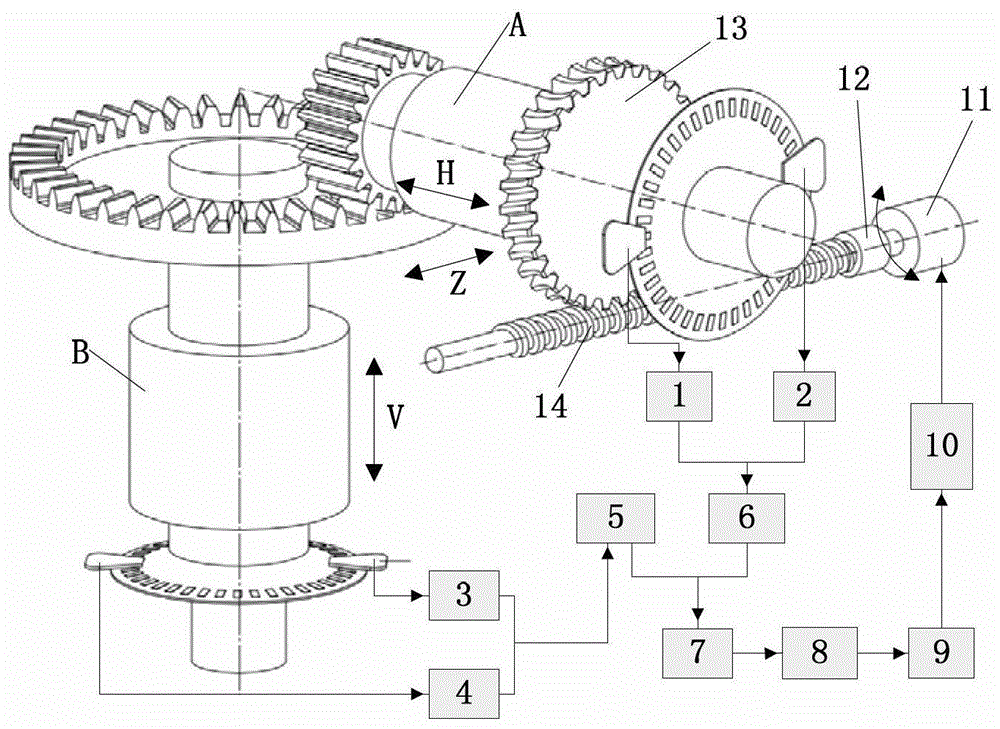

Single-sided meshing measurement device for face gear errors

ActiveCN103267480AImprove versatilityPrecise position adjustmentUsing optical meansGratingMeasurement device

The invention belongs to the field of a precision measurement technology, and provides a single-sided meshing measurement device for face gear errors. The single-sided meshing measurement device comprises a cylindrical gear shafting, a cylindrical gear installation mechanism, a face gear shafting, a face gear installation mechanism, a motor, a coupler, a worm, a controller, a drive unit, a circular grating system, a subdividing device, a DSI card, a data acquisition card and an industrial personal computer. The cylindrical gear shafting is an active shafting and is driven by a servo motor. The single-sided meshing measurement device reduces the quantity of parts of an instrument, and enhances stability of a system.

Owner:BEIJING UNIV OF TECH

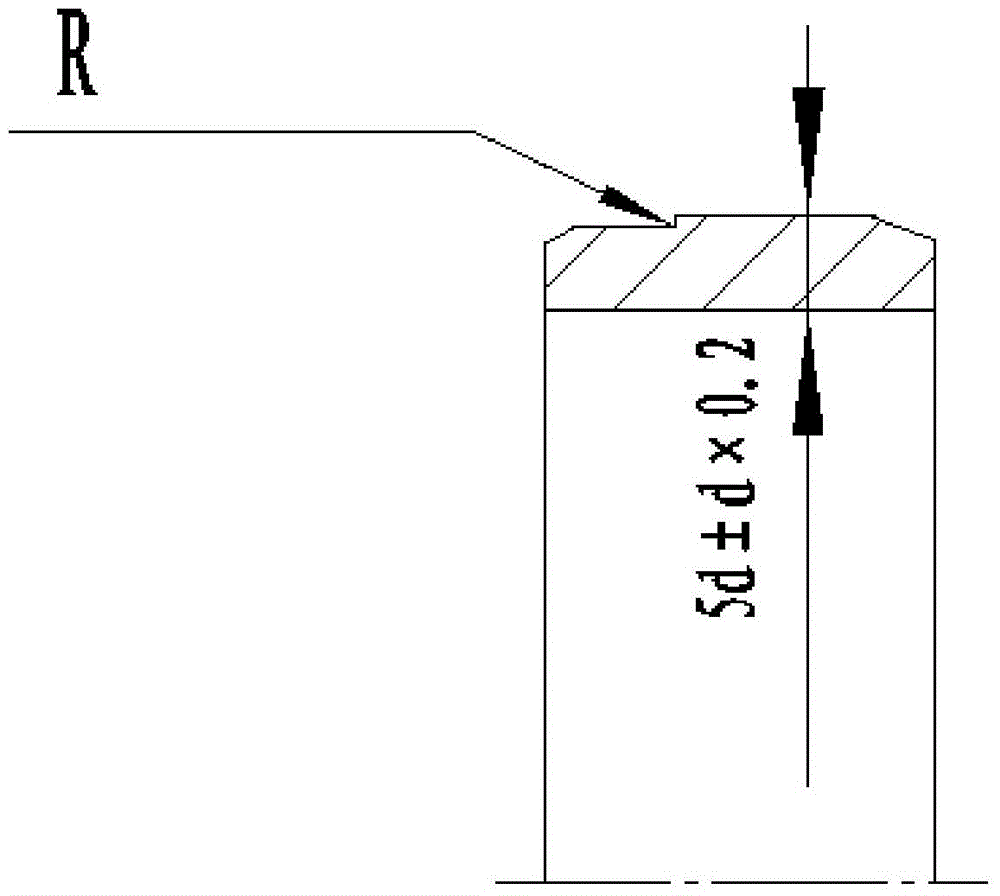

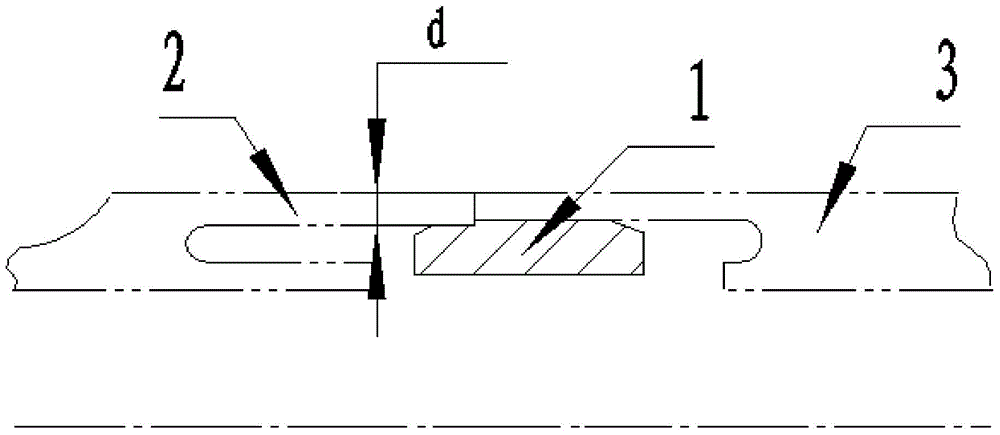

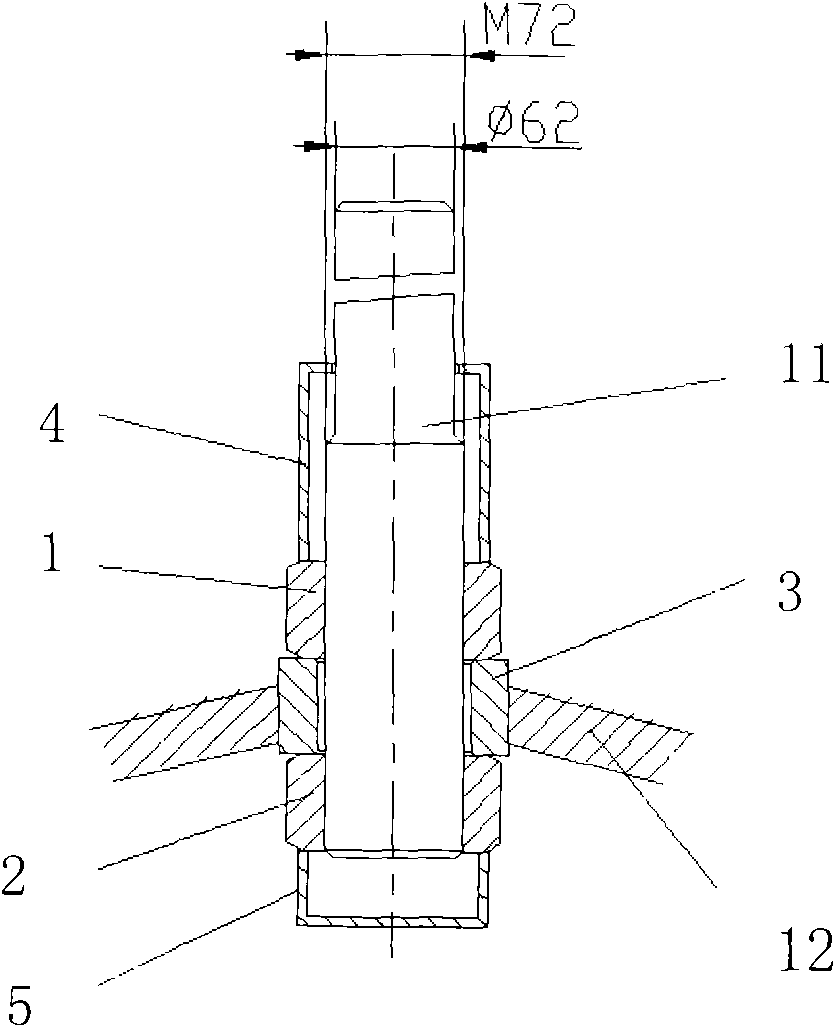

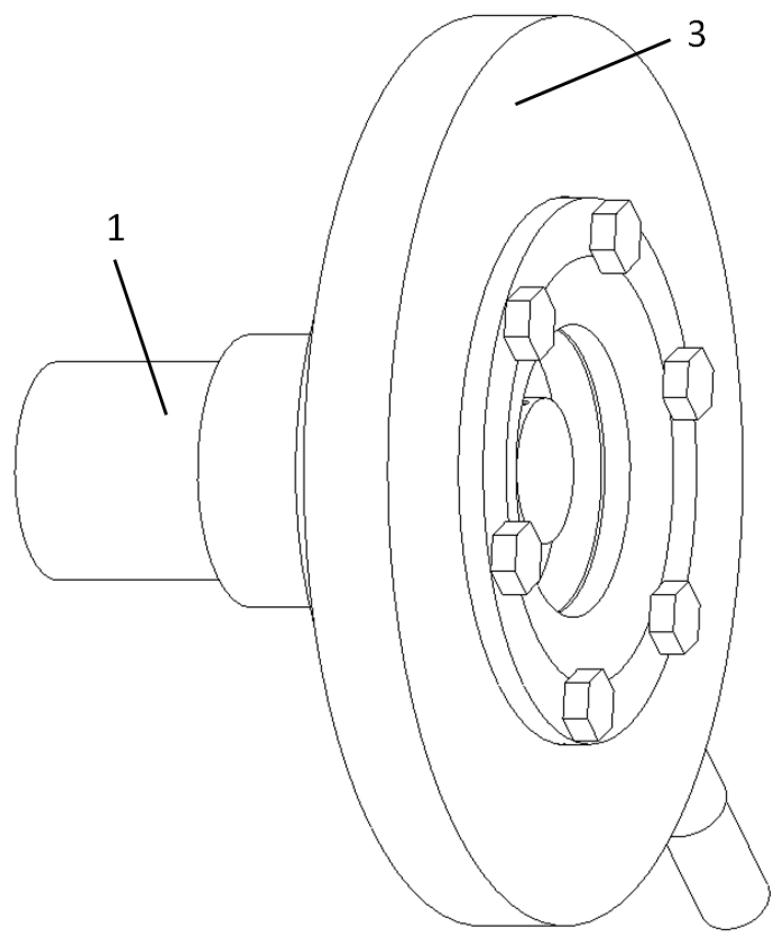

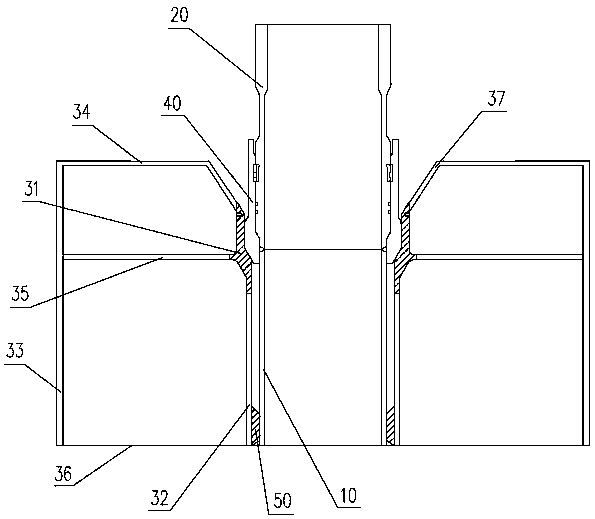

Welding lap joint structure and method for thin-wall pipes

ActiveCN105014293APrecise positioningAvoid the problem that part of the surface of the part cannot be processedWelding/cutting auxillary devicesAuxillary welding devicesButt jointLap joint

The invention discloses a welding lap joint structure and method for thin-wall pipes. The welding lap joint structure and method aim at avoiding limitation of electron beam welding to the structures of welded parts. According to the technical scheme, the welding lap joint structure comprises a supporting bushing ring (1) made of the material the same as that of the welded pipes. The supporting bushing ring (1) is of a two-step-shaped structure. The lap joint portion of the short welded pipe (2) is assembled at the small end of the supporting bushing ring (1). The lap joint portion of the long welded pipe (3) is assembled at the large end of the supporting bushing ring (1). The lap joint portions of the short welded pipe (2) and the long welded pipe (3) are each of an orifice-shaped or groove-shaped structure. The supporting bushing ring (1) can be assembled in the orifice-shaped or groove-shaped structures. The lap joint portions of the short welded pipe (2) and the long welded pipe (3) are flush and end faces are in butt joint in the lap joint process of the supporting bushing ring (1).

