Chlorinated polyethylene-neoprene mixed polymer

A technology of blending polymer and chlorinated polyethylene, which is applied in the field of blending polymers of chlorinated polyethylene and chloroprene, can solve the problems such as the limitation of the blending ratio of chlorinated polyethylene and chloroprene, and reduce the The effect of dosage and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A blended polymer of chlorinated polyethylene-chloroprene rubber, wherein the proportion of chlorinated polyethylene is greater than 40% of the weight of the blended polymer.

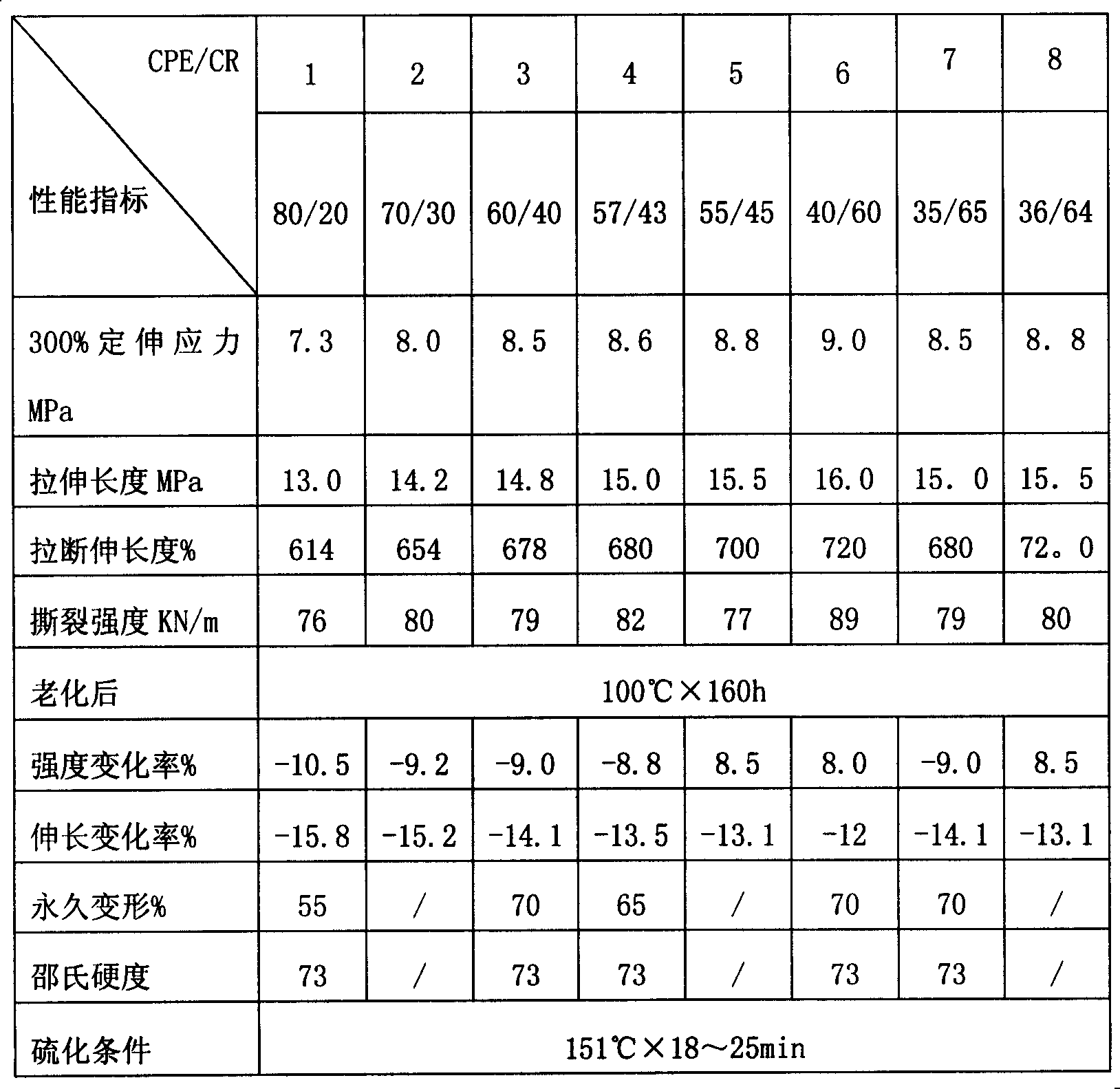

[0014] The blended polymers of chlorinated polyethylene and neoprene described in the present invention are mixed according to the following parts by weight, and an open rubber mixer or a twin-screw blending extruder is used to obtain chlorinated polyvinyl chloride blended in any proportion. The copolymer of ethylene-chloroprene rubber is blended by rubber-plastic mechanical melt blending method. The ratio of chlorinated polyethylene and neoprene rubber and the obtained performance indicators are shown in Table 1:

[0015] Table 1

[0016] In the above-mentioned blend polymer, also added the following composition by weight, as table 2:

[0017] Composition and content

1

2

3

4

5

6

7

8

Vulcanizing agent

s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com