Impeller pull rod machining method

A processing method and impeller pull rod technology are applied in the field of machining, which can solve the problems of poor accuracy of the external thread of the impeller pull rod, poor coaxiality of the external threads at both ends, and poor coaxiality of the external thread, so as to improve production efficiency and reduce processing time. The difficulty of ensuring the effect of coaxiality requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific implementation manner of the present invention will be described in further detail below in conjunction with the accompanying drawings.

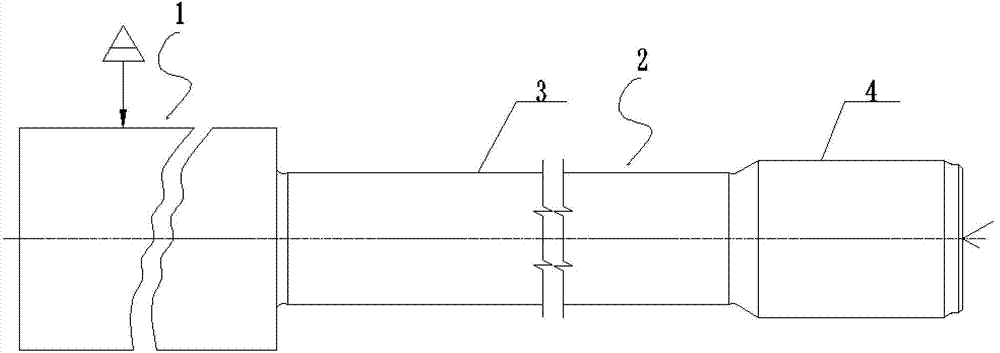

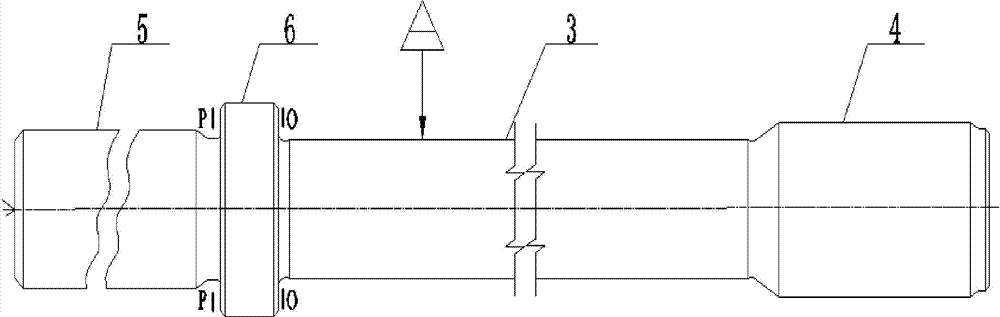

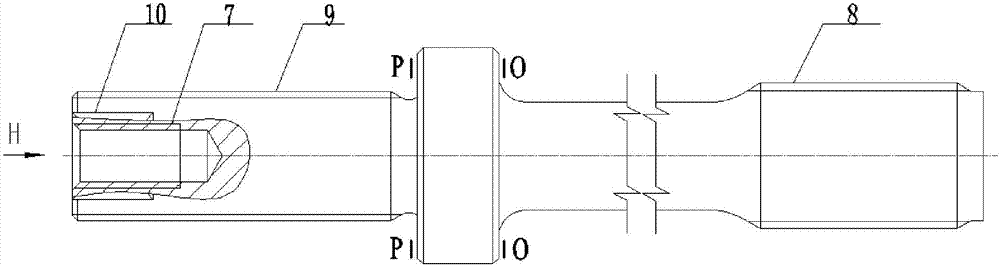

[0030] Such as figure 1 , figure 2 and image 3 Place Figure 4 As shown, the impeller tie rod processing method of the present invention comprises the following steps: 1) heat treatment quenching and tempering is carried out to the blank;

[0031] 2) The outer circle and end face of the positioning end 2 of rough turning, and punch the center hole;

[0032] 3) The outer circle and end face of the rough turning pressing end 1, and punch the center hole;

[0033] 4) Ultrasonic flaw detection;

[0034] 5) Grinding the outer circles of each gear and the two ends of the positioning outer circle 6;

[0035] 6) Tapping the internal thread hole 7 of the compression end 1, and chamfering;

[0036] 7) The external threads of the pressing end 1 and the positioning end 2 of the finish car;

[0037] 8) The external thread mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com