Owner:AECC AVIATION POWER CO LTD

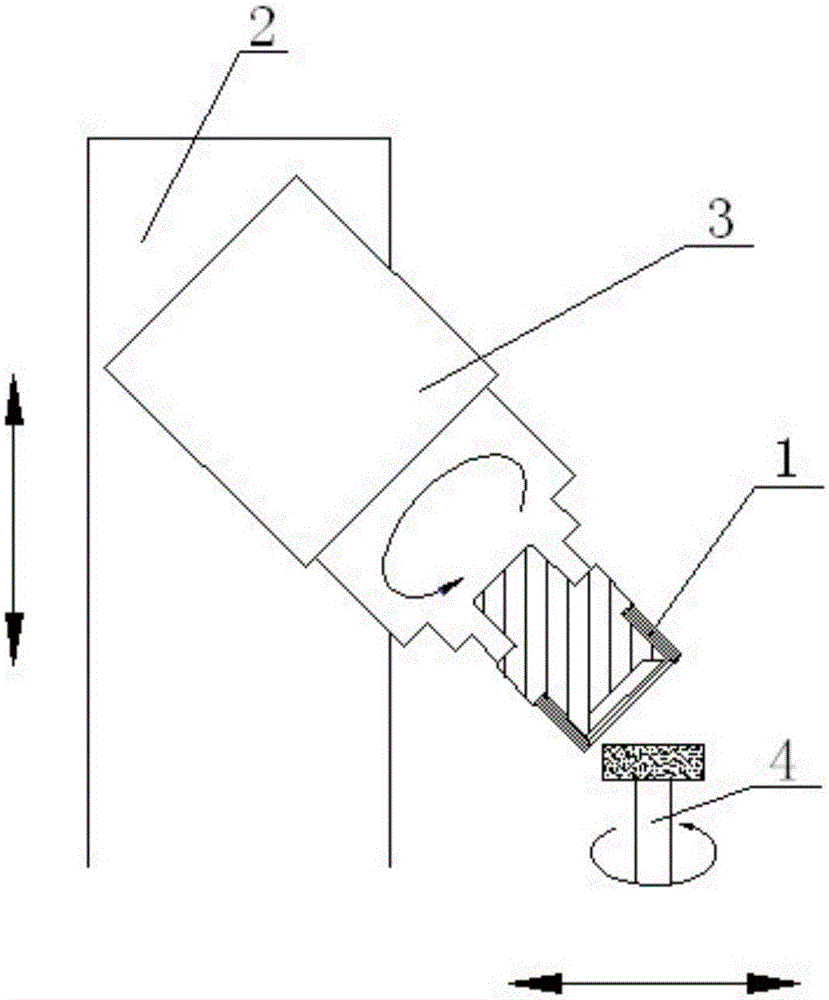

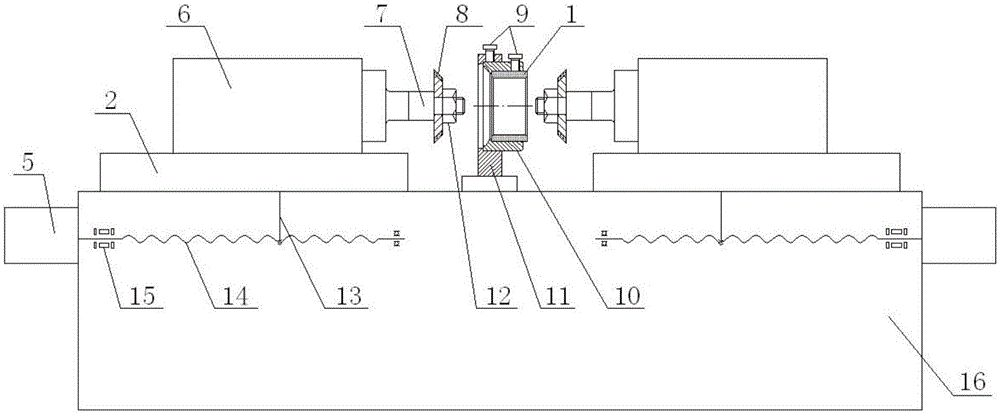

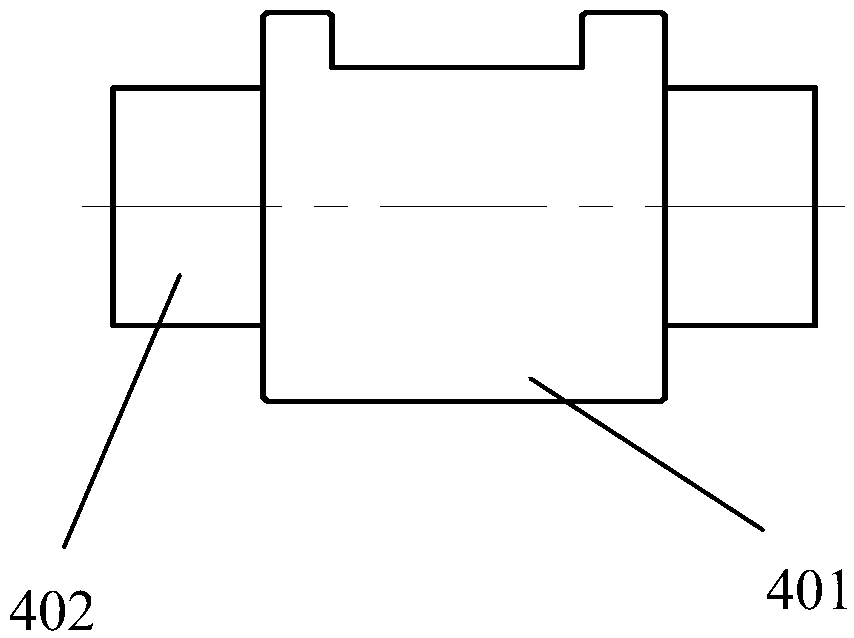

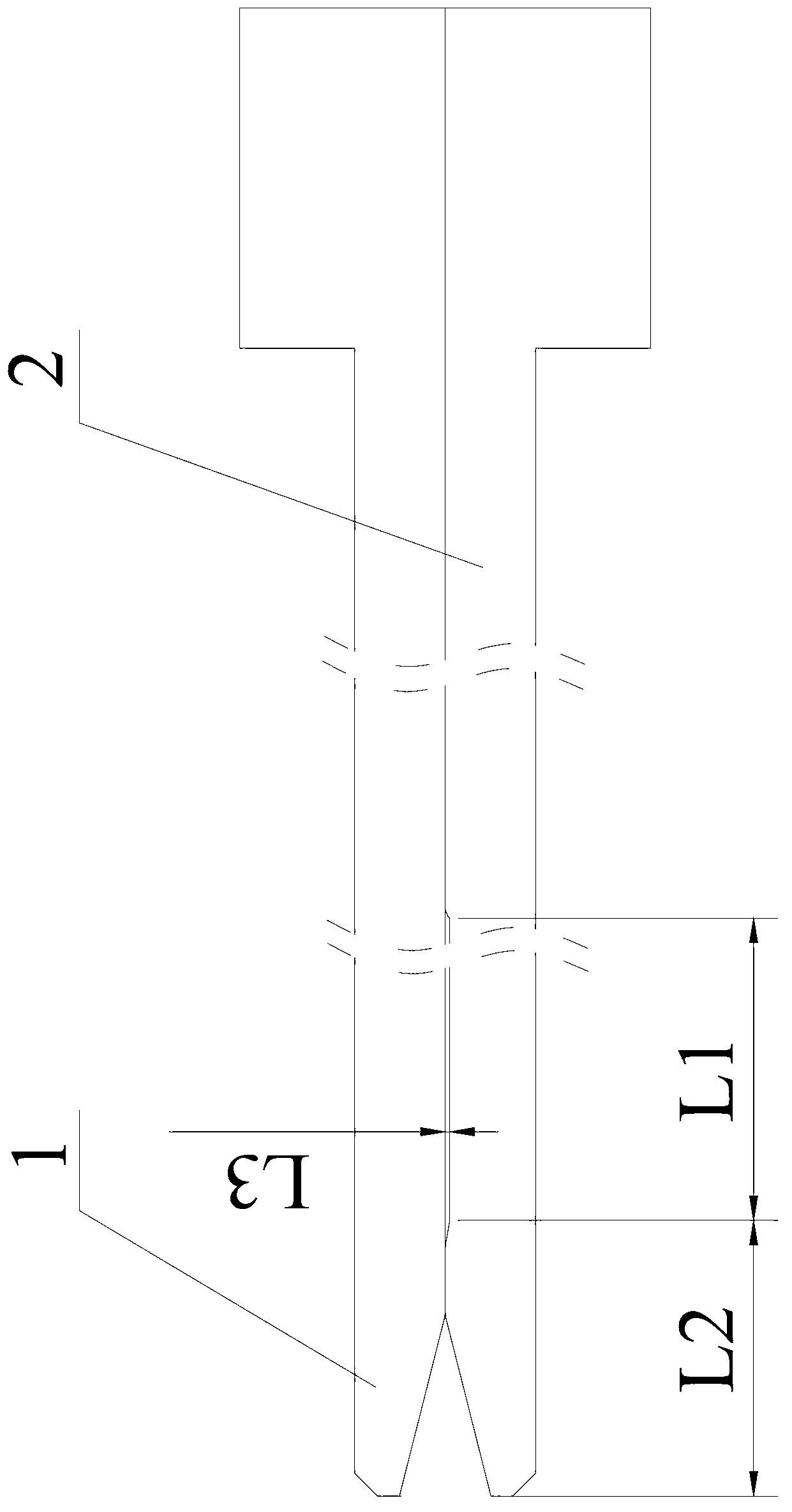

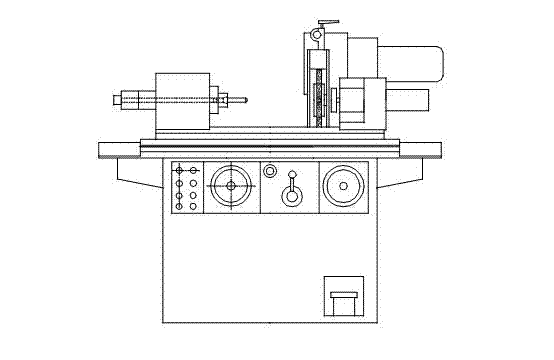

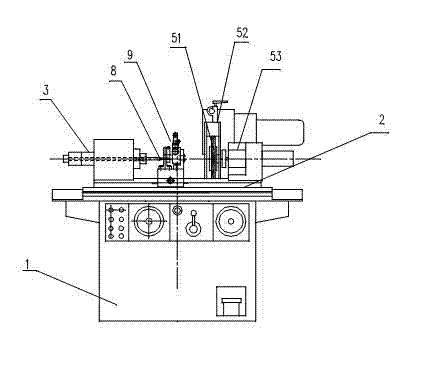

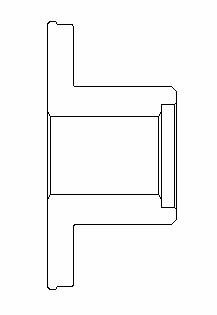

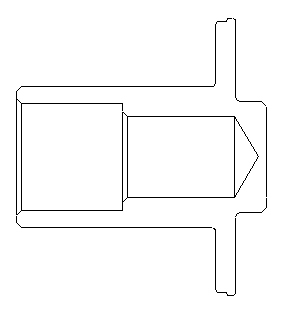

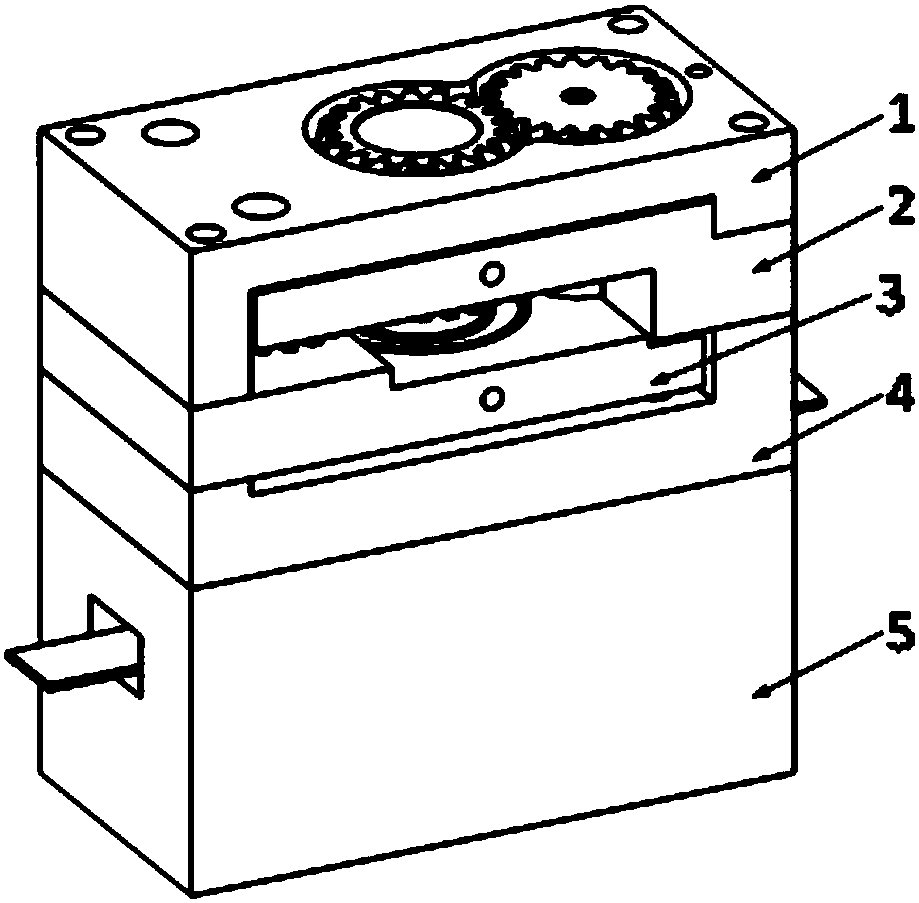

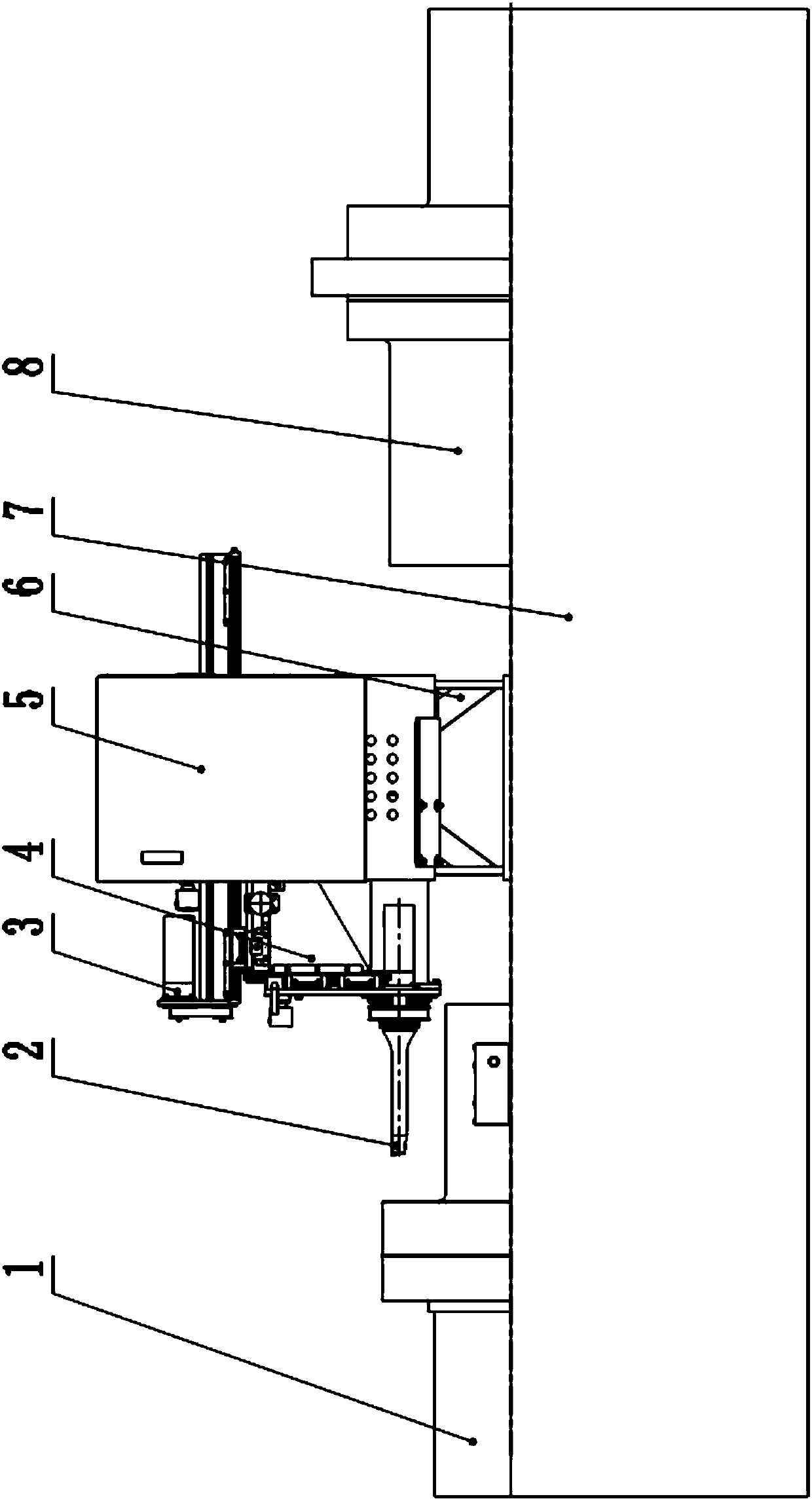

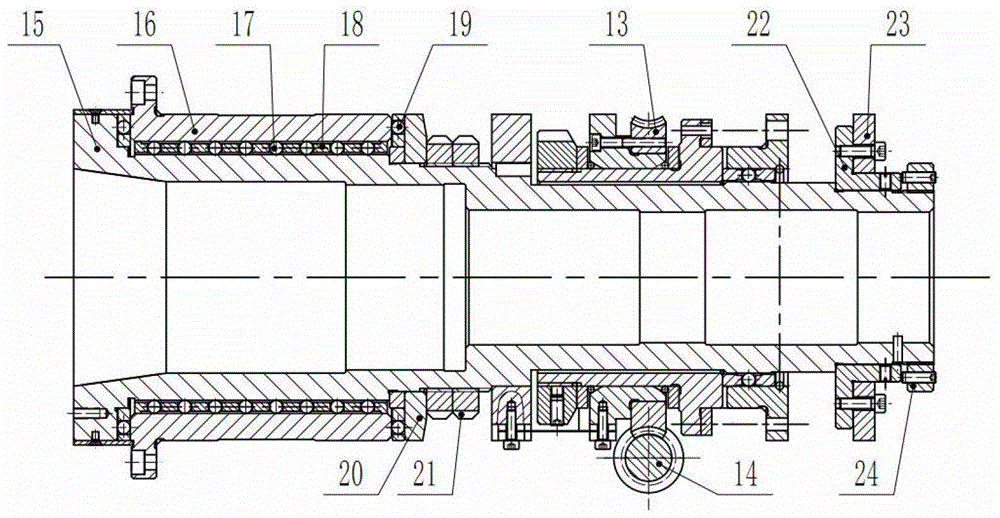

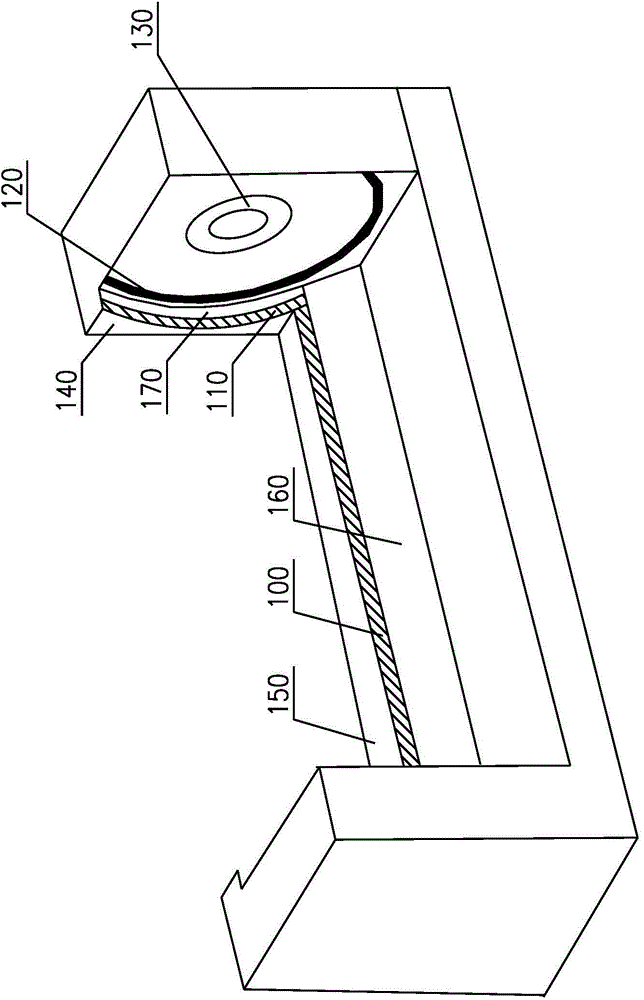

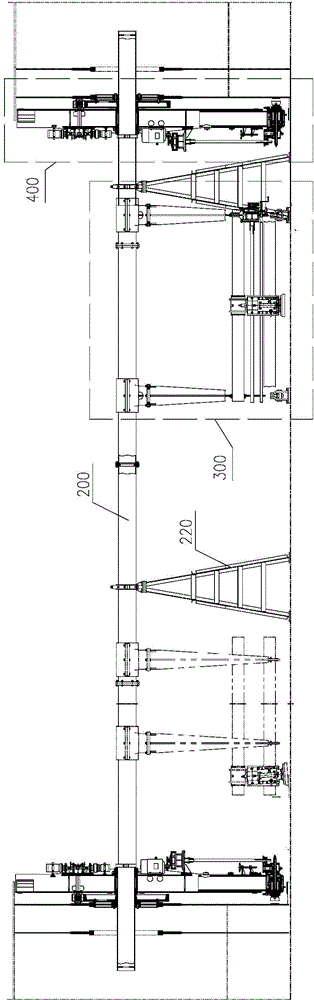

Machining grinding machine and method for taper holes

InactiveCN105058178ASatisfy the requirement of coaxialityImprove efficiencyRevolution surface grinding machinesGrinding drivesIndependent groupEngineering

The invention provides a machining grinding machine and method for taper holes. The machining grinding machine comprises feeding mechanisms, grinding mechanisms and a clamping mechanism. Two sets of independent feeding mechanisms and two sets of independent grinding mechanisms are arranged. Each group of the grinding mechanism comprises second motors and a grinding wheel. The two second motors are fixedly connected with the corresponding independent group of the feeding mechanism. Output shafts of the two motors are fixedly connected with the grinding wheels respectively. The central axes of the two grinding wheels coincide with each other and the grinding faces of the two grinding wheels are erected opposite to each other. The grinding faces of the two grinding wheels are conical surfaces which are consistent with the tapers of the taper holes to be machined. The clamping mechanism is fixedly installed on a grinding machine base and located between the two grinding wheels. According to the machining grinding machine and method for the taper holes, a forming grinding mode is adopted; only one-time clamping operation of a workpiece needs to be conducted to achieve the synchronous machining of the taper holes in the two ends of the workpiece, so that the forming machining efficiency and the machining precision of the taper holes in the workpiece are improved greatly; moreover, the coaxiality of the taper holes in the two ends of the workpiece can reach up to 0.01 so that the coaxiality requirement of the taper holes in the two ends of the workpiece can be fully met.

