Integrally molded continuous variable valve timing fuel control valve

An integral molding, valve timing technology, applied in valve details, valve device, valve operation/release device, etc., can solve the deformation of the outer yoke sleeve port, increase the cost of parts manufacturing, and the inability of the roundness and coaxiality of the two ports. to achieve the effect of simplifying the structure, stable performance, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

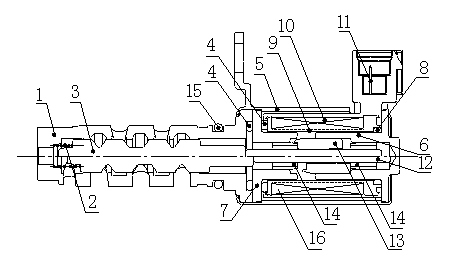

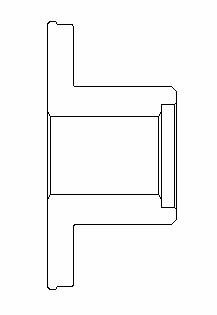

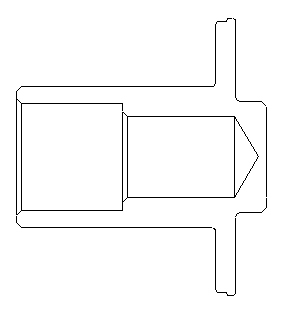

[0019] Further describe technical scheme of the present invention below in conjunction with embodiment, as figure 1 , an integrally formed continuously variable valve timing fuel control valve, which includes a valve sleeve assembly, a rear yoke assembly, a front yoke assembly, an iron core assembly, an outer yoke sleeve bracket 5 and is composed of a skeleton 9, an enameled wire 10 and a lug 11 The winding assembly 16, wherein the valve sleeve assembly is composed of the return spring 2, the valve core 3 and the front ring 4, the rear yoke assembly is composed of the rear yoke 6 and the guide sleeve 14, and the front yoke assembly is composed of the front yoke The yoke 7 and the guide sleeve 14 are riveted, the iron core assembly is composed of the shaft 12 and the iron core 13, and the winding assembly 16, the rear ring 8 and the rear yoke assembly are placed at the rear end of the outer yoke bracket 5 and carried out. The end is riveted and fixed, the iron core assembly, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com