Patents

Literature

59results about How to "Guarantee product quality requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Film solar battery module with transparence and process method thereof

InactiveCN101894880AReduce manufacturing costSimple processEnergy conversion devicesPhotovoltaic energy generationSand blastingEngineering

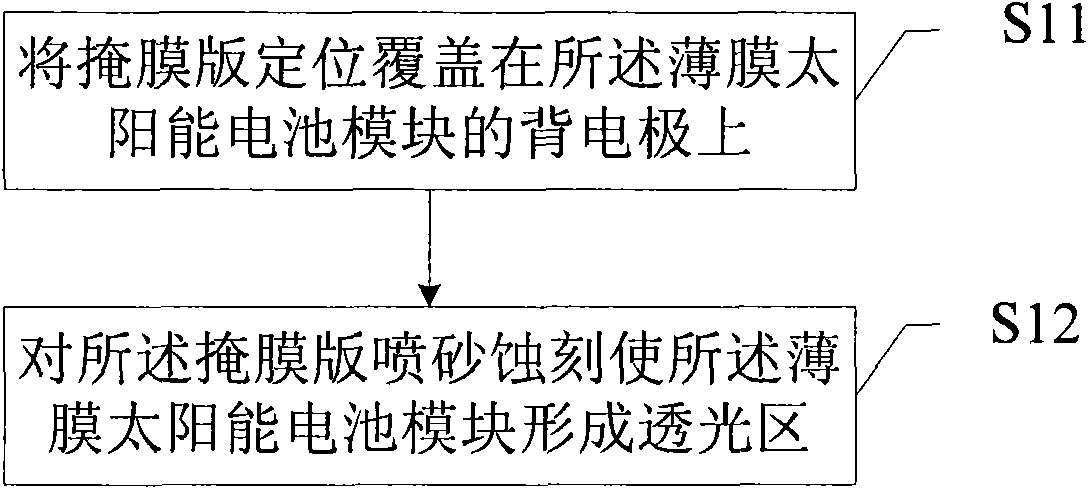

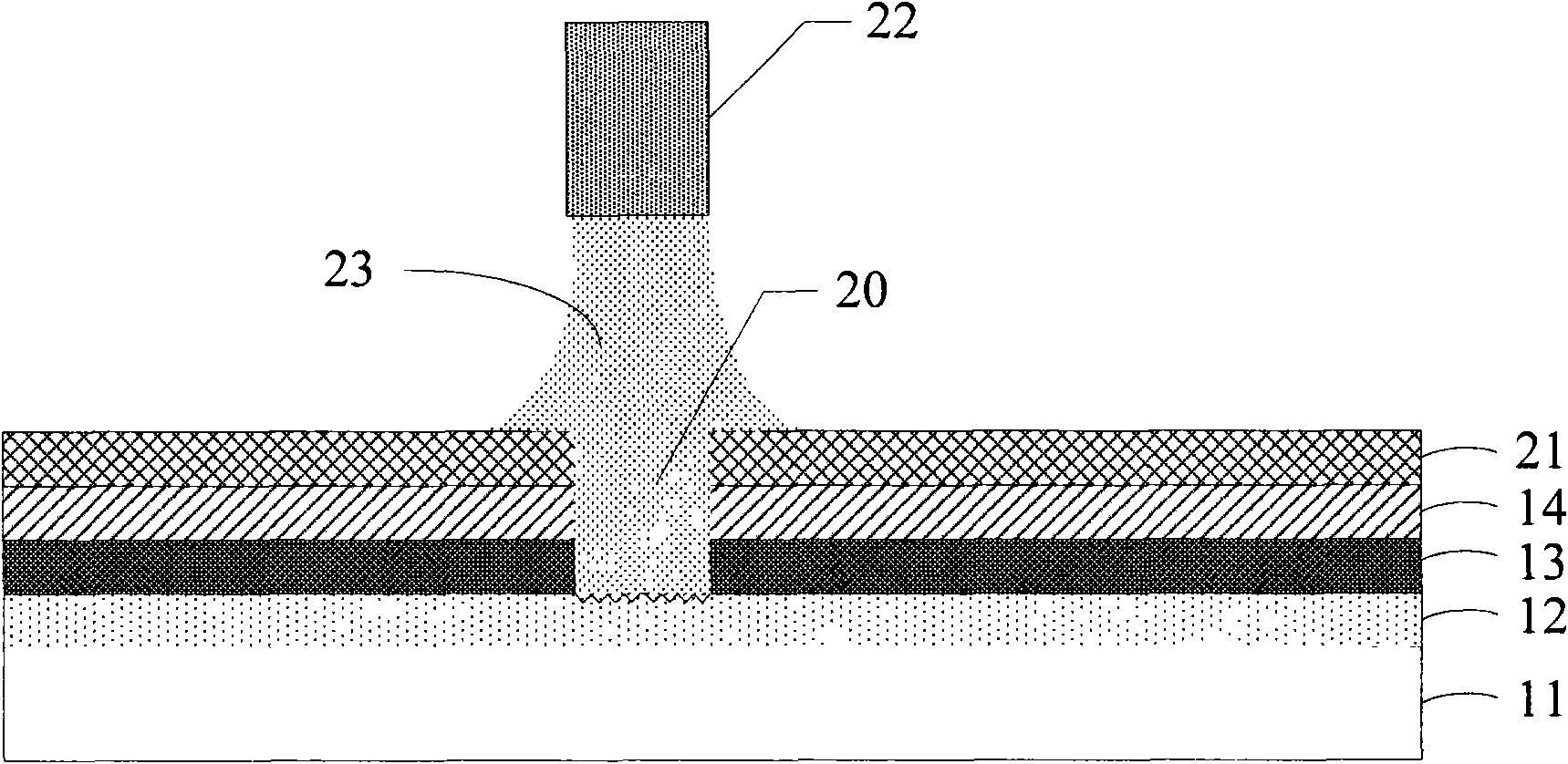

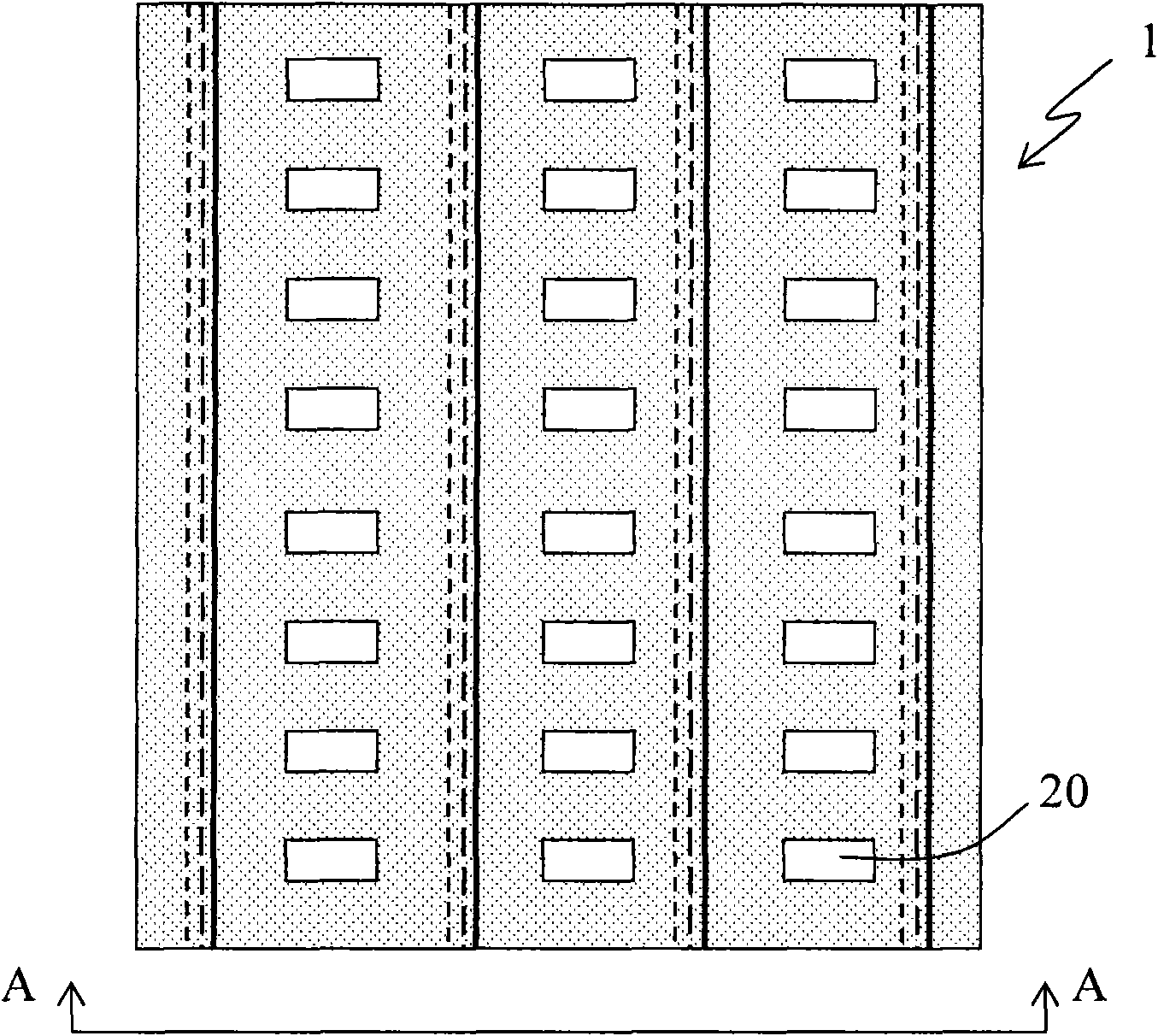

The invention discloses a film solar battery module with transparence and a process method thereof. In the process method, a mask assisted sand-blasting etch process is used for forming a transparent area, and the process method specifically comprises the following steps of: positioning and covering a mask on a back electrode of the film solar battery module; and performing sand-blasting etching on the mask to ensure that the transparent area is formed on the film solar battery module. By using the process method of the invention to manufacture the film solar battery module with transparence, the transparent area with any patterns can be formed, and the production cost is low, and the process method is suitable for mass production.

Owner:WUXI SUNTECH POWER CO LTD +1

Organic soilless vegetable culture substrate

InactiveCN102823479ASuitable for planting requirementsEasy plantingAgriculture gas emission reductionCultivating equipmentsBiotechnologyPoultry manure

The invention discloses an organic soilless vegetable culture substrate. Under the soilless condition, vegetables are difficult to plant. The organic soilless vegetable culture substrate is characterized in that cassava bark, poultry manure and peanut bran are utilized to be simultaneously fermented with fermentation bacterium liquid, and the organic soilless vegetable culture substrate is prepared. The raw materials adopted by the organic soilless vegetable culture substrate are respectively organic matter raw materials, the reasonable and scientific mixture ratio is adopted, the vegetable planting requirement is properly met, particularly, the waste and abandoned cassava bark after the cassava deep processing is used as raw materials, nitrogen and calcium obtained through conversion after the cassava fermentation are utilized, the technical problem of soilless culture is solved, and the vegetable planting can be conveniently carried out by utilizing the organic soilless vegetable culture substrate in places without planting conditions. The organic soilless vegetable culture substrate overcomes the defects of the soilless vegetable planting in the prior art, the energy saving and the environment protection are favorably realized, the pest and disease occurrence quantity of the vegetable planting is low, the pesticide consumption is reduced, and no chemical fertilizer is used, so the product quality and yield requirement of green vegetable products can be ensured.

Owner:北海市蔬菜研究所

Recycling method of unqualified battery for electric bicycle

InactiveCN101958441AGuarantee product quality requirementsMeet the use requirementsWaste accumulators reclaimingBattery recyclingSocial benefitsResource saving

The invention discloses a recycling method of an unqualified battery for an electric bicycle, comprising the following steps of: disassembling 12 V series unqualified batteries with production time less than 6 months and returned to factories through market feedback; selecting qualified polar groups from six polar groups disassembled from each battery according to a certain standard; then detecting and sorting the qualified polar groups; and then reassembling the polar groups in same sorts into new batteries used for the service replacement of the market feedback batteries by referring to the requirements of a normal battery assembly process. The recycling method has the advantages of resource saving, environmental protection, high application value, outstanding economic and social benefit, easy operation, normative process and suitability of popularization and use.

Owner:JIANGSU SHUANGDENG GROUP

Manufacturing method of carbon steel wire with diameter of 0.05 mm

ActiveCN109940054AImprove plastic deformationInhibit expansionFurnace typesHeat treatment furnacesWork in processUltimate tensile strength

The invention discloses a manufacturing method of a carbon steel wire with a diameter of 0.05 mm. The manufacturing method comprises the steps of raw material selection-primary semi-finished steel wire cold drawing-primary semi-finished steel wire continuous heat treatment-secondary semi-finished steel wire cold drawing-secondary semi-finished steel wire continuous heat treatment-ternary semi-finished steel wire cold drawing-ternary semi-finished steel wire continuous heat treatment-finished steel wire drawing-finished steel wire inspection. The stress is eliminated to recover plasticity through the drawing combination mode and three times of heat treatment; through optimization of heat treatment parameters and specific drawing routes, the metal deformation under high compression ratio isadapted to, so that the smooth drawing process can be effectively guaranteed; through plastic deformation in the whole process, the diameter of the steel wire can be smoothly reduced; meanwhile, the tensile strength of a product is continuously improved, and the strength reaches above 2300 MPa to meet the requirements of appearance, surface quality, mechanical performances and toughness of the steel wire product; and meanwhile, the batch production is realized, and the product quality is guaranteed.