Owner:自贡中兴耐磨新材料有限公司

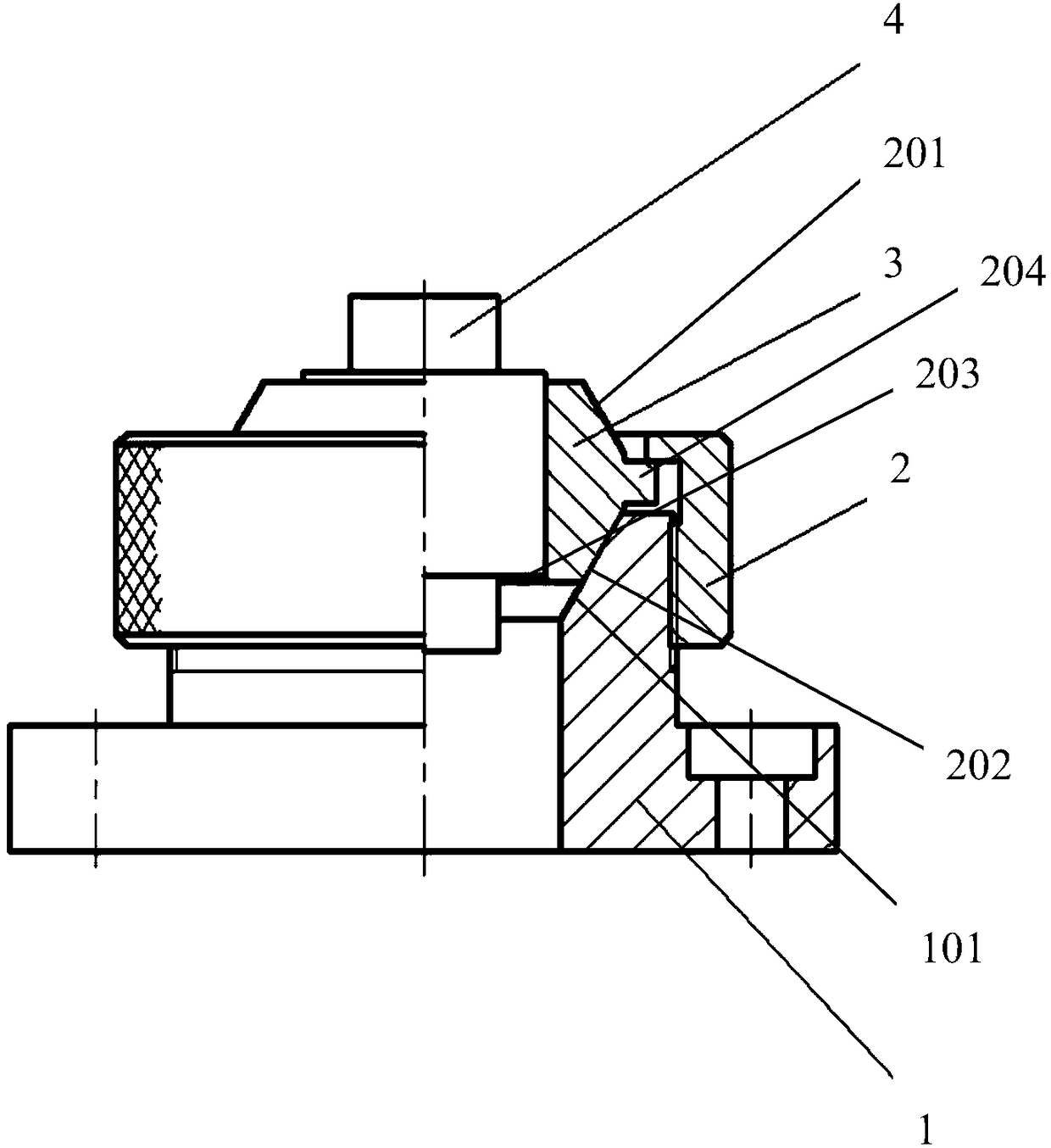

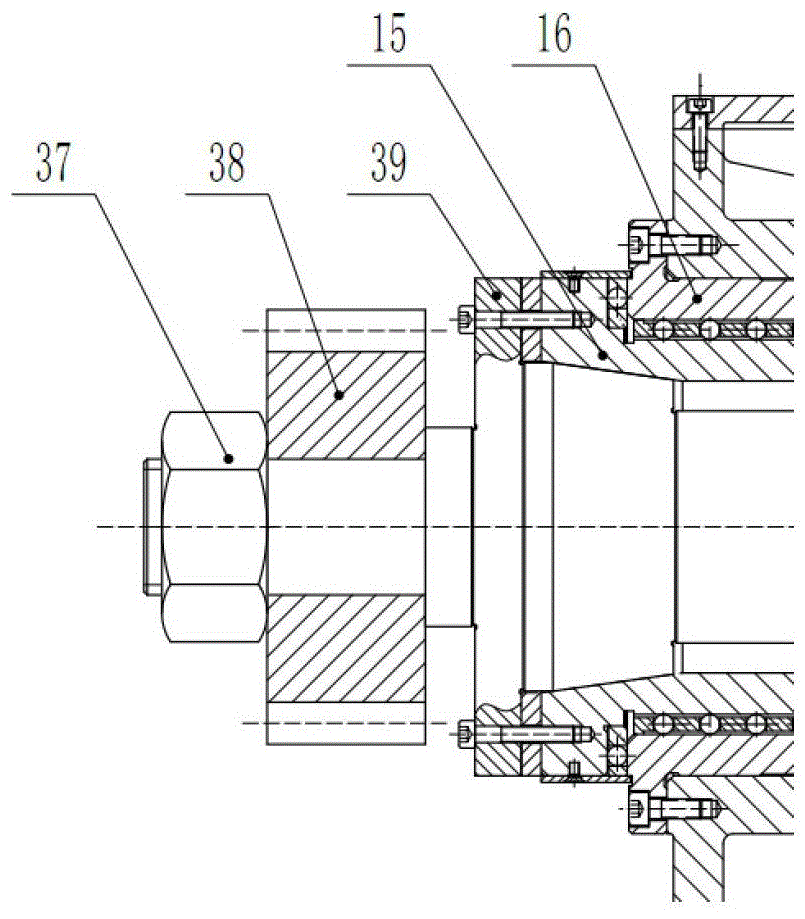

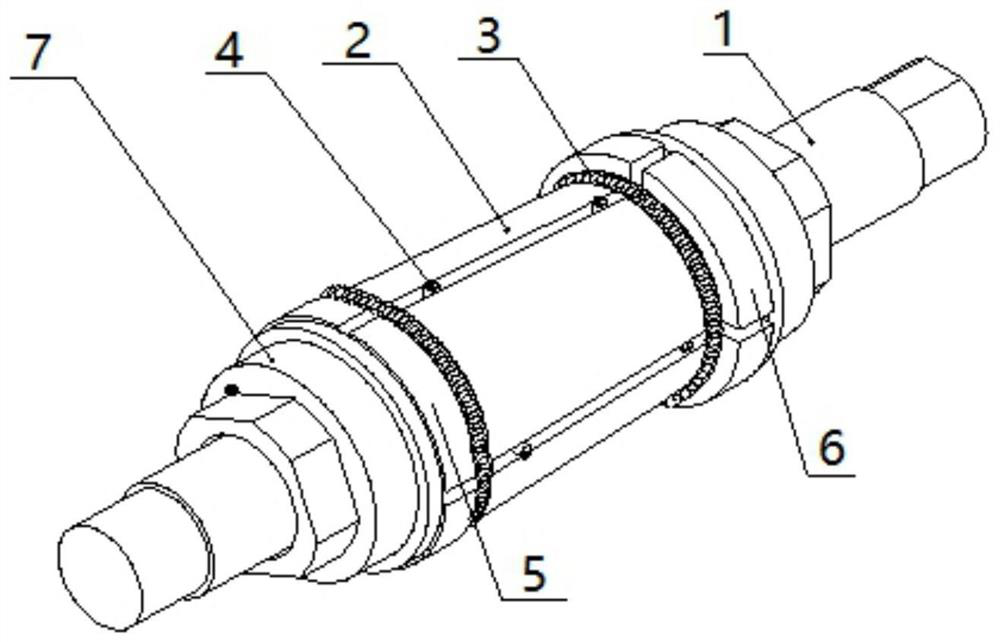

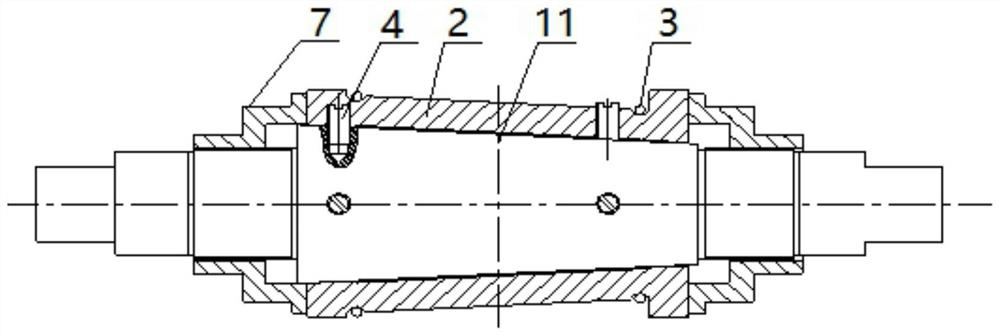

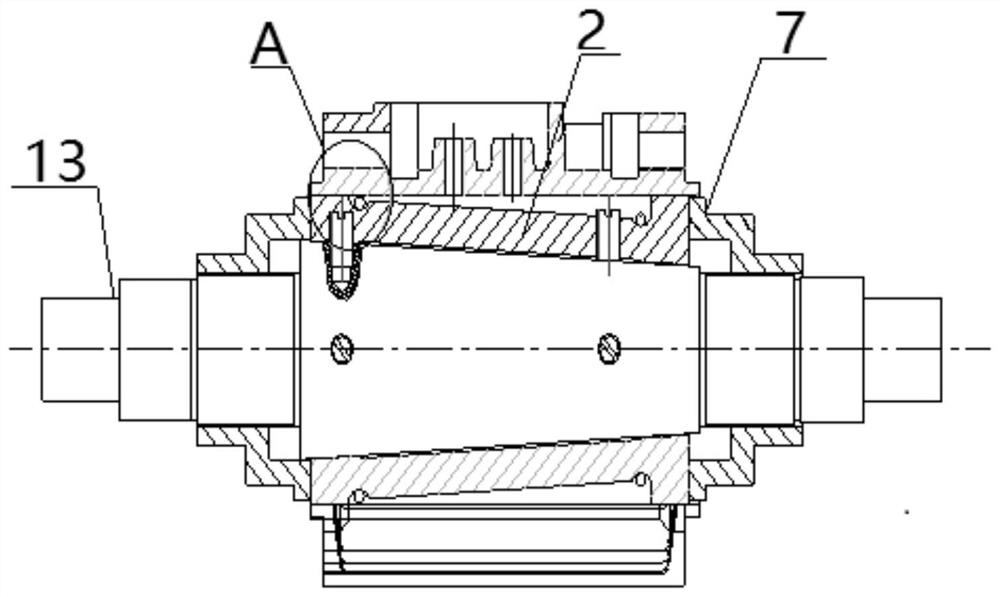

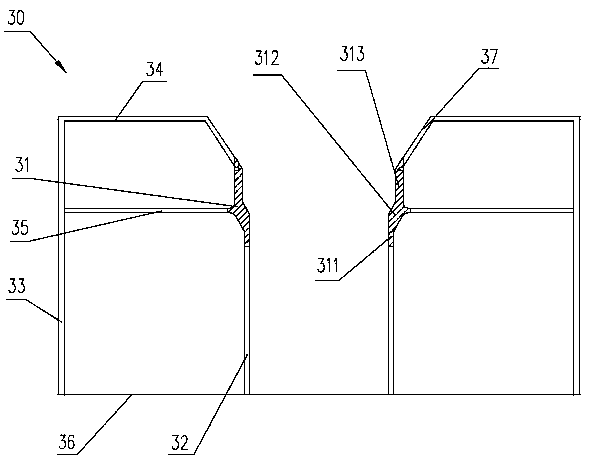

Conical surface efficient self-centering high-precision clamping device

InactiveCN109262314AEasy to assemble and disassembleGood accuracy retentionPositioning apparatusMetal-working holdersStandard samplesEngineering

The invention relates to a conical surface efficient self-centering high-precision clamping device which comprises a sleeve mandrel, a conical surface element clamp body, a locking nut and a coaxiality calibration standard sample part, wherein the inner surface of the sleeve mandrel has a conical surface; the conical surface element clamp body is disposed on the sleeve mandrel and is provided withan inner through hole, a first conical surface and a second conical surface, wherein the first conical surface and the second conical surface are disposed on the upper portion and the lower portion of the conical surface element clamp body respectively, the inclination angles of the first conical surface and the second conical surface are consistent with the inclination angle of the conical surface of the sleeve mandrel. The locking nut sleeves the conical surface element clamp body and the sleeve mandrel and is in threaded connection with the sleeve mandrel. The coaxiality calibration standard sample part is used for achieving the alignment between the sleeve mandrel and a lathe spindle. The two mandrels matched with the conical surface are utilized to perform quickly overturning for clamping, and the conical surface matching has the advantages of no radial clearance, high coaxiality and convenience in mounting and dismantling. Besides, when the cone angle is small, the centering stability is high, very large torque can be transmitted, so that the processing of characteristics of rotating bodies at the two ends of irregular parts is achieved, and the coaxiality requirements are ensured.

Owner:SHANGHAI AEROSPACE CONTROL TECH INST

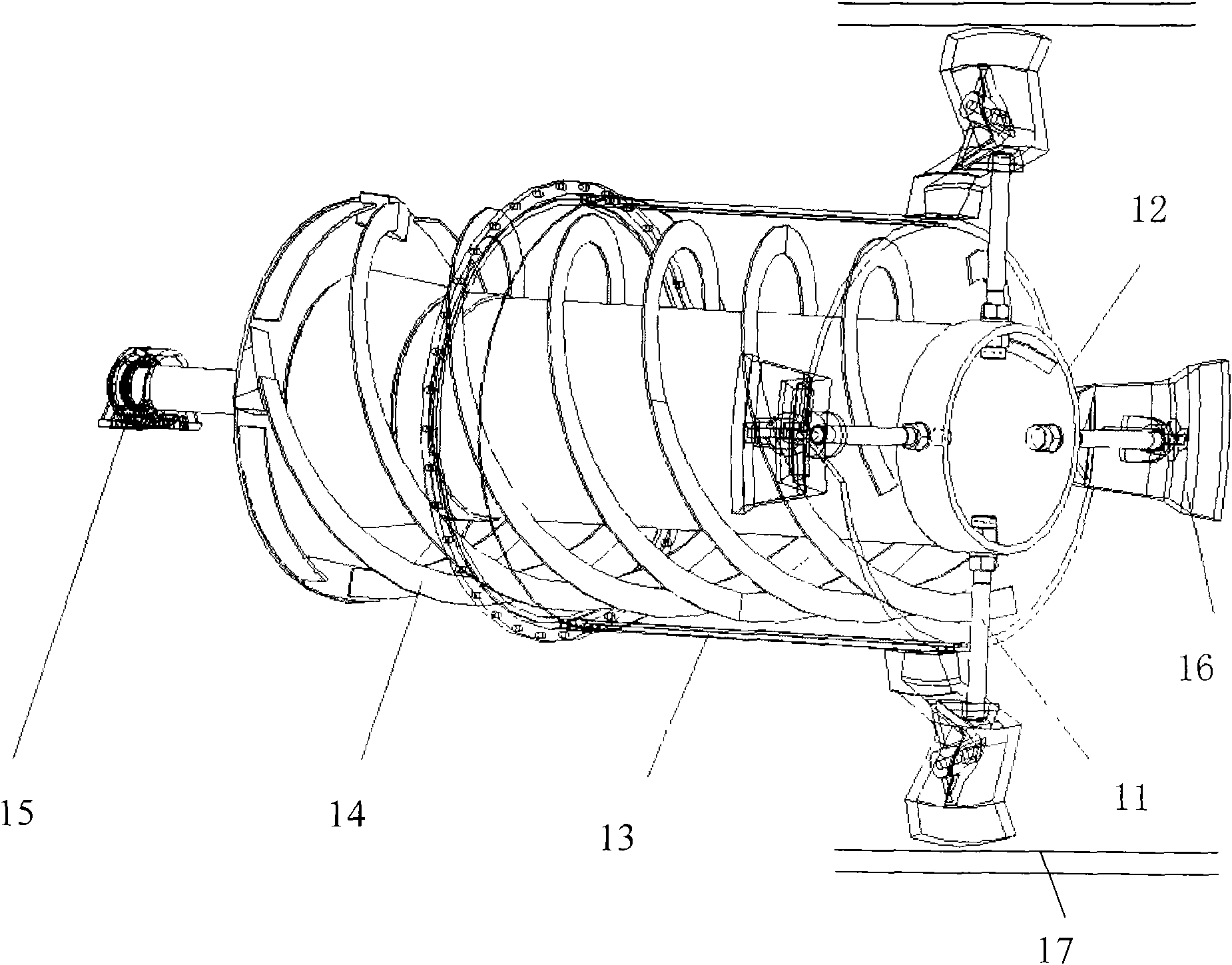

Thread-free floating type supporting bar

InactiveCN101898161AChange the state of stressStress state is simpleGrain treatmentsPropellerEngineering

The invention relates to a thread-free floating type supporting bar, in particular to a construction member used for fixing a spiral propeller onto a coal mill barrel in a BBD steel ball coal mill. The invention solves the problems that the existing supporting bar is inconvenient for maintenance, has poor strength and is easy to break and compensatory is poor. The shaft sleeve of the supporting bar main body penetrates a hole opened on the side wall of a central tube and is fixedly connected with the central tube, one end of the supporting bar main body is inserted and arranged in one end of the supporting bar main body shaft sleeve outside the central tube, a disk spring is arranged in the other end of the supporting bar main body shaft sleeve inside the central tube, one end of the supporting bar main body is connected with the disk spring by contact, and the other end of the supporting bar main body shaft sleeve is connected with a gland by a connecting piece in a dismountable way. The invention has simple and feasible mounting, can be dismounted and can be repeatedly used; clearance compensation changes the stress state of the supporting bar, thus improving the strength of the supporting bar; and different axiality compensation between the spiral propeller and the barrel optimizes the working condition of the spiral propeller.

Owner:关海龙 +1

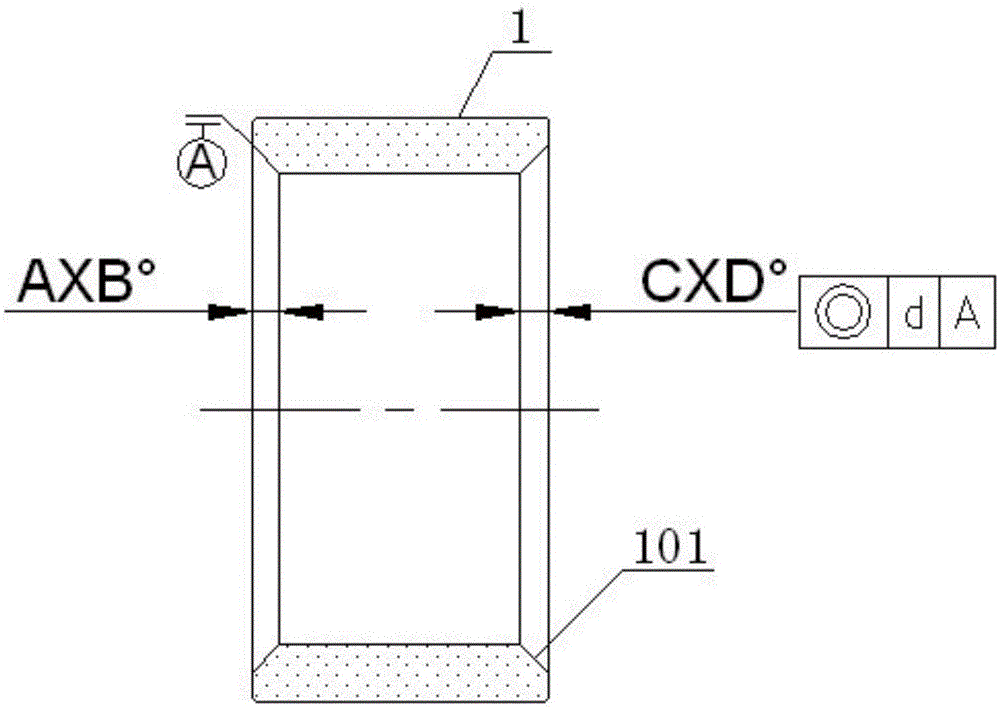

Battery winding machine and winding needle mechanism thereof

ActiveCN103296316ASatisfy the requirement of coaxialityThe pins are inserted smoothlyFinal product manufactureNon-aqueous electrolyte cellsWinding machineConductor Coil

The invention relates to the technical field of a battery winding machine, and provides a winding needle mechanism. The winding needle mechanism comprises a winding needle assembly, a needle withdraw rod assembly and a rotating sleeve, wherein the winding needle assembly comprises a first winding needle and a second winding needle; the needle withdraw rod assembly comprises a primary needle withdraw rod and a secondary needle withdraw rod, and the winding needle assembly is installed on the needle withdraw rod assembly through a positioning assembly; the needle withdraw rod assembly is sleeved and positioned inside the rotating sleeve, and the coaxial rotation of the rotating sleeve, the needle withdraw rod assembly and the winding needle assembly can be realized. The invention also provided with a battery winding machine. The winding needle mechanism and the battery winding machine can meet the concentricity requirement of relative stations of the winding needles.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

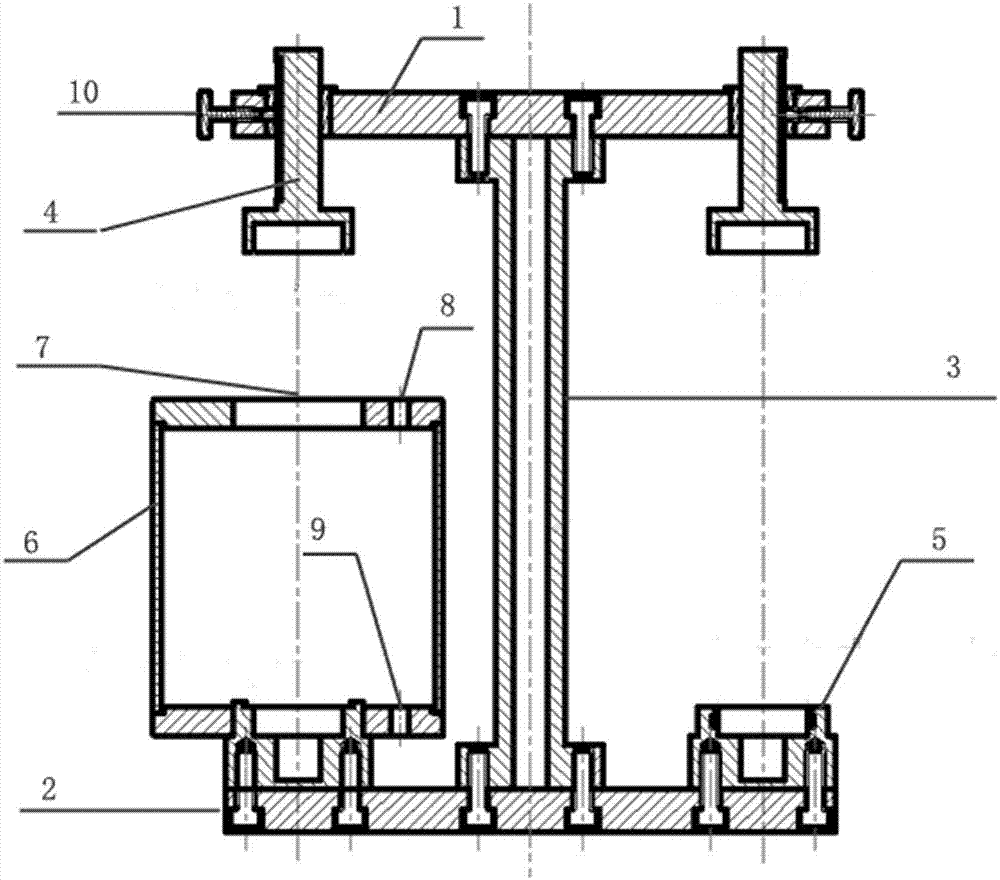

Coaxiality precise control device and method used for carrying out brazing on guide pipe in long and straight structure

ActiveCN107999924AGuaranteed weld qualityVersatileWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBrazing

The invention provides a coaxiality precise control device and method used for carrying out brazing on a guide pipe in a long and straight structure. The device comprises an upper installing plate anda lower installing plate. The upper installing plate and the lower installing plate are connected through a supporting column. Locating pins are arranged at the two ends of the upper installing platerespectively. Locating bases opposite to the locating pins are arranged at the two ends of the lower installing plate respectively, wherein the locating bases share the same central axis. The controldevice further comprises an argon protection bin which is fixedly installed on one locating base. A guide pipe installing opening of the argon protection bin and the locating base on which the argonprotection bin is located share the same central axis. The method comprises the three steps that the first to-be-brazed guide pipe in the long and straight structure is installed between the locatingbase with the argon protection bin and the corresponding locating pin, and the to-be-brazed portion is totally arranged in the argon protection bin; argon is introduced, and brazing is started; afterbrazing on the first pipeline is finished, in-situ cooling is carried out, the argon protection bin is moved to the other locating base, and the brazing process of the second to-be-brazed guide pipe in the long and straight structure is started.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

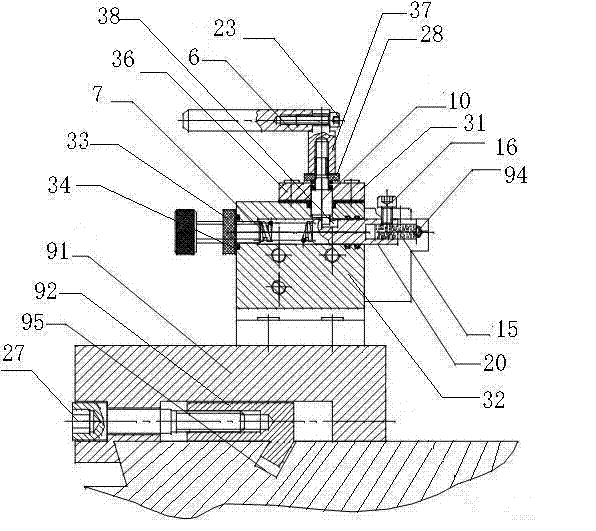

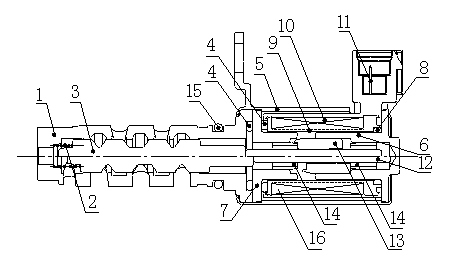

A cylindrical grinder

ActiveCN102267071AImprove machining accuracyImprove coaxialityRevolution surface grinding machinesCylindrical grindingMachining process

The invention relates to an improved cylindrical grinding machine. The cylindrical grinding machine comprises a machine body and a working sliding table being placed on the machine body and being capable of horizontally sliding relative to the machine body, wherein a clamping device of a machined workpiece is fixed at one end of the working sliding table; a grinding device for cutting and grinding the machined workpiece is arranged at the other end of the working sliding table; between the clamping device and the grinding device, a supporting device of the machined workpiece is arranged at a position having a preset distance from the grinding; the supporting device is fixed on the horizontal sliding table; and by using the supporting device, an edge part of the machined workpiece jumps within a reasonable range relative to a handle part in the machining process so that the edge part and the handle part of the workpiece are always kept with good coaxiality to improve the machining accuracy of the workpiece.

