Screw sleeve part inner hole processing lathe clamp

A technology of lathe fixtures and screw sleeves, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of workpiece clamping deformation, small contact area, and difficulty in guaranteeing workpiece processing quality, and achieve small clamping deformation , meet the requirements of coaxiality, and the effect of easy to guarantee the processing quality of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

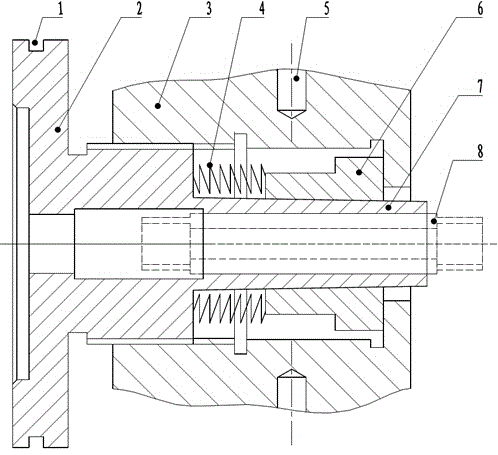

[0012] A lathe fixture for processing inner holes of screw sleeve parts, see figure 1 , the lathe clamp includes a clamp body 2, a return spring 4, a taper sleeve 6, a nut 3 and a nut turning handle (not shown in the figure). The clamp body 2 positioned by the spigot is installed on the lathe spindle through the transition plate; the return spring 4 is set on the front thin wall of the clamp body 2 and is located between the threaded step of the clamp body 2 and the taper sleeve 6; the taper sleeve 6 is set on the clamp body Concretely at the thin-walled front end of the clamp body 2; the nut 3 passes through the thin-walled front end of the clamp body 2 and the taper sleeve 6, and is threadedly connected with the clamp body 2; the nut turning handle (not shown) is connected with the nut 3 by a clearance fit.

[0013] During processing, after the outer circle of the screw sleeve part 8 is pre-positioned in the thin-walled inner hole at the front end of the clamp body 2, the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com