Assembly type structure with concrete-filled-steel-tubular radial gate support and pier

A technology of steel pipe concrete and support gate piers, which is applied in water conservancy projects, sea area projects, coastline protection, etc., can solve problems such as difficulty in guaranteeing the quality of concrete pouring, poor crack resistance of concrete, and poor coaxiality of gate hinge seats, etc., to achieve The effect of reducing complexity, good shock resistance, and high manufacturing and installation precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

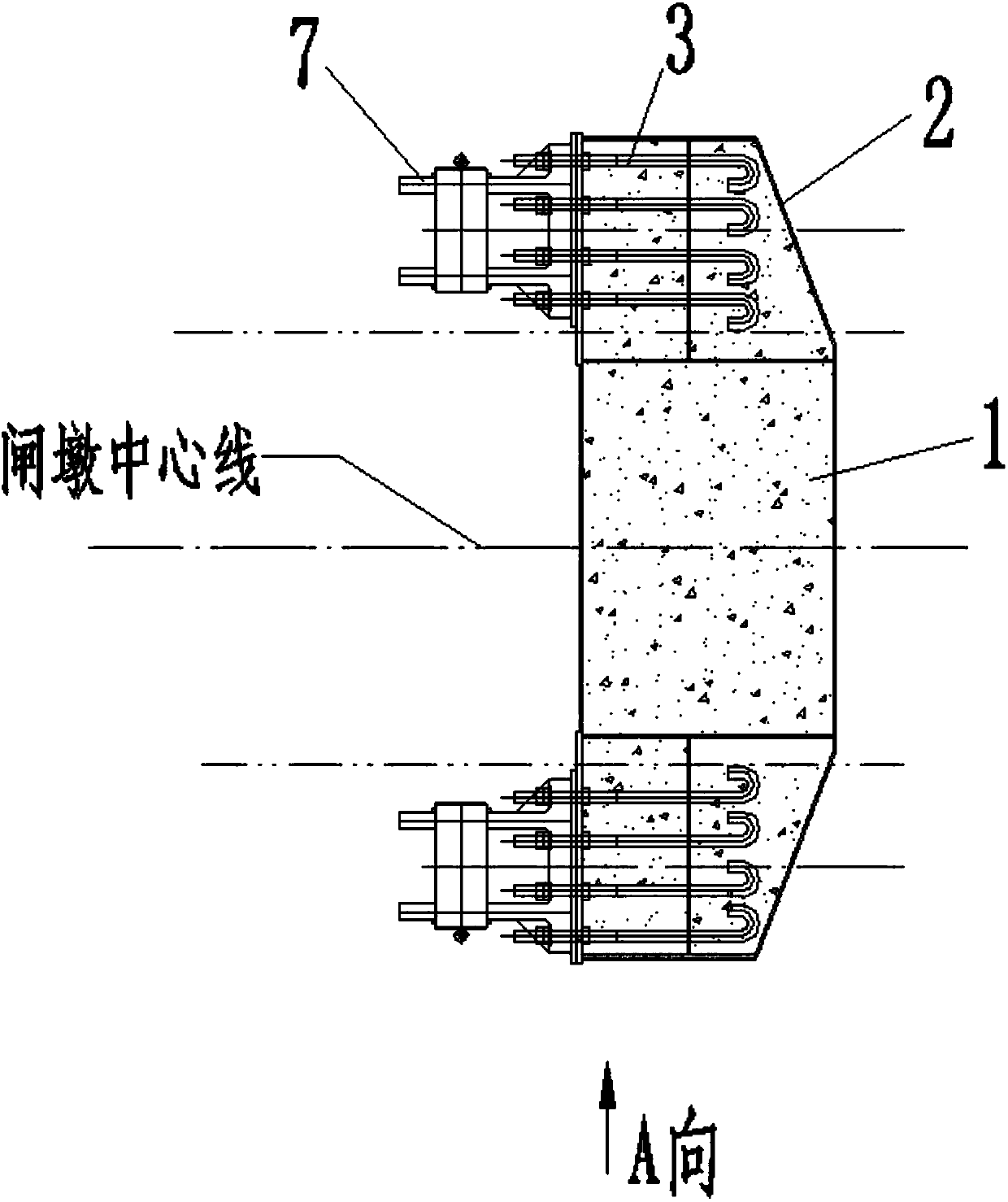

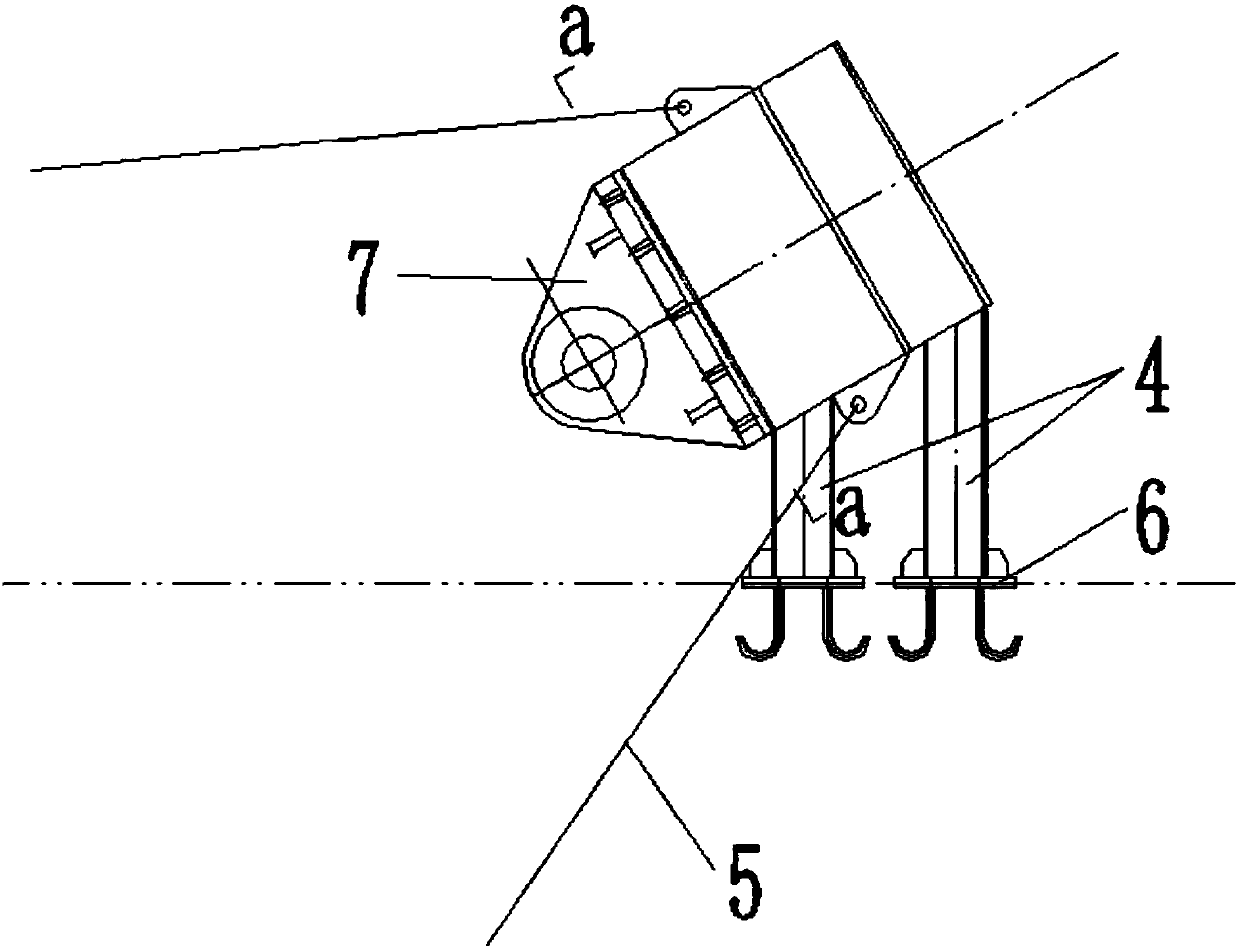

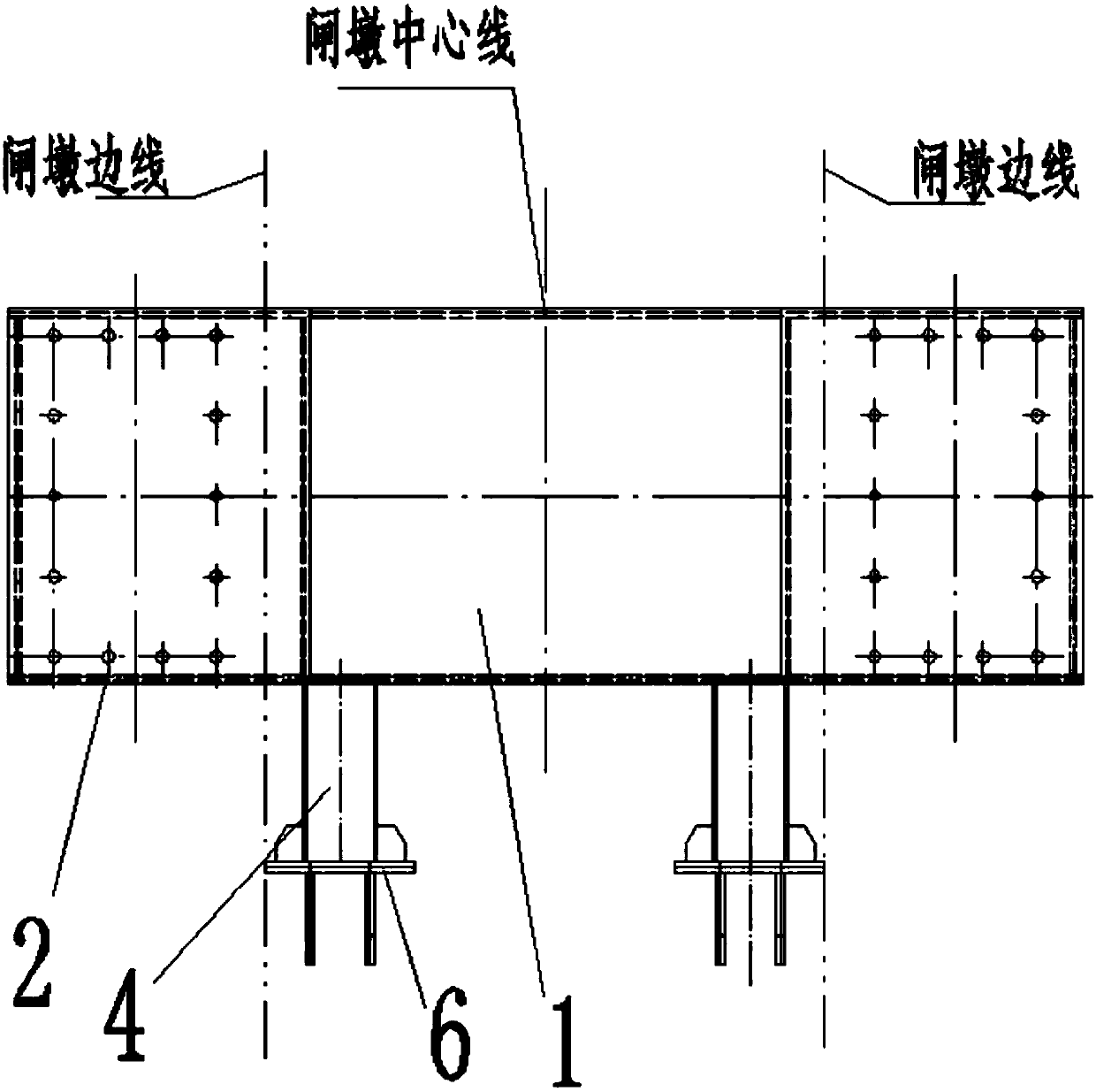

[0018] As shown in the accompanying drawings, a prefabricated steel pipe concrete arc door support gate pier structure includes a concrete gate pier 1 and an arc gate support 2 connected with the gate pier 1 . The arc door support 2 is a steel pipe concrete member formed by filling concrete in a steel pipe with a polygonal cross section. Part of it is buried inside the gate pier 1. The arc door support 2 is embedded outside the inner part of the gate pier 1, and a plurality of radiating steel bars 5 are connected to the gate pier 1, and one end of the radial steel bars 5 is welded on the outside of the arc gate support 2 embedded in the inner part of the gate pier. The other end is welded with the steel bar in the gate pier or welded with the anchor plate embedded in the gate pier to form the force-bearing structure of the arc door support gate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com