Owner:ZHEJIANG DEWEI CEMENTED CARBIDE MFG CO LTD

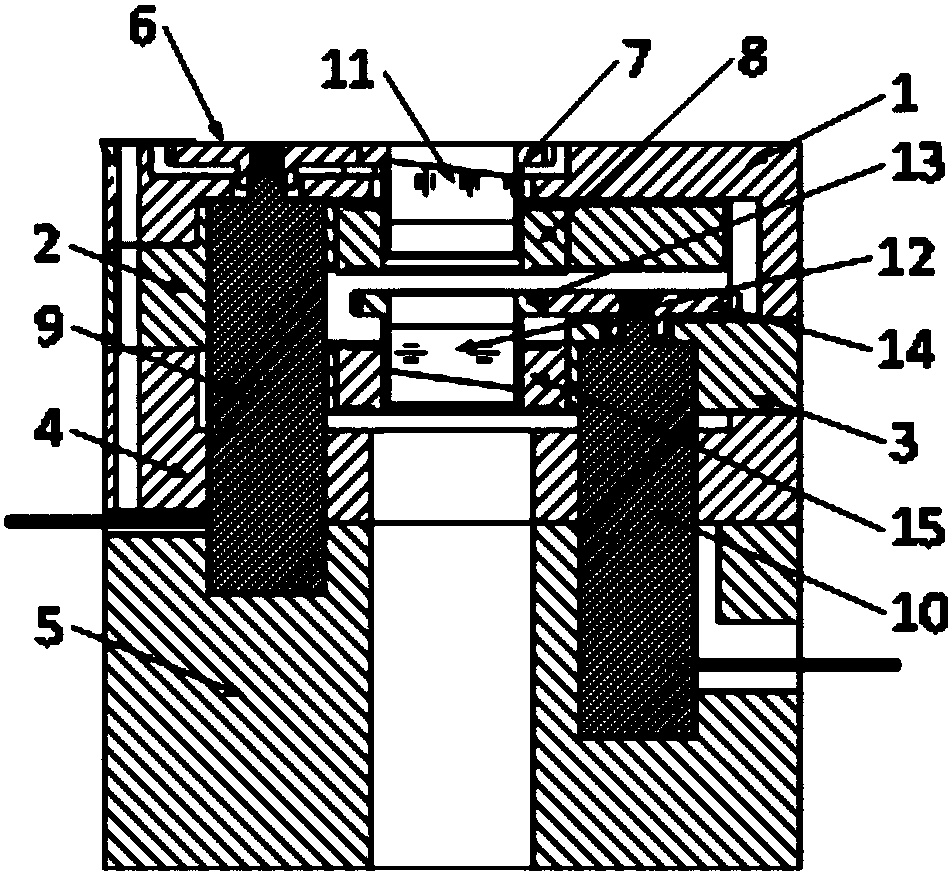

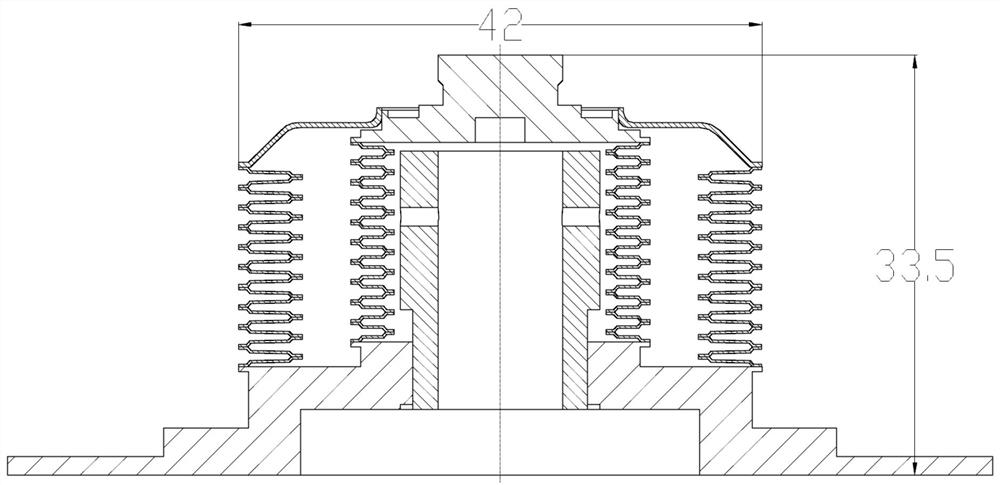

Integrally molded continuous variable valve timing fuel control valve

InactiveCN102052115AReduce manufacturing costSimple structureOperating means/releasing devices for valvesMachines/enginesWind componentVariable valve timing

The invention discloses an integrally molded continuous variable valve timing fuel control valve, which comprises a valve sleeve component, a rear yoke iron component, a front yoke iron component, an iron core component, an outer yoke sleeve bracket (5), and a winding component (16) consisting of a frame (9), an enameled wire (10) and a plug plate (11), wherein the valve sleeve component consists of a valve sleeve (1), a return spring (2), a valve core (3) and a front ring (4); the rear yoke iron component is formed by riveting rear yoke iron (6) and a guide sleeve (14); the front yoke iron component is formed by riveting the front yoke iron (7) and the guide sleeve (14); and the iron core component is formed by riveting a shaft (12) and an iron core (13). The integrally molded continuous variable valve timing fuel control valve has the advantages that: the control valve meets the requirement of the iron core component on coaxility, the manufacturing cost of the fuel control valve is reduced, the structure of the control valve is simplified, the performance of the control valve is more stable, sand the installation requirements of various complicatedly shaped engines can be met.

Owner:成都恒高机械电子有限公司

Method for reaming on latch lock connectors of airplane cargo space

The invention discloses a method for reaming on latch lock connectors of an airplane cargo space. The method includes that: an airplane cargo space door to be processed is clamped onto a frame, and an initial positioning pin (8) is used for positioning latch lock connector initial holes before reaming; appropriate reamers (7) are selected according to the size of the latch lock connector initial holes; the initial step positioning pin (8) of the latch lock connectors (6) is demounted and replaced by the reamers, and the latch lock connector initial holes are subjected to reaming processing with the rotating speed to be 2000r / min; the finish machining reamers (7) are sequentially replaced for at least one time, the latch lock connectors (6) are subjected to graded reaming processing with the rotating speed to be 2000r / min, and when the reamers (7) are needed to be replaced, a pneumatic drill is firstly demounted from an operation space formed among the latch lock connectors (6) and then the reamers (7) are taken out; a molded step positioning pin is used for positioning latch lock connector molded holes which are already subjected to finish machining; and other latch lock connectors (6) which are not processed are processed. The method is low in manufacture cost.

Owner:AVIC CHENGFEI COMML AIRCRAFT COMPANY

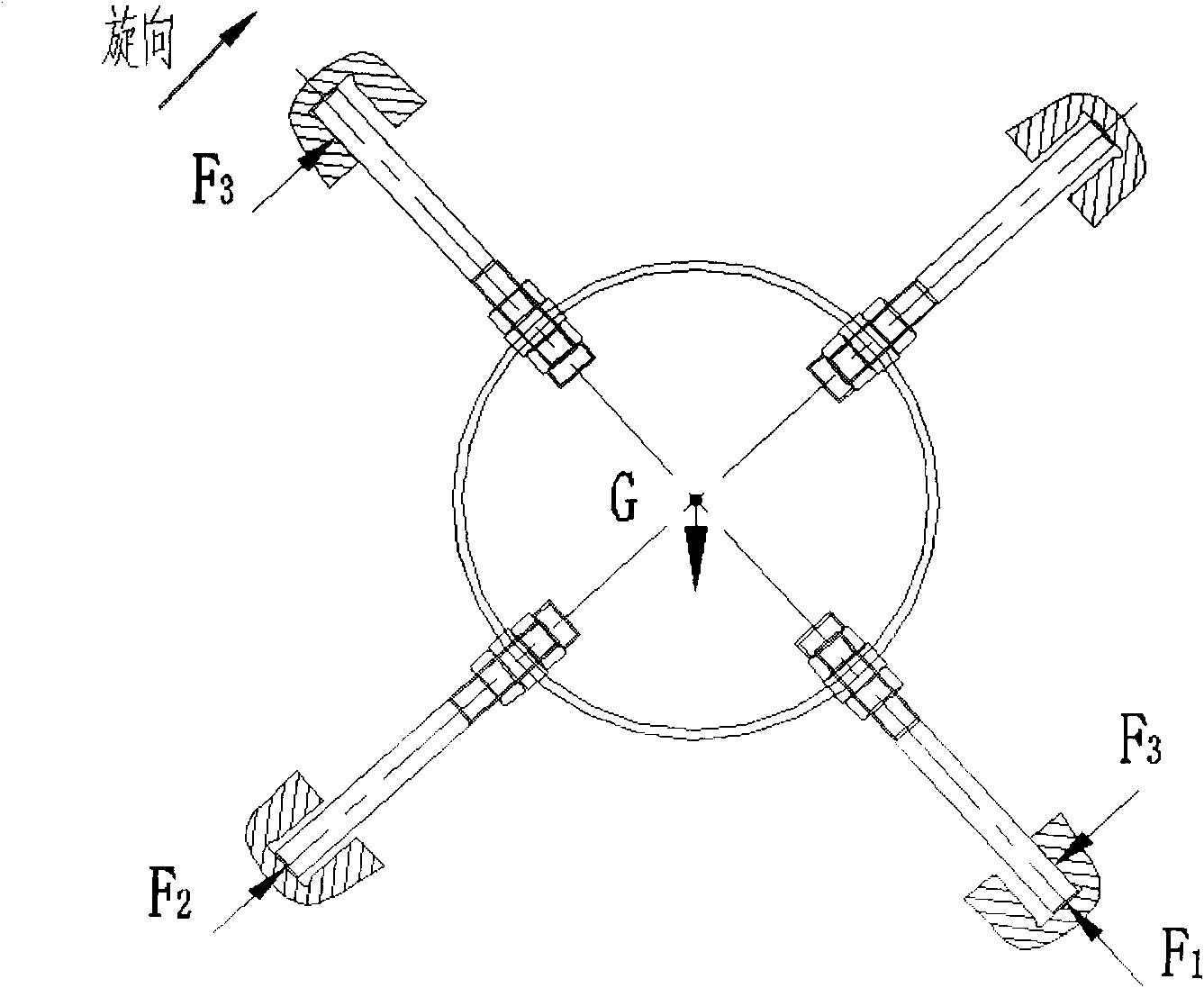

Impeller pull rod machining method

ActiveCN104259754ASatisfy the requirement of coaxialityGuaranteed accuracy level requirementsImpellerEngineering

The invention belongs to the field of machining, and particularly relates to an impeller pull rod machining method. The impeller pull rod machining method is characterized by including: subjecting to a blank to thermal treating and tempering; roughly turning outer circles and end faces of a positioning end; roughly turning outer circles and end faces of a pressing end; performing ultrasonic flow detection; grinding the outer circles of each grade and positioning the two end faces of each outer circle; tapping an inner thread hole and a chamfer of the pressing end; finely turning outer threads at two ends; milling flat potential; bench workers deburring and inspecting the external threads especially at the position of the flat potential; performing surface penetrant inspection and comprehensive inspection. With the impeller pull rod machining method, coaxiality of the outer circle and thread as well as thread accuracy requirements on the external thread is guaranteed, and yield of impeller rods reaches up to 100%.

Owner:CHONGQING JIANGJIN SHIPBUILDING IND

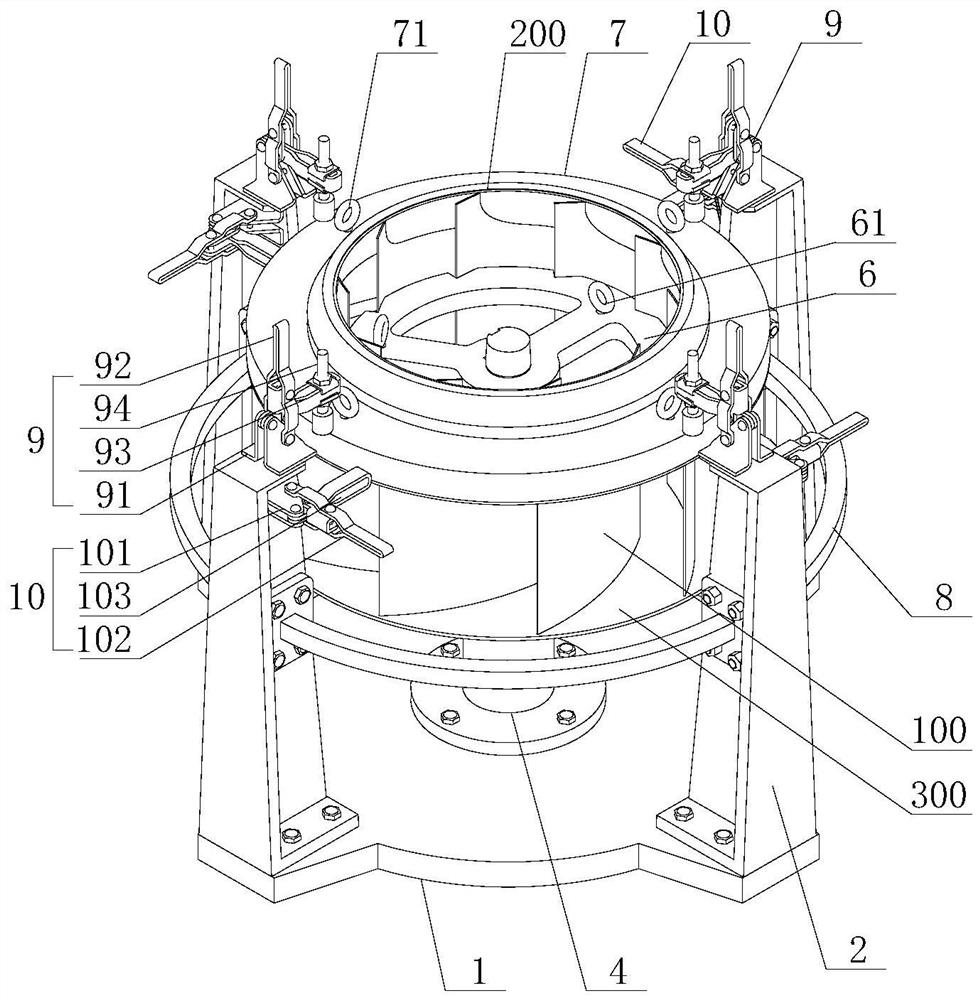

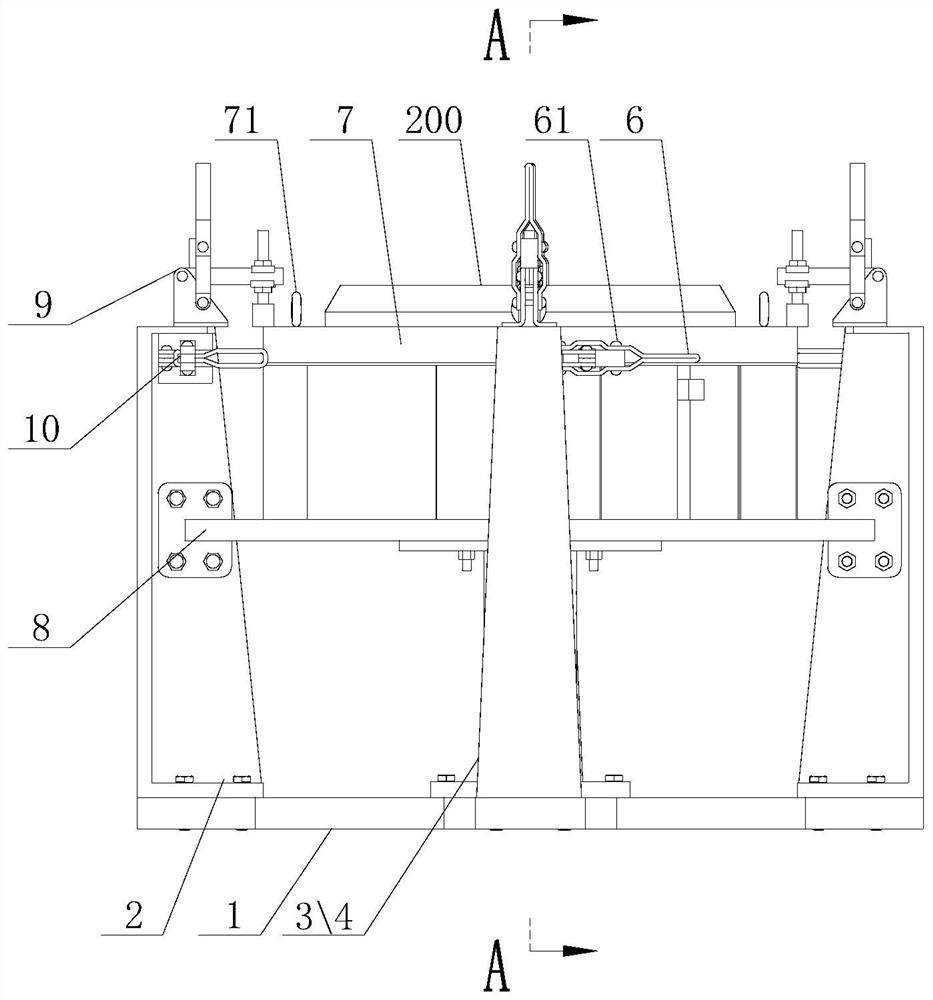

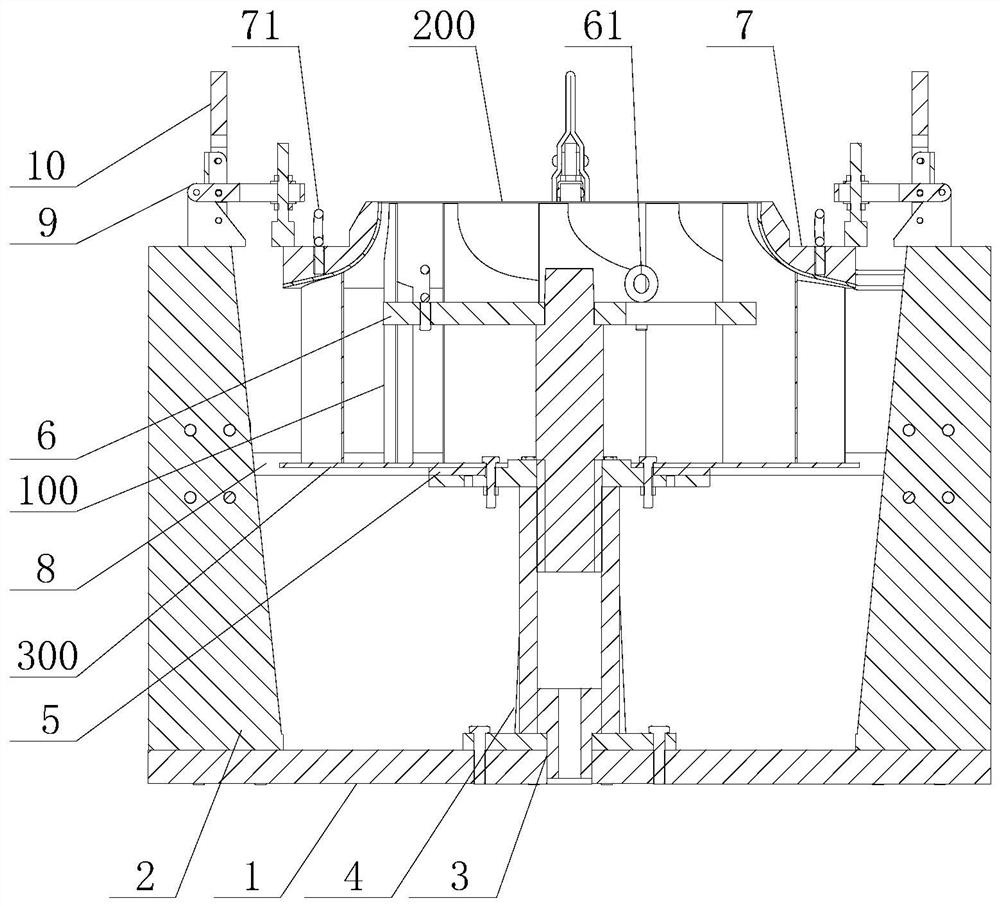

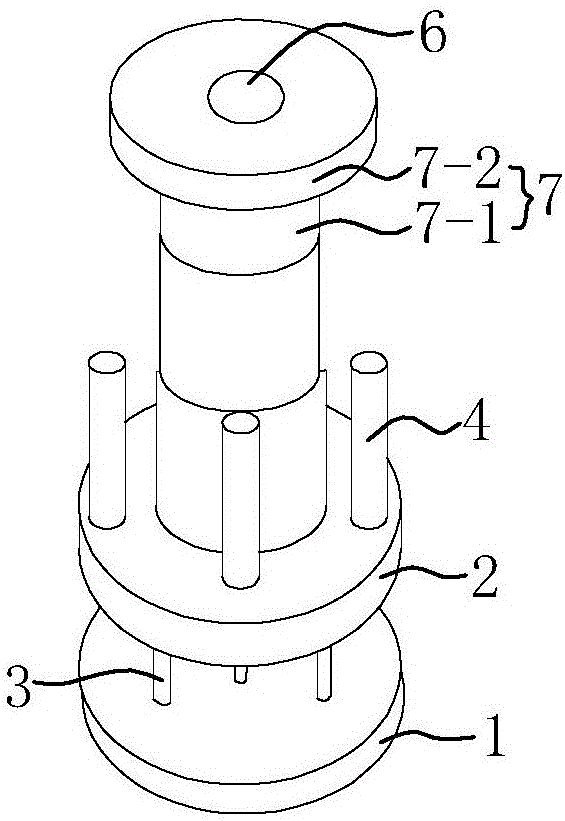

Welding positioning clamp for double-air-inlet impeller and positioning method of welding positioning clamp