Owner:GUIZHOU WIRE ROPE

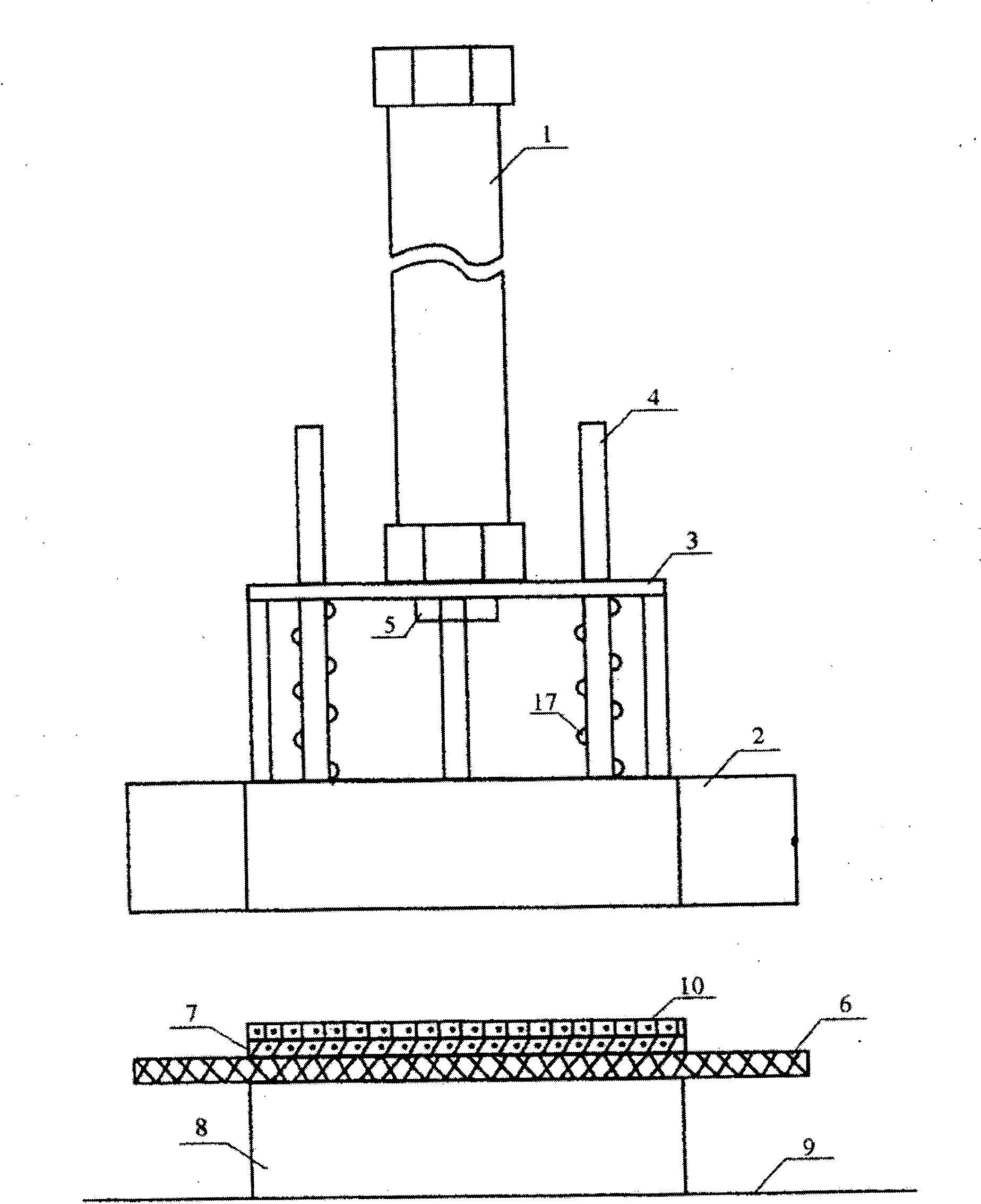

Automatic ironing device and method of clothing logos

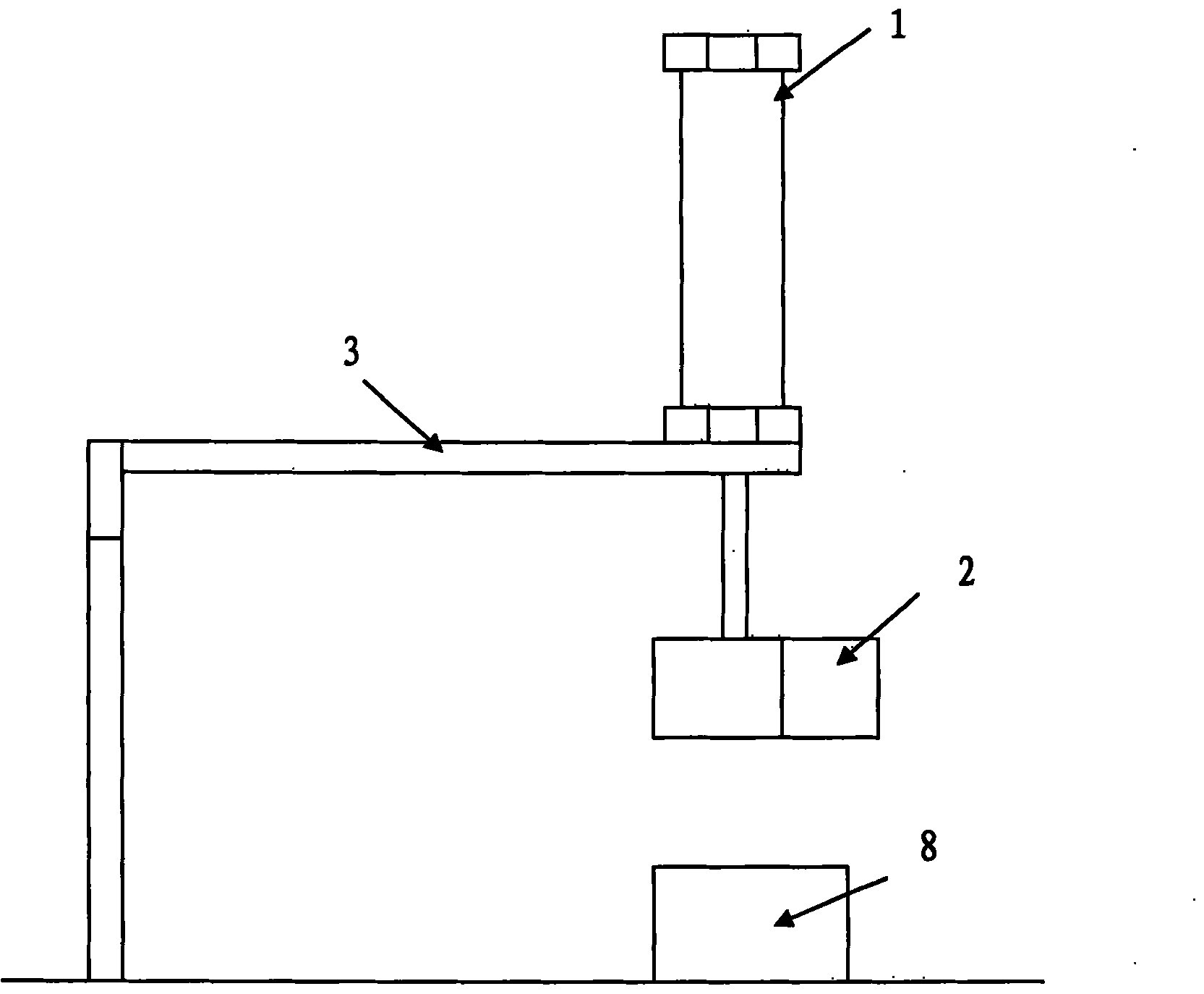

ActiveCN101871174AReduce labor intensityReduce areaIroning apparatusTextile decorationAutomatic controlCantilever

The invention discloses automatic ironing device and method of clothing logos, aiming to solve the problems of poor logo ironing effect, and the like in the prior art. The device comprises a bracket, drive mechanisms, press plates and a cushion block, wherein the upper end of the bracket is horizontally provided with at least one cantilever; the drive mechanisms are fixed at the front ends of the cantilevers and used for driving the press plates to ascend and descend; the press plates are arranged at the lower ends of the drive mechanisms; the cushion block is arranged below the press plate; and the press plates and / or the cushion block are / is internally provided with an electric heating device. In the device and the method, because digital temperature automatic control is adopted and the press plates are driven by a cylinder and controlled by timing, the requirement on product quality is guaranteed, and the consistency on the product quality is improved during ironing; because the cantilevers and the press plates are adopted, the labor intensity of operators is lightened, the operation time is shortened, and the labor efficiency is improved; and because the area of the cushion block is small, only an electric heating rod of 100 watts is used, thus the power consumption is reduced.

Owner:JIHUA 3543 KNITTING CLOTHING

Method for cultivating vegetables

InactiveCN104365454AReduce pests and diseasesReduce productionExcrement fertilisersBioloigcal waste fertilisersBiotechnologyTrace element

The invention discloses a method for cultivating vegetables. The method includes steps of firstly, preparing organic soilless vegetable culture substrates; secondly, measuring fertilizer contents of the organic soilless vegetable culture substrates obtained in the first step, and adding sufficient nitrogen, phosphorus, potassium and other trace-element fertilizers to the organic soilless vegetable culture substrates as needed; thirdly, placing the organic soilless vegetable culture substrates processed in the second step into containers, and planting the vegetables in the organic soilless vegetable culture substrates. Shortcomings of high cost, poor effects, incomplete nutrition ingredients and environmental pollution of existing soilless culture substrates can be overcome by the aid of the method, and the method for planting the vegetables has the advantages of simplicity, understandability and convenience in operation.

Owner:LIANGMEIJIA TIANJIN AGRI TECH CO LTD

Cultivation mediums of using flammulina velutipes mushroom dregs to produce organic hydroponic vegetables and method thereof

InactiveCN103125357AEasy to save energyImprove protectionClimate change adaptationExcrement fertilisersLivestock manureVegetable farming

The invention discloses a method of producing organic hydroponic vegetables cultivation mediums by using flammulina velutipes mushroom dregs. The method includes the steps: (1), processing medium raw materials; (2), processing medium livestock manure; (2), manufacturing microbial fermentation cultures; (4), fermenting the mediums; (5) curing the fermented medium. Under the conditions without soils, vegetables are difficult to plant. Abandoned mushroom dregs after flammulina velutipes is produced are used for fermenting with fermentation liquors, and organic hydroponic vegetablee cultivation mediums are manufactured. The used raw materials are all raw materials with organic materials, a scientific match is reasonable, vegetable planting requirements are suitable, the mushroom dregs after using and resoling by the flammulina velutipes serves as the raw materials, the mushroom dregs after fermenting which are converted into nitrogen and calcium are used. The technical problem of hydroponic cultivation is solved, and in the places without planting conditions, the method of producing the organic hydroponic vegetables cultivation mediums by using the flammulina velutipes mushroom dregs can be used for carrying out vegetable planting conveniently.

Owner:湖北富士峰生物科技有限公司

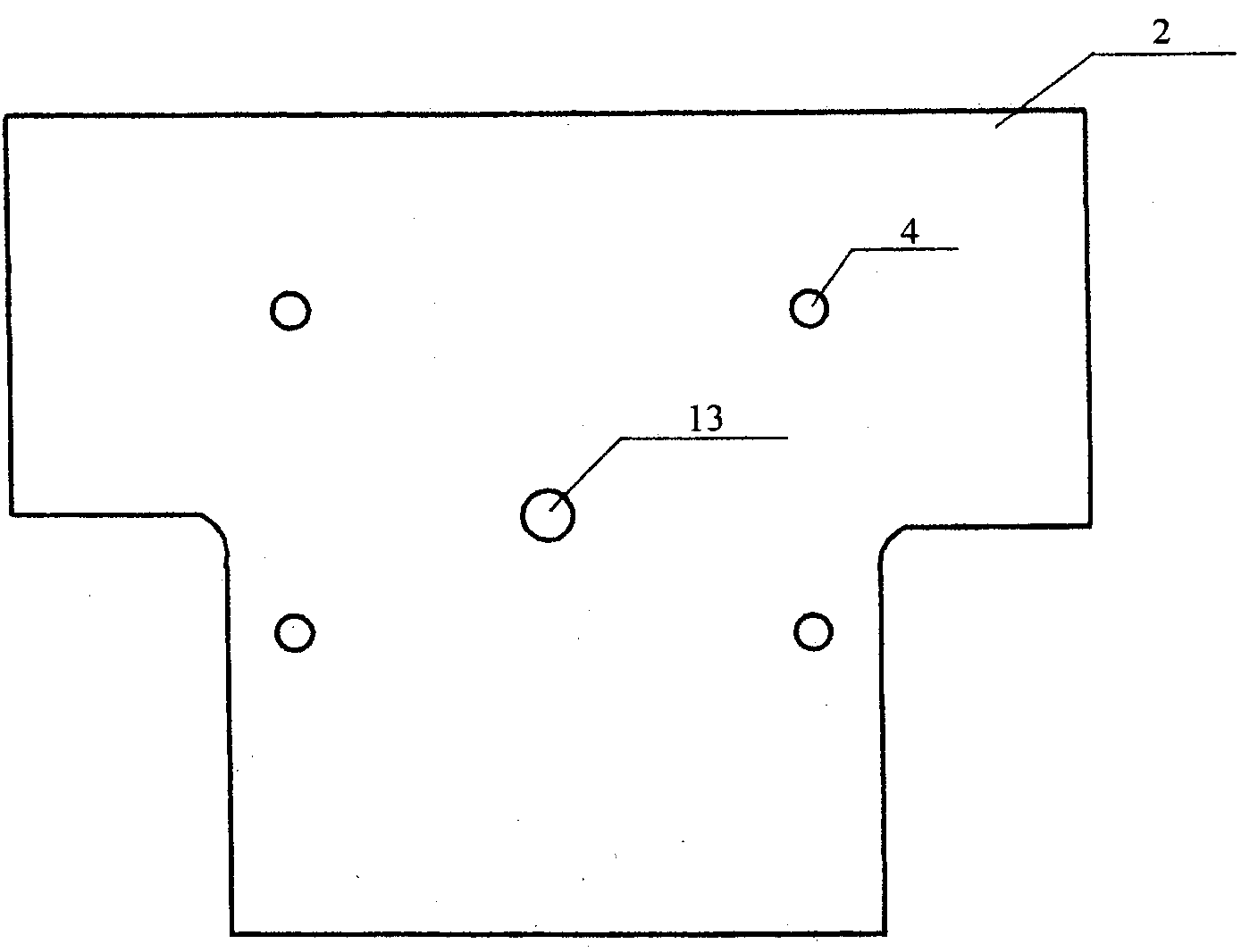

Lithium ion battery self-discharge screening and matching method

InactiveCN111063951AReduce capacityReduce varianceSecondary cells charging/dischargingInternal resistanceState of charge

The invention provides a lithium ion battery self-discharge screening and matching method. The method comprises the steps of charging a capacity-graded battery to a preset state of charge, and selecting alternative batteries of which the battery voltage is within a set range; According to the method, the battery is capacity-graded; the battery with the first-grade capacity is tested, meanwhile, the subsequent voltage difference and the numerical value of the DC internal resistance DCIR are analyzed, so as to guarantee that the difference among the capacity, the self-discharge voltage and the internal resistance of the assembled battery is small; the problems of large voltage difference, rapid capacity attenuation and the like in the using process of the lithium ion battery due to mismatching of the assembled battery are solved; high-temperature shelving of the battery is beneficial to infiltration of the electrolyte of the lithium ion battery, and micro short-circuit points in the battery can be aggravated due to the high-temperature expansion effect, so that later-period self-discharge screening is facilitated; the method is convenient to operate; the cycle performance and safetyperformance of the battery pack are improved; the method is suitable for batch production; the product quality requirement is met; and a basis is provided for single battery process inspection.

