Containers and mining dump trucks

A technology for mining dump trucks and cargo boxes, which is applied in the direction of inclined load-carrying vehicles, etc., can solve the problems of unsatisfactory precision and difficulty in the manufacture of cargo boxes, and achieve the effects of saving production costs and time, and improving manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

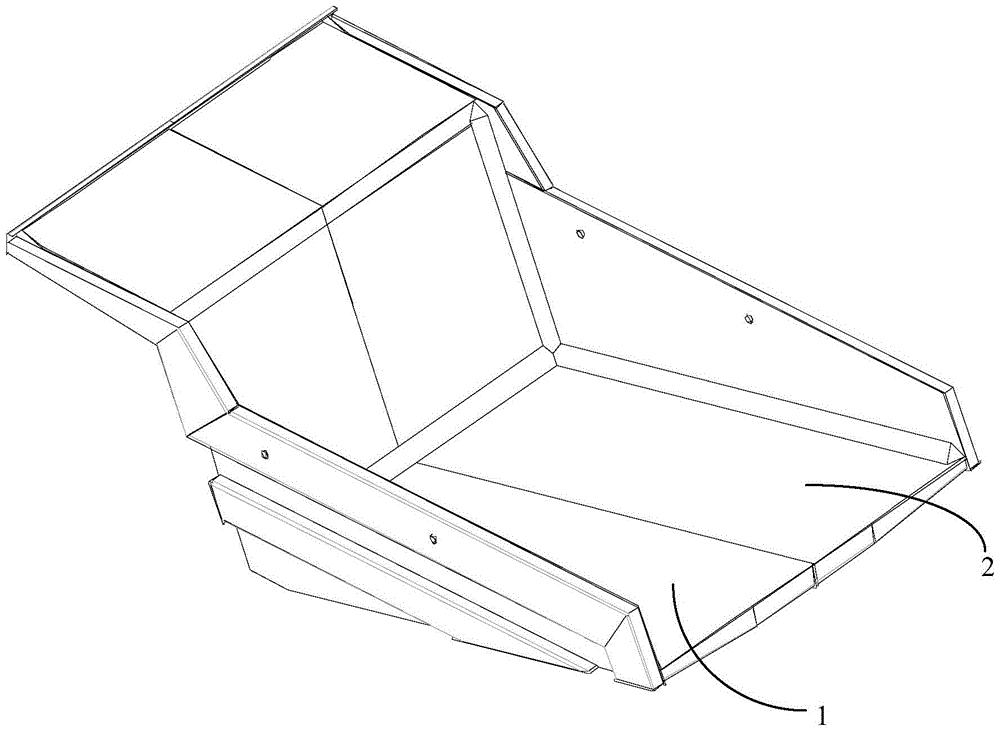

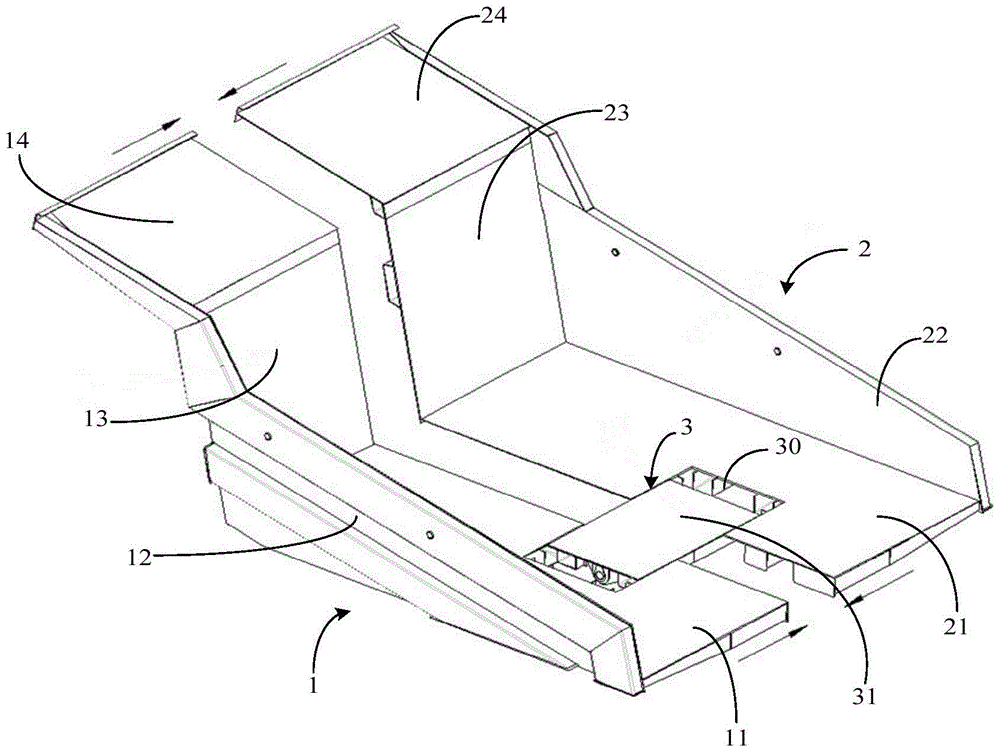

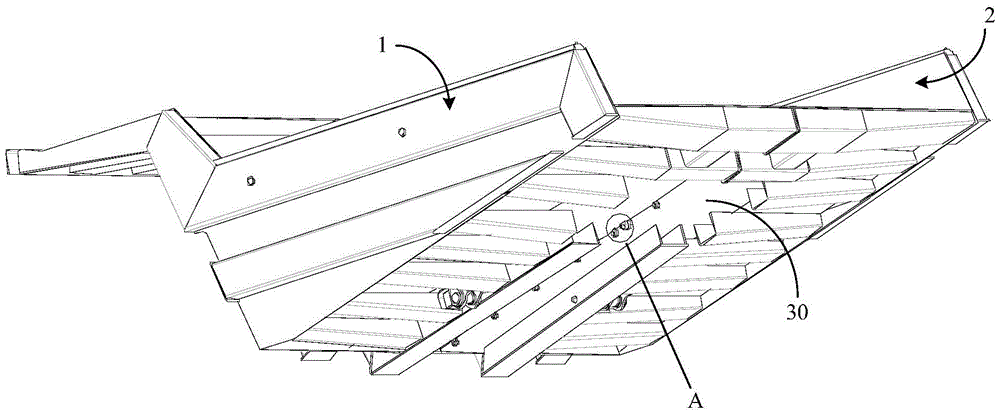

[0027] figure 2 It is a schematic structural diagram of the container provided by the embodiment of the present invention, image 3 Another structural schematic diagram of the container provided by the embodiment of the present invention; Figure 4 for image 3 The magnified image at A in the middle; Figure 5 Schematic diagram of the structure of the support part of the hinge support provided by the embodiment of the present invention. Please refer to Figure 2-5 , the cargo box provided in this embodiment includes a left cargo box part 1, a right cargo box part 2 and a hinge support part 3; openings are correspondingly opened at the edges where the left cargo box part 1 and the right cargo box part 2 are spliced together structure, the opening structure is docked to form the installation port 30 ( figure 2 Shown) Specifically, the left cargo box part 1 may include a spliced left bottom plate 11, a left side plate 12, a left front plate 13 and a left guard plate 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com