Automatic alignment type auxiliary mounting frame for mounting vehicle roller shaft

An automatic alignment and roller shaft technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of loss of physical strength, low accuracy of vehicle roller shafts, and reduce the intuitiveness of vehicle roller shaft alignment, etc., to improve The effect of stability and good precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

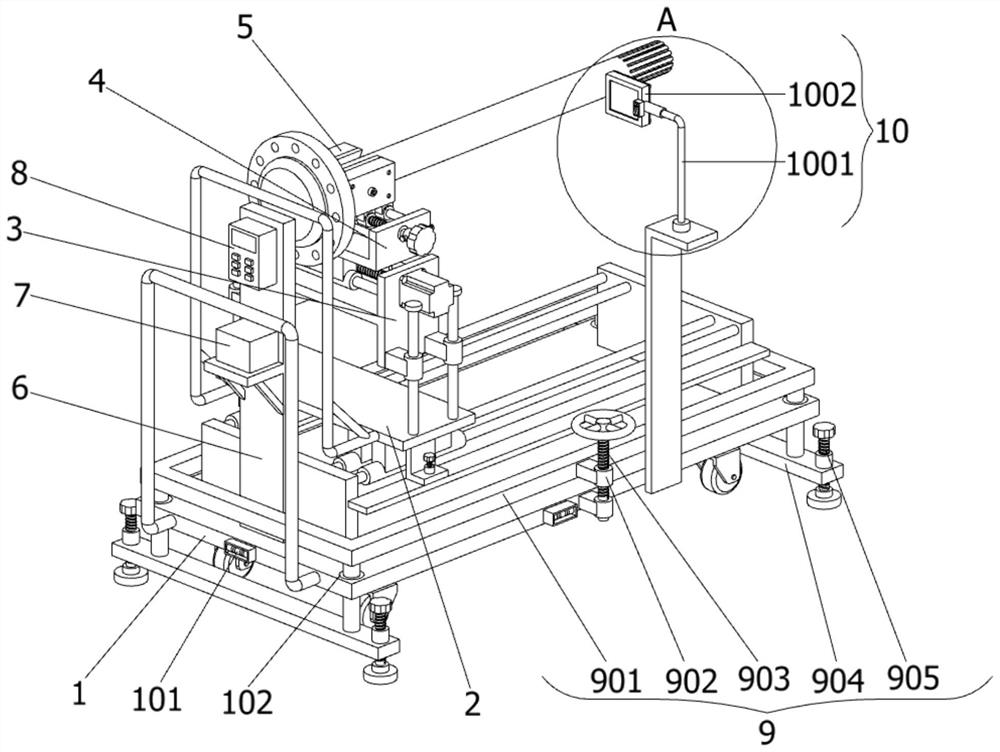

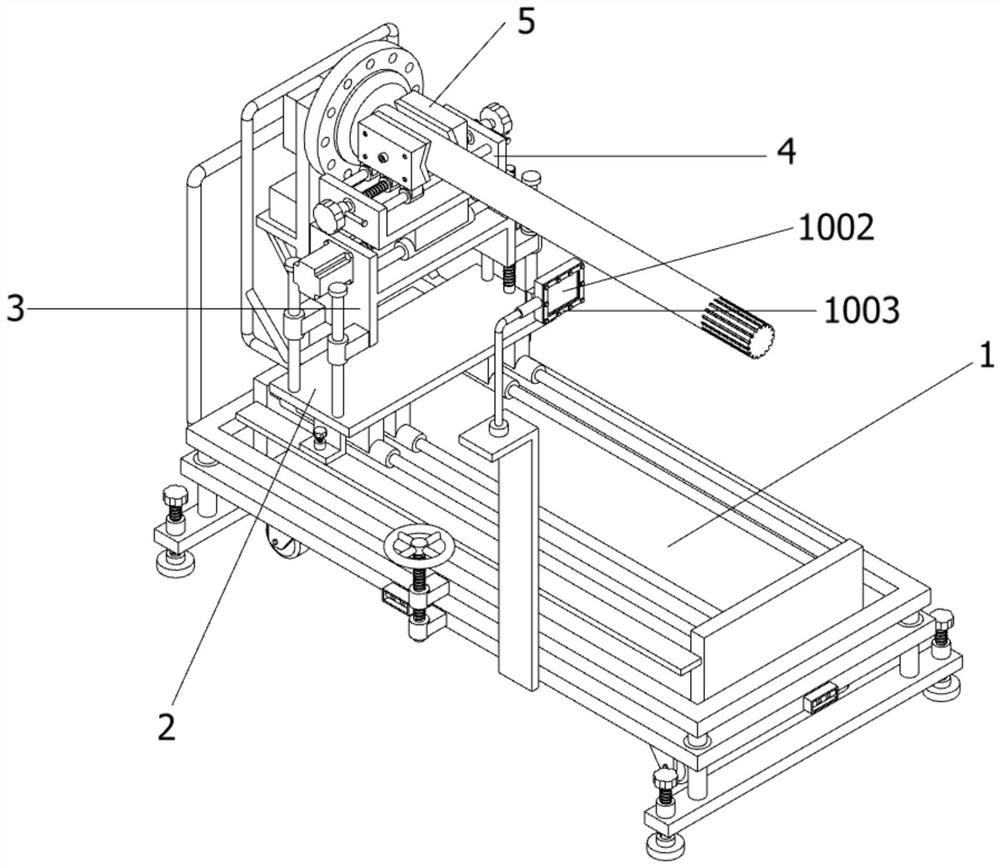

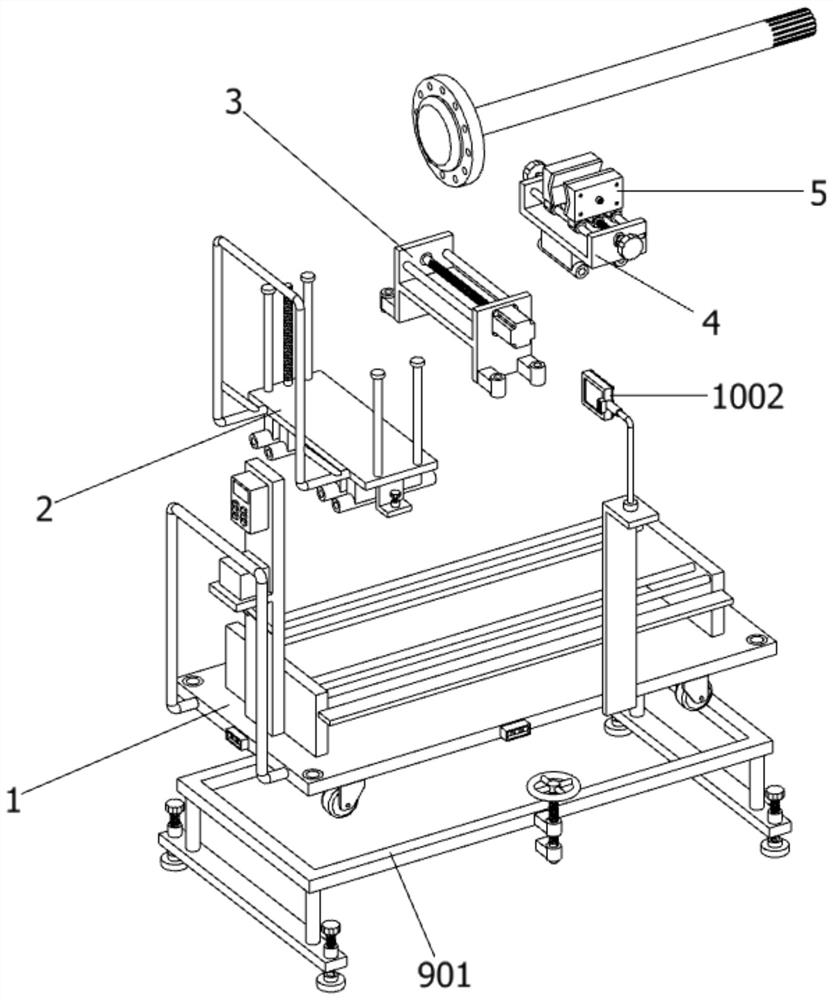

[0037] as attached figure 1 to attach Figure 10 As shown, the automatic alignment auxiliary mounting frame for the installation of the vehicle roller shaft in the preferred embodiment of the present invention includes: a bottom plate 1, the upper part of the bottom plate 1 is slidably connected with a sliding mechanism 2, the bottom plate 1 includes a vial 101 and a bushing 102, and the sliding The upper part of the mechanism 2 is provided with a height adjusting member 3 . The height adjustment member 3 includes an I-shaped lifting plate 301, a first sliding sleeve 302, an elevating motor 303 and a lifting screw 304, and the lower part of the left and right ends of the I-shaped lifting plate 301 is provided with two first sliding sleeves 302, and each first The inside of the sliding sleeve 302 is slidably connected with a limit sliding column fixed on the upper end surface of the sliding table 201 . Lifting motor 303 is installed on the left side of the bottom end surface ...

Embodiment 2