Owner:安徽益佳通电池有限公司

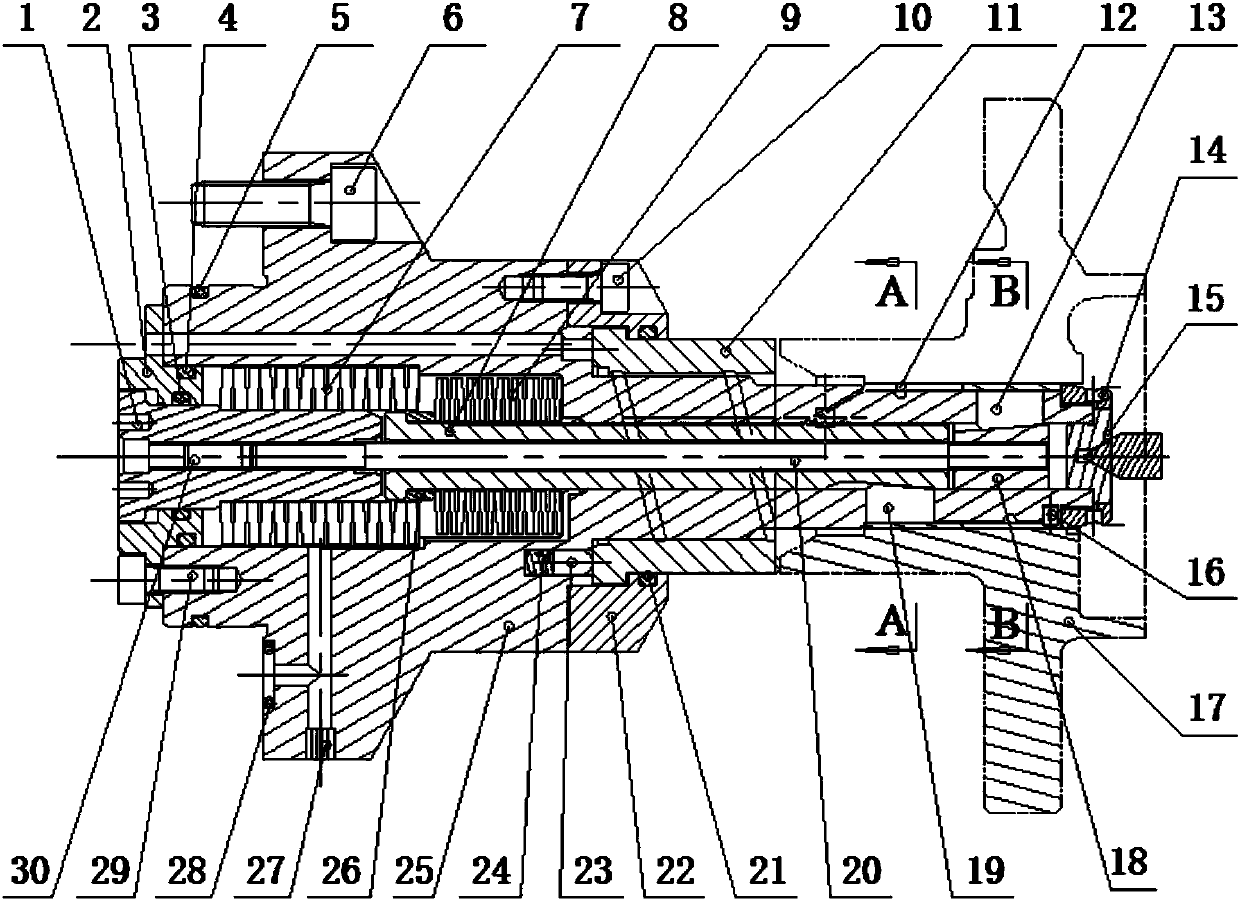

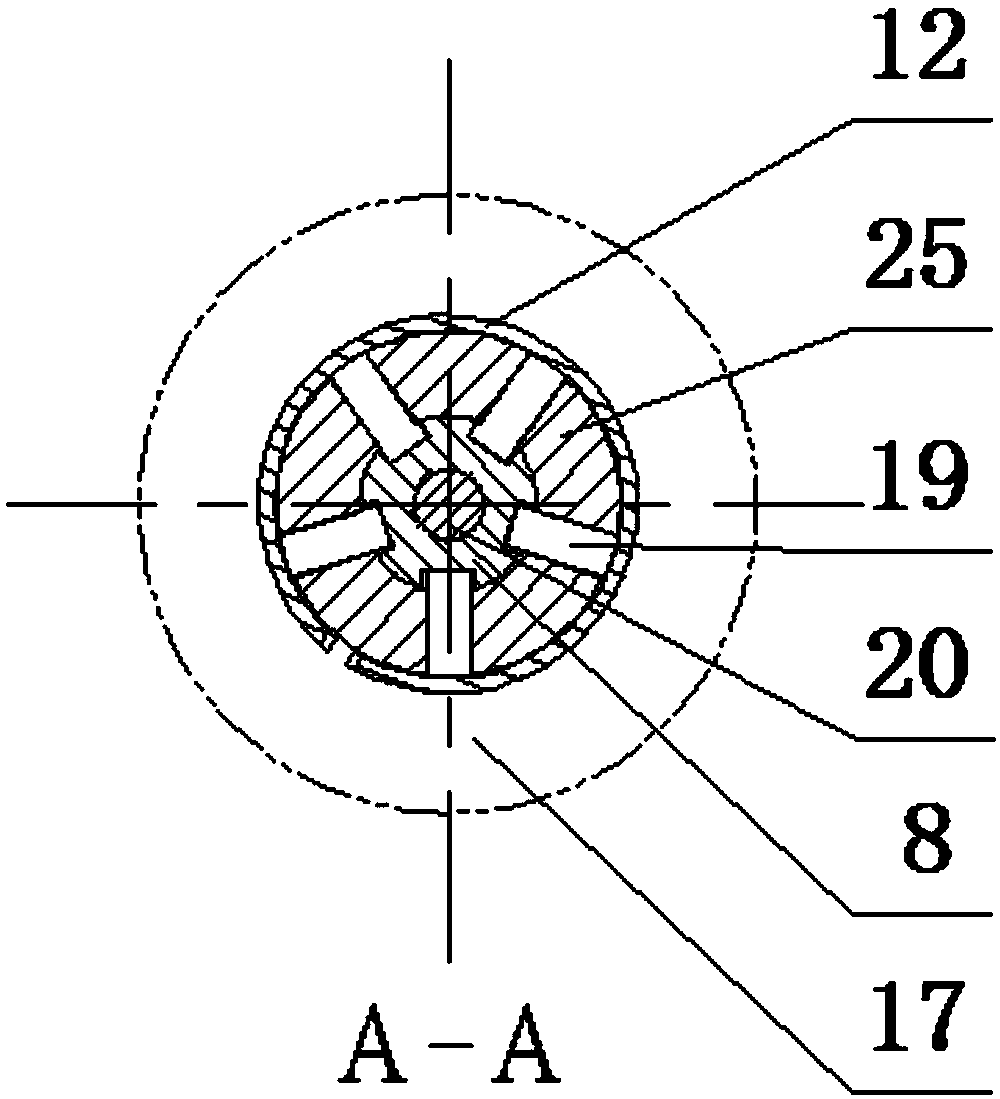

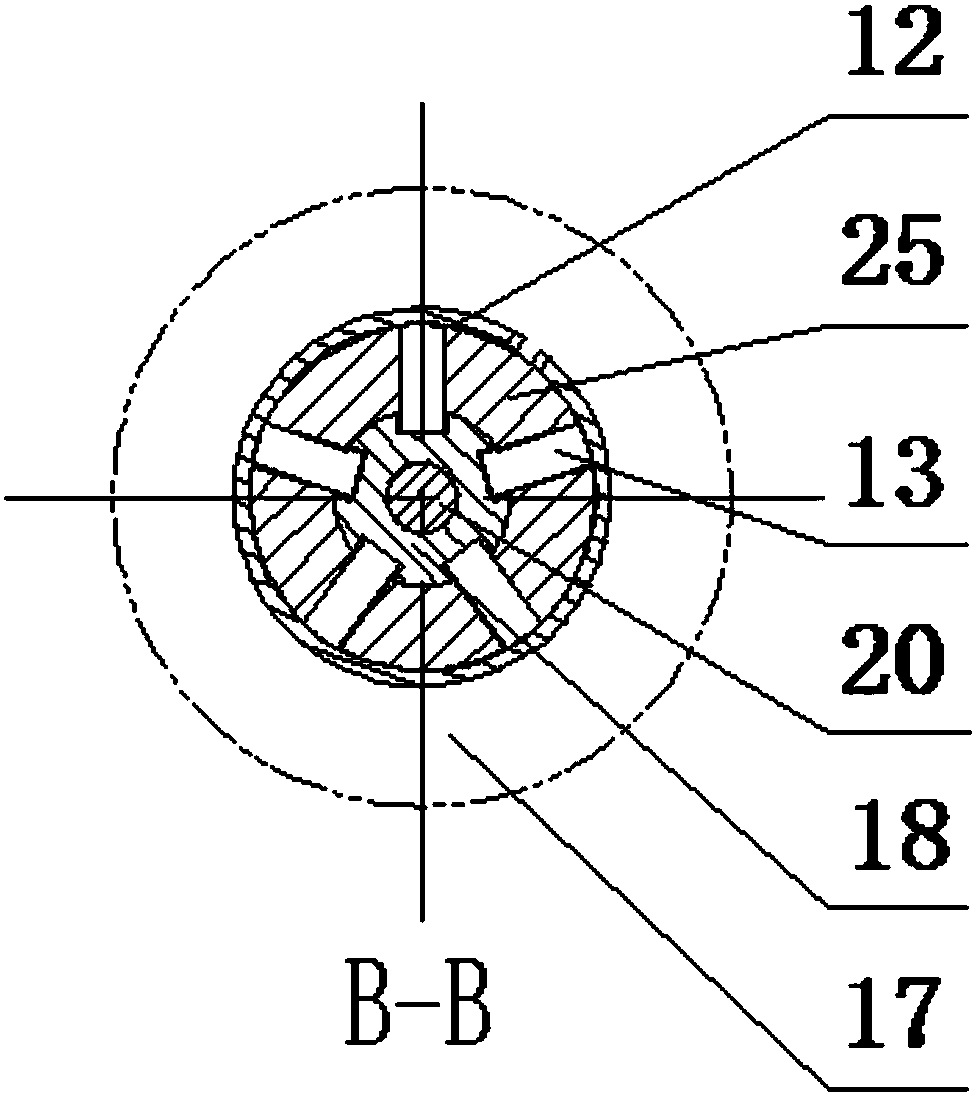

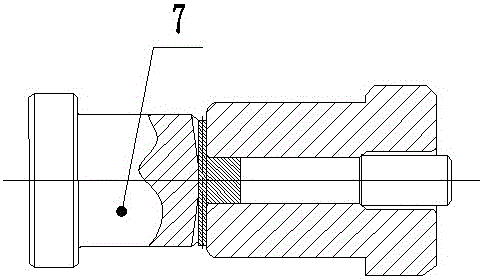

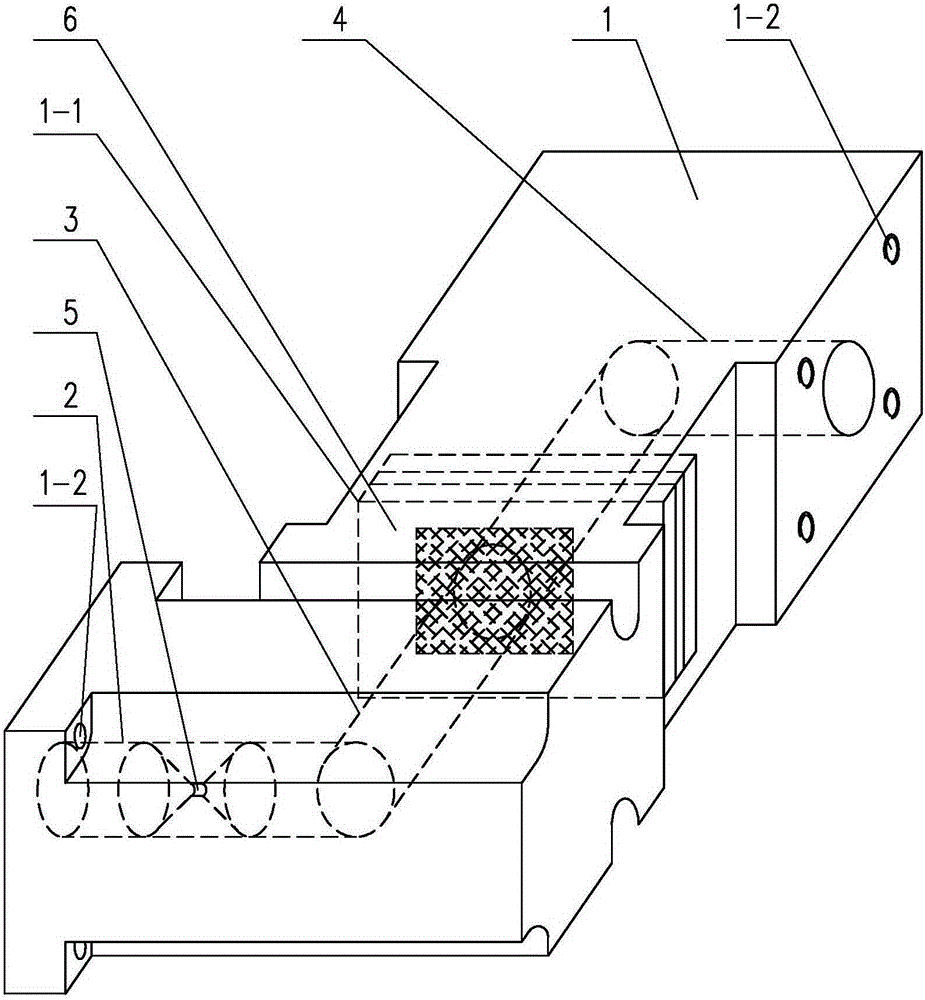

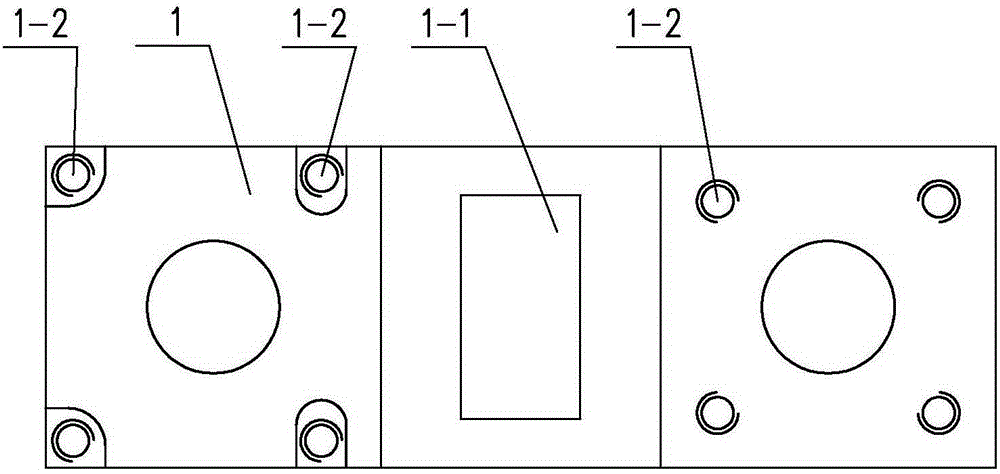

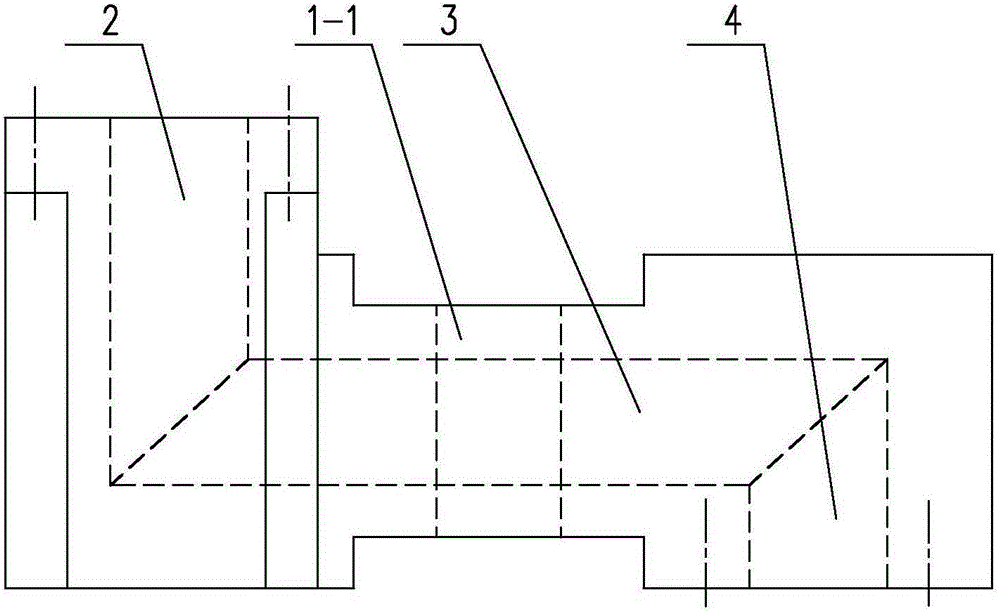

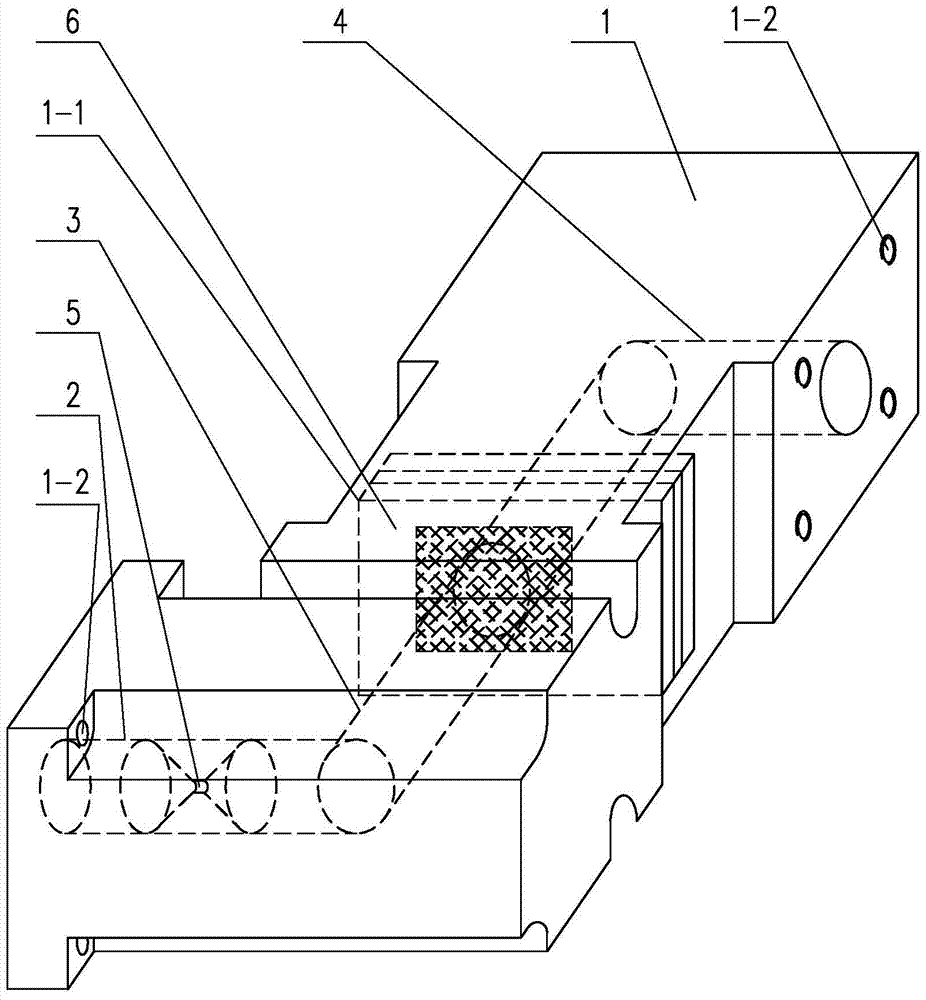

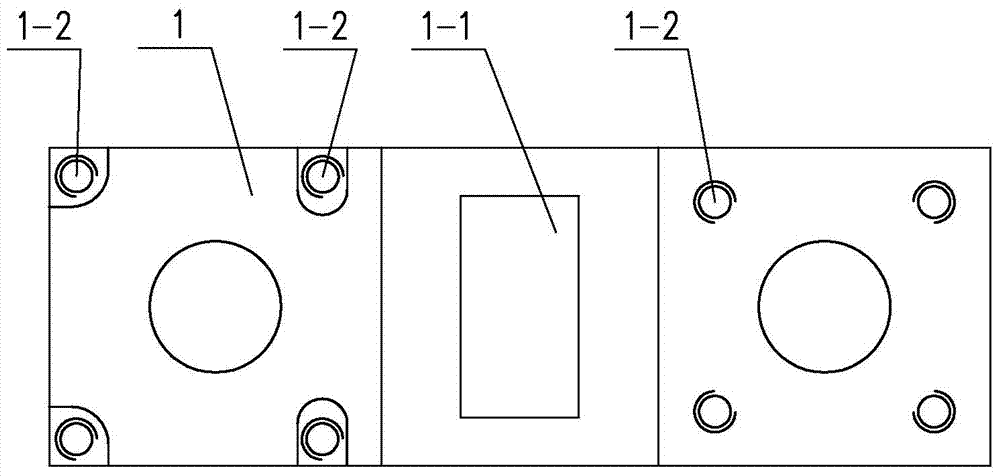

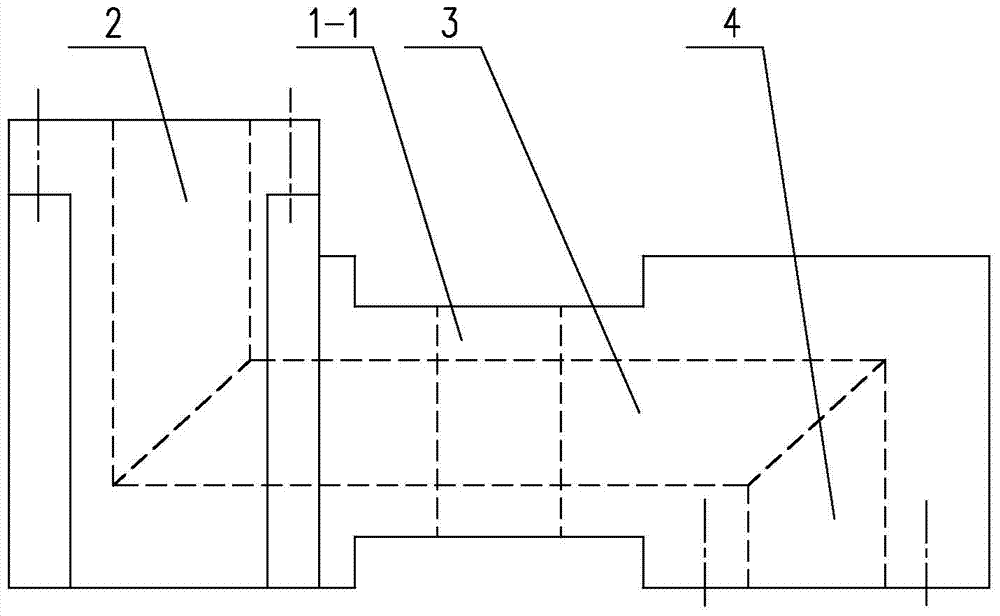

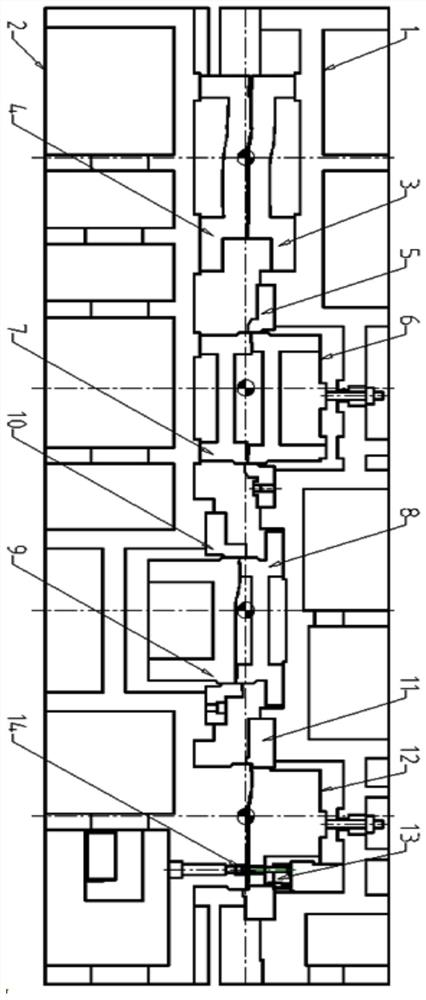

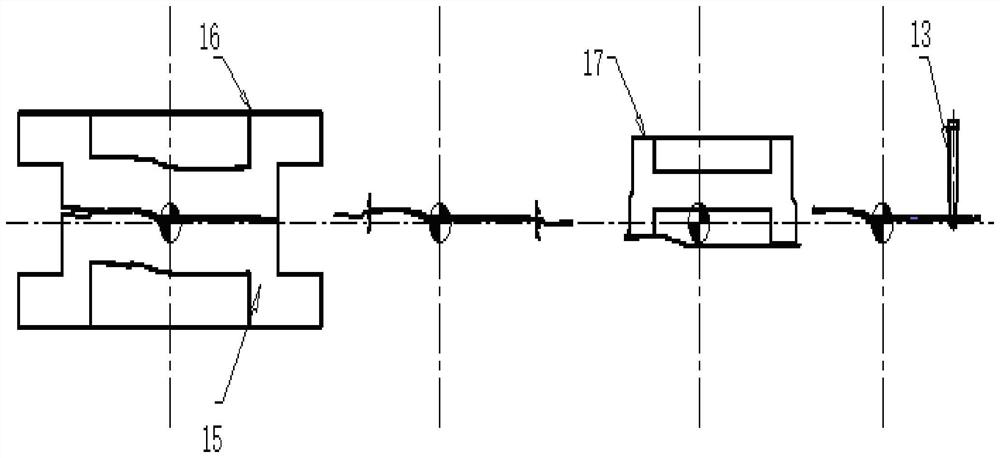

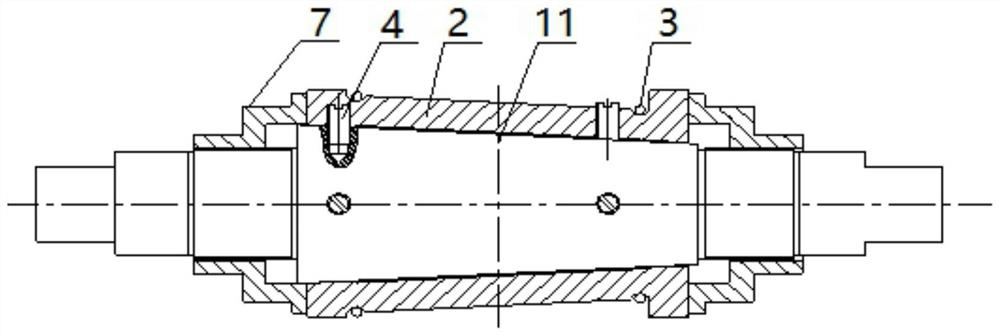

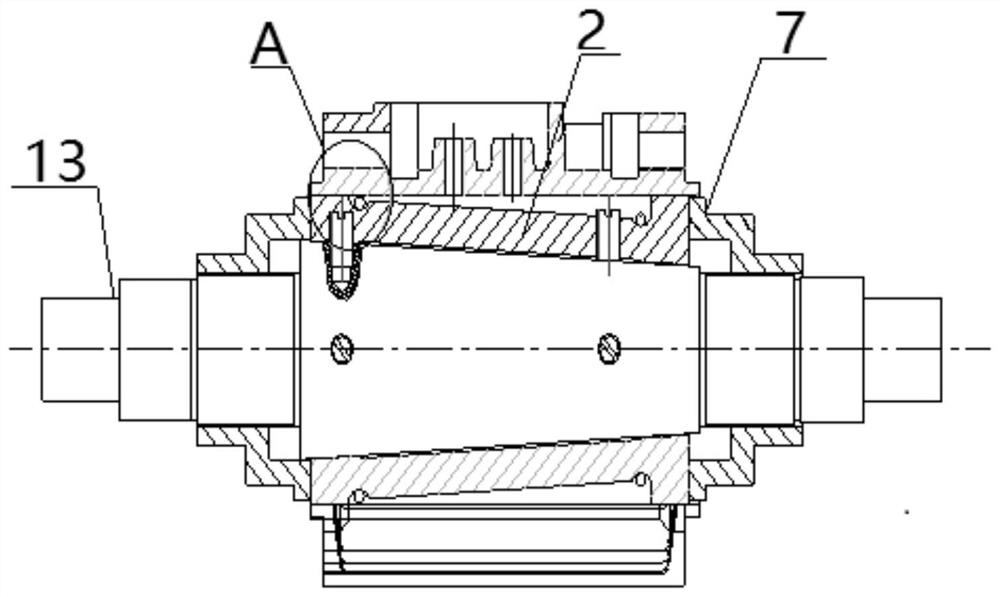

High-precision grinding machine coupled twin tensioning self-centering mechanism fixture and grinding machine thereof

ActiveCN108044505ASolve high-precision positioningSolve high-efficiency productionGrinding machinesGrinding work supportsEngineeringMechanical engineering

The invention discloses a high-precision grinding machine coupled twin tensioning self-centering mechanism fixture and a grinding machine thereof. The high-precision grinding machine coupled twin tensioning self-centering mechanism fixture comprises a fixture body provided with a step hole, a first auxiliary wedge-caulking mechanism and a second auxiliary wedge-caulking mechanism are arranged in the step hole, the second auxiliary wedge-caulking mechanism is slidably arranged on the outer side of the first auxiliary wedge-caulking mechanism in a sleeving mode, and the second auxiliary wedge-caulking mechanism is slidably mounted in the step hole in a matched mode. A first wedge-shaped tensioning block set, a second wedge-shaped tensioning block set and a workpiece tensioning sleeve are arranged on the fixture body, the first wedge-shaped tensioning block set is in wedge fit with the first auxiliary wedge-caulking mechanism, the second wedge-shaped tensioning block set is in wedge fit with the second auxiliary wedge-caulking mechanism, and the peripheral surfaces of the first wedge-shaped tensioning block set and the second wedge-shaped tensioning block set are matched with the inner wall of the workpiece tensioning sleeve. The high-procession grinding machine coupled twin tensioning self-centering mechanism fixture effectively achieves high-precision positioning and high efficiency production of the grinding machine, the risks of damage to equipment and workpieces caused by traditional power off, gas off and hydraulic off are effectively controlled, and self protection effects on the workpieces and the equipment are achieved through a fixture gas inspection device.

Owner:东风汽车动力零部件有限公司

