Numerical-control automatic boring machine tool for shaft coupler hole

A boring coupling and automatic technology, which is applied in the field of CNC automatic boring coupling hole machine tools, can solve the problem of not being able to meet the hole size tolerance, smoothness and coaxiality consistency, not being able to realize automatic boring, automatic alignment, and not being able to meet the requirements of power plants. Run power generation and other issues on schedule to achieve the effect of convenient reading, high positioning accuracy and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

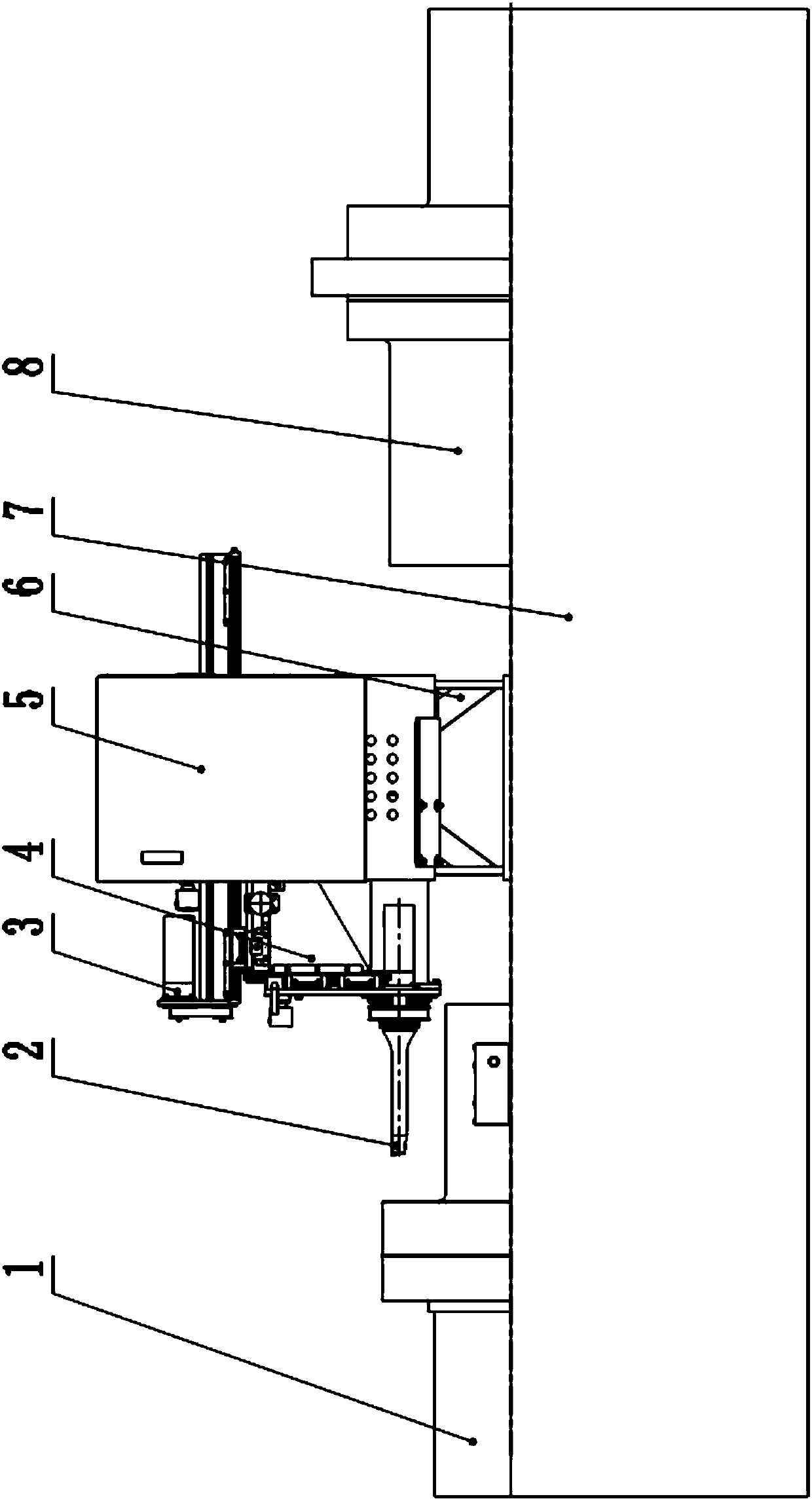

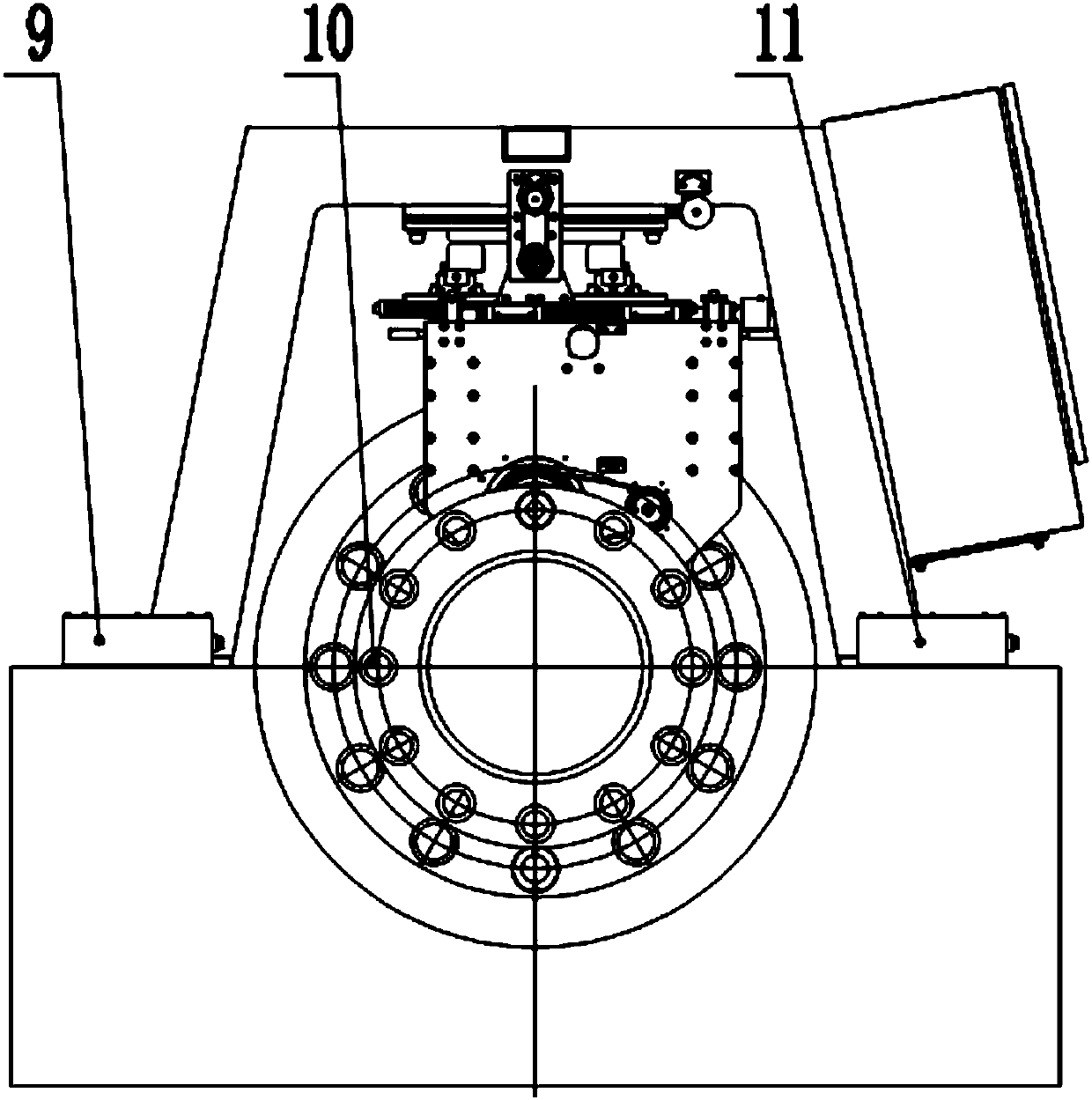

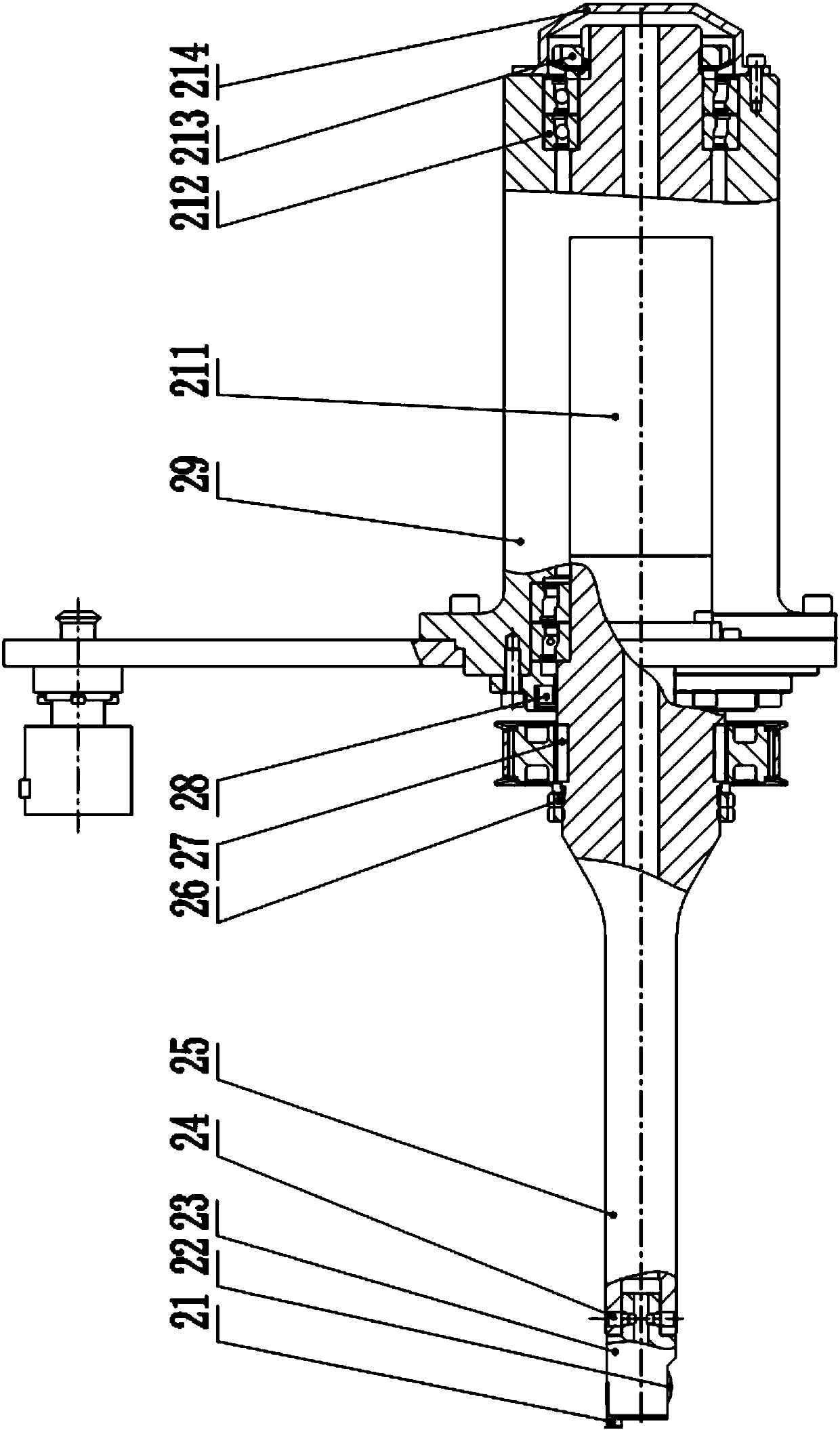

[0032] Such as Figure 1-2 As shown, the present invention discloses a numerical control automatic boring coupling hole machine tool, which includes a frame 6 fixed on a cylinder block 7 of a steam turbine, on which a rotary assembly 2, a feed assembly 3, an adjusting Control part 4, electric control box 5, laser alignment instrument 9 and control touch screen 11; described rotary assembly 2, feed assembly 3, adjustment control part 4, laser alignment instrument 9 and control touch screen 11 are all connected with electric control The box 5 is connected; the rotary assembly 2 is used to realize the forward rotation or reverse rotation of the boring head for boring the bolt hole of the coupling, and the feed assembly 3 realizes that the rotary assembly 2 including the boring head advances and retreats toward the coupling, The laser al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com