Connecting box bus bar welding machine and welding detecting method thereof

A technology of bus bars and welding machines, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low degree of automation, burnt out components, and can not work normally, so as to improve the degree of automation, ensure stability, welding accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

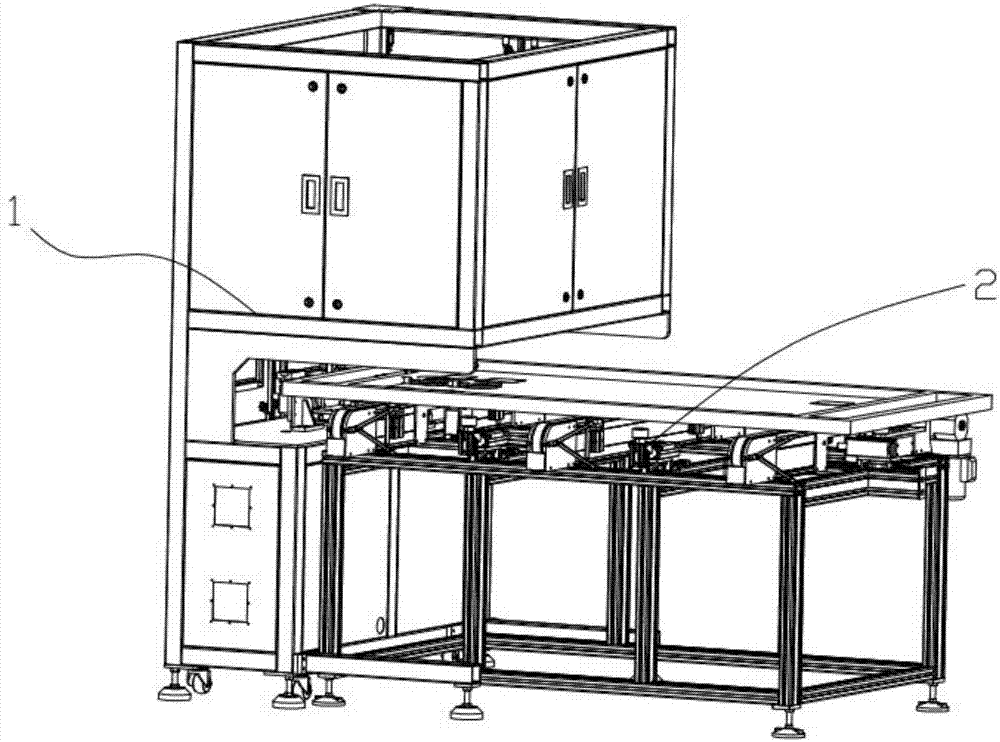

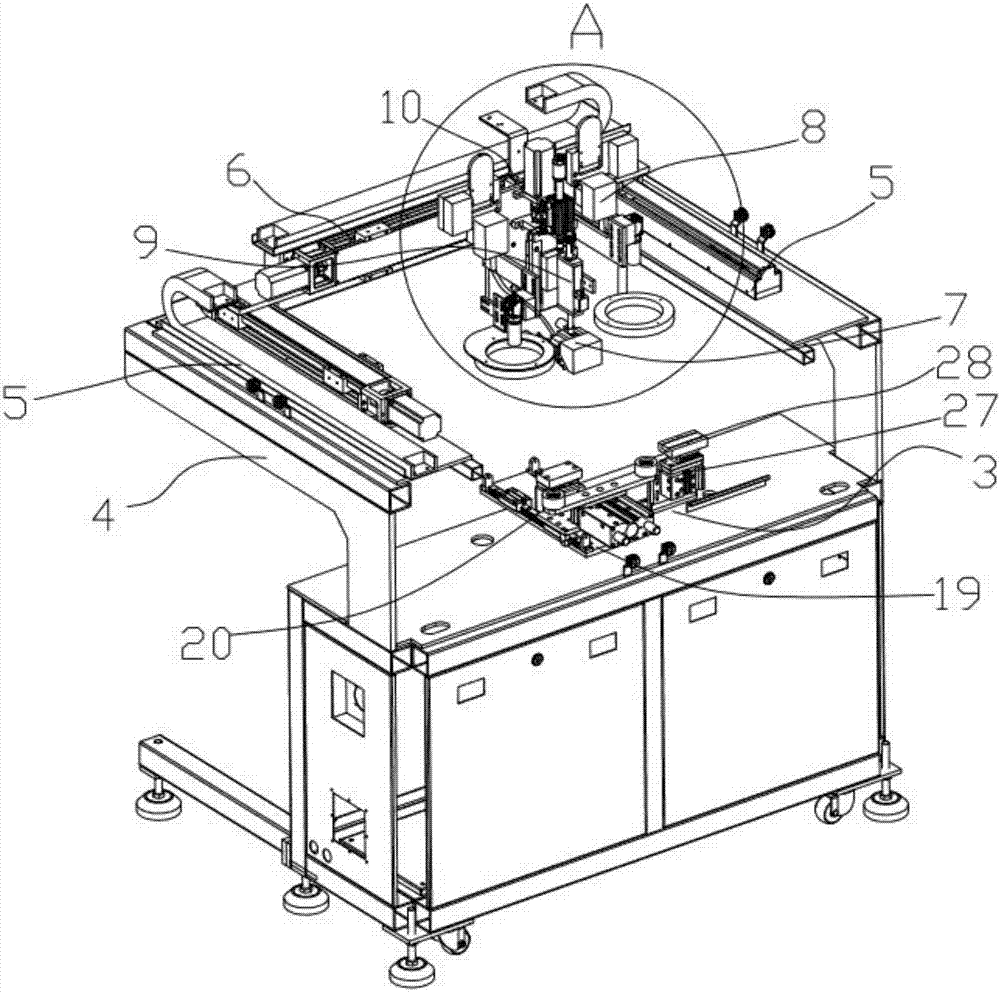

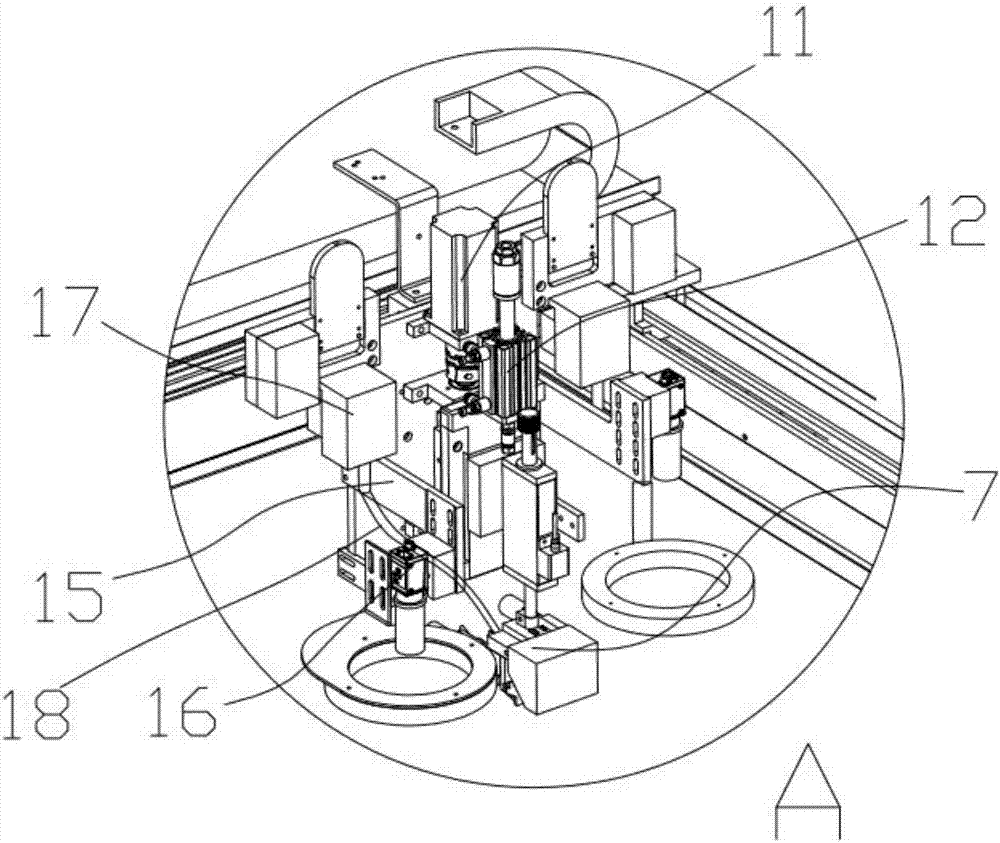

[0026] Such as figure 1 , figure 2 , image 3 As shown, the present invention proposes a junction box bus bar welding machine, including a welding part 1, a loading part 3 and a transmission mechanism 2, the welding part 1 is located on the upper part of the loading part 3, and the transmission mechanism 2 is located on the On the side of the loading part 3, the loading part 3 includes a bottom plate 21, a slide rail 20 is arranged on the bottom plate 21, a slide plate is engaged on the slide rail 20, and a pulling cylinder 22 is connected to the slide plate , the upper part of the pulling cylinder 22 is connected with a guide plate 23, the two sides of the guide plate 23 are provided with guide wheels 24, and the guide plate 23 is perpendicular to the direction of the slide rail 20; the output end of the pulling cylinder 22 is connected with Jacking cylinder 25, the output end of described jacking cylinder 25 is connected with top plate 26, as Figure 5 As shown, the mate...

Embodiment 2

