System and method of intelligent bulk loading of dry powder mortar production line

A technology of dry powder mortar and production line, which is applied in the direction of lifting device, loading/unloading, transportation and packaging, etc. It can solve the problems of high operating costs such as fast and accurate positioning of the material inlet of bulk trucks and bulk loading machines, and shorten the parking preparation time. Overcome equipment wear and save the effect of dealing with material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

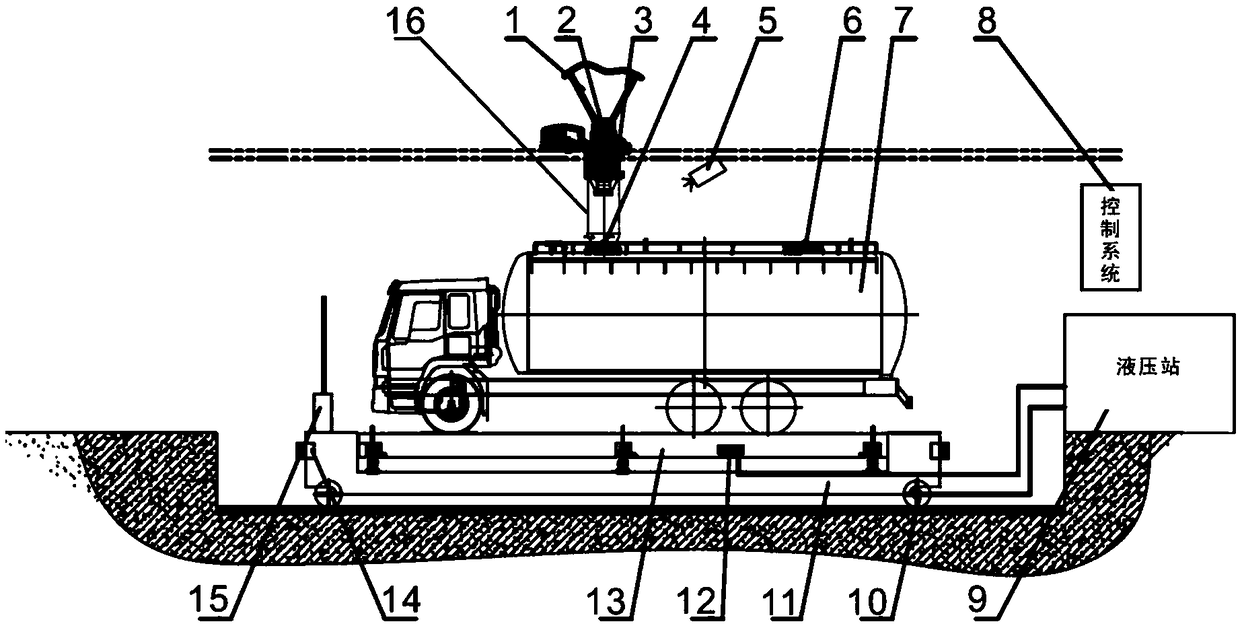

[0036] A specific embodiment of the present invention discloses an intelligent bulk loading system for a dry powder mortar production line, including a loading rack and a control system 8, a bulk loading machine 3 and a vision system 5 are arranged on the loading rack, and the control system 8 is used to control The dry powder mortar loading process also includes a large crane 11 that moves laterally and a small crane 13 that moves vertically. The small crane 13 is set on the large crane 11. The large crane 11 and the small The moving direction of the trolley 13 on the plane is vertical. Preferably, the moving direction of the large trolley 11 is the same as the direction in which the bulk vehicle 7 drives in or out. Or the direction of driving out is vertical; the visual system 5 can obtain the coordinates of the center point of the bulk vehicle feed inlet and the center point coordinates of the bulk machine outlet, and calculate the distance that the bulk vehicle 7 needs to m...

Embodiment 2

[0048] This embodiment discloses a method for loading vehicles using the intelligent bulk loading system of the dry powder mortar production line in Embodiment 1, which specifically includes the following steps:

[0049] Step 1: Park the bulk vehicle 7 on the trolley 13.

[0050] The driver operates the bulk vehicle 7 to travel to the driving movement, parks the bulk vehicle 7 on the trolley 13, and installs a vehicle in-position detection device 15 on the driving movement. The in-position detection device 15 can detect the movement state of the vehicle on the trolley 13, When the in-position detection device 15 detects that a vehicle enters the trolley 13 and determines that the vehicle has stopped, the in-position information of the bulk vehicle 7 is sent to the control system 8 .

[0051] Step 2: The visual system 5 collects and processes information.

[0052] After the control system 8 receives the information that the bulk vehicle 7 is parked and in place, the vision sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com