Laser welding device and method for thin-wall corrugated diaphragm for aerospace diaphragm capsule

A corrugated diaphragm, aerospace technology, used in laser welding equipment, auxiliary devices, welding equipment, etc., can solve problems such as unilateral, weld bead, wave weld, etc., achieve simple tooling structure, improve diaphragm heat dissipation, forming good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further introduced below in conjunction with the accompanying drawings and specific embodiments. (Here is a detailed description of the technical solution)

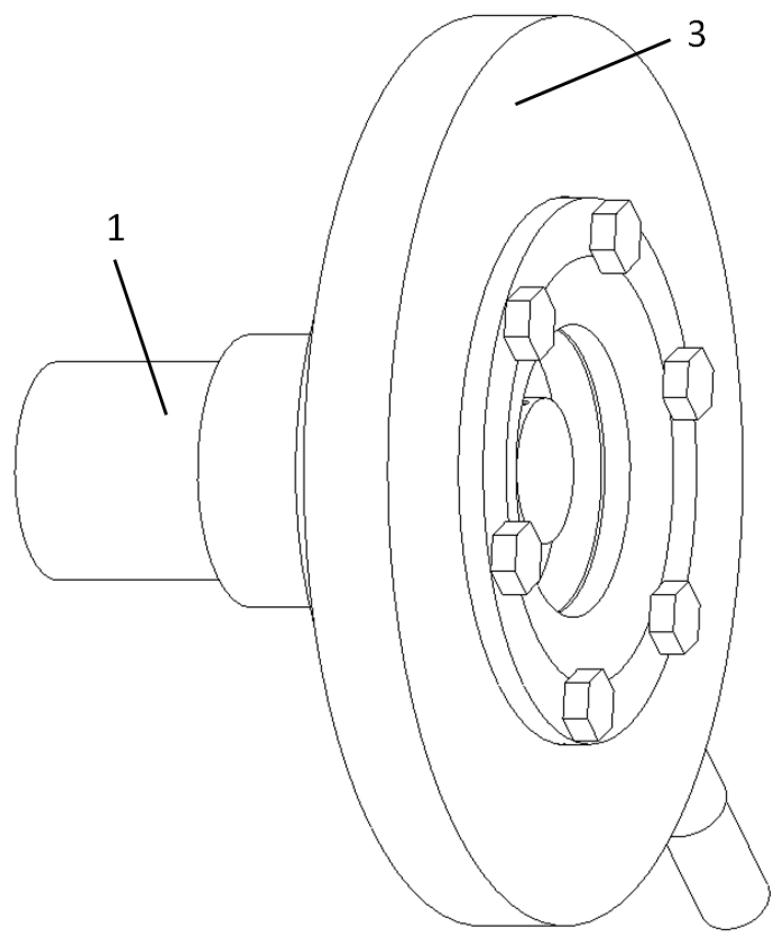

[0031] combine Figure 1-Figure 2 , a laser welding device for a thin-walled corrugated diaphragm used in an aerospace capsule of the present invention mainly includes three parts: a diaphragm inner ring welding tool 1, a diaphragm outer ring welding tool 2 and a coaxial gas protection tool 3.

[0032] Among them, the coaxial gas protection tool 3 and the diaphragm inner ring welding tool 1 are used together to provide gas protection when the diaphragm inner ring is welded;

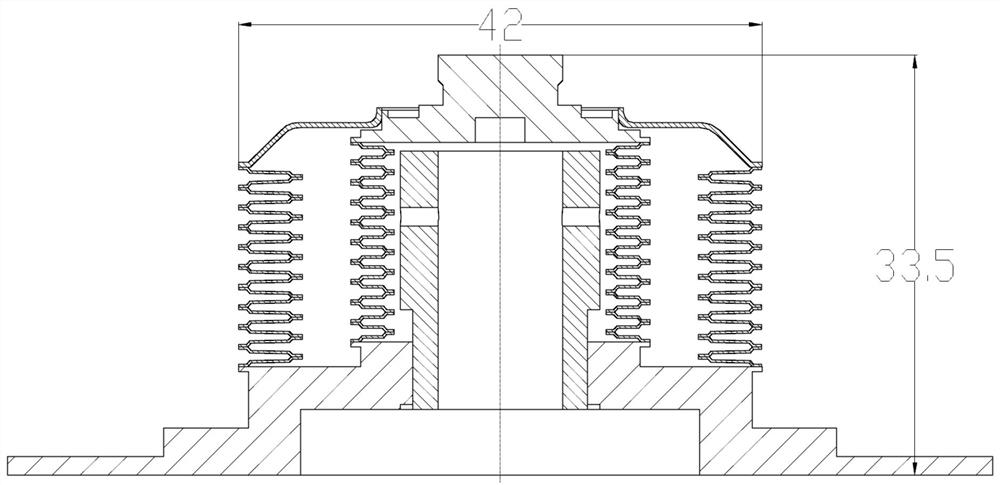

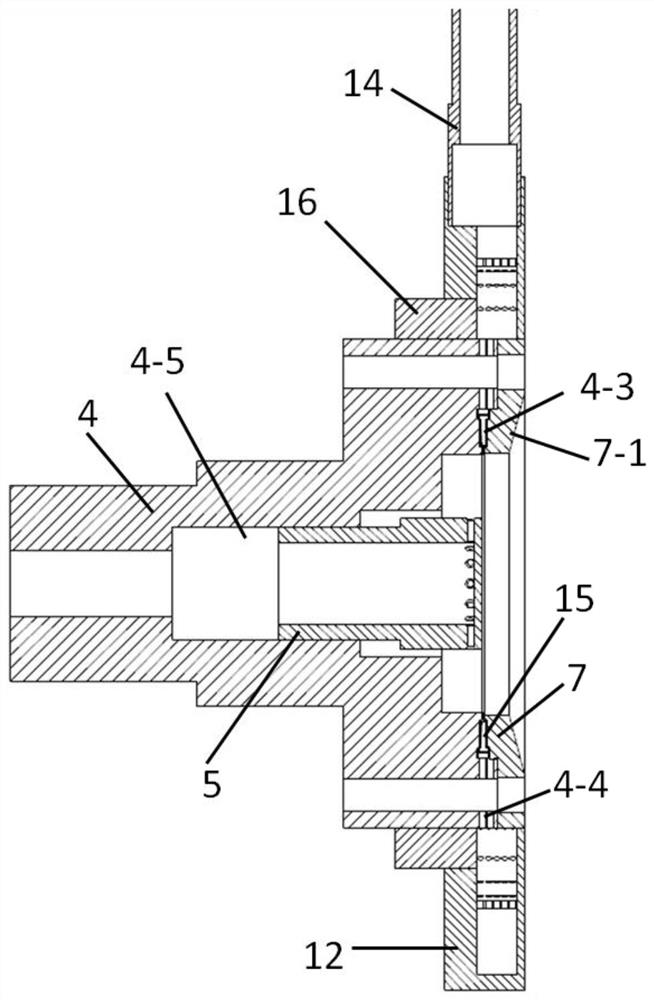

[0033] The welding tool 1 for the inner ring of the diaphragm is in the shape of a cylinder as a whole, and an annular diaphragm receiving groove 4-3 is arranged inside the cylinder for placing the diaphragm; the tooling mainly consists of the inner ring welding tool base 4, the air supply device 5, the inner We...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com