Method for reaming on latch lock connectors of airplane cargo space

A door latch and aircraft technology, applied in the field of mechanical processing, can solve the problem of high cost and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

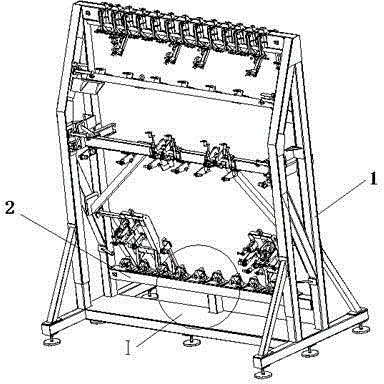

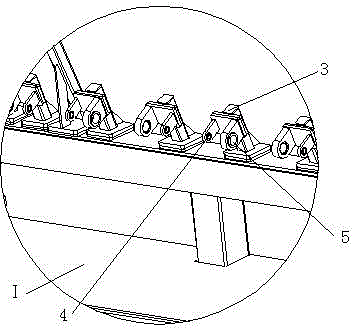

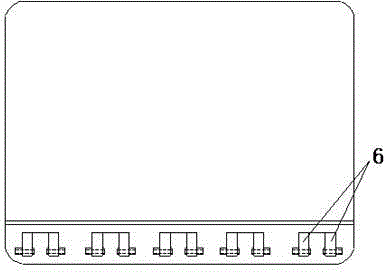

[0022] Taking the reaming hole of the latch joint of the main cargo door of Boeing 747 passenger-to-cargo aircraft as an example, five main load-bearing locks are distributed laterally at intervals within a range of 3.5 meters on the lower edge of the main cargo door, and each main load-bearing lock has two ends. Latch connector 6, such as image 3 , the initial hole of the latch joint is Φ39.06mm (mm, unit: mm). Since the distance between two adjacent latch joints 6 is only 237.6 mm, the operating space for processing is very small. After processing, the latch joint The hole size needs to reach Φ40.7mm, and the coaxiality requirement of the ten latch joint holes distributed at intervals in the transverse direction is required to be Φ0.13mm.

[0023] Aircraft cargo door latch joint reaming method of the present invention comprises the following steps:

[0024] 1. Clamp the aircraft cargo door to be processed on the frame, and use the initial positioning pin 8 to locate the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com