Local double layer open chord spherical reticulated shell

A double-layer, local technology, applied in the direction of roofs, building components, arched structures, etc., can solve the problems of inability to self-adjust internal force, self-adjustment, less actual structure, etc., to achieve simple and transparent architectural effects and improved strength utilization. , the clear effect of structural stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

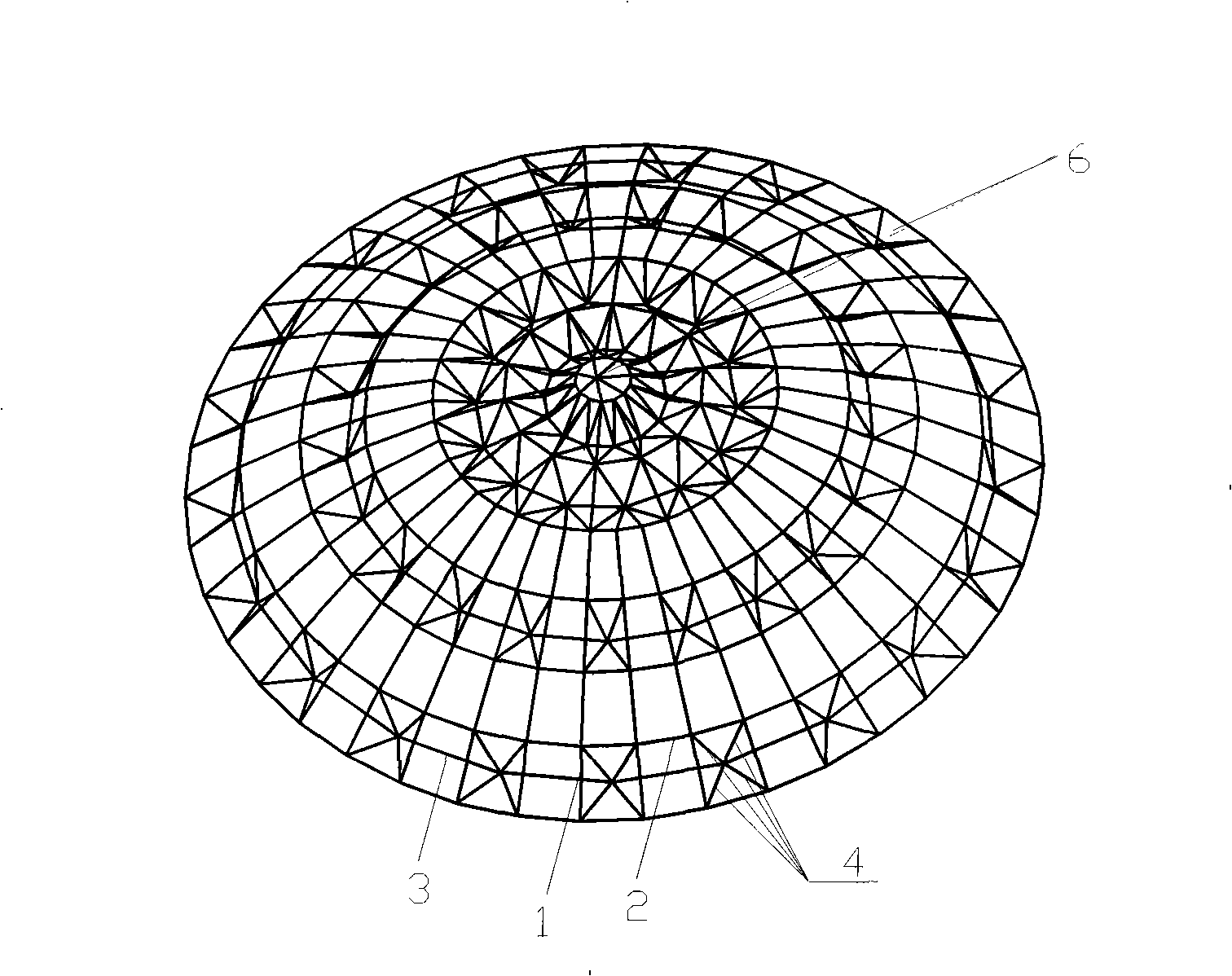

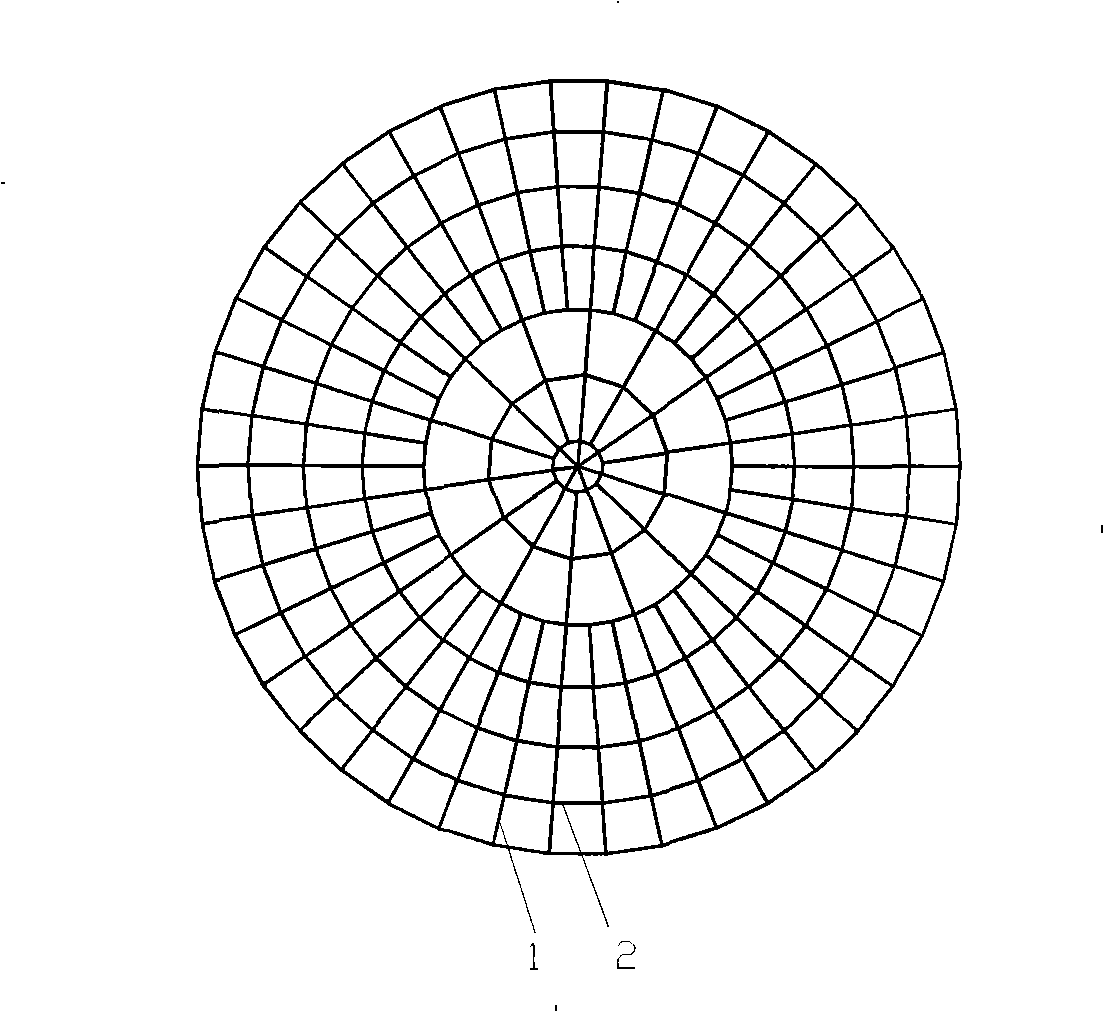