InactiveCN113458694AImprove welding qualitySatisfy the requirement of coaxialityWelding/cutting auxillary devicesAuxillary welding devicesImpellerEngineering

The invention belongs to the technical field of fan impeller welding, and particularly discloses a welding positioning clamp for a double-air-inlet impeller. The welding positioning clamp comprises a bottom plate, a plurality of upright posts fixed to the edge of the bottom plate, and a central shaft fixed to the central position of the bottom plate, wherein a shaft support, a gasket used for accommodating a middle disc, an index plate used for accommodating blades and a pressing ring are sequentially and fixedly installed on the center shaft from bottom to top; and a locking mechanism used for limiting the position of the pressing ring and capable of pressing the pressing ring is arranged at the top of the stand column. All clamp body parts of the double-air-inlet impeller welding clamp are detachably installed on the impeller welding clamp, so that high fault tolerance in use is achieved, high-precision positioning welding of a to-be-machined double-air-inlet impeller is achieved with the bottom plate as a first positioning reference and the pressing ring as a second positioning reference, the machining efficiency is improved; the welding quality and the welding efficiency of the blades, a front disc and the middle disc are improved, and the stability of subsequent use of the double-air-inlet impeller is enhanced.

Owner:GUANGDONG ZHAOQING DETON

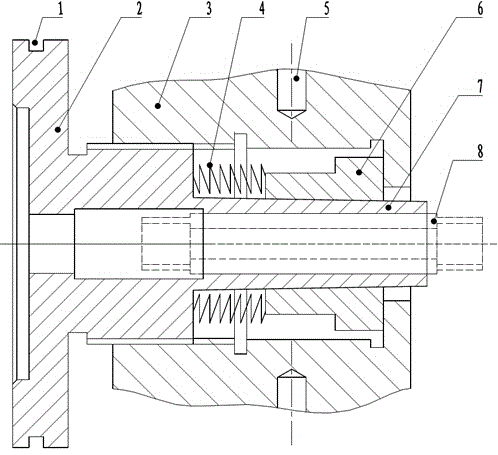

Screw sleeve part inner hole processing lathe clamp

ActiveCN104647101AGuaranteed reliabilityGuarantee processing qualityPositioning apparatusMetal-working holdersBarrel ShapedBody positions

The invention discloses a screw sleeve part inner hole processing lathe clamp, which comprises a clamp body, a screw nut, a cone sleeve and a reset spring, wherein a clamp body positioned by a notch is arranged on a lathe main shaft through a transition disc, the front end of the clamp body is a barrel-shaped thin wall with the external taper, in addition, the outer diameter of the back end of the thin wall is greater than the outer diameter of the front end, the inner diameter of the thin wall is matched with the outer diameter of a screw sleeve to be processed, the cone sleeve with the internal taper matched with the external taper of the thin wall is arranged on the outer side of the thin wall in a sleeving way, the reset spring is arranged at the thin wall part in a sleeving way and is positioned between a cone sleeve and a threaded step positioned at the back part of the clamp body, and the screw nut passes through the thin wall and the cone sleeve and is connected with the clamp body through screw threads. The screw sleeve part inner hole processing lathe clamp has the advantages that the structure is compact, the operation is simple, convenient and reliable, the positioning precision is very high, the processing quality can be easily ensured, and higher practicability is realized.

Owner:南京力全科技有限公司

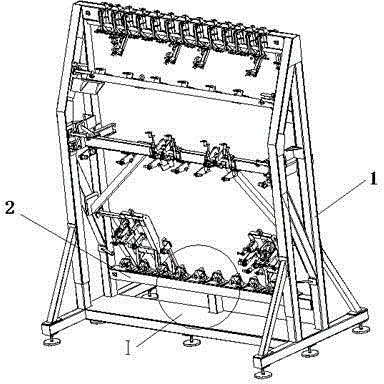

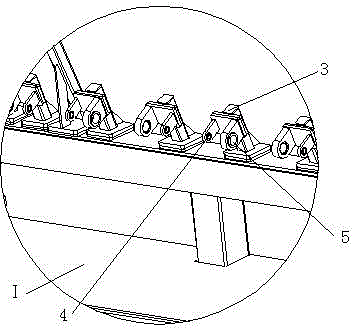

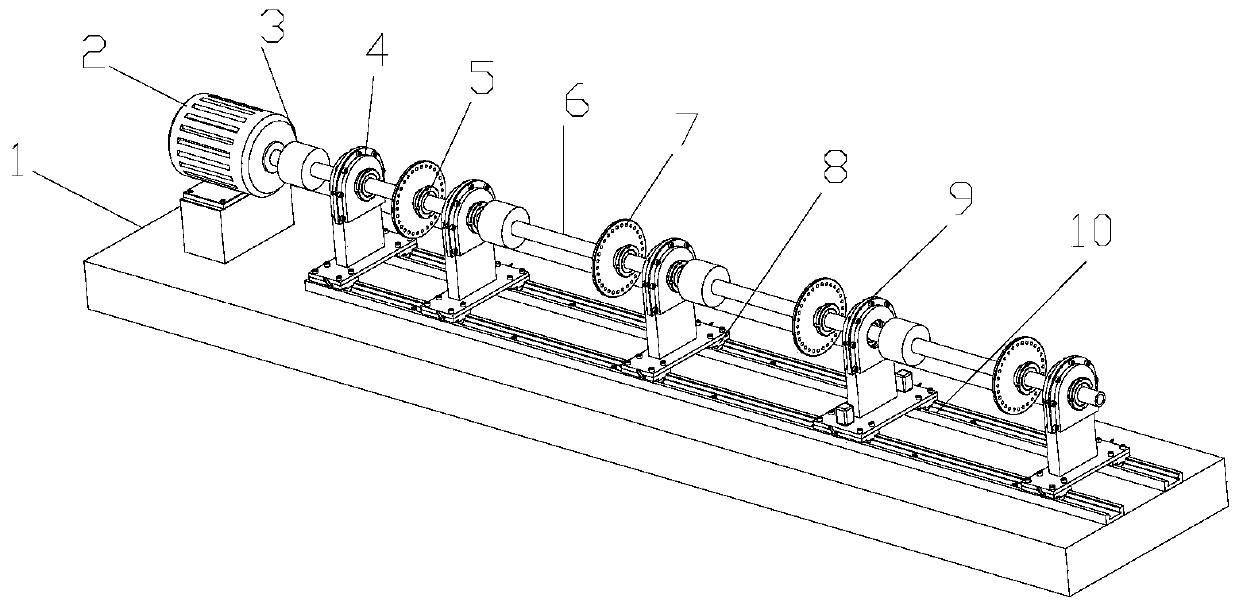

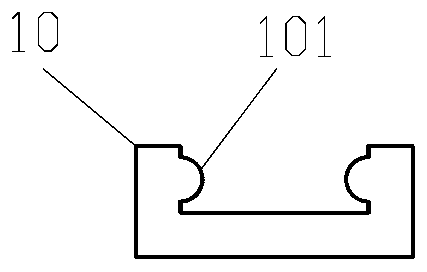

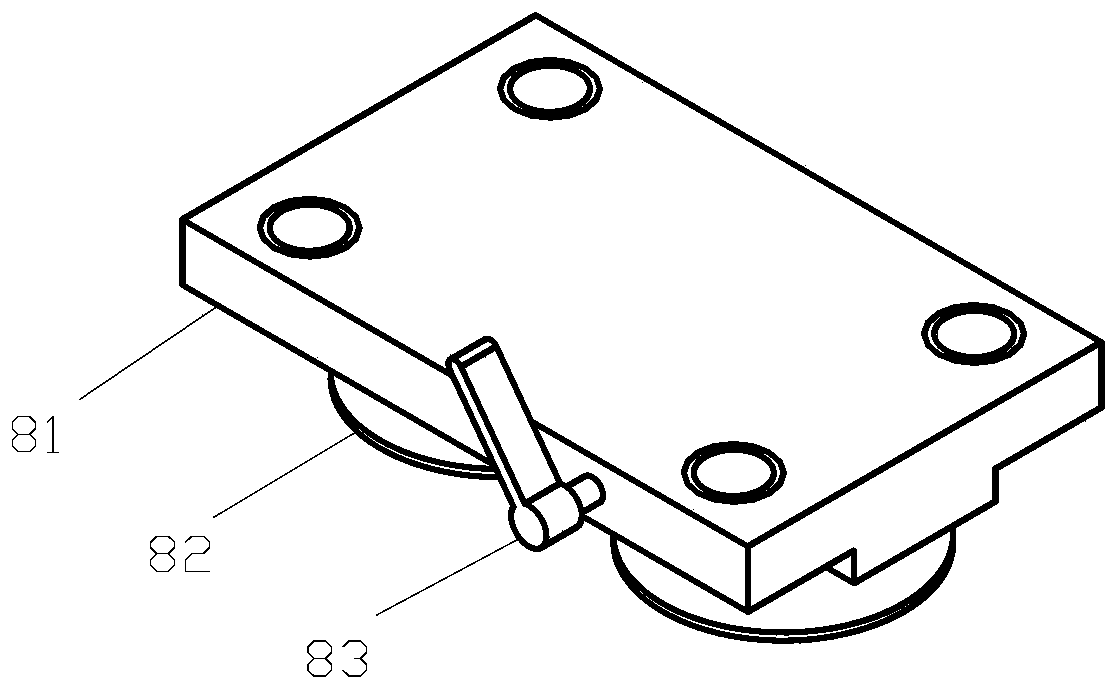

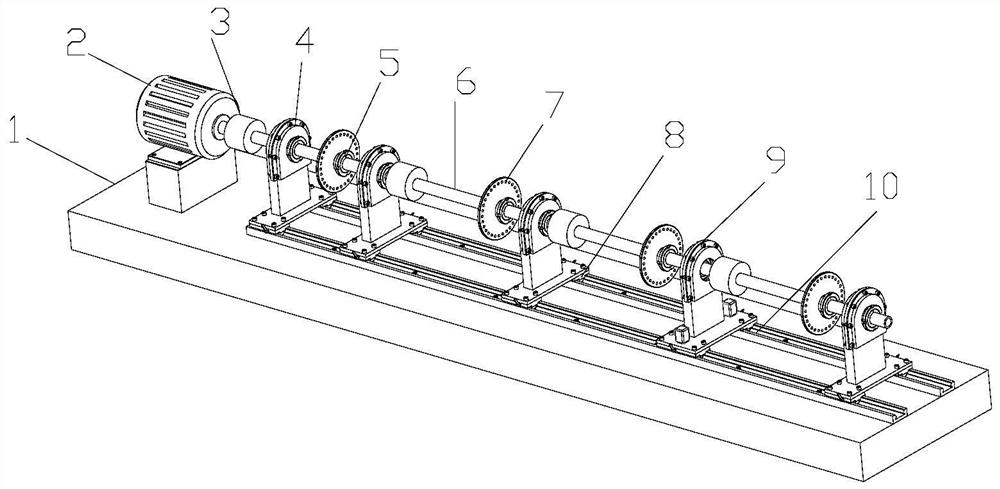

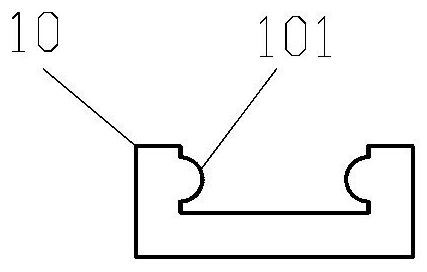

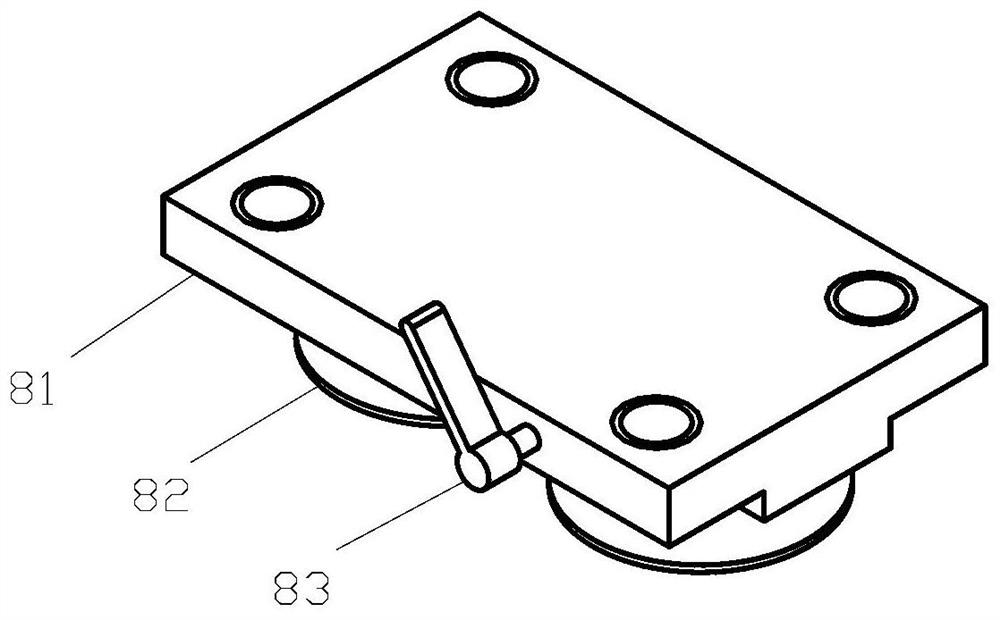

Multi-span rotor test bench with adjustable shaft sections and supports

ActiveCN109774968AEasy to changeTest accuracy is easy to guaranteeAircraft components testingCircular discExperimental research

The invention discloses a multi-span rotor test bench with adjustable shaft sections and supports. The bench comprises a drive motor, a drive shaft module, a sliding groove guide positioning module, amovable support module and a self-centering disc rotor module which are arranged on a base; the drive shaft module includes a plurality of drive shafts and a coupling, and the sliding groove guide positioning module includes a sliding block assembly sliding along a linear guide rail; the movable support module includes a self-centering sleeve in corresponding connection with the sliding block assembly through a support assembly, and the self-centering sleeve achieves locking fixing with the drive shafts by a locking assembly; the self-centering disc rotor module includes a counterweight discwhich is locked fixedly with the drive shafts by a locking assembly. The bench has the advantages of simple structure, convenient operation and reliable test, can effectively ensure high coaxiality between the shaft sections, carries out experimental researches of variable support position, variable shaft section length, variable shaft section outer diameter and the like, provides a practical andefficient rotor test system and greatly accelerates the research process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

