Aligning method and aligning device of silk screen boards

A technology of screen printing screen and alignment device, which is applied in screen printing machines, general parts of printing machinery, printing and other directions, can solve problems such as cost reduction, low efficiency, waste of glass screens, etc. bit, reduce production costs, improve production efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

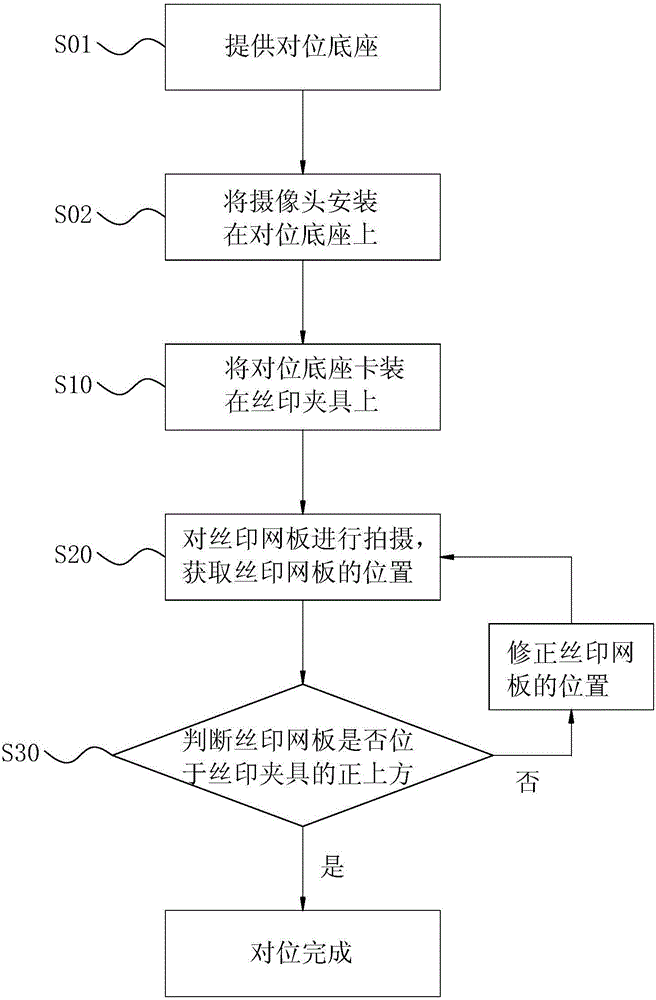

[0043] On the one hand, a method for alignment of screen printing screens is provided, comprising the following steps:

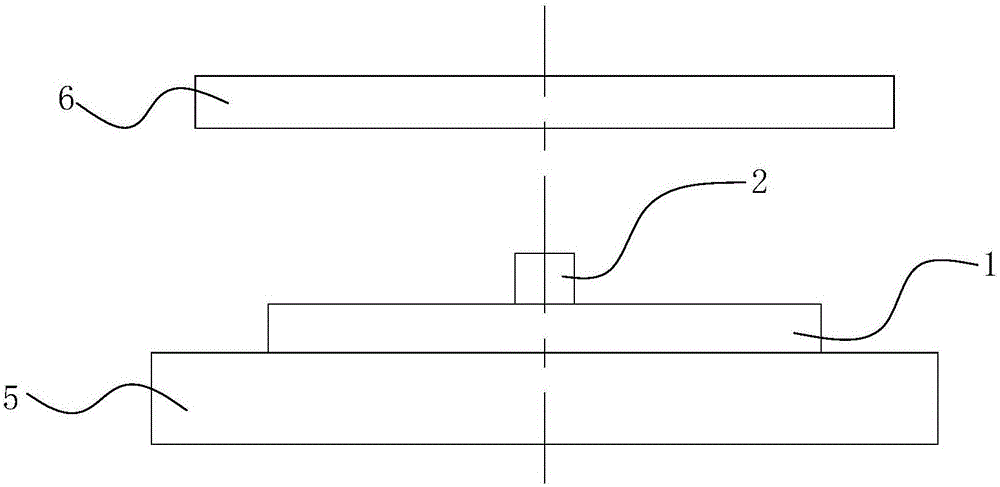

[0044] S10, clamping the alignment base 1 equipped with the camera 2 on the silk screen fixture 5;

