Laser cladding device based on 3D printing and spraying nozzle of laser cladding device

A 3D printing and laser cladding technology, applied in metal material coating process, coating, additive processing, etc., can solve problems such as complex cladding nozzle structure, achieve strong forming ability, prevent powder pipe clogging, and solve oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with specific embodiments.

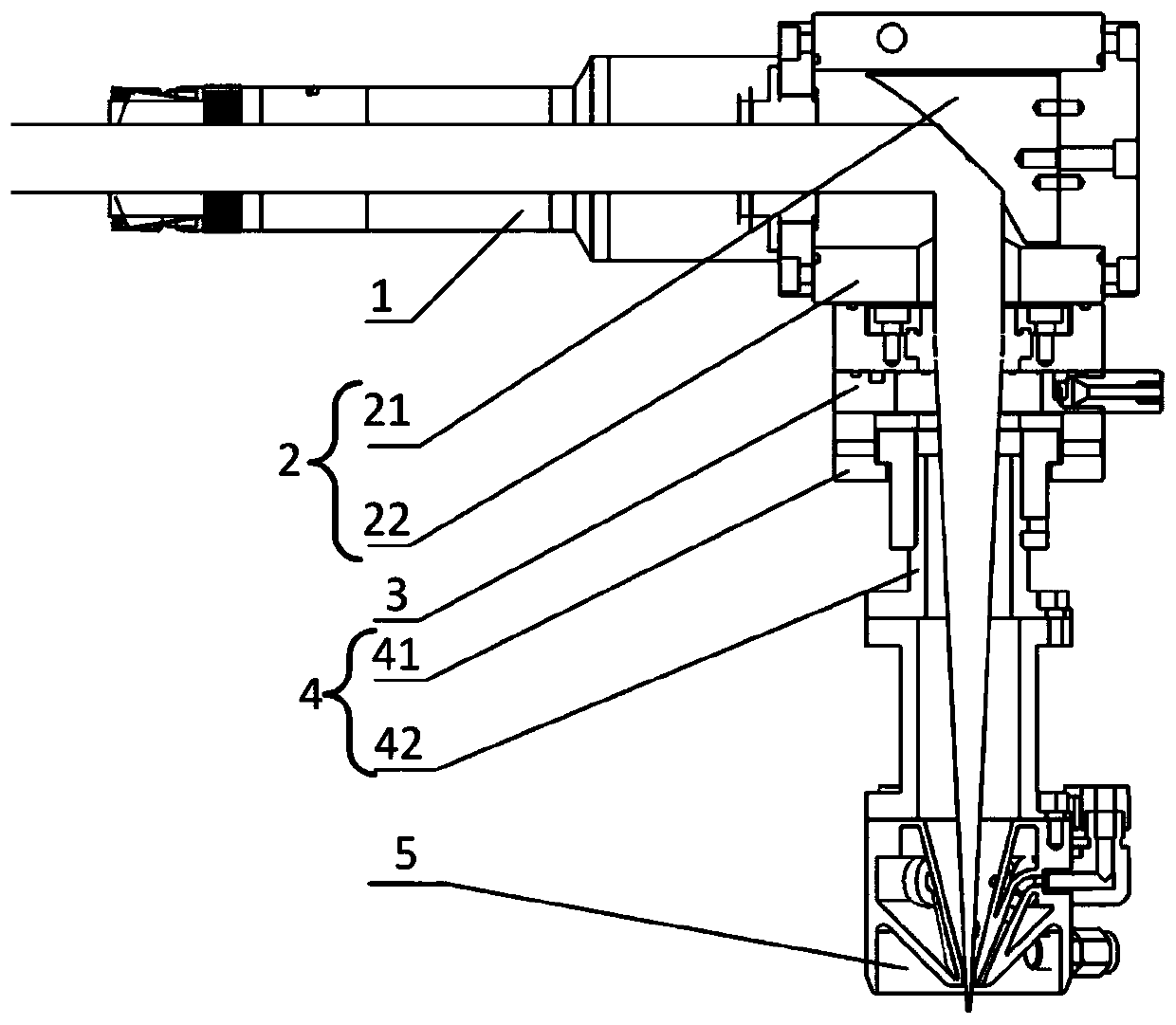

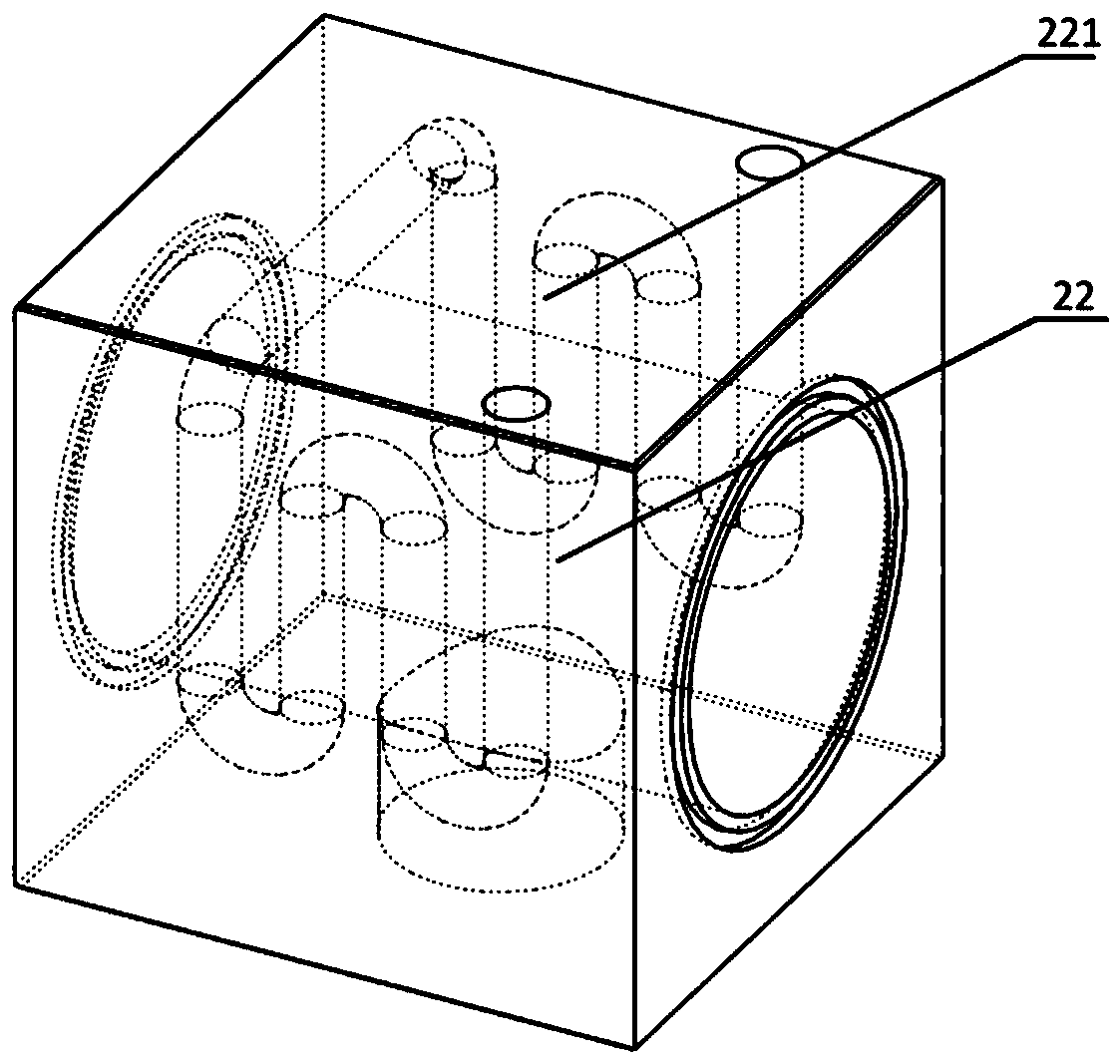

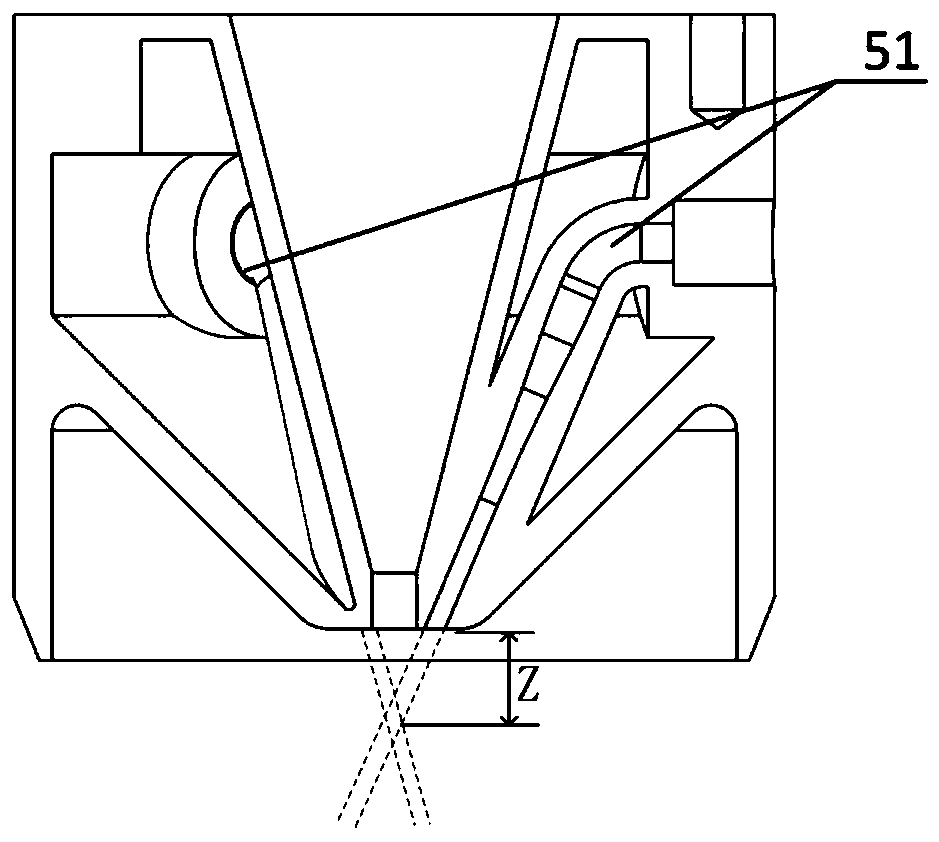

[0038] A nozzle of a laser cladding device based on 3D printing, the nozzle 5 is a metal 3D printing nozzle, including a powder flow channel 51, a cooling structure 52 and an air path structure 53; the powder flow channel 51, cooling structure 52 and The gas path structure 53 is not interconnected, and is integrated inside the nozzle 5, which is integrally formed by metal 3D printing technology;

[0039] Such as image 3 As shown, the powder flow channel 51 will control the position and size of the powder spots after the powder converges. The angle between the outlet direction of the powder flow channel 51 and the vertical direction is 23°, and the distance between the powder convergence point and the bottom plane of the powder flow channel 51 is Z Between 6-10mm, to prevent the nozzle from overheating during cladding and causing powder clogging;

[0040] Such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com