[0039] In a preferred embodiment, the auxiliary mechanism 10 includes a metal shaping hose 1001 , a magnifying glass 1002 , an LED light strip 1003 and a control switch 1004 . The metal shaping hose 1001 is fixedly connected to the top of the L-shaped support plate on the right side of the bottom plate 1, and the other end of the metal shaping hose 1001 is connected to a magnifying glass 1002, which is a square structure.

[0040] Further, an LED light strip 1003 is provided at the edge of the rear end of the magnifying glass 1002, and a control switch 1004 is installed on the right side of the front end of the magnifying glass 1002. The illumination effect of the magnifying glass cooperates with the magnifying effect of the magnifying glass 1002, thereby improving the intuition when the vehicle roller shaft is aligned.

Embodiment 3

[0042] In a preferred embodiment, two anti-slip parts 11 are arranged symmetrically inside the clamping mechanism 5 , and the anti-slip parts 11 include rubber anti-slip pads 1101 , limit posts 1102 , injection tubes 1103 and white powder 1104 . The middle part on the left side of the rubber anti-slip mat 1101 is connected with an injection pipe 1103, and the four corners on the left side of the rubber anti-slip mat 1101 are provided with a limit post 1102, and the interior of the injection pipe 1103 is connected with a sealing bolt through a thread, and the interior of the rubber anti-slip mat 1101 Filled with white powder 1104, by filling the inside of the rubber anti-slip mat 1101 with white powder 1104, when the rubber anti-slip mat 1101 is severely worn, the white powder 1104 will leak out from the inside of the rubber anti-slip mat 1101, so that the staff can find the rubber anti-slip in time The severe wear of the pad 1101 improves the reliability of the anti-skid member...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com