Method for manufacturing spring steel wire with excellent stability and stress resistance

ActiveCN112453080AHigh stability and stress resistanceHigh tensile strengthFurnace typesProcess efficiency improvementWire rodSpring steel

The invention discloses a method for manufacturing a spring steel wire with excellent stability and stress resistance. The method comprises the following steps of selecting raw materials, namely selecting a high-carbon steel hot-rolled high-quality wire rod for production; descaling the high-carbon steel hot-rolled wire rod through a stripping wheel, drawing the high-carbon steel hot-rolled wire rod to the diameter of a pre-drawn semi-finished steel wire required by process design through a tungsten steel wire drawing die by adopting a pre-drawing machine, and then conducting primary drawing treatment; and conducting continuous heat treatment on the semi-finished steel wire, namely conducting lead bath quenching treatment on the pre-drawn semi-finished steel wire through a heat treatment furnace, wherein the tensile strength of the semi-finished steel wire obtained after heat treatment is 880-1100 MPa. According to the method, the steel wire is high in stability and stress resistance,drawing tension and tension can be conveniently controlled to produce carbon thin spring steel wires of different sizes and standards, the tensile strength of the steel wire can be continuously improved, the requirements for the appearance, the surface quality, the mechanical property and the toughness of a steel wire product are met, meanwhile, batch production is achieved, and the product quality requirement is met.

Owner:德清林缘金属制品有限公司

Molding method for angled screw cap of airplane

InactiveCN106345958AImprove ergonomicsLow costNutsForging/hammering/pressing machinesWork cycleHead shape

The invention relates to amolding method for an angledscrew capofan airplane, which is mainly used for connecting sheet metal parts of the airplane. A cold upsetting mold is arranged on a cold upsetting machine; a blank is conveyed into a cutting bushing through a pulley, and is then conveyed to a female mold through a cutter, so that the blank and the female mold are kept on the same horizontal line; when the blank slightly enters the female mold, the cutter gets back to an original position, and the blank is upset into the female mold through a stamping mold I, so that the blank is pressed against a female mold mandrel; when the stamping mold I moves forwards continually, the blank is pre-molded by aprimary upsetting master mold on the head part of a workpiece, so that