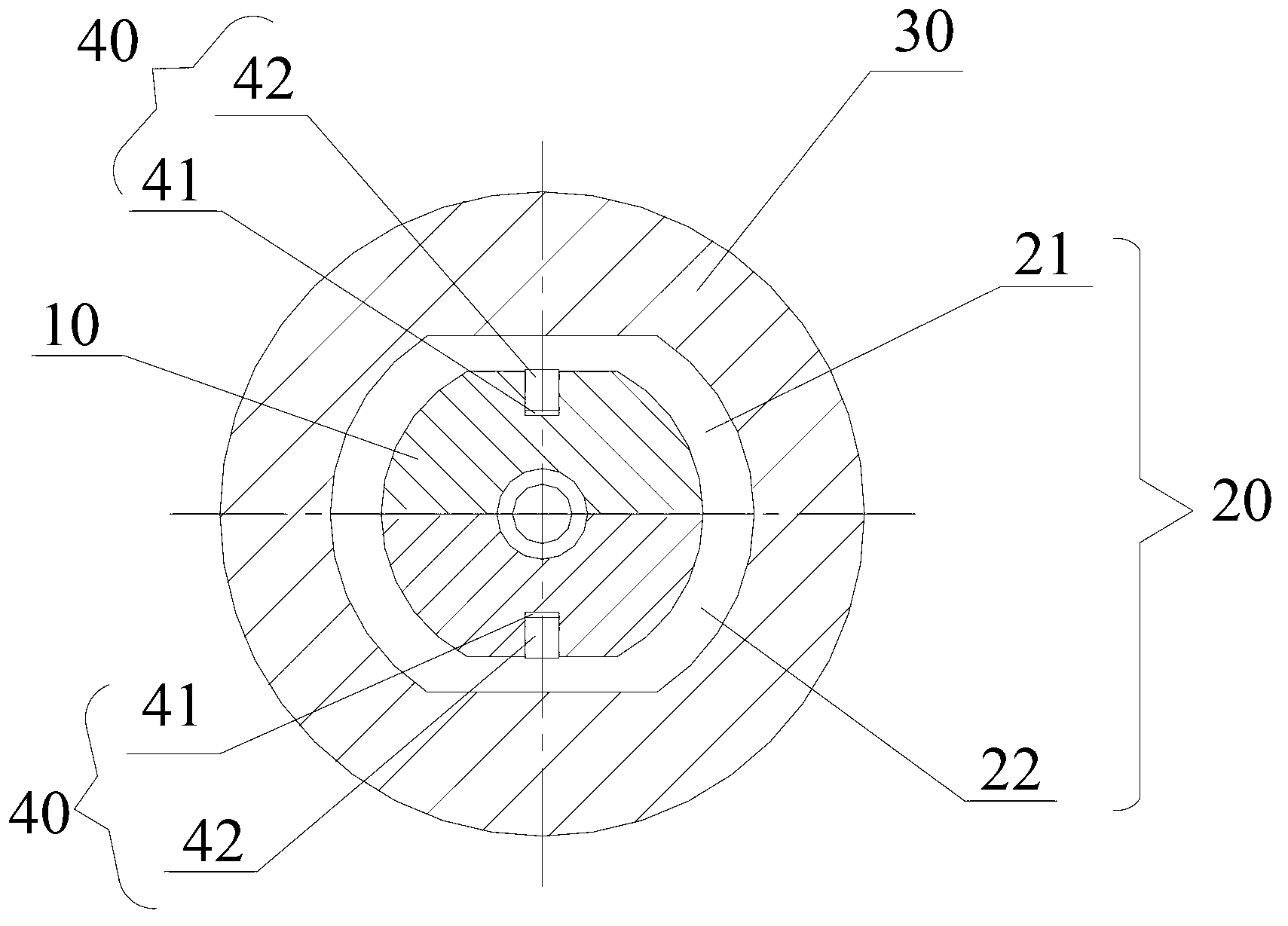

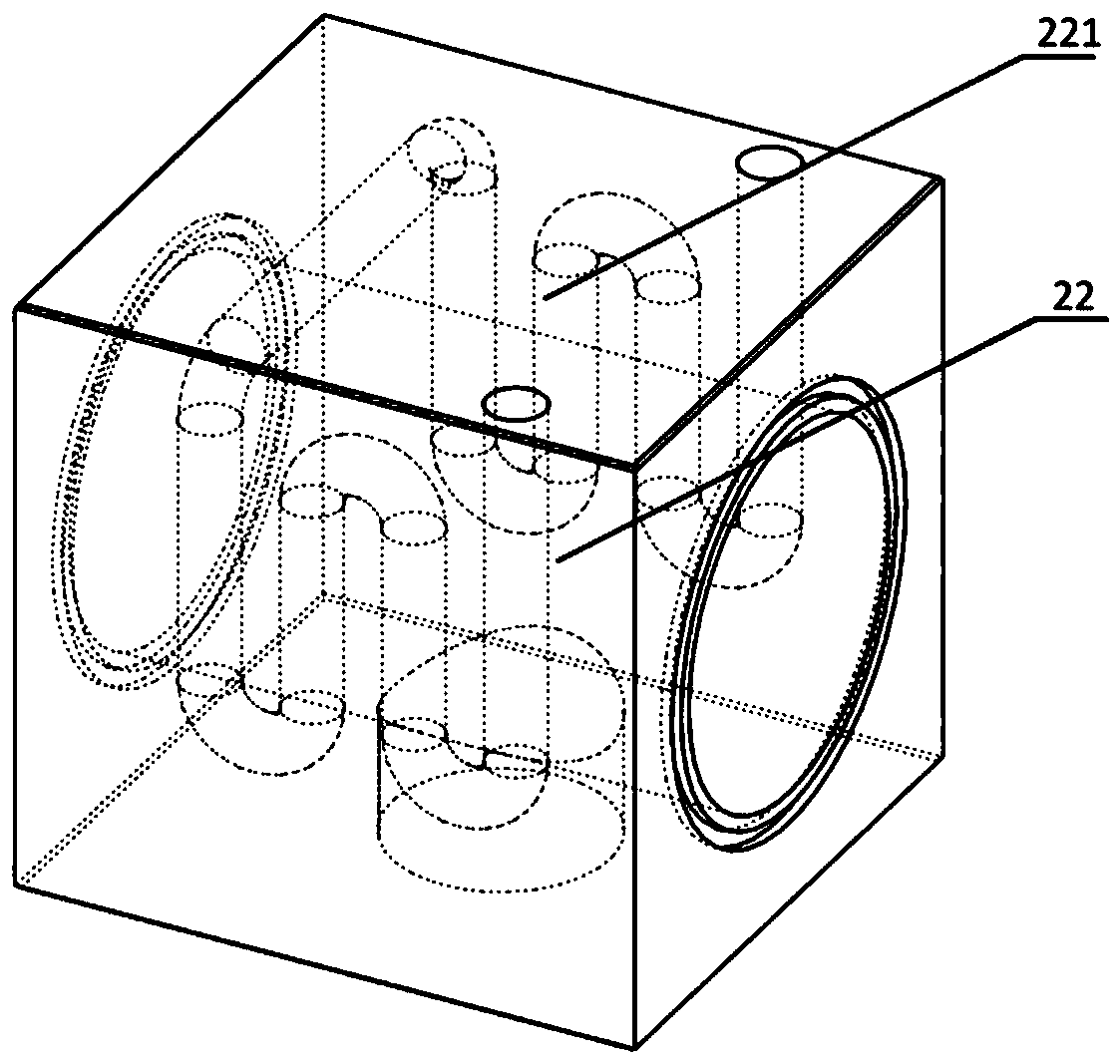

Laser cladding device based on 3D printing and spraying nozzle of laser cladding device

PendingCN110923706ASimplify the installation processSatisfy the requirement of coaxialityAdditive manufacturing apparatusMetallic material coating processesSpray nozzleEngineering

The invention provides a laser cladding device based on 3D printing and a spraying nozzle of the laser cladding device. The laser cladding device comprises a collimator, a focusing reflecting structure, a protecting structure, an adjusting structure and the spraying nozzle, wherein the collimator is coaxially connected with the incidence light path direction of the focusing reflecting structure; the focusing reflecting structure is coaxially connected with protecting structure in the emitting light path direction; and the protecting structure, the adjusting structure and the spraying nozzle are mutually coaxial from top to bottom and are coaxially connected in a sealed mode through screws. The spraying nozzle comprises a powder flow channel, a cooling structure and an air path structure, and the powder flow channel, the cooling structure and the air path structure do not communicate with one another and are integrally formed with a metal 3D printing technology. Machining and installation of the cladding device and the spraying nozzle are simplified, the cooling area of the spraying nozzle is effectively increased, the later-stage machining treatment can be performed on the integrated spraying nozzle, and workpiece oxidization of the cladding process is reduced.

Owner:SOUTH CHINA UNIV OF TECH

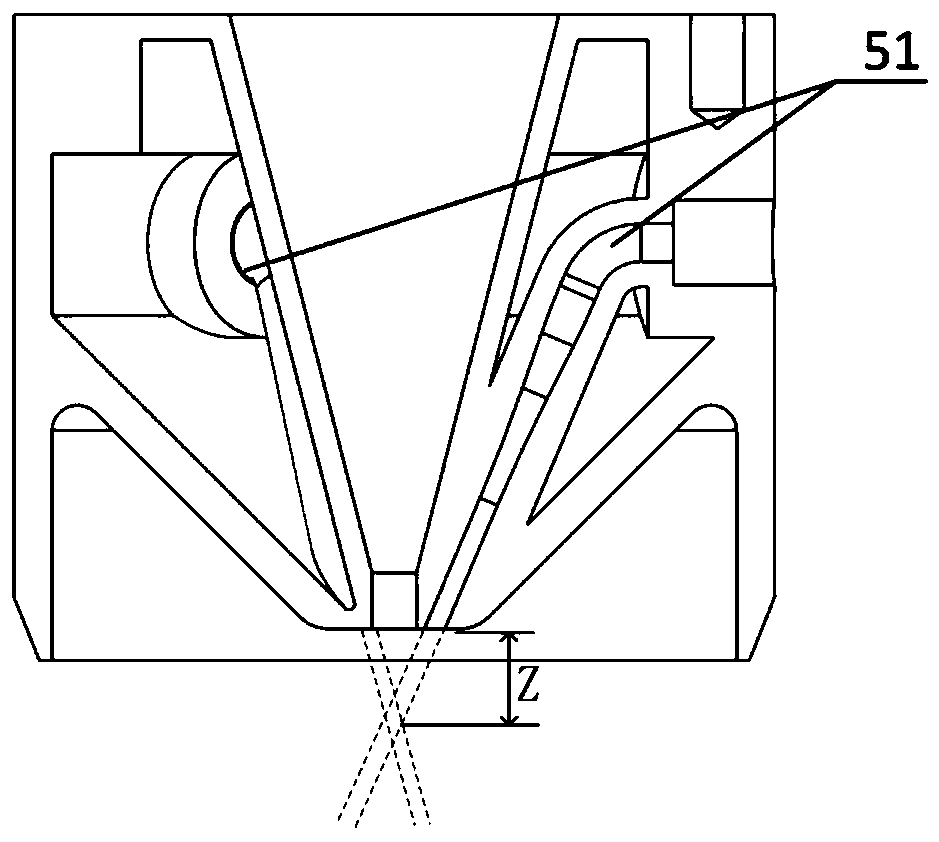

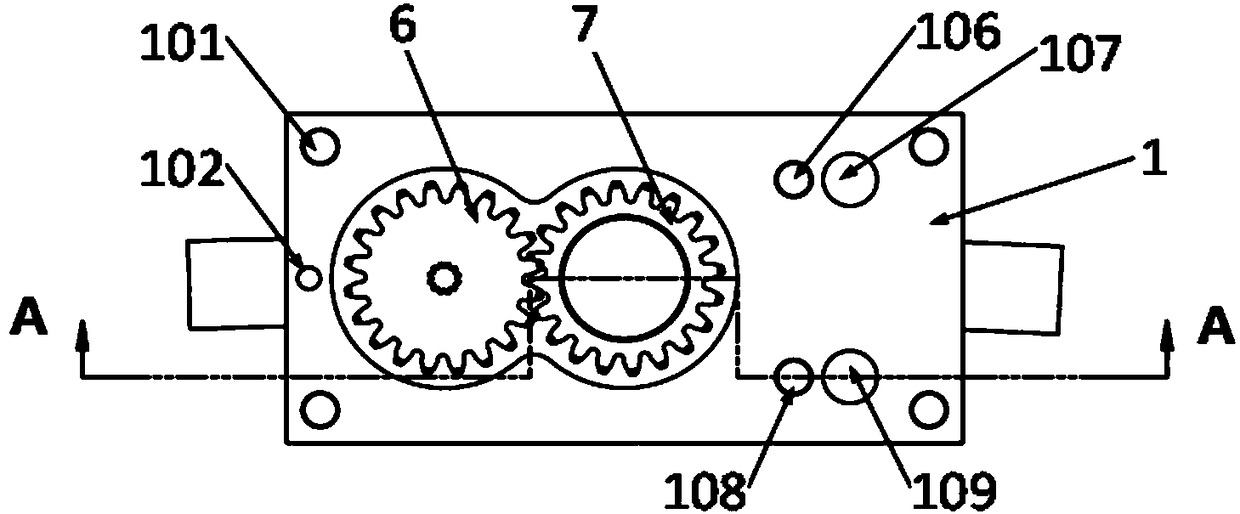

An adjustable double-wedge laser scanning actuator based on cantilever beam structure

InactiveCN105938246BSatisfy the requirement of coaxialityReduce volumeOptical elementsLaser scanningEngineering

The invention provides an adjustable dual-optical-wedge laser scanning performing mechanism based on a cantilever beam structure. The adjustable dual-optical-wedge laser scanning performing mechanism comprises an upper end cap, an upper optical wedge support arm, a lower optical wedge support arm, a high motor support body, a low motor support body, a high motor output gear, an upper optical wedge bearing transmission gear, an upper optical wedge high speed bearing, a high micro-motor, a low micro-motor, an upper optical wedge, a lower optical wedge, a lower optical wedge bearing transmission gear, a low motor output gear and a lower optical wedge high speed bearing. The upper end cap and the high motor support body are respectively provided with a fine adjustment set screw and a fine adjustment bolt which apply force to the upper optical wedge support arm and the lower optical wedge support arm so as to realize a fine adjustment function of the position and the axial deflection angle of the upper optical wedge and the lower optical wedge. The high micro-motor and the low micro-motor respectively drive the upper optical wedge and the lower optical wedge to relatively rotate around the common optical axis, wherein rotation is different in speed and opposite in direction, so that scanning paths of different speed ratios are generated. The adjustable dual-optical-wedge laser scanning performing mechanism has the advantages of being small in size, adjustable in optical wedge axial inclination angle and reliable in structure so that scanning and imaging distortion caused by installation error of the optical wedges can be avoided, and the adjustable dual-optical-wedge laser scanning performing mechanism is suitable for the field of flexible and high speed application.

Owner:SHANGHAI JIAO TONG UNIV +1

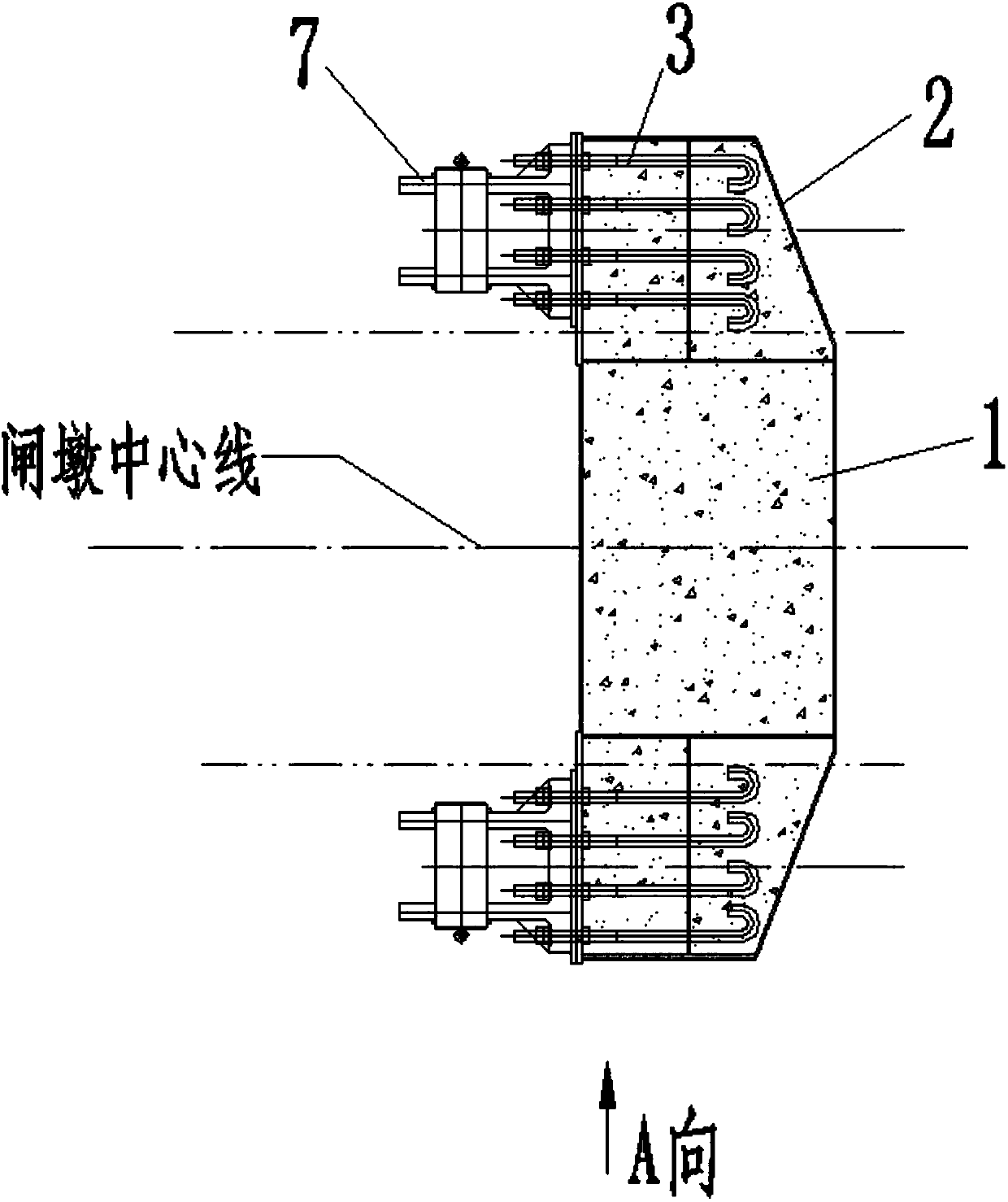

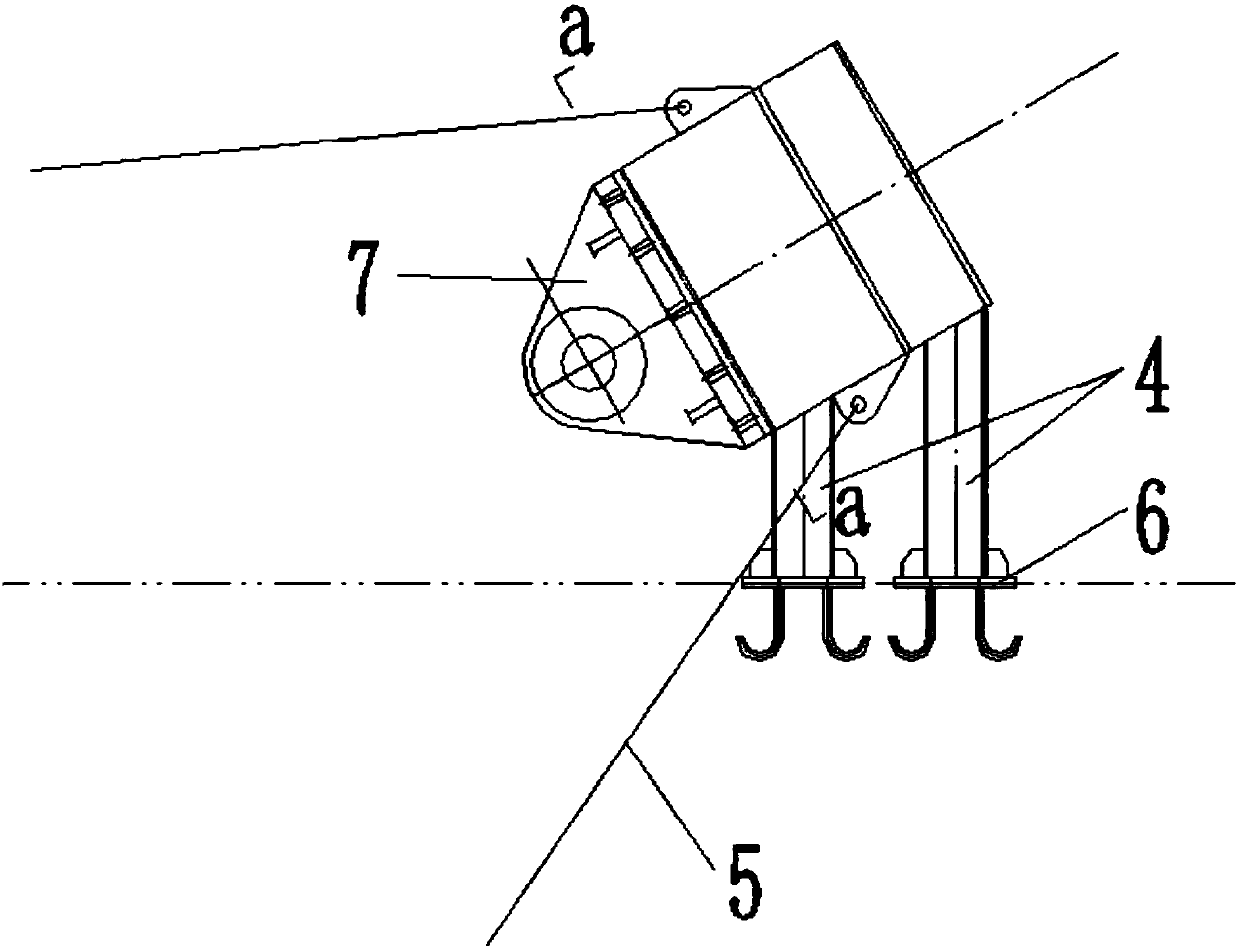

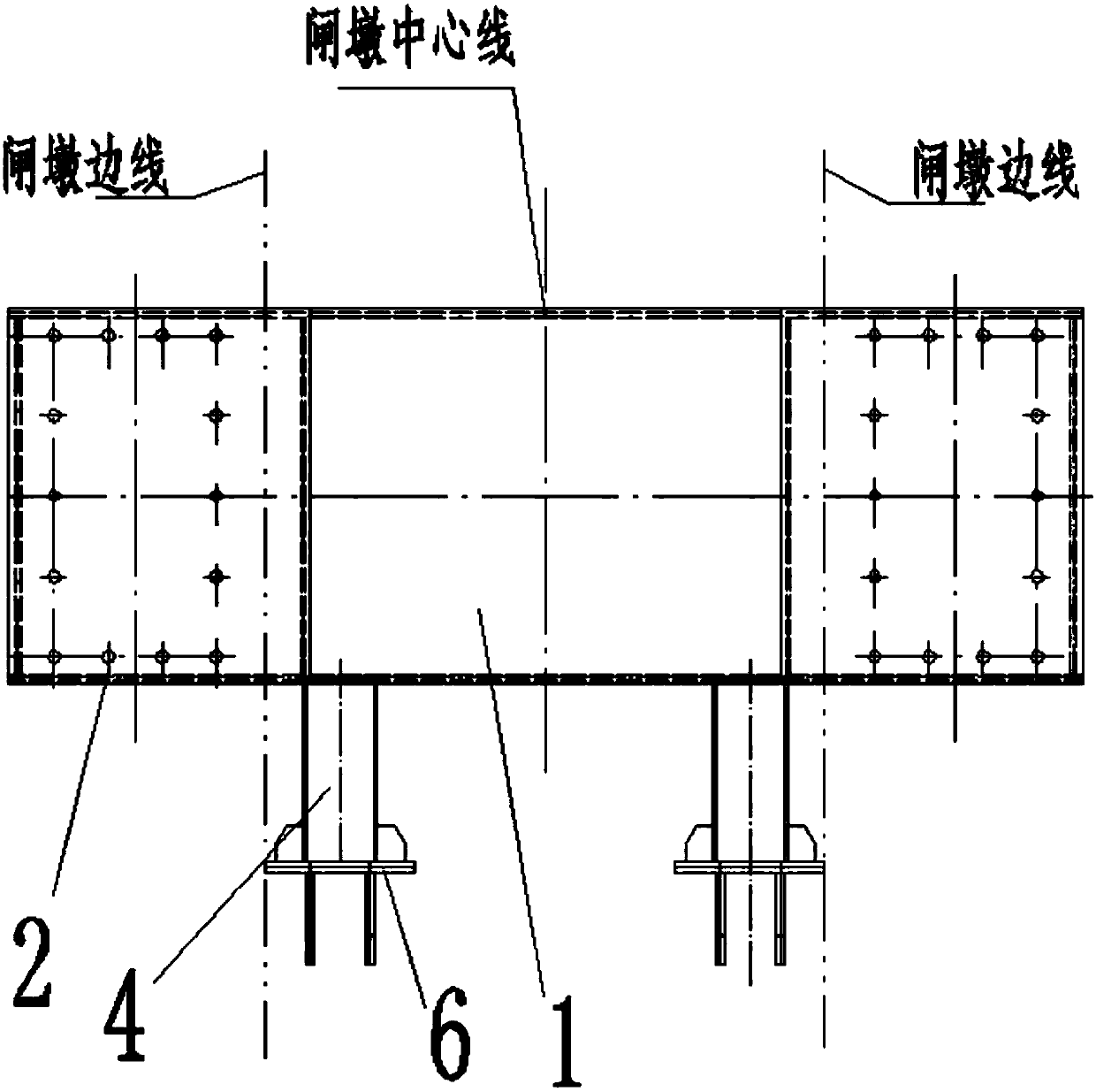

Assembly type structure with concrete-filled-steel-tubular radial gate support and pier

ActiveCN107700438AClear forceReduce volumeBarrages/weirsHydro energy generationRebarUltimate tensile strength

The invention discloses an assembly type structure with a concrete-filled-steel-tubular radial gate support and a pier. The assembly type structure comprises a concrete pier and a radial gate supportconnected with the pier, and foundation bolts are arranged on the radial gate support; the structure is characterized in that the radial gate support is a concrete-filled-steel-tubular member formed by filling concrete in a steel tube with a polygonal cross section, the part, connected with the pier, of the radial gate support is cast to be integrated with the pier through the concrete, and the radial gate support is partially buried inside the pier; a plurality of radiation steel bars arranged outside the part, buried inside the pier, of the radial gate support are connected with the piers, and supporting legs are fixedly connected with the bottom of the part, buried inside the pier, of the radial gate support; and the supporting legs is fixedly connected with anchor plates pre-buried onthe pier. The structure is simple, the connection strength between the support and the pier is high, the support can be adjusted in the construction process, the accuracy of the installation positionis high, the construction difficulty is low, the problems of a conventional structure with a concrete corbel type support and a pier are solved, and the structure can be widely applied to water gate engineering.