[0045] S20, the camera 2 photographs the screen printing screen 6, and acquires the position of the screen printing screen 6;

[0046] S30, judging whether the position of the screen printing screen 6 is directly above the position of the screen printing fixture 5:

[0047] If so, the alignment is complete;

[0048] If not, correct the position of the screen printing screen 6 , and return to S20 : the camera 2 photographs the screen printing screen 6 to acquire the position of the screen printing screen 6 .

[0049] After the alignment is completed, the alignment base 1 is removed, and the glass screen to be screen-printed can be placed for processing.

[0050] In this embodiment, step S20, the camera 2 photographing the screen printing screen 6 to obtai...

Embodiment 2

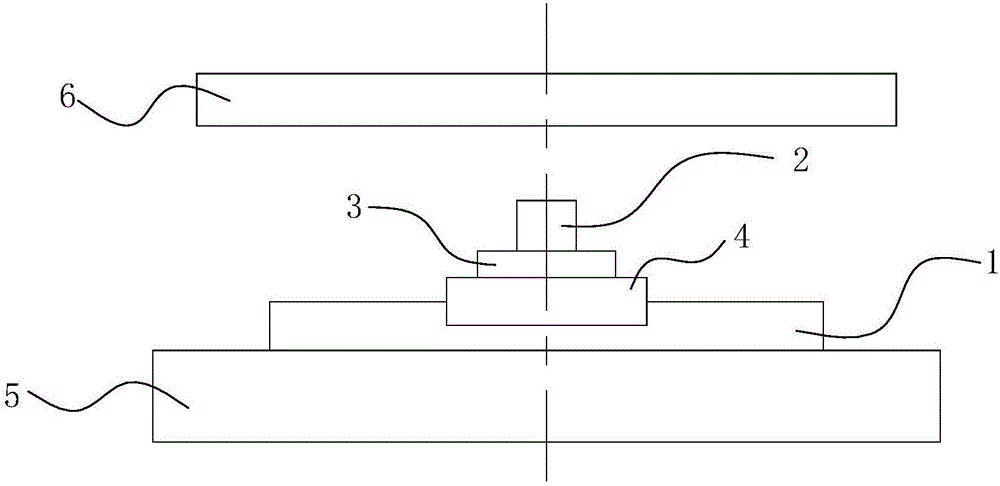

[0059] On the one hand, if image 3 As shown, an alignment method for screen printing stencils is provided, including the following steps:

[0060] S01. Provide an alignment base 1 that is the same size as the glass screen to be screen printed;

[0061] S02, installing the camera 2 on the alignment base 1;

[0062] S10, clamping the alignment base 1 equipped with the camera 2 on the silk screen fixture 5;

[0063] S20, the camera 2 photographs the screen printing screen 6, and acquires the position of the screen printing screen 6;

[0064] S30, judging whether the position of the screen printing screen 6 is directly above the position of the screen printing fixture 5:

[0065] If so, the alignment is complete;

[0066] If not, correct the position of the screen printing screen 6 , and return to S20 : the camera 2 photographs the screen printing screen 6 to acquire the position of the screen printing screen 6 .

[0067] After the alignment is completed, the alignment bas...

Embodiment 3

[0080] The difference between this embodiment and embodiment two is:

[0081] The alignment device of the screen printing screen also includes a human-computer interaction interface, which is electrically connected to the control chip, and the human-computer interaction interface can selectively display the standard positions of the four corners of the screen printing screen and In the actual position, the operator can also manually adjust the traveling mechanism of the screen printing screen through the human-computer interaction interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com