High-precision grinding machine coupled twin tensioning self-centering mechanism fixture and grinding machine thereof

A high-precision, self-centering technology, used in grinding machines, manufacturing tools, grinding workpiece supports, etc., can solve the problems of prolonging the labor time and labor intensity of processing workers, damage to equipment and workpieces, and poor positioning accuracy. Cost and labor intensity of workers, ensuring stability and accuracy, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

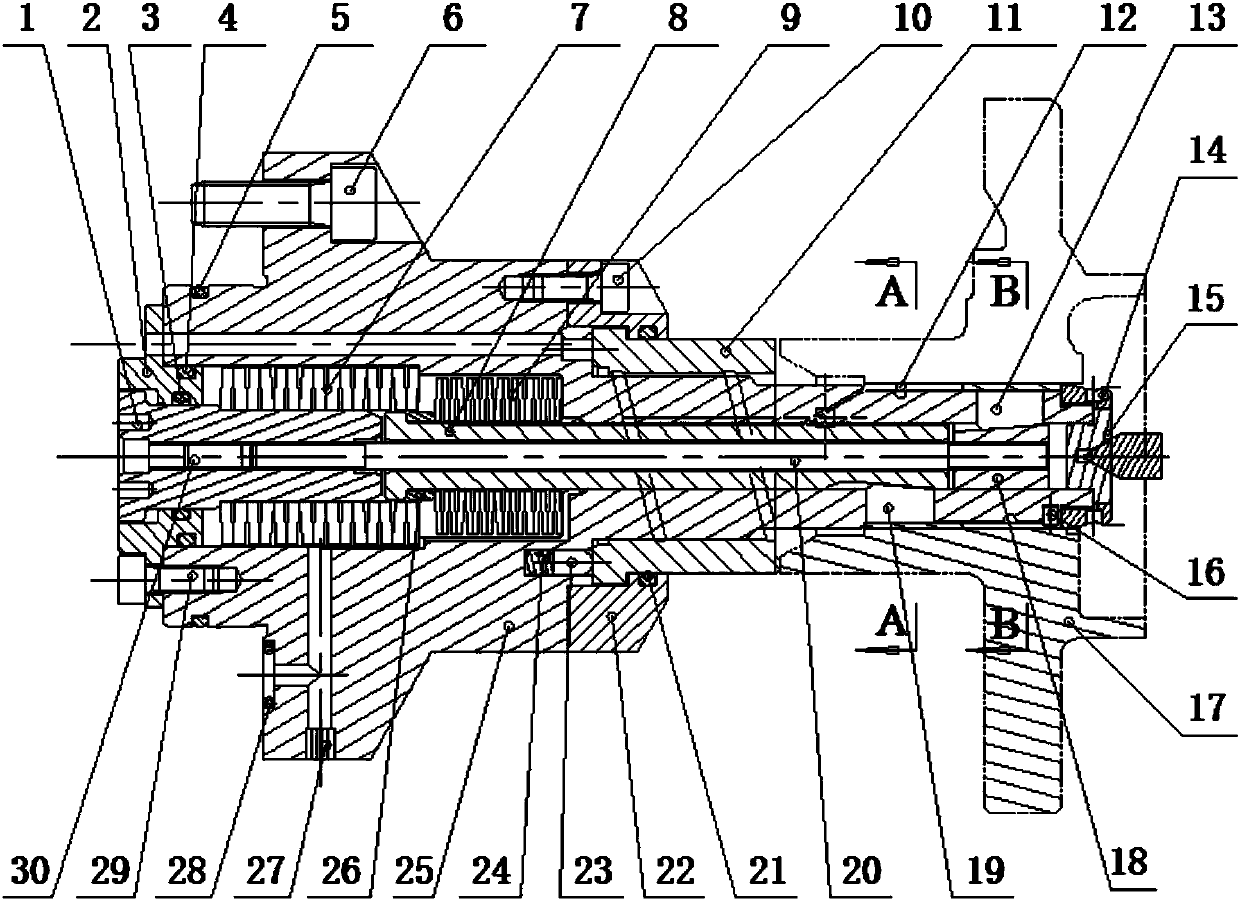

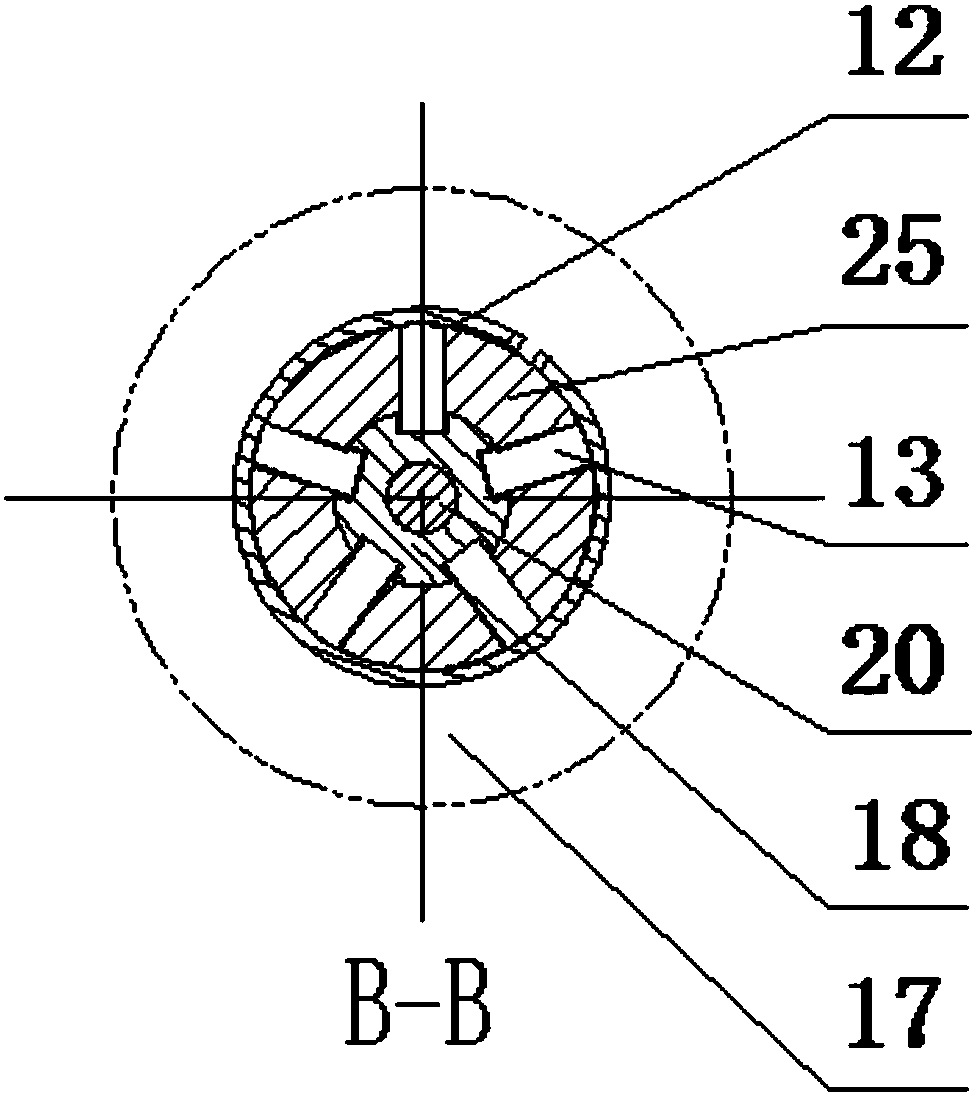

[0039] Adjust the lock nut 1, the double-headed screw 20, the first pull rod 18, the first wedge-shaped expansion block group 13, and the tension sleeve 12, and move back and forth along the axis of the clamp body 25 under the action of the first disc spring 7;