the head part of the workpiece becomes an eccentric mushroom head shape; after the end of pre-molding, the stamping mold I and a stamping mold II move vertically through a slide block on a machine tool, and the stamping mold II is conveyed onto an upsetting line, so that finial upsetting is performed on the head, and the upset workpiece is pushed out of the female mold mandrel; meanwhile, a charging roller starts to rotate, so that a new working cycle is started.

Owner:JIANGXI HONGDU AVIATION IND GRP

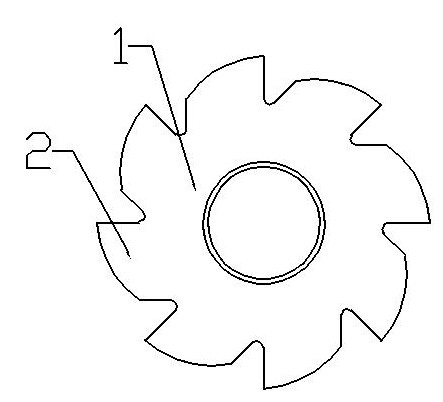

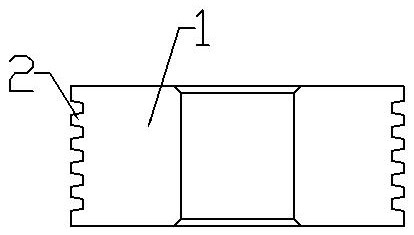

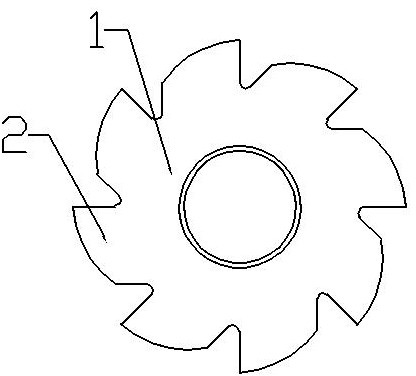

Special disc-shaped milling cutter for processing toothed welding fork

InactiveCN102642044AImprove efficiencyIncrease work intensityMilling cuttersMilling cutterEngineering

The invention discloses a double-ear-hole special tool for a constant-speed center fork. The special tool is characterized in that: a first transition sleeve and a second transition sleeve are arranged on two screw holes at the front end of a lengthened tool body respectively; a thin bore hole alloy block is welded in the first transition sleeve and fixed by a first fastening screw; and a thick bore hole alloy block is connected in the second transition sleeve and fixed by a second fastening screw. The special tool disclosed by the invention is convenient to process, has high efficiency and can meet the technical requirement for the high precision of the constant-speed center fork of a four-drive automobile.

Owner:瓦房店轴承砂轮制造有限公司

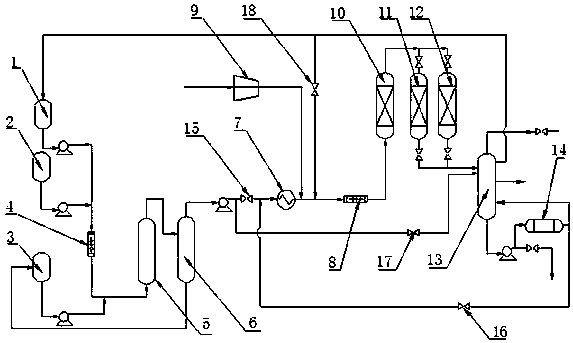

Method for purifying and preparing polypeptide

InactiveCN105504005AImprove efficiencyRealize regulationPeptide preparation methodsDistillationAcetonitriles

The invention relates to a method for purifying and preparing polypeptide. The technical problems that in an existing polypeptide purification and preparation method, the cost is high, and volatile organic compounds are discharged, and salt transfer is difficult are solved. According to the technical scheme, separation and purification, concentration, salt transfer and re-concentration are conducted on the polypeptide, produced high-concentration acetonitrile waste fluid is recycled by a system after distillation recovery is conducted, and the high-concentration acetonitrile waste fluid is synchronously applied to a polypeptide separation and purification method. The method for purifying and preparing the polypeptide greatly reduces the cost of polypeptide purification and preparation, and discharging of the acetonitrile waste fluid is reduced.

