Conical surface efficient self-centering high-precision clamping device

A clamping device and self-centering technology, which is applied in the direction of positioning device, clamping, support, etc., can solve the problems that the finishing cannot be aligned, the accuracy is difficult to guarantee, and the manual adjustment is complicated, so as to achieve convenient and fast assembly and disassembly, and easy processing , good economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

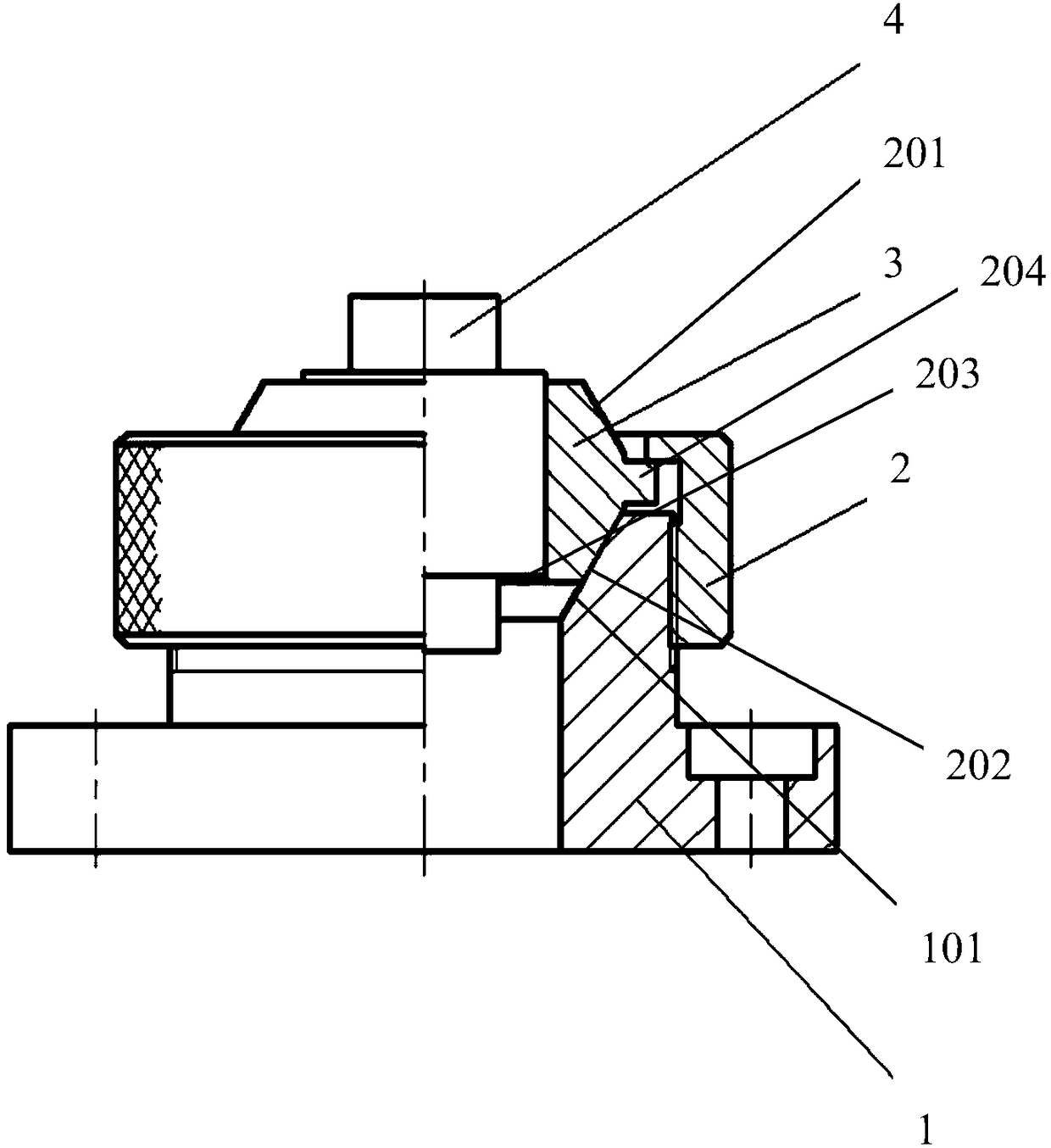

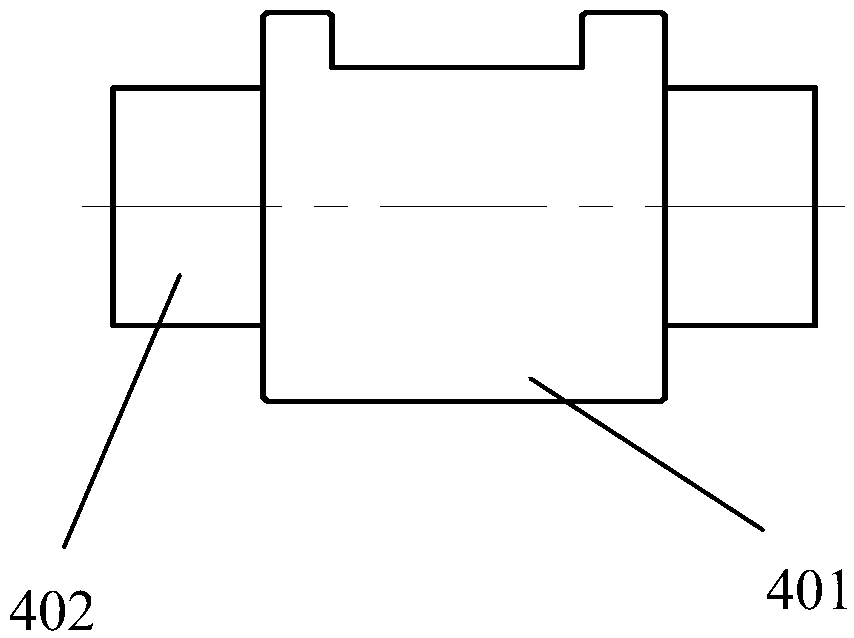

[0019] based on the following figure 1 and figure 2 Preferred embodiments of the present invention will be described in detail.

[0020] Such as figure 1 As shown, the present invention provides a high-efficiency self-centering and high-precision clamping device for conical surfaces, including:

[0021] The sleeve mandrel 1 has a conical surface 101 on its inner surface, and the inclination angle of the conical surface ranges from 3° to 10°;

[0022] The tapered surface element holder body 3, which is arranged on the sleeve mandrel 1, has a raised portion 204 and a first tapered surface 201 and a second tapered surface 202 respectively arranged on both sides of the raised portion 204, the first tapered surface 201 and the inclination angle of the second conical surface 202 are consistent with the inclination angle of the conical surface of the sleeve mandrel. It is used to achieve interference fit with the cone surface 101 of the sleeve mandrel. The cone element clamp bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com