Embodiment 2

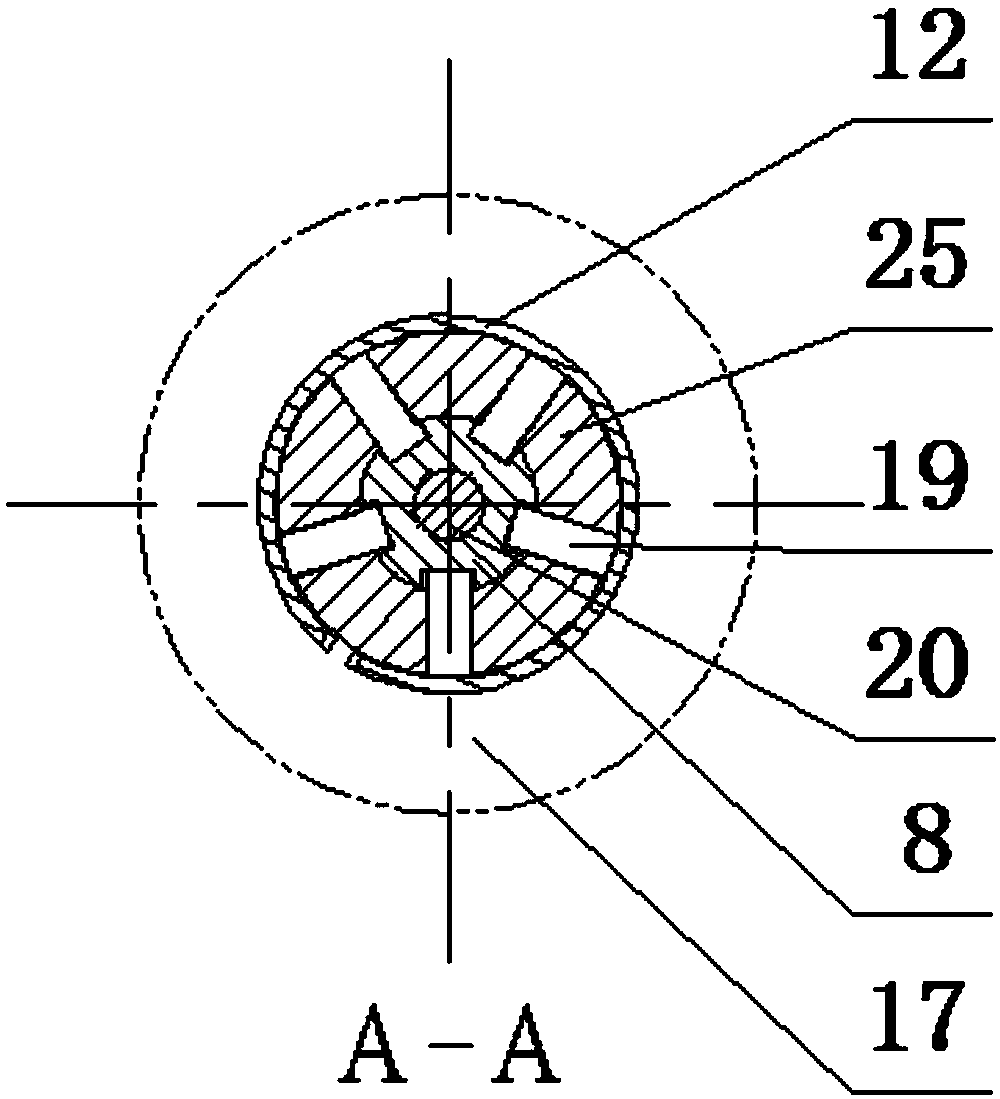

[0041] The first wedge-shaped expansion block group 13 is precisely matched with the clamp body 25, and moves radially along the axis of the clamp body 25 under the action of the first pull rod 18;

Embodiment 3

[0043] The second pull rod 8, the second wedge-shaped expansion block group 19, the tensioner sleeve 12 are supported and matched with the body 25, and are reciprocated along the axis of the clamp body 25 under the action of the second disc spring 9;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com