[0032]In order to ensure the cleanliness of the welding head, after using for a certain period of time, it can automatically move to the upper part of the welding head grinding device for automatic grinding, and remove the solder on the surface. The side of the loading part 3 is equipped with a welding head grinding device. The welding head grinding device includes a bearing cylinder 27, on which a grinding block 28 is arranged, and the temperature-controlled welding head 7 is transported to the grinding block 28 by a horizontal and vertical conveying mechanism to move back and forth for grinding.

Embodiment 3

[0034] Such as Figure 7 As shown, due to the heavy weight and large volume of solar energy, the transmission mechanism 2 includes a frame 29 on which several conveyor belts 31 are arranged, and the ends of the conveyor belts 31 are connected with a conveyor motor 30 A horizontal cylinder 32 is arranged between the conveyor belts 31, the output end of the horizontal cylinder 32 is connected with a positioning cylinder 33, the conveyor motor 30 controls the transmission of the conveyor belt 31, and the solar panel moves along the conveyor belt 31 to the welding part 1, the lower part The positioning cylinder 33 stretches upwards and has a supporting effect on the solar panel.

[0035] After the product welded by the above-mentioned embodiment is welded by the welding head welder, after the CCD camera obtains the surface image of the junction box, detect the black spots on both sides of the welding point, if the area of the black spots is less than or equal to 10% of the overa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com