Owner:山东省水利勘测设计院有限公司

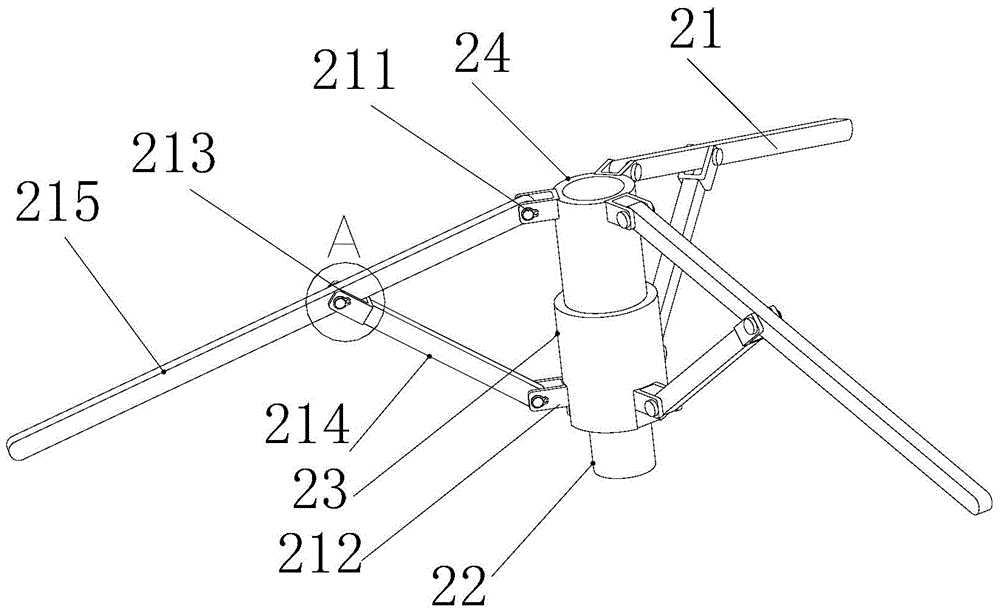

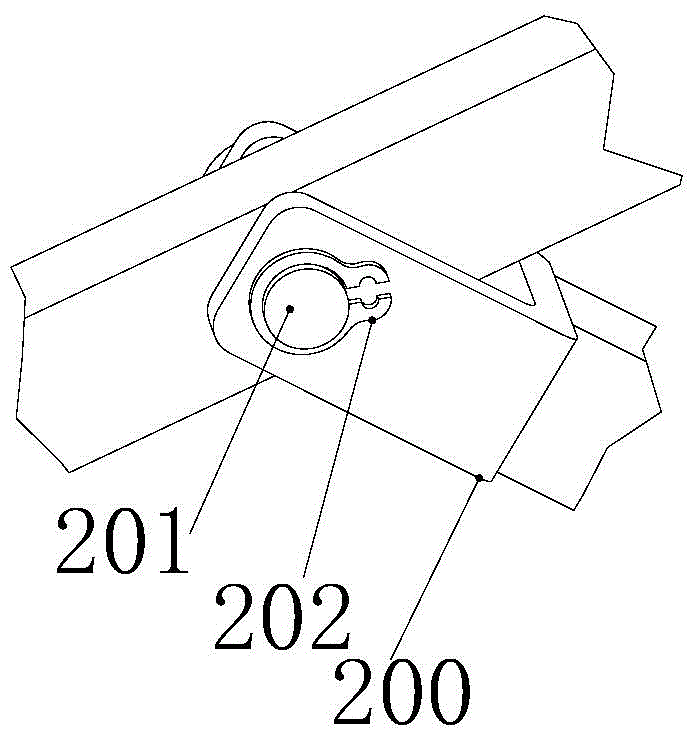

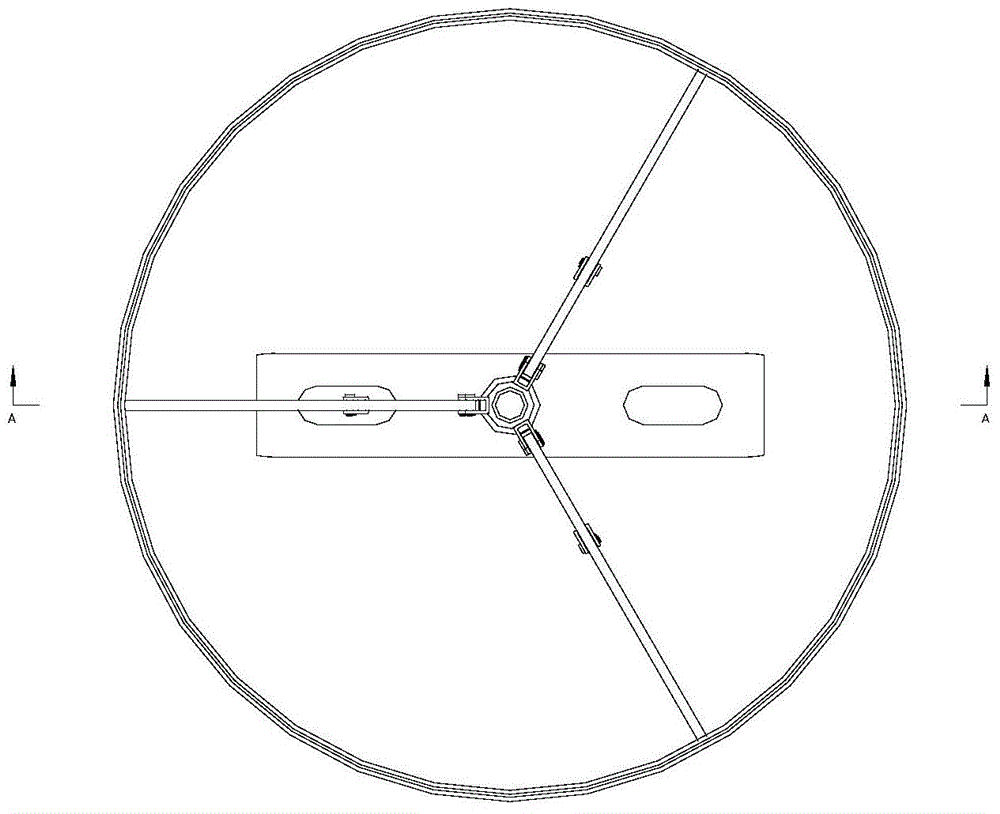

Flexible coaxiality centering device and seal with same

ActiveCN104374306ASatisfy the requirement of coaxialityConcentricity requirements are easy to guaranteeMechanical measuring arrangementsEngineering

The invention discloses a flexible coaxiality centering device and a seal with the same. First connectors are fixed on a center pipe, second connectors are fixed on a slide sleeve, third connectors are fixed on connecting rods, and the first connectors, the second connectors and the third connectors are arranged on three peaks of a triangle respectively. One end of each elongated claw is hinged to each first connector, and the other end is hung in the air. One ends of the connecting rods are hinged to the second connectors and the other ends are hinged to the elongated claws through the third connectors. A positioning sleeve is connected with the bottom of the slide sleeve, the center pipe is sleeved with the slide sleeve, and included angles of adjacent positioning mechanisms are the same along the circumference of the center pipe. The flexible coaxiality centering device can meet the requirement for higher coaxiality. When the diameter of the seal changes as tolerance, the flexible coaxiliaty centering device also changes so as to ensure the requirement for the coaxiality, and flexible centering is embodied.