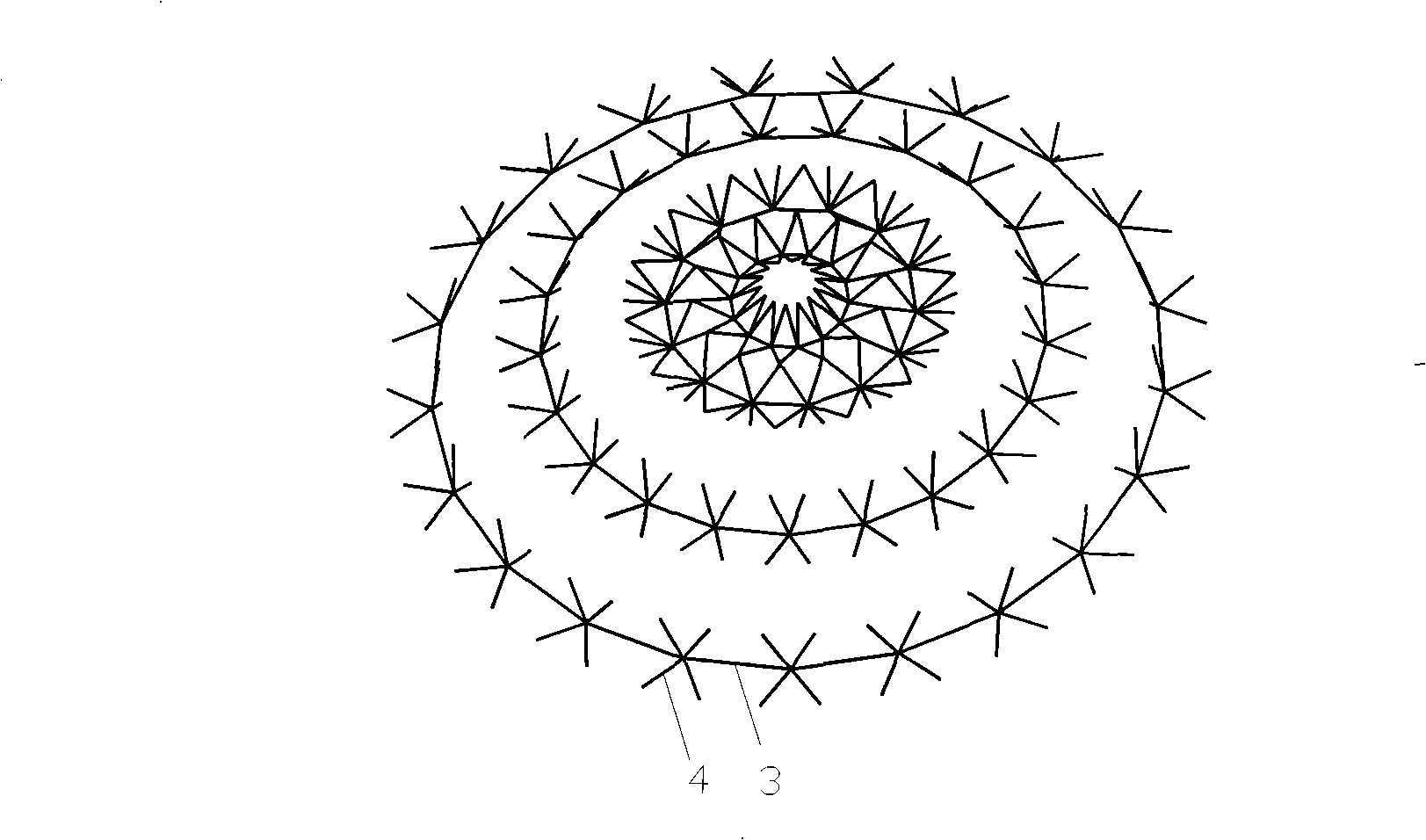

[0019] The local double-layer tensioned spherical reticulated shell includes upper, middle and lower layers. The upper layer is composed of radial rods 1 and circumferential rods 2. The spherical surface is arranged in a ribbed ring grid shape, and it is connected by multiple circumferential rods 2. There are multiple parallels forming the spherical surface, and radial rods 1 are connected between the connection points of the circumferential rods 2 of two adjacent parallels, forming the warp of the spherical surface, wherein the circular rods 2 of the innermost circle of latitudes are connected The point is connected to one end of the radial rod 1, and the other end of the radial rod 1 is hinged to the central vertex 6 of the spherical reticulated shell. The middle layer includes a plurality of unit pyramids, and the unit pyramids are along the meridian and latitude in the upper rib ring grid. The directions are arranged at intervals, and the unit pyramids are arranged continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com