Device and method for machining waterstop structure of arc-shaped door of ship lift and waterstop structure

A processing device and arc-shaped door technology, which is applied to positioning devices, driving devices, feeding devices, etc., can solve the problems of inability to ensure coaxiality requirements, wear of water-stop rubber, affecting water sealing effect, etc., to reduce errors and labor. The effect of investment, small processing tolerance, and shortened processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

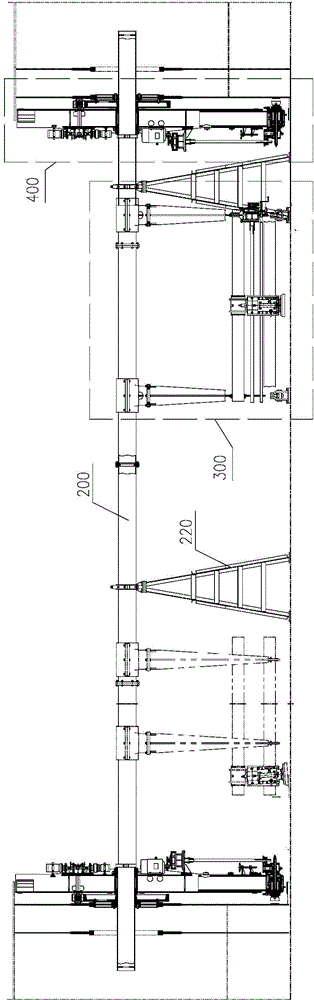

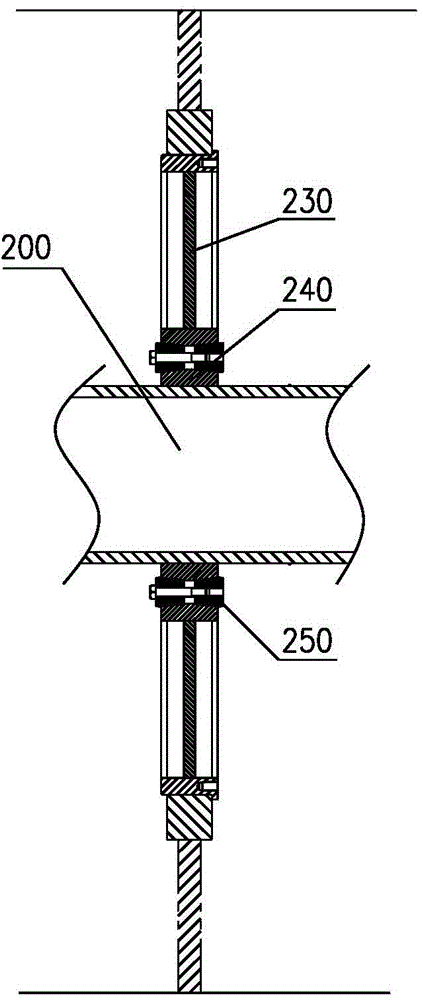

[0070] see figure 2 As shown, the embodiment of the present invention provides a water-stop structure processing device for an arc door in a ship lift, which includes a horizontally erected main shaft 200, and the two ends of the main shaft 200 are sequentially provided with expansion hubs 230 and side shafts from outside to inside. Towards the processing assembly 400 , the main shaft 200 between the two lateral processing assemblies 400 is also provided with a bottom water stop processing assembly 300 .

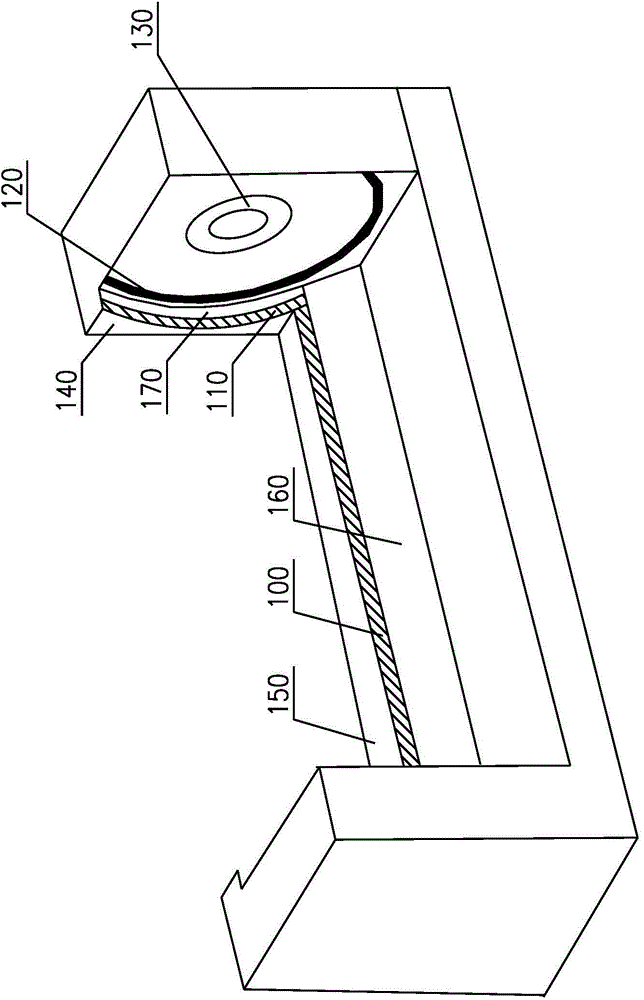

[0071] see image 3 As shown, the expansion hub 230 is fixedly installed in the support arm hole 130, the two ends of the main shaft 200 are respectively fitted with expansion sleeves 240, and the end of the main shaft 200 and the expansion sleeve 240 are inserted into the central hole of the expansion hub 230 together. inside, and locked...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com