Owner:ANHUI DAPAN SPECIAL EQUIP VEHICLE CO LTD

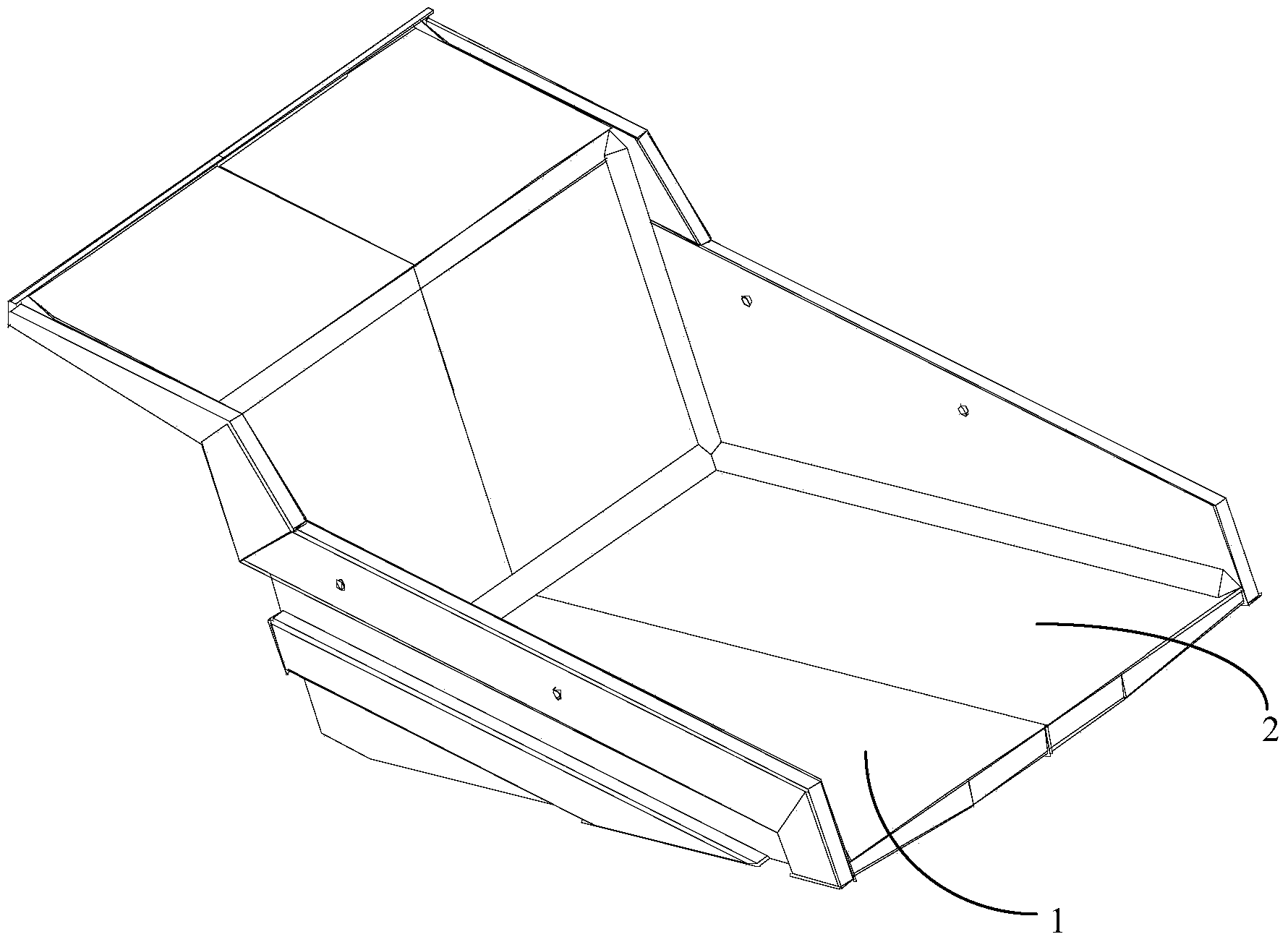

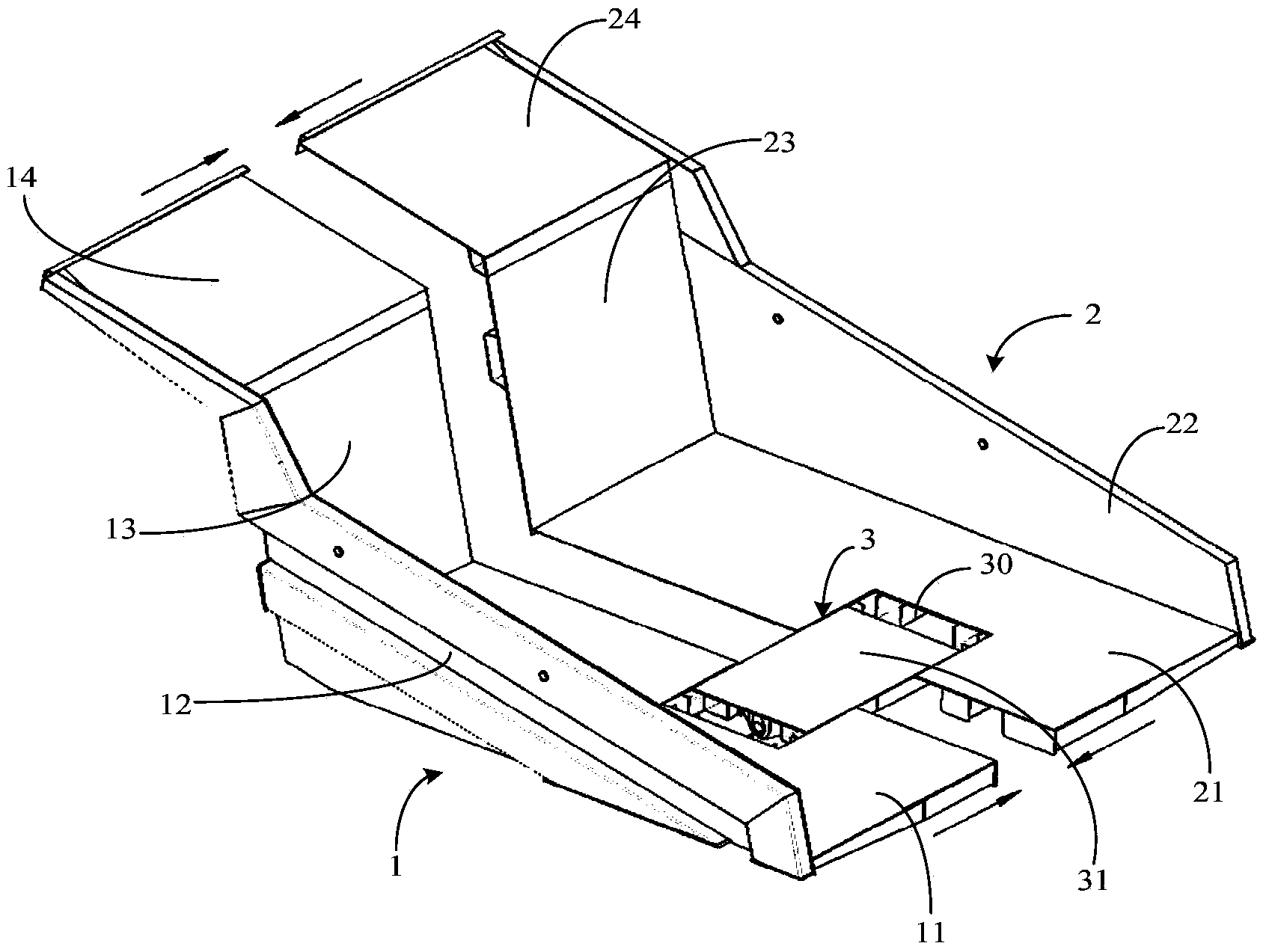

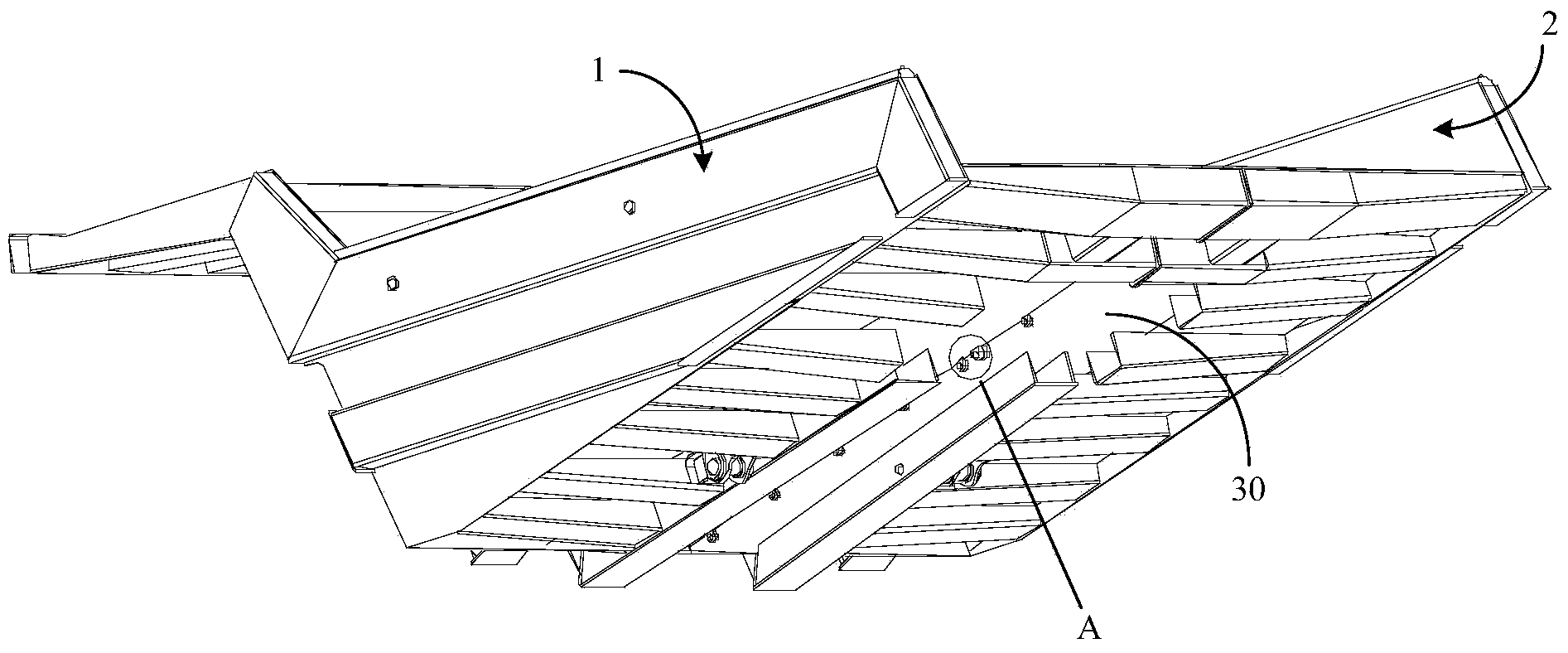

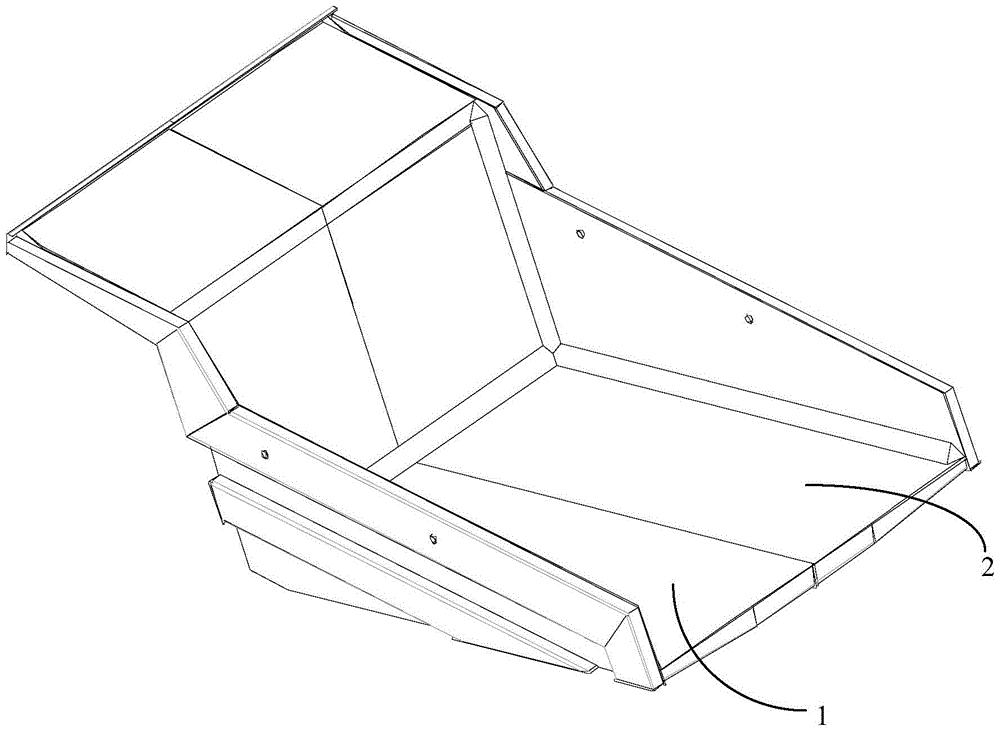

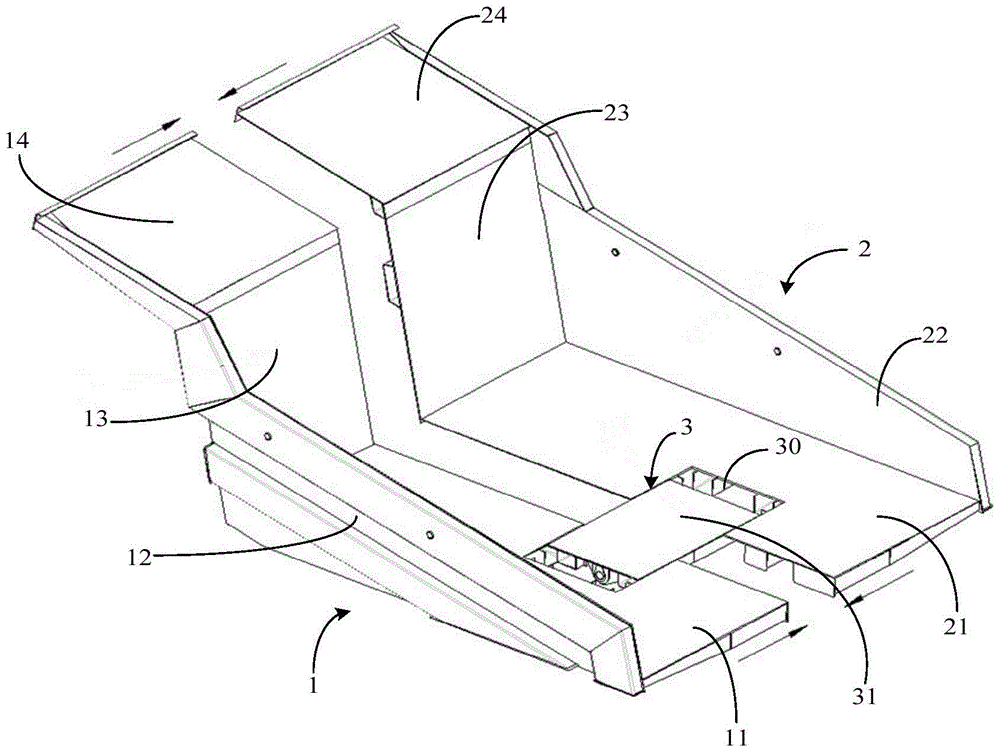

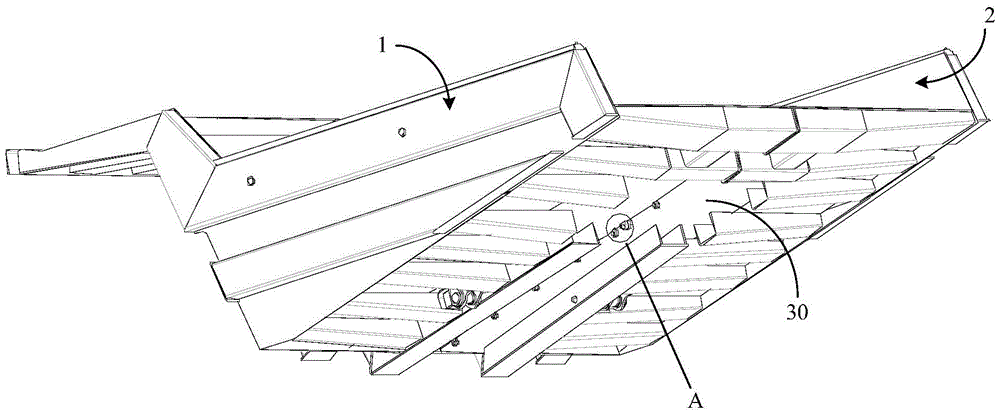

Container and mining dumper

ActiveCN103707793AImprove manufacturing precisionSave production cost and timeVehicle with tipping movementOpen structureEngineering

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Laser welding device and method for thin-wall corrugated diaphragm for aerospace diaphragm capsule

PendingCN113634892AGuaranteed assembly accuracyImproved Diaphragm Heat DissipationWelding/cutting auxillary devicesAuxillary welding devicesPhysicsLaser soldering

The invention relates to the technical field of welding, in particular to a laser welding device and method for a thin-wall corrugated diaphragm for an aerospace diaphragm capsule. The device mainly comprises a thin-wall corrugated diaphragm inner ring welding tool, a thin-wall corrugated diaphragm outer ring welding tool and a coaxial gas protection tool. According to the device, precise positioning and assembling of a diaphragm before welding are achieved mainly through the inner ring welding tool for positioning the outer circle of the diaphragm and the outer ring welding tool for positioning the inner circle of the diaphragm, and the requirement for the overall coaxiality after the diaphragm capsule is subjected to series welding is met; by adding a red copper heat dissipation clamping piece, the heat dissipation condition of the diaphragm is improved, good heat conduction of the diaphragm in the welding process is achieved, and the forming defects such as weld beading, weld joint sinking and wave weld joints are avoided; and the coaxial gas protection tool is used in cooperation, so that oxidation of a circumferential weld of the diaphragm is avoided.

Owner:NANJING CHENGUANG GRP

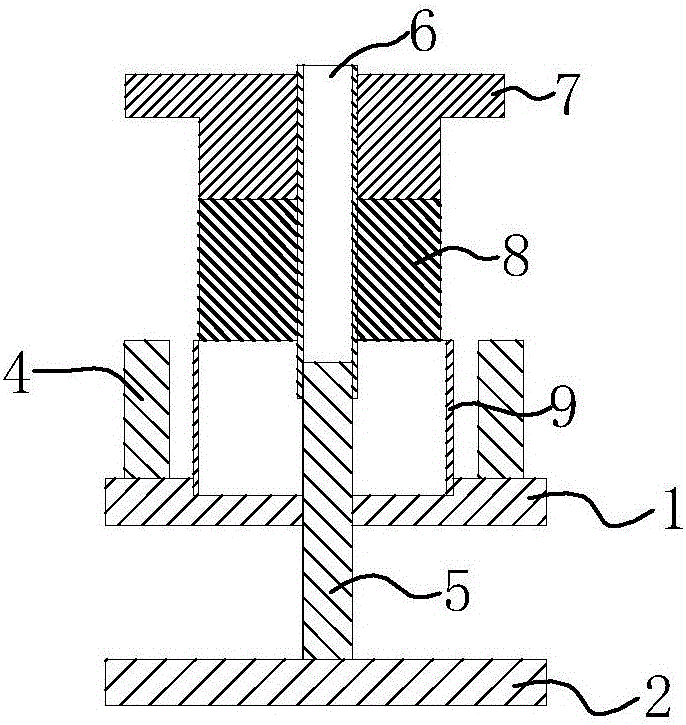

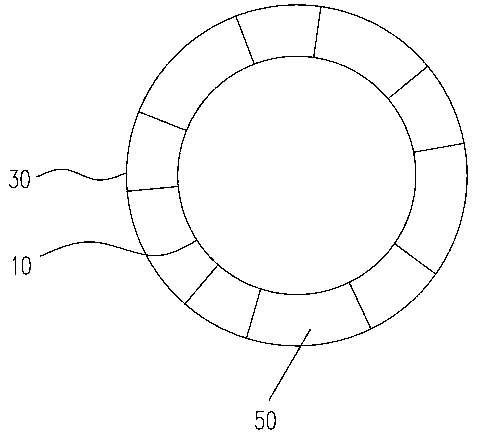

Stator and casing stamping tool

PendingCN106533092ASatisfy the requirement of coaxialityReduce difficultyManufacturing dynamo-electric machinesEngineeringStator

The invention discloses a stator and casing stamping tool, which comprises a base for placing a casing, wherein the base comprises an upper base plate, a lower base plate, a centering sleeve matched with a centering post and a pressure plate; the lower base plate is arranged in parallel to the upper base plate; the upper base plate is connected with the lower base plate through a plurality of connecting posts; the upper base plate is in a circular shape; the circular shape comprises an inner circle, an outer circle and a circular part between the inner circle and the outer circle; the inner circle is provided with a step for locating the casing; the circular part is provided with a plurality of top posts; the center of the lower base plate is vertically provided with the centering post; the pressure plate is arranged vertically to the centering sleeve; and the top posts limit up-and-down action of the pressure plate. According to the stator and casing stamping tool, the preliminary fixing difficulty is reduced through coordination of the centering post and the centering sleeve and arrangement of the structures of the pressure plate sleeving the outside of the centering sleeve and the like; the installation efficiency is improved; the stator and casing stamping tool can meet the coaxiality requirement of a stator and the casing and the quality of a product is ensured.

Owner:鹤山市源创电机有限公司

Numerical-control automatic boring machine tool for shaft coupler hole

ActiveCN107838470ARealize automatic alignmentQuick alignmentAutomatic control devicesDrilling/boring measurement devicesEngineeringTouchscreen

The invention discloses a numerical-control automatic boring machine tool for a shaft coupler hole. The numerical-control automatic boring machine tool comprises a rack which is fixedly arranged on asteam turbine cylinder body, wherein a rotary assembly, a feeding assembly, a regulating control part, an electric control box, a laser centering apparatus and a control touch screen are arranged on the rack; the rotary assembly, the feeding assembly, the regulating control part, the laser centering apparatus and the touch control screen are connected with the electric control box; the rotary assembly is used for realizing positive rotation or negative rotation of a boring head for boring a shaft coupler bolt hole; the feeding assembly realizes enabling the rotary assembly including the boringhead to advance and retreat towards a shaft coupler; the laser centering apparatus is used for measuring a coaxiality value of the shaft coupler bolt hole and the boring head, feeding back the valueto the electric control box, controlling a corresponding button of the control touch screen according to the fed-back value, and realizing horizontal front-rear movement, vertical up-down movement andhorizontal swing-angle movement of the boring head by automatic linkage of the regulating control part. The numerical-control automatic boring machine tool is used for automatic boring for holes in ashaft coupler of a steam turbine, and can realize functions of automatically centering, automatically feeding and boring, and controlling the action of the touch control screen.

Owner:河北国源电气股份有限公司

Containers and mining dump trucks

ActiveCN103707793BImprove manufacturing precisionSatisfy the requirement of coaxialityVehicle with tipping movementCargo containerTruck

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Coaxiality precision control device and method for long straight structure conduit brazing

ActiveCN107999924BGuaranteed sealing requirementsGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCatheter

The invention provides a coaxiality precise control device and method used for carrying out brazing on a guide pipe in a long and straight structure. The device comprises an upper installing plate anda lower installing plate. The upper installing plate and the lower installing plate are connected through a supporting column. Locating pins are arranged at the two ends of the upper installing platerespectively. Locating bases opposite to the locating pins are arranged at the two ends of the lower installing plate respectively, wherein the locating bases share the same central axis. The controldevice further comprises an argon protection bin which is fixedly installed on one locating base. A guide pipe installing opening of the argon protection bin and the locating base on which the argonprotection bin is located share the same central axis. The method comprises the three steps that the first to-be-brazed guide pipe in the long and straight structure is installed between the locatingbase with the argon protection bin and the corresponding locating pin, and the to-be-brazed portion is totally arranged in the argon protection bin; argon is introduced, and brazing is started; afterbrazing on the first pipeline is finished, in-situ cooling is carried out, the argon protection bin is moved to the other locating base, and the brazing process of the second to-be-brazed guide pipe in the long and straight structure is started.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

A Measuring Device for Single Face Measuring Error of Face Gears

ActiveCN103267480BImprove versatilityPrecise position adjustmentUsing optical meansMeasurement deviceGrating

The invention belongs to the field of a precision measurement technology, and provides a single-sided meshing measurement device for face gear errors. The single-sided meshing measurement device comprises a cylindrical gear shafting, a cylindrical gear installation mechanism, a face gear shafting, a face gear installation mechanism, a motor, a coupler, a worm, a controller, a drive unit, a circular grating system, a subdividing device, a DSI card, a data acquisition card and an industrial personal computer. The cylindrical gear shafting is an active shafting and is driven by a servo motor. The single-sided meshing measurement device reduces the quantity of parts of an instrument, and enhances stability of a system.

Owner:BEIJING UNIV OF TECH

A multi-span rotor test bench with adjustable shaft sections and supports

ActiveCN109774968BEasy to changeTest accuracy is easy to guaranteeAircraft components testingCircular discDrive shaft

The invention discloses a multi-span rotor test bench with adjustable shaft sections and supports, which comprises a driving motor arranged on a base, a transmission shaft module, a chute guiding and positioning module, a movable supporting module, and a self-centering disc rotor module The drive shaft module includes a number of drive shafts and couplings, the chute guide positioning module includes a slider assembly that slides along a linear guide rail; the movable support module includes a self-centering that is connected to the slider assembly through a support assembly The self-centering sleeve is locked and fixed to the transmission shaft through a locking assembly; the self-centering disk rotor module includes a counterweight disk that is locked and fixed to the transmission shaft through a locking assembly. The present invention has the characteristics of simple structure, convenient operation, reliable test, etc., can effectively guarantee high coaxiality between each shaft section, and can carry out experimental researches such as variable support position, variable shaft section length, variable shaft section outer diameter, etc. A practical and efficient rotor test system is provided, which greatly speeds up the research process.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Finish turning core expanding die of machine base

PendingCN113145884AGuarantee product quality requirementsEnsure consistencyExpansion mandrelsSet screwMachine

The invention discloses a finish turning core expanding die of a machine base. The finish turning core expanding die of the machine base comprises a center shaft, wherein a plurality of sliding blocks are arranged on the outer surface of the center shaft, annular springs are arranged on the two sides of the outer surface of each sliding block correspondingly, a plurality of threaded holes are formed in the outer surface of the center shaft, and the inner surfaces of the threaded holes are in threaded connection with set screws. A finish turning die and a workpiece can be quickly fixed on a lathe, the machining benchmark of the machine base can be quickly found, the whole process is efficient and quick, the working efficiency is improved, meanwhile, the quality requirement of a finish turning product of the machine base is met, and the finish turning core expanding die of the machine base can be used for finish turning machining of the machine base clamping workpieces with different sizes and specifications by replacing sliding blocks with different flange outer diameters.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

Device and method for machining waterstop structure of arc-shaped door of ship lift and waterstop structure

ActiveCN104985242ASatisfy the requirement of coaxialityGuaranteed coaxialityFeeding apparatusLarge fixed membersEngineeringMachining

The invention discloses a waterstop structure machining device, a method and waterstop structures of an arc-shaped door of a ship lift, and relates to the technical field of mechanical machining devices. The machining device comprises a main shaft which is horizontally erected, and expansion hubs and side machining components are sequentially arranged at the two ends of the main shaft from outside to inside; and a bottom waterstop machining component is arranged at the position, between the two side machining components, of the main shaft. According to the device, the machining period is shortened, the requirement for the coaxiality between two arc-shaped waterstop plates and between two arc-shaped rails is ensured, and the requirement for the radian of a bottom waterstop plate is ensured.

Owner:HEAVY EQUIP ENG CO LTD OF WUCHANG SHIPBUILDING IND

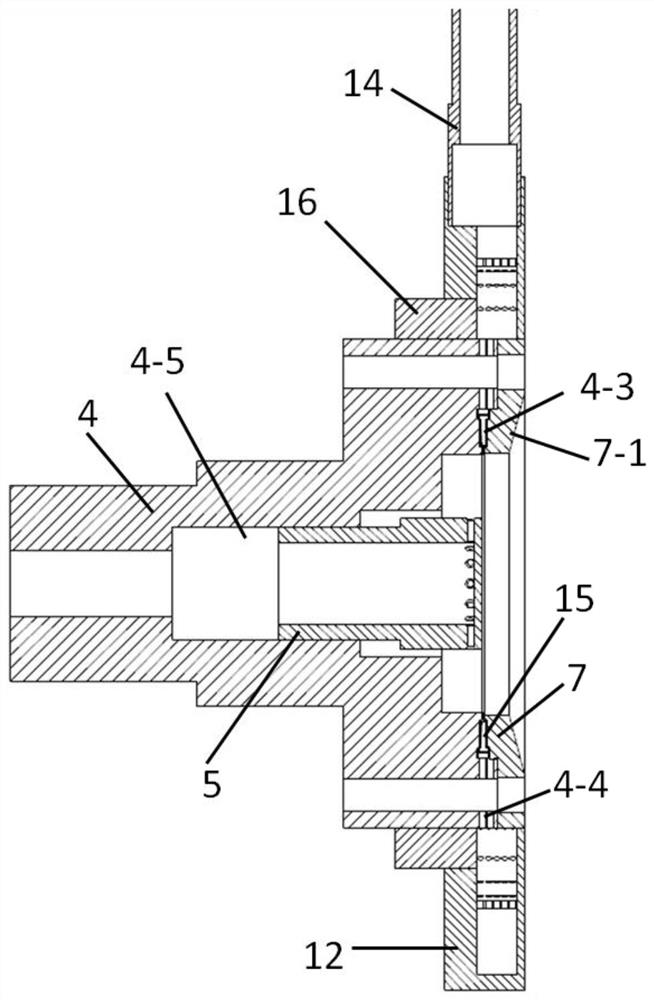

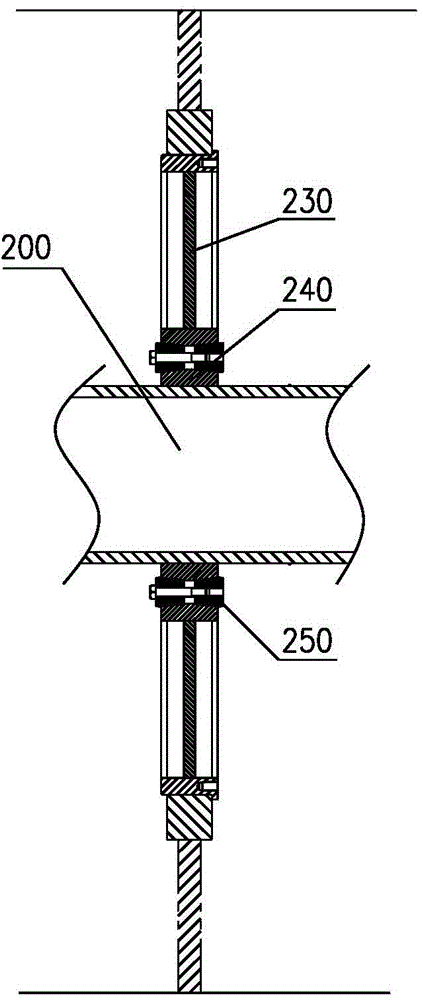

Wellhead systems for subsea resource extraction

ActiveCN111219161BShorten working timeEasy to useDrilling rodsSealing/packingSuction forceWater flow

The present invention relates to a wellhead system for mining underwater resources, which includes: a casing, used for mining underwater resources; a casing head, arranged on the top of the casing; a suction pile, covered and arranged on the outer periphery of the casing; wherein, The suction pile is covered with a casing catcher at the inner upper end of the outer periphery of the casing, and the outer periphery of the casing is provided with a locking structure matched with the casing catcher structure. The slope surface of the inner circumference of the upper end of the device realizes structural cooperation, so that the locking structure and the casing catcher cooperate to form a "double suspension" structure that reduces the water flow resistance when the casing moves down. The wellhead system used for underwater resource exploitation provided by the present invention can be installed within ±1°; no cementing is required, so the working time at sea is saved; all underwater wellhead systems can be recycled, which is very convenient to use .

Owner:SHANGHAI LINXI INTELLIGENT TECH CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com