Owner:上海吉尔多肽有限公司 +1

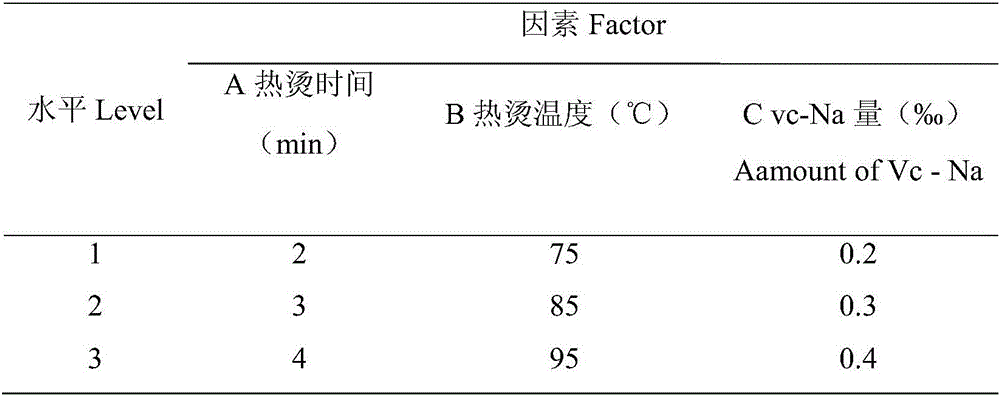

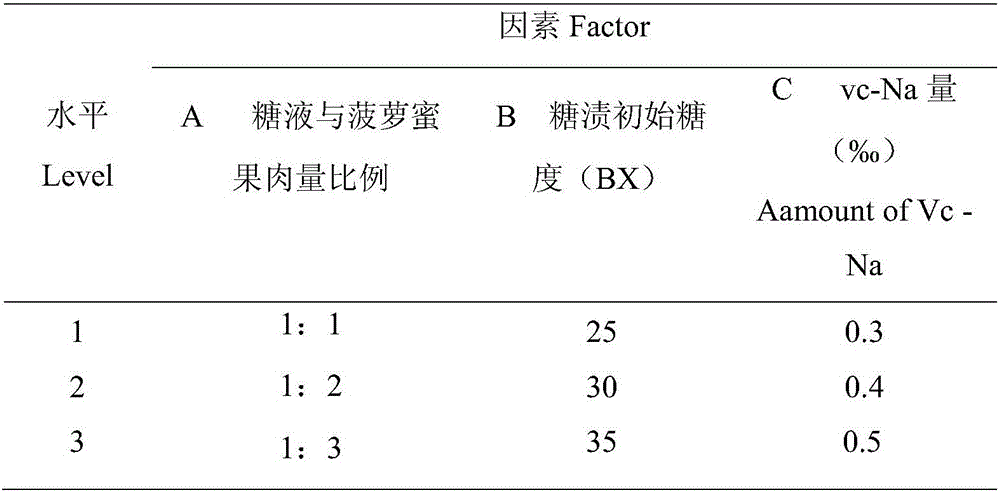

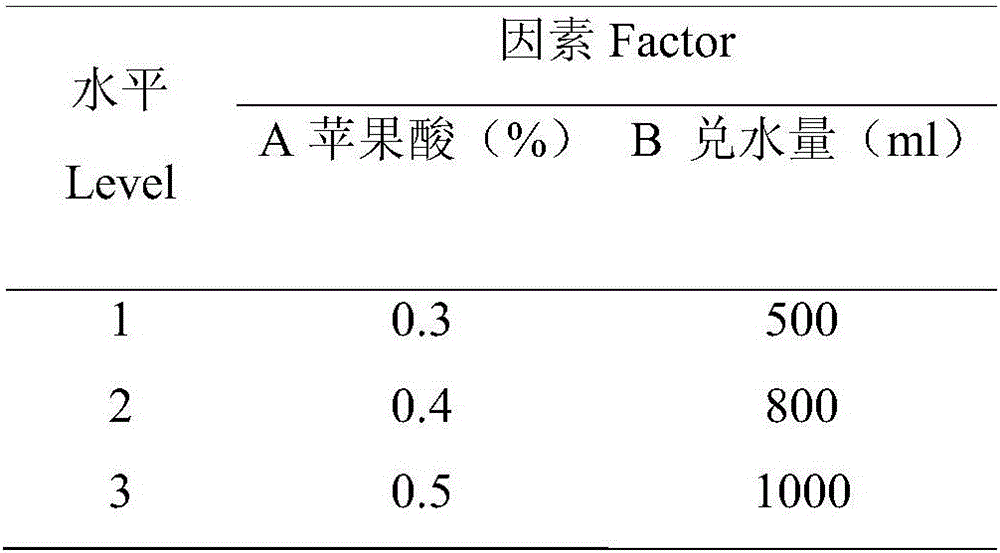

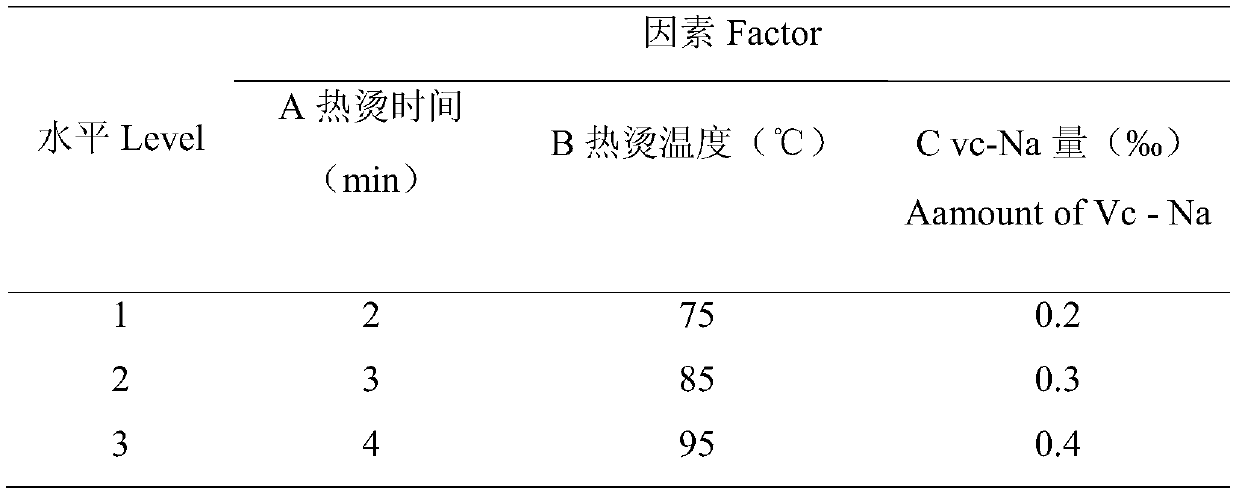

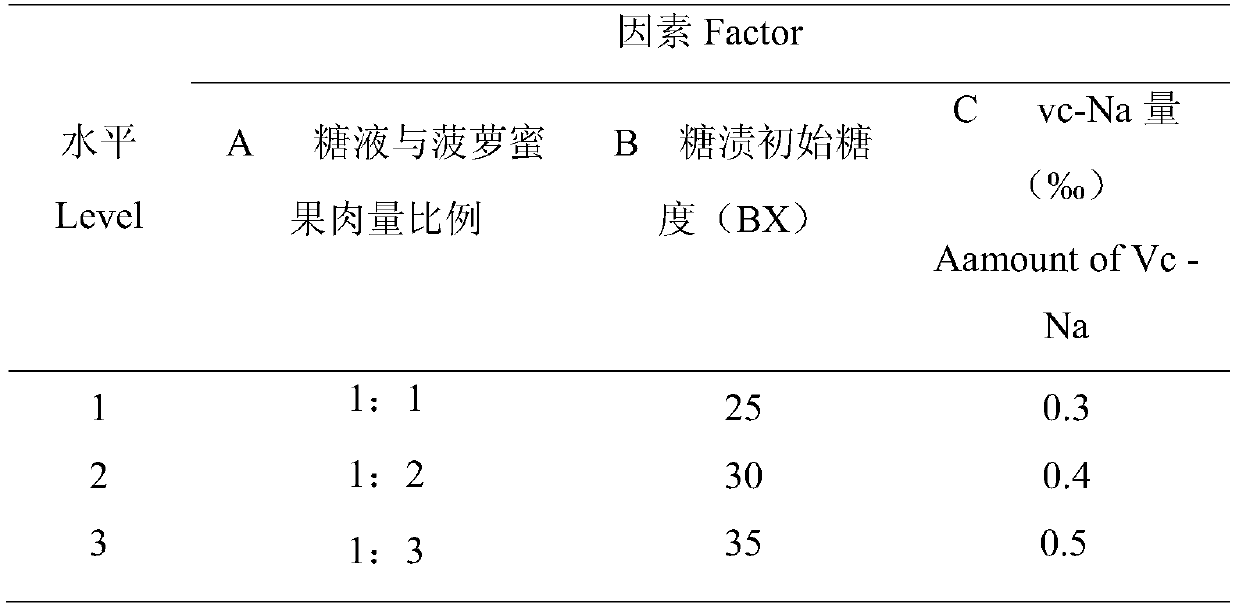

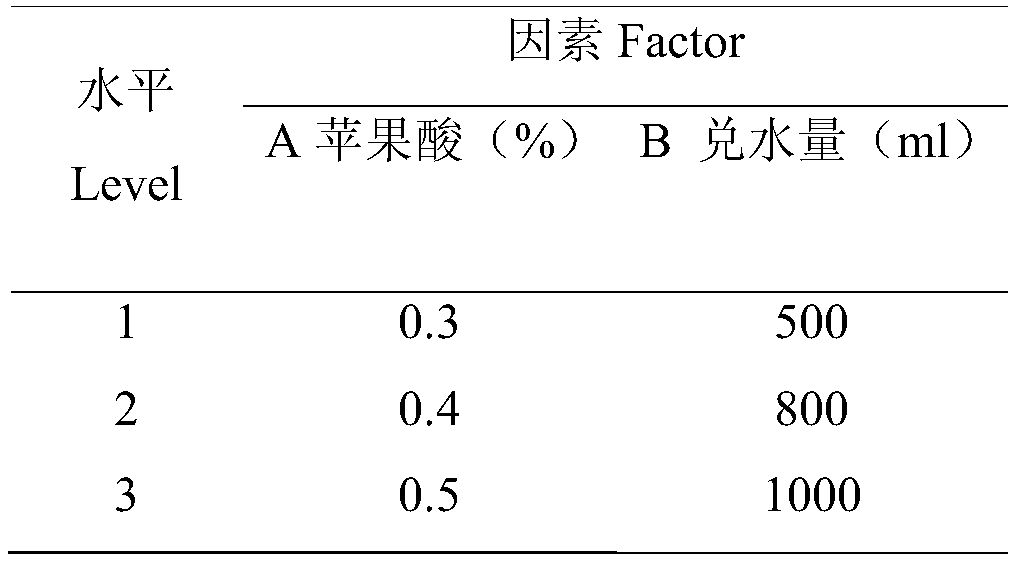

Sulfur-free processing method for primary-taste and primary-color dried jack fruits

The invention discloses a sulfur-free processing method for primary-taste and primary-color dried jack fruits and belongs to the technical field of fruit deep processing.The method sequentially comprises the following steps that 1, 80-90 percent ripe fresh jack fruit slices are subjected to sterilization, enzyme deactivation and color protection unified treatment; 2, an intermittent forced circulation liquid glucose sugaring method is adopted for sulfur-free sugaring at normal temperature for 24 hours; 3, an intermittent softening temperature-varying drying method is adopted for semi-drying, and then acid is mixed to make the materials contain a certain quantity of sour agent.The dried jack fruits processed through the method have the taste and color of primary jack fruits and a proper sour and sweet flavor without preservatives.The problems that when jack fruits are processed, it is hard to present and keep a peculiar flavor, sulfur dioxide is needed for color protection, and product quality is affected due to a high reducing sugar ratio as a result of repeated utilization of sugar water in the preserved fruit processing industry are solved.The novel technical method can be provided for jack fruit processing.

Owner:广西果晶园食品有限责任公司 +2

Technology for manufacturing rubber floor covering

The invention discloses a technology for manufacturing rubber floor covering. The technology comprises the following steps: materials packing, smelting, mixing, drying sheets in air, remixing, extruding, calendering by three rollers and sulfuring. The steps of smelting, mixing, remixing, extruding, calendering by three rollers and sulfuring are controlled by a PC machine. The present invention has the advantages that a real time monitoring is realized by the PC machine during the production process, and has the characteristics of no dust loss and healthy process environment, which accords with high standard requirements.

Owner:江苏昌达环保科技有限公司

Dry ice particle treatment device and dry ice particle treatment method

The invention relates to a treatment device and a treatment method, and discloses a dry ice particle treatment device and a dry ice particle treatment method to solve the problems that the conventional dry ice particles are high in particle diameter and high in destructive power, and can not clean an instrument or an equipment having higher requirement on the accuracy, resulting in a blank of particle cleaning in the dry ice cleaning industry in China. The dry ice particle treatment device comprises an outer housing, a first pipeline, a second pipeline, a third pipeline, a throat pipe and a sieve plate, wherein the first pipeline, the second pipeline and the third pipeline are arranged in the outer housing; one end of the first pipeline is connected with a discharge port of a feeding assembly; the other end of the first pipeline is vertically communicated with one end of the second pipeline; the other end of the second pipeline is vertically communicated with the third pipeline; the throat pipe is arranged in the first pipeline; and the sieve plate is vertically mounted on the second pipeline in an inserting manner. The dry ice particle treatment method comprises the steps of setting a position of the outer housing, conveying materials, carrying out four times of crushing, and outputting the particles. The dry ice particle treatment device and the dry ice particle treatment method are applied to the crushing treatment of the dry ice particles.

