Prefabricated assembling whole type shear wall connected with staggered-height vertical steel bar

A vertical steel bar, prefabricated assembly technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of increasing the amount of construction on site, developing into through seams, and easily forming horizontal cracks, etc., to reduce construction difficulty, increase area, The effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following describes the present invention further in conjunction with specific embodiments and with reference to the drawings:

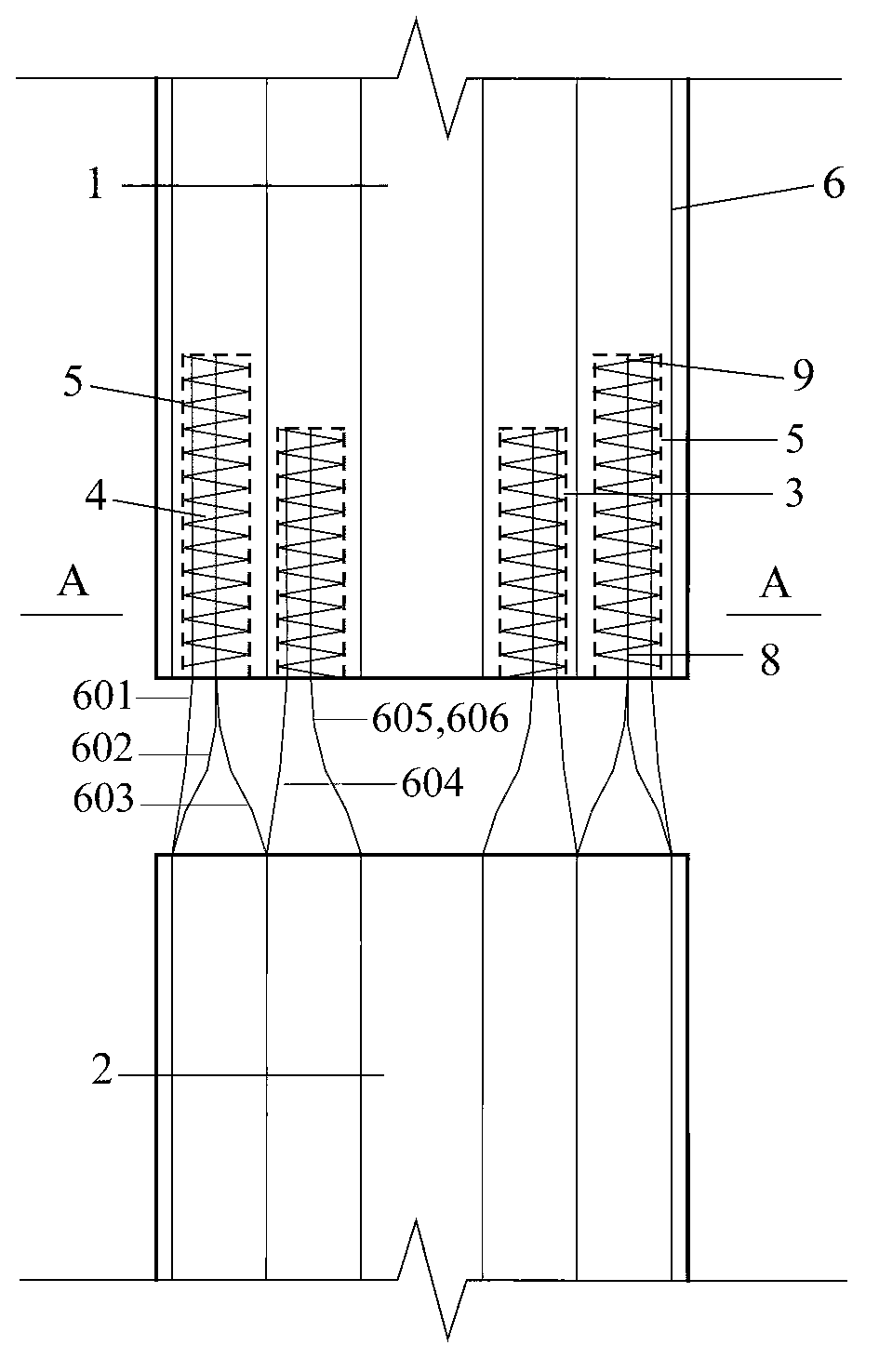

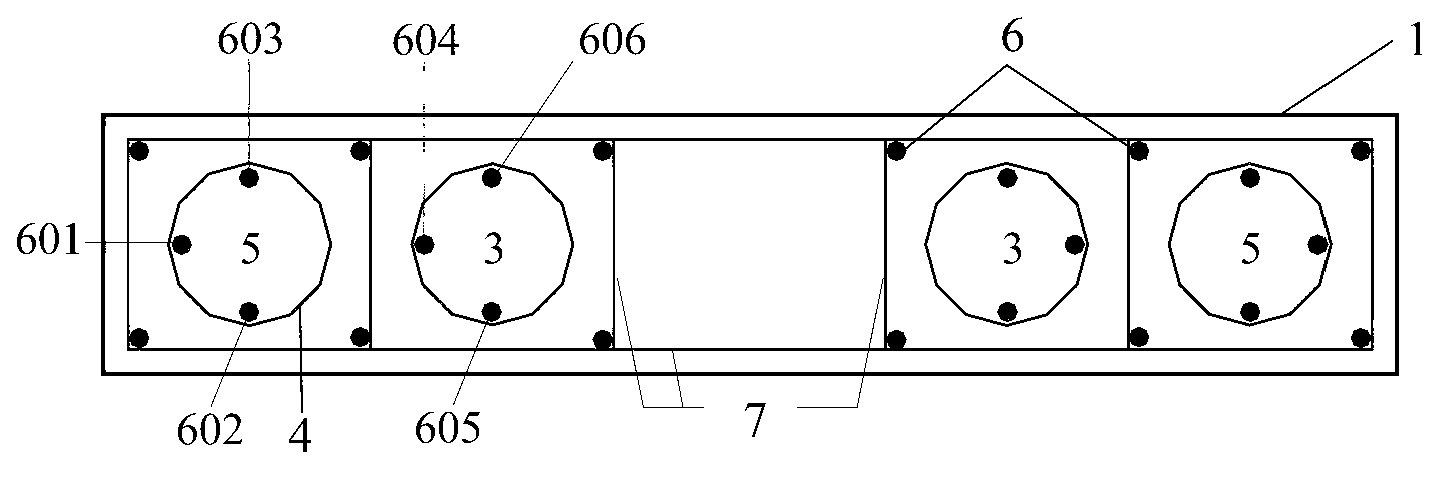

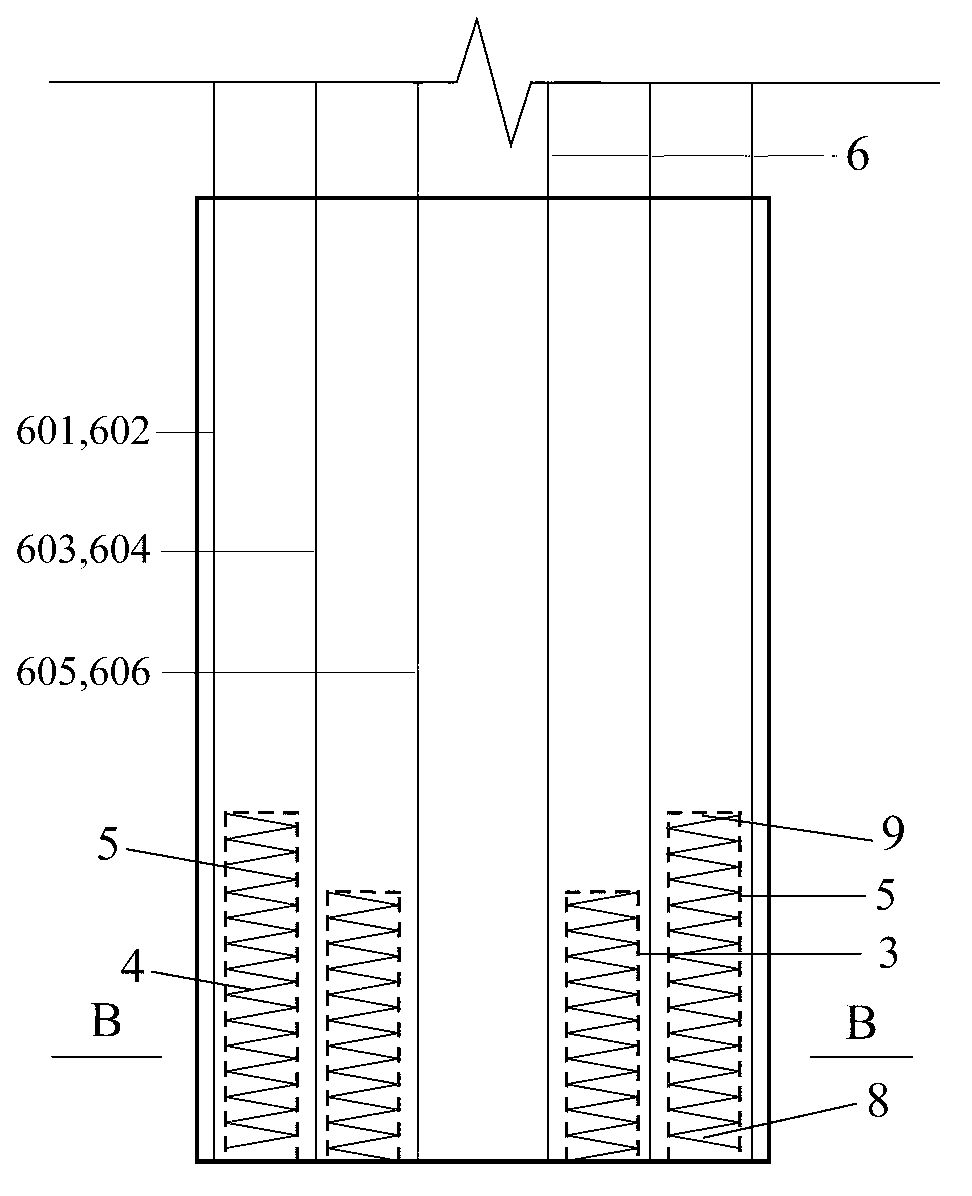

[0024] figure 1 It is a schematic diagram of the vertical steel connection of the upper wall 1 and the lower wall 2 in the prefabricated and assembled integral shear wall with the staggered height vertical steel connection of the present invention, and figure 2 corresponding figure 1 A-A section view of layer 1 on the mid-shear wall. Such as figure 1 , figure 2 As shown, a prefabricated integral shear wall with staggered height and vertical steel bars is connected. Its main components include: upper wall of shear wall structure 1, lower wall 2, first reserved hole 3, spiral stirrup 4. The second reserved hole 5 and the vertical steel bar 6, wherein the cylindrical first reserved hole 3 and the second reserved hole 5 are vertically arranged at both ends of the bottom section of the upper wall 1, and the second The reserved hole 5 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com