Electrode rotating and clamping device for electrosparking of insulating ceramic coated metal

A technology of insulating ceramics and clamping devices, which is applied in the field of electric discharge machining and forming, can solve the problems such as the inability to use oil-based working fluid, and achieve the effect of meeting the requirements of coaxiality, good compressibility and elongation, and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

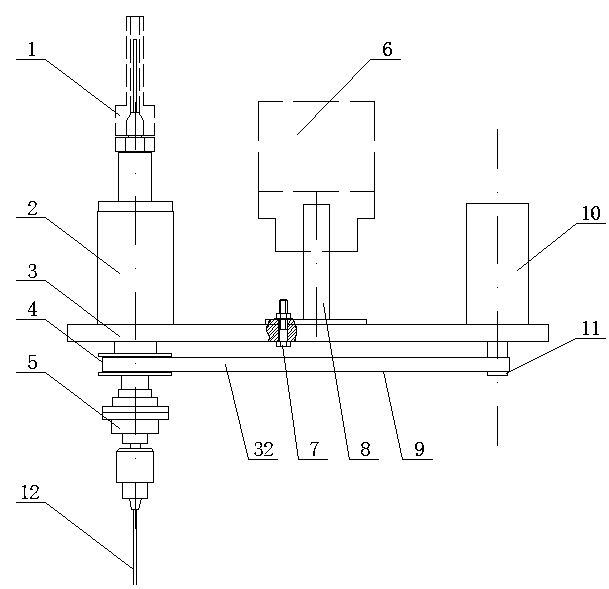

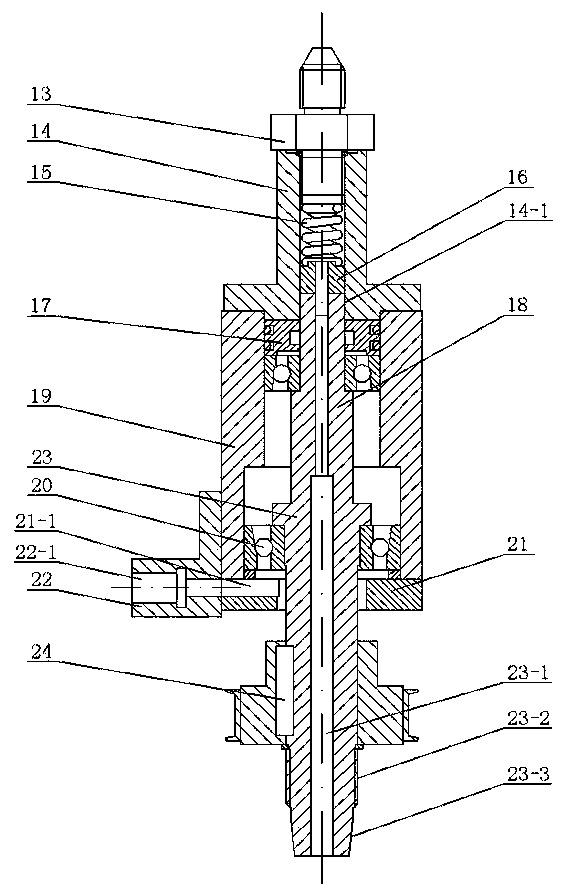

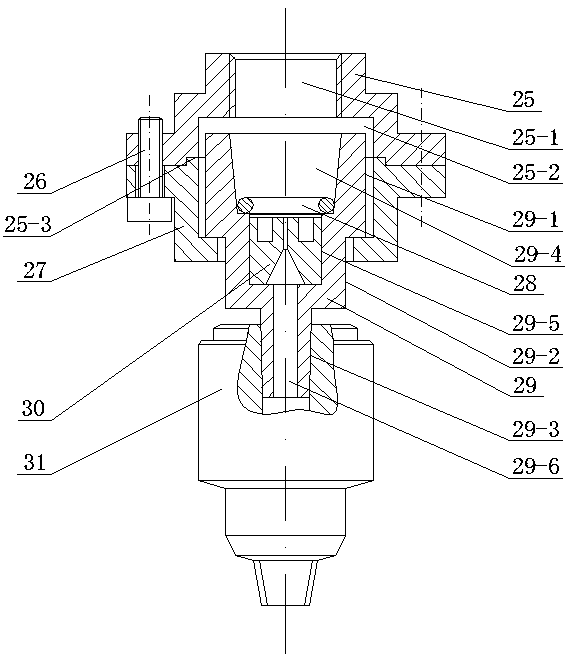

[0017] Specific implementation mode one: Such as Figure 1-3 As shown, an electrode rotation and clamping device for insulating ceramic coating metal electric discharge machining, the electrode rotation and clamping device includes an electrode rotation device 2, an insulating substrate 3, an electrode clamping device 5, a fixed block 8, Synchronous belt transmission mechanism 9, DC deceleration motor 10 and electrode 12, electrode 12 adopts hollow tubular electrode, described electrode rotation device 2 includes pressure oil interface 13, upper end cover 14, spring 15, sealing block 16, sealing assembly 17, upper Bearing 18, base body 19, lower bearing 20, lower end cover 21, brush holder 22 and hollow shaft 23, the electrode clamping device 5 includes upper pressing cover 25, lower pressing cover 27, sealing plug 30, O-shaped The sealing ring 28, the taper connecting shaft 29 and the drill chuck 31, the first shaft hole and the second shaft hole are arranged on the insulat...

specific Embodiment approach 2

[0020] Specific implementation mode two: Such as figure 2 As shown in the specific embodiment 1, an electrode rotation and clamping device for electrical discharge machining of insulating ceramic coated metal, the taper of the conical surface of the positioning section 23-3 is 1:5.

specific Embodiment approach 3

[0021] Specific implementation mode three: Such as image 3 As shown in the specific embodiment 1 or 2, an electrode rotation and clamping device for electric discharge machining of insulating ceramic coated metal, the lower end surface of the upper pressing cover 25 is located at the end of the first shoulder hole 25-2. The edge is processed with a ring groove 25-3 that is conveniently positioned with the lower compression cover 27 to the center.

[0022] working principle: The electrode rotating device 2 provides the rotating movement of the electrode, and the sealing assembly 17 in it can prevent the leakage of pressure oil when the electrode 12 is flushed, and supplies power to the rotating electrode 12 through the brush holder 22 on the side. The electrode clamping device 5 provides clamping of the electrode 12 , and the electrode 12 is driven to rotate through the electrode rotating device 2 . The epoxy resin insulating substrate 3 has good insulating performance, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com