Owner:HARBIN DERUISIWO SCI & TECH CO LTD

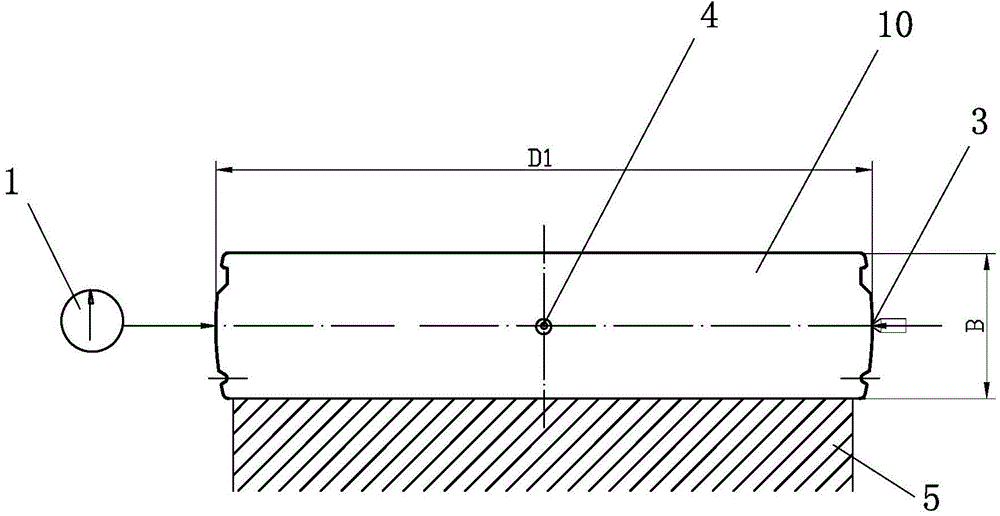

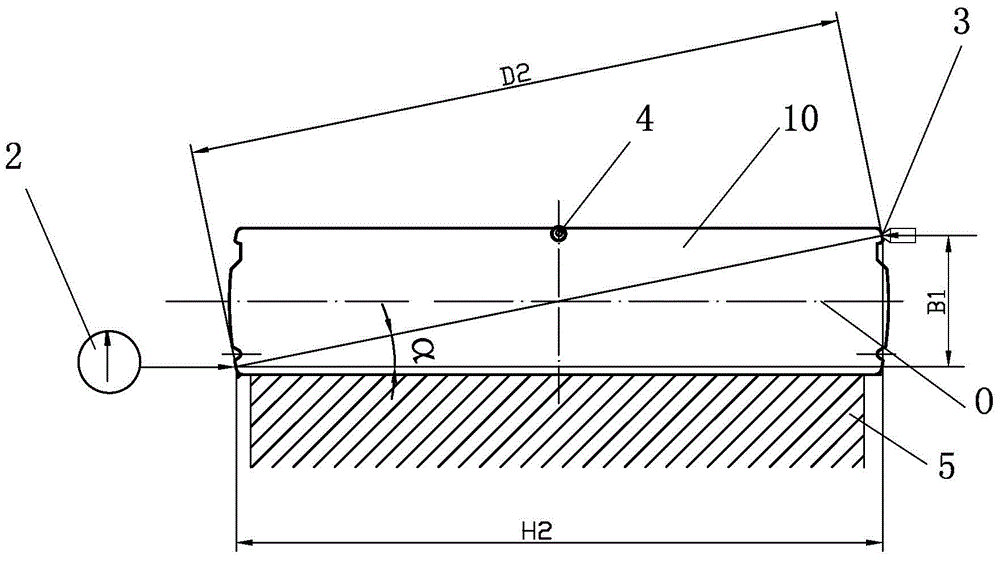

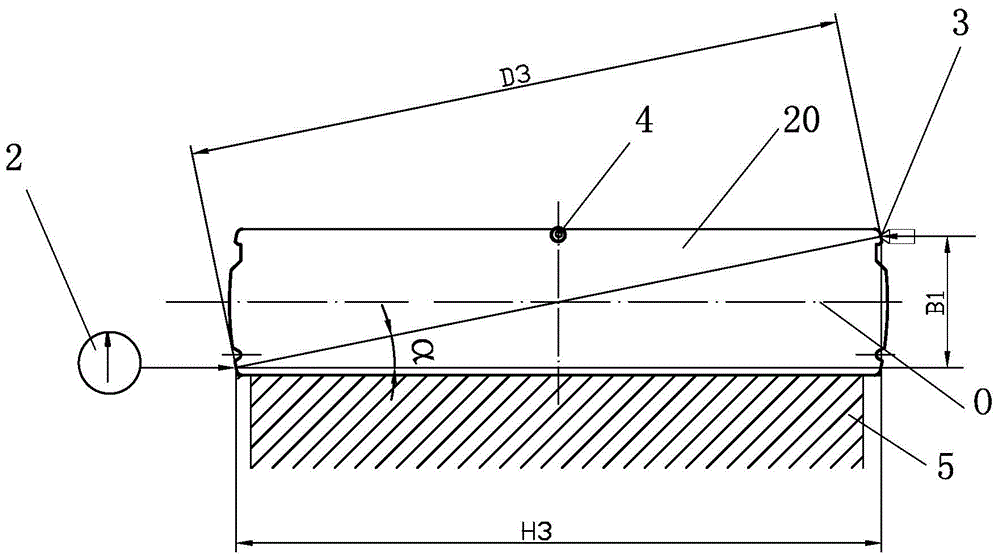

Method for measuring spherical outside surface of bearing

InactiveCN104019727AEasy to measureSimple stepsMechanical counters/curvatures measurementsSpherical shapedEngineering

The invention provides a method for measuring a spherical outside surface of a bearing. The method comprises the following steps: (1) selecting a standard element, measuring and labeling a sphere diameter D1 at the center point in the width direction of the standard element and a sphere diameter D2 at opposite angles; (2) calibrating a first instrument by using the spherical diameter D1 at the center point of the standard element; (3) calibrating a second instrument by using the sphere diameter D2 at opposite angles of the standard element, wherein the support force of a measurement head and a support point of the second instrument points to the axis of the standard element; (4) measuring the sphere diameter in the middle of a workpiece by using the first instrument under the condition that the calibration state is same as the calibration states in the steps (2) and (3), so as to obtain a deviation value D1', and measuring the sphere diameter at the opposite angles by using the second instrument, so as to obtain a deviation value D2'; and (5) obtaining a difference value by using D1'-D2' and comparing the difference value with the set spherical deviation. The method is convenient and accurate to measure, and is not dependent on the judgment experience of detecting personnel, and the requirements of the product quality are ensured.

Owner:奥新(厦门)轴承有限公司

Formation method for cylindrical lithium battery

ActiveCN102403536BReduce electricity costsReduce labor costsFinal product manufactureSecondary cells charging/dischargingElectrical batteryLow voltage

The invention provides a formation method for a cylindrical lithium battery. In the formation process, three and a half charge-discharge cycles are performed; meanwhile, a solid electrolyte interface (SEI) film of the negative electrode of a battery is formed, and the capacity grading and low-voltage screening of the battery are performed. By the method, cylindrical lithium battery with a steel shell is manufactured, the formation cycle times are reduced, and process parameters are optimized, so the process is simplified and standardized, production cycle is shortened, and production cost is effectively reduced. Moreover, the method is convenient to operate, and suitable for bulk production; and by the method, quality of products can be guaranteed.

Owner:SHUANGDENG GRP

A kind of dry ice particle processor and the processing method of dry ice particle

InactiveCN105170298BReduce labor intensityImprove work efficiencyGrain treatmentsParticulatesDry ice

A dry ice particle processor and a dry ice particle processing method relate to a processor and a processing method thereof. The present invention solves the problem that existing dry ice particles have larger particle diameters and greater destructive power, and cannot clean instruments or equipment with high precision requirements, resulting in blank particle cleaning in the domestic dry ice cleaning industry. A dry ice particle processor comprises an outer shell, a first pipeline, a second pipeline, a third pipeline, a throat and a sieve plate, the first pipeline, the second pipeline and the third pipeline are respectively arranged in the housing, and one end of the first pipeline It is connected with the discharge port of the feeding assembly, the other end of the first pipe is vertically connected with one end of the second pipe, the other end of the second pipe is vertically connected with one end of the third pipe, and the throat is set on the first pipe Inside, the sieve plate is inserted vertically on the second pipe. Processing method: set the position of the outer shell; convey and feed the material; crush four times; output the particles. The invention is used for crushing treatment of dry ice particles.

Owner:HARBIN DERUISIWO SCI & TECH CO LTD

Hydrodechlorination method for alkylated oil

ActiveCN109694735AImprove removal efficiencyOvercome stabilityTreatment with hydrotreatment processesGasoline stabilisationAlkyl transferGasoline

The invention discloses a hydrodechlorination method for alkylated oil. The hydrodechlorination method comprises that an ionic liquid catalyst is separated after an alkylation reaction is completed; and the alkylated mixed product is sequentially subjected to hydrodechlorination, adsorption HCl-removal and rectification by a rectification tower. According to the method, at the start of operation,the alkylated mixed product first enters a rectification tower, and is rectified; the tower bottom material of the rectification tower is introduced into a hydrodechlorination reactor, and is subjected to hydrodechlorination; adsorption is performed by an adsorption hydrodechlorination device; the obtained material is introduced into the rectification tower for 5 min-24 h after the adsorption is completed; the direct introducing of the alkylated mixed product into the rectification tower is stopped, and the introducing of the tower bottom material of the rectification tower into the hydrodechlorination reactor is stopped; and the alkylated mixed product is directly introduced into the hydrodechlorination reactor, and is subjected to a normal hydrodechlorination reaction process. With the method of the present invention, the chlorine content can be reduced to less than 1 ppm after the alkylated oil with high chlorine ions is treated so as to be used as the high-quality vehicle gasolineblending component.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ultrasonic fault detection method for heat check compound filling defect of thick-wall aluminum alloy pipe

ActiveCN101446569AFill defects accuratelyAccurate judgmentAnalysing solids using sonic/ultrasonic/infrasonic wavesReference sampleThick wall

The invention relates to an ultrasonic fault detection method for a heat check compound filling defect of a thick-wall aluminum alloy pipe and relates to the field of aluminum alloy production, solving a problem concerning nondestructive examination of the radial heat check compound filling defect of the thick-wall aluminum alloy pipe. The method comprises the following steps: firstly, selecting an ultrasonic fault detection device and an ultrasonic probe, grinding the probe to cause the probe to have certain curvature, choosing a reference sample and producing an artificial groove fault; then, debugging the ultrasonic fault detection device; then, detecting a sample of the radial heat check compound filling defect of the thick-wall aluminum alloy pipe according to debugged fault detection parameters, and carrying out scanning by moving the probe along the circumferential direction of a pipe workpiece; and finally, repeating the previous steps after the scanning and the detection are finished, and finally finishing the fault detection of the sample by detecting the sample of the radial heat check compound filling defect of the thick-wall aluminum alloy pipe according to the debugged fault detection parameters. The method is used for detecting the thick-wall aluminum alloy pipe, and dozens of batches of thick-wall aluminum alloy pipes which undergo fault diction by using the fault detection method provided by the invention does not suffer any quality dissidence after the delivery.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Heat treatment process of carbon structural steel

ActiveCN102409143BUniform hardnessQuenching hardenability is goodHeat treatment process controlQuenchingMaterials science

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

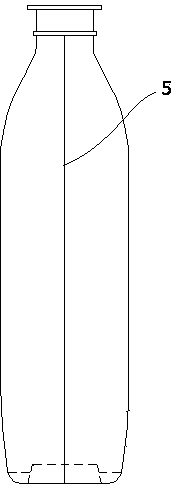

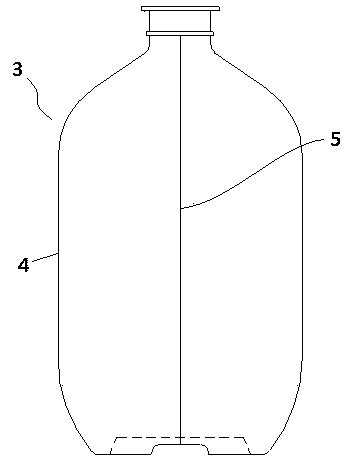

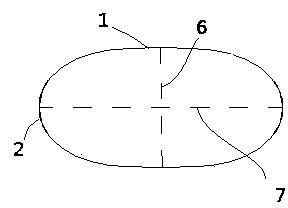

Infusion bottle or infusion bag and preparation method thereof

ActiveCN102895111BOvercome the defect of not being able to produce high-thickness ratio medical soft bagsGood value for moneyInfusion devicesPharmaceutical containersBottleInjection molding process

The invention discloses an infusion bottle or an infusion bag and a preparation method thereof. The infusion bottle or the infusion bag comprises a liquid vessel, wherein the liquid vessel is in a flat structure when filled with liquor; the width of the liquid vessel is greater than the thickness of the liquid vessel on the cross section perpendicular to a port and a tail connecting line; the liquid vessel is formed by compounding dies of a left part and a right part; and die compounding lines are intersecting lines between the symmetry plane in the thickness direction and the side wall surface of the liquid vessel. According to the infusion bottle or the infusion bag, the defect that the high-thickness ratio medical soft bags cannot be produced in the conventional injection molding process is overcome, and the requirement on product quality is met; the infusion bottle or the infusion bag is reasonable in structure and convenient to use, is shrunk in volume after being used and is easy to dispose; and the cost performance of raw materials is high, and the cost is reduced. Particularly, the die compounding lines of the liquid vessel is arranged on the side wall in the thickness direction, the product molding can be effectively ensured, the product molding rate is improved, and the product quality is ensured.

Owner:SICHUAN KELUN PHARMA CO LTD

A sulfur-free processing method of dried jackfruit with original flavor and color

The invention discloses a sulfur-free processing method for primary-taste and primary-color dried jack fruits and belongs to the technical field of fruit deep processing.The method sequentially comprises the following steps that 1, 80-90 percent ripe fresh jack fruit slices are subjected to sterilization, enzyme deactivation and color protection unified treatment; 2, an intermittent forced circulation liquid glucose sugaring method is adopted for sulfur-free sugaring at normal temperature for 24 hours; 3, an intermittent softening temperature-varying drying method is adopted for semi-drying, and then acid is mixed to make the materials contain a certain quantity of sour agent.The dried jack fruits processed through the method have the taste and color of primary jack fruits and a proper sour and sweet flavor without preservatives.The problems that when jack fruits are processed, it is hard to present and keep a peculiar flavor, sulfur dioxide is needed for color protection, and product quality is affected due to a high reducing sugar ratio as a result of repeated utilization of sugar water in the preserved fruit processing industry are solved.The novel technical method can be provided for jack fruit processing.

Owner:广西果晶园食品有限责任公司 +2

Process method of heat insulation sample sample car sample

ActiveCN109719194BLow input costShort manufacturing cyclePreparing sample for investigationPunchingThermal insulation

The invention discloses a process method for a heat-insulating sample car sample, which comprises the following steps: designing a forming punch, a forming concave die, and a flanging punch according to the product profile, and preparing product trimming lines, product hole positions and product apertures Line program; stamping forming; draw product trimming line, product hole position line, product aperture line on the part; manual trimming; manual punching; manual trimming; manual wrapping; finally get the product. The adjusted process method of the invention ensures the product quality requirements. In the traditional technical scheme, it takes a lot of time and invests a lot of mold material costs to reduce the link of mold production and processing. It saves the technical preparation time, reduces the mold input cost, thereby reduces the cycle of heat insulation sample production, and improves the competitiveness of the enterprise in the market economy.

