Dry ice particle treatment device and dry ice particle treatment method

A processor and particle technology, applied in the direction of grain processing, etc., can solve the problems of large destructive force, large particle diameter, and inability to clean instruments or equipment, and achieve the effect of reducing labor costs, reducing labor intensity, and meeting the requirements of mechanical automation operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

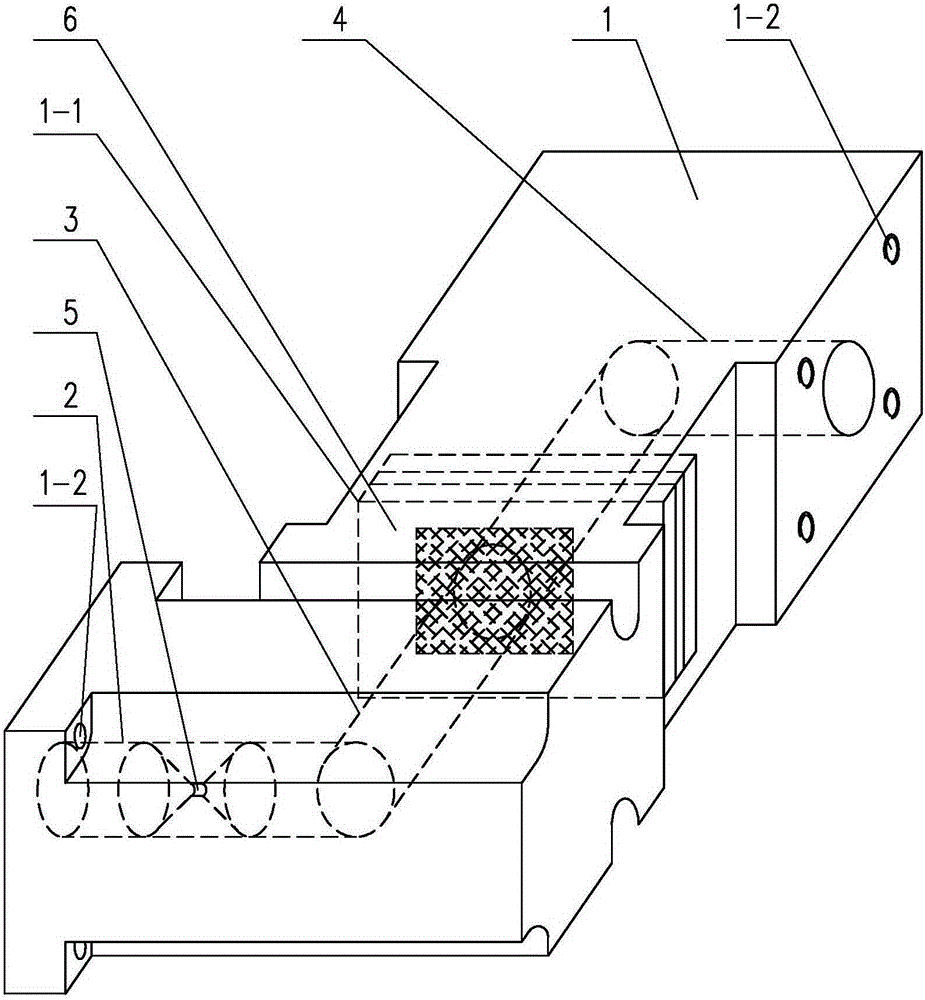

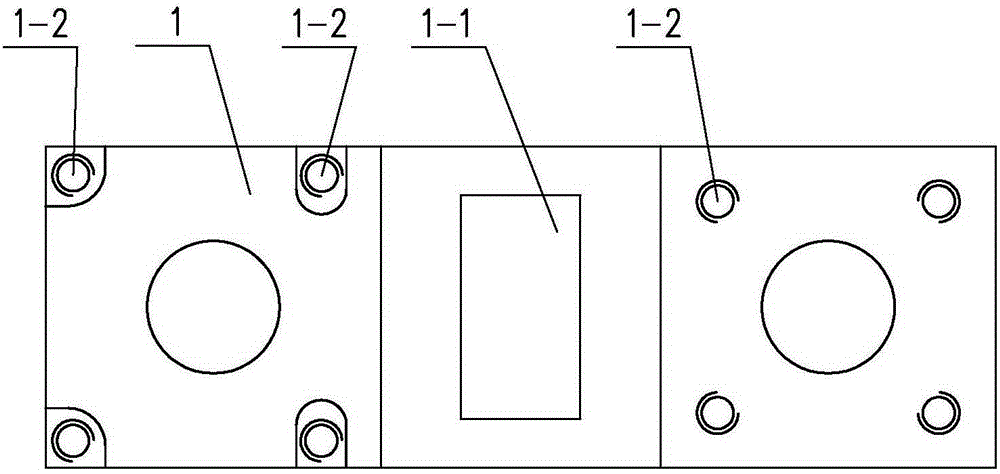

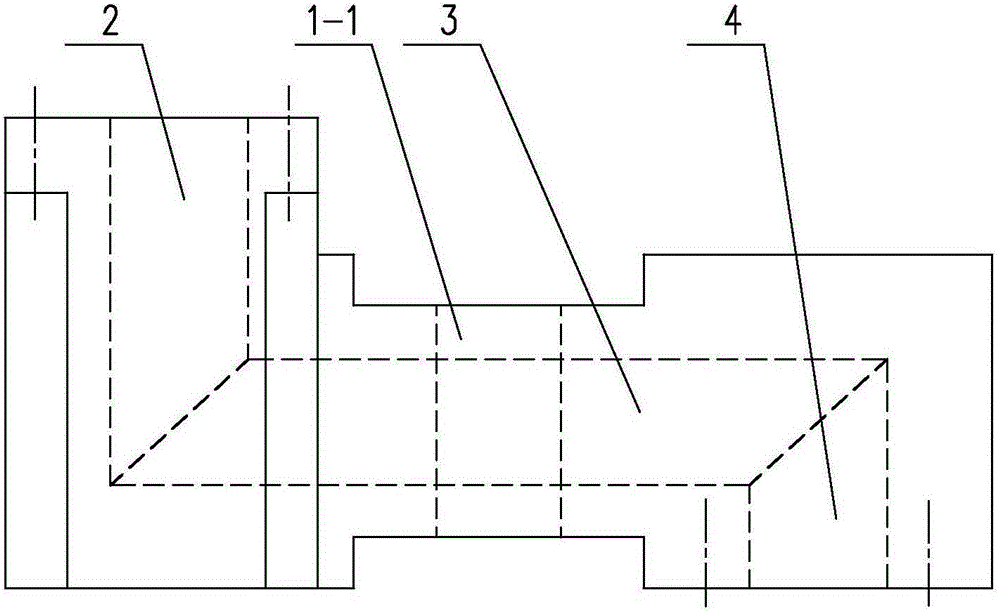

[0025] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, a dry ice particle processor described in this embodiment includes an outer casing 1, a first pipeline 2, a second pipeline 3, a third pipeline 4, a throat 5 and a sieve plate 6, the first pipeline 2, the second pipeline The second pipeline 3 and the third pipeline 4 are arranged in the outer casing 1 respectively, one end of the first pipeline 2 is connected with the outlet of the material supply assembly, and the other end of the first pipeline 2 is vertically connected with one end of the second pipeline 3 , the other end of the second pipeline 3 is vertically connected with one end of the third pipeline 4, the other end of the third pipeline 4 is connected with the ice outlet pipe, the throat pipe 5 is arranged in the first pipeline 2, and the throat pipe 5 includes two cones Pipe 5-1, the two conical pipes 5-1 are arranged opposite to each other horizontally, the tips of the t...

specific Embodiment approach 2

[0028] Specific implementation mode two: combination Figure 1 to Figure 3 To illustrate this embodiment, the outer casing 1 in this embodiment is provided with a slot 1-1, the slot 1-1 is arranged perpendicular to the axial direction of the second pipeline 3, and the sieve plate 6 is inserted into the slot 1-1 . The undisclosed technical features in this embodiment are the same as those in the first embodiment.

[0029] With such a design, when the sieve plate 6 needs to be cleaned, maintained or replaced, it is only necessary to pull the sieve plate 6 out of the slot 1-1 to facilitate its disassembly and installation.

specific Embodiment approach 3

[0030] Specific implementation mode three: combination Figure 1 to Figure 3 , Figure 5 and Figure 6 To illustrate this embodiment, the sieve plate 6 in this embodiment is provided with a screen 6 - 1 , and the edge of the screen 6 - 1 is arranged outside the second pipeline 3 . The undisclosed technical features in this embodiment are the same as those in the first or second specific embodiment.

[0031] This design ensures that all the dry ice particles are impacted and pulverized on the screen 6-1 before passing through.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com