Owner:四川成飞集成吉文汽车零部件有限公司

A method of manufacturing steel wire for spring with excellent stability and stress resistance

ActiveCN112453080BHigh stability and stress resistanceHigh tensile strengthFurnace typesProcess efficiency improvementProcess designIndustrial engineering

The invention discloses a method for manufacturing steel wires for springs with excellent stability and stress resistance, comprising the following steps: raw material selection: selecting high-carbon steel hot-rolled high-quality wire rods for production; Scale treatment, and use a pre-drawing machine to draw it to the diameter of the pre-drawn semi-finished steel wire required by the process design through a tungsten steel wire drawing die, and then perform preliminary drawing treatment; continuous heat treatment of the semi-finished steel wire: heat the pre-drawn semi-finished steel wire The furnace is subjected to lead bath quenching treatment, and the tensile strength of the semi-finished steel wire after heat treatment is 880-1100MPa. The invention can make the steel wire have high stability and stress resistance, and it is convenient to control the pulling force and tension of drawing to produce carbon fine spring steel wires of different sizes and standards. Mechanical properties and toughness requirements, but also meet mass production and ensure product quality requirements.

Owner:德清林缘金属制品有限公司

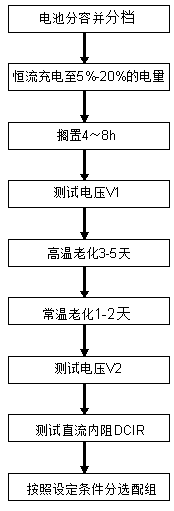

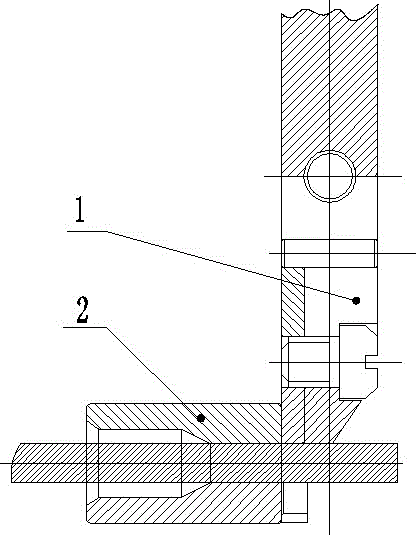

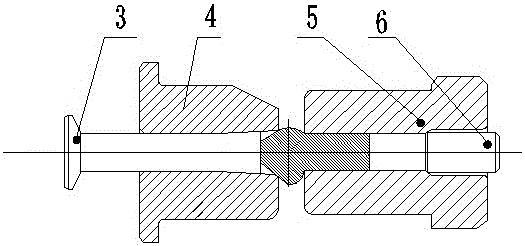

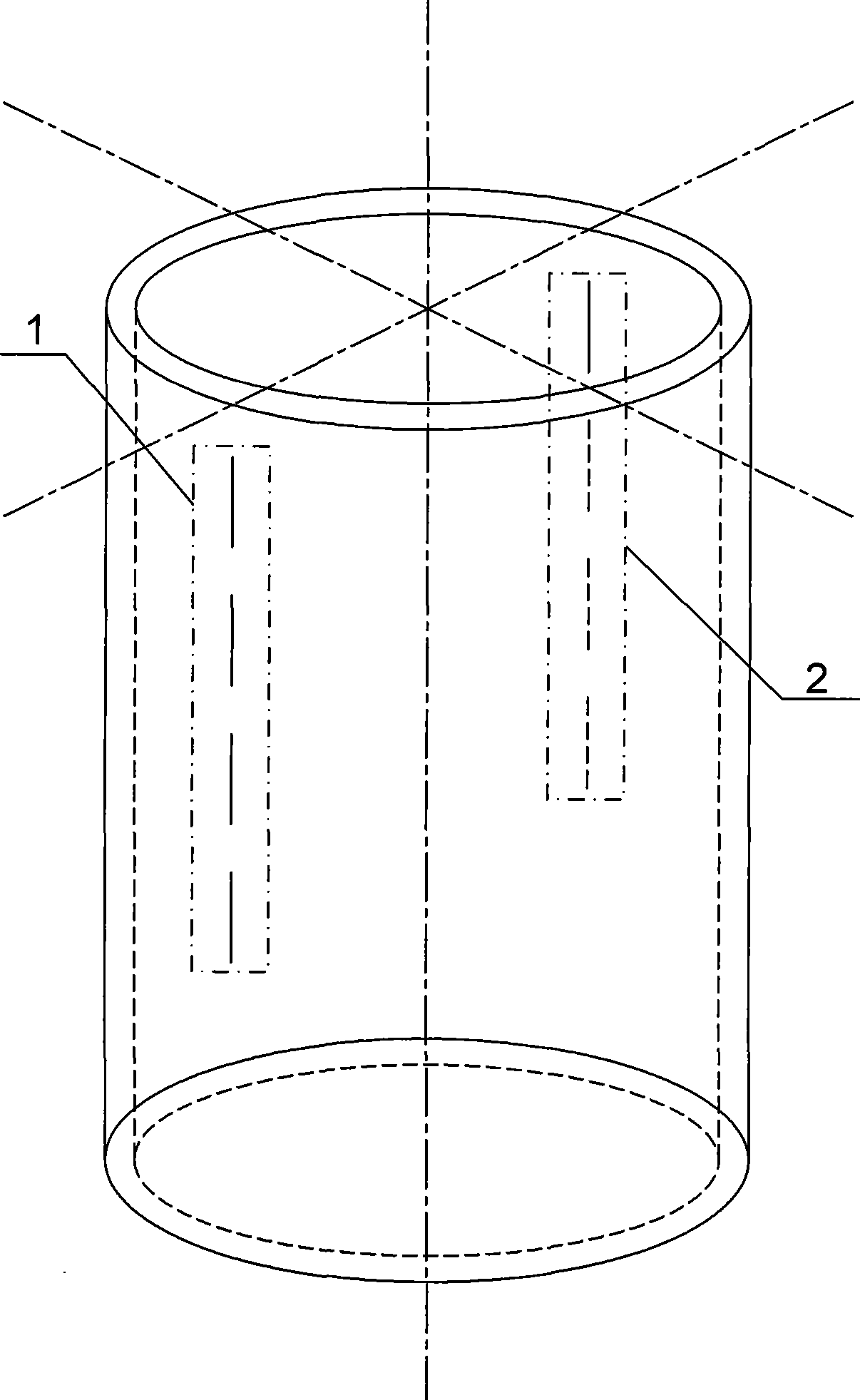

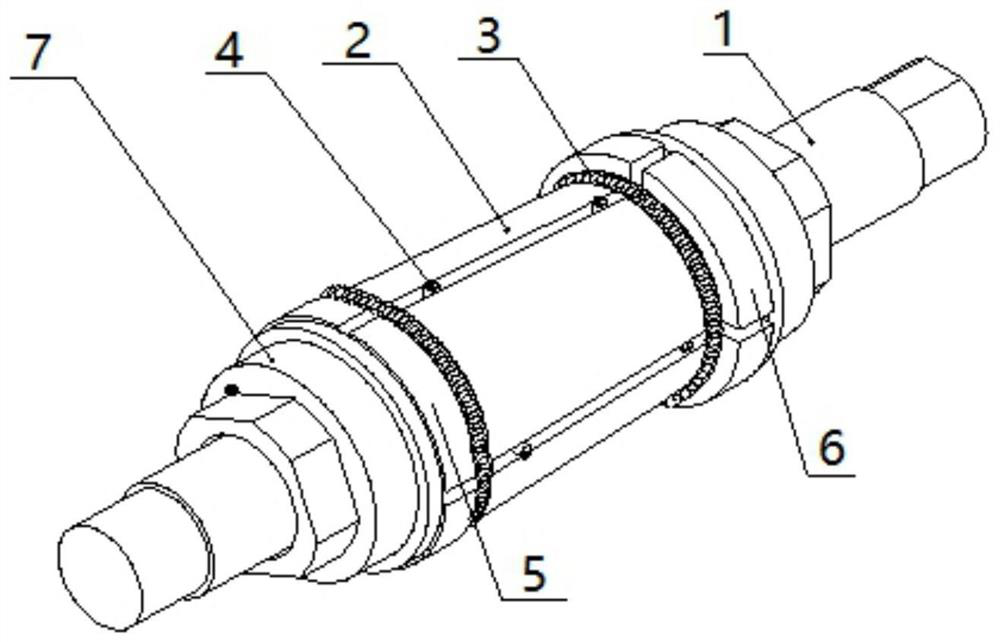

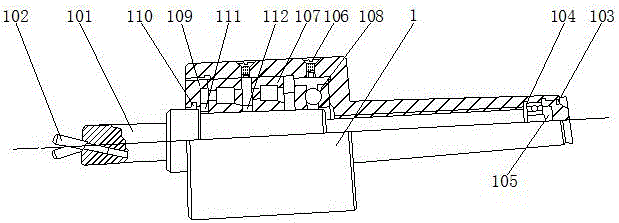

Finish turning core expanding die of machine base

PendingCN113145884AGuarantee product quality requirementsEnsure consistencyExpansion mandrelsSet screwMachine

The invention discloses a finish turning core expanding die of a machine base. The finish turning core expanding die of the machine base comprises a center shaft, wherein a plurality of sliding blocks are arranged on the outer surface of the center shaft, annular springs are arranged on the two sides of the outer surface of each sliding block correspondingly, a plurality of threaded holes are formed in the outer surface of the center shaft, and the inner surfaces of the threaded holes are in threaded connection with set screws. A finish turning die and a workpiece can be quickly fixed on a lathe, the machining benchmark of the machine base can be quickly found, the whole process is efficient and quick, the working efficiency is improved, meanwhile, the quality requirement of a finish turning product of the machine base is met, and the finish turning core expanding die of the machine base can be used for finish turning machining of the machine base clamping workpieces with different sizes and specifications by replacing sliding blocks with different flange outer diameters.

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

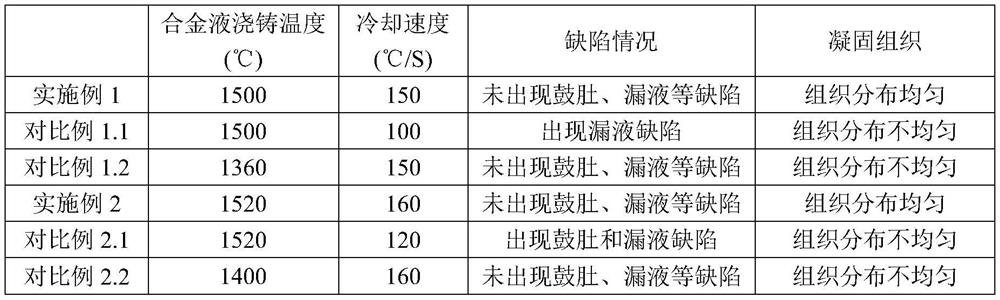

High-temperature alloy double-roller cast rolling process

According to the high-temperature alloy double-roller cast-rolling process, the double-roller cast-rolling process is used for high-temperature alloy preparation for the first time, cast-rolling process parameters are adjusted from the characteristics of the high-temperature alloy and the cooperative research of the casting temperature and the cooling speed according to the defects in the preparation process, and the high-temperature alloy is prepared. The defects of bulging, liquid leakage, uneven structures and the like are avoided, meanwhile, the stability of the solidification process is guaranteed through control over the vacuum degree and periodic detection, finally, the alloy liquid stands for a period of time after being poured into the baked tundish, the temperature of the alloy liquid is uniform, and the alloy quality is improved. And the alloy liquid is heated by adopting the electric heating wire embedded in the tundish refractory material, so that the alloy liquid is not polluted while heat is provided. By the adoption of the technology adjusted through the method, cast rolling production of high-temperature alloys with different components can be achieved, the production efficiency can be improved while the product quality requirement is met, and the production cost is reduced.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Symmetric clamp for grinding of drill core

InactiveCN106002621AReasonable layoutImprove clamping effectGrinding work supportsBall bearingEngineering

The invention discloses a symmetrical jig for grinding drill cores, which comprises a jig cylinder, a mandrel is arranged on the jig cylinder, two positioning columns are arranged at one end of the mandrel, and a rear end is arranged at the other end of the mandrel. The inner side of the rear plug is provided with a radial ball bearing, and a rear washer is arranged between the rear plug and the radial ball bearing, and the upper side and the lower side of the inside of the clamp cylinder are symmetrically arranged with For a cylindrical bearing and a thrust ball bearing, an adjusting nut is arranged on one side of the cylindrical bearing, and a sealing ring is arranged on the side of the adjusting nut close to the mandrel. This jig for grinding the drill core symmetry, when grinding the outer circle of the drill bit, and when the drill core and the outer circle are asymmetrical, the drill tip of the drill bit is placed in the jig, and the symmetry tolerance of the two positioning columns is not greater than 0.03mm, good clamping effect, simple structure, reasonable layout of bearings and adjusting nuts, simple and practical, easy to operate, can ensure the outer circle of the symmetrical sharpening part of the drill core, and ensure product quality requirements.

Owner:HENAN YIGONG DRILLING IND

Sealing method of metal pipes

The present invention relates to a sealing method, especially a sealing method for metal pipes; the purpose of the invention is to provide a sealing method for metal pipes that reduces labor intensity, improves production efficiency and ensures the quality requirements of joints; the first The first step is to punch the sealing end of the metal tube that needs to be sealed into a trumpet shape; the second step is to turn up the edge of the circular metal block through the wrapping machine and wrap the horn-shaped part of the metal tube. Therefore, the metal block seals the end of the metal pipe; the sealing method of a metal pipe designed in the present invention changes the original spot welding method, and seals the metal pipe through the edge wrapping method, so that it is no longer The connecting parts need to be polished and refined, which reduces labor intensity, improves work efficiency, and ensures the production quality requirements of the product.

Owner:JIAXING YONGFA ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com