Patents

Literature

177results about How to "Ozone resistant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

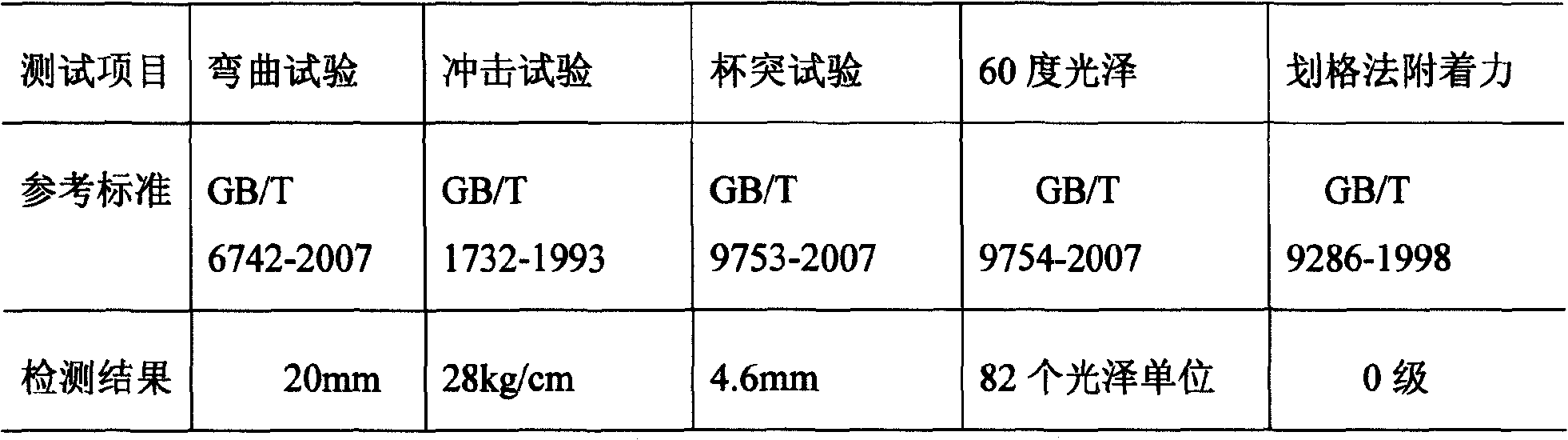

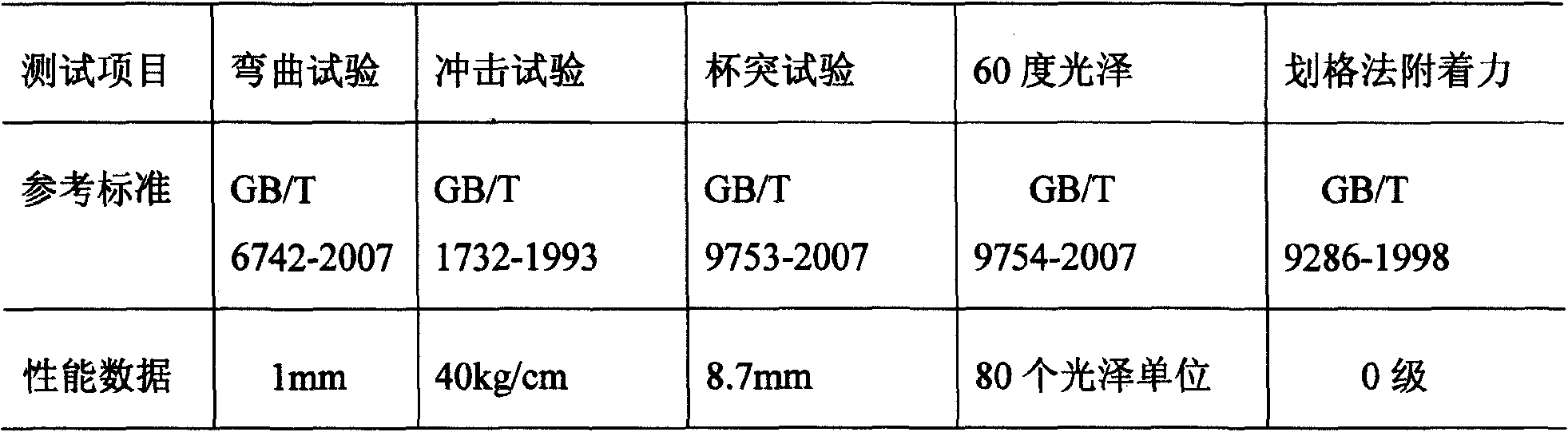

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

Low-smoke halogen-free flame-retardant cable material

InactiveCN105037899ASoft textureHigh tensile strengthPlastic/resin/waxes insulatorsInsulated cablesEpoxyAntioxidant

The invention discloses a low-smoke halogen-free flame-retardant cable material, and belongs to the field of materials. The low-smoke halogen-free flame-retardant cable material solves the problem that an existing cable material is poor in mechanical property and electrical property. The low-smoke halogen-free flame-retardant cable material is composed of 50-60 parts of high density polyethylene, 20-30 parts of ethylene-ethyl acrylate copolymers, 20-30 parts of methyl vinyl silicone rubber resin, 1-3 parts of magnesium stearate, 2-5 parts of novolac epoxy resin, 15-25 parts of isopropyl phenyl diphenyl phosphate, 1-2 parts of dilauryl thiodipropionate, 10-20 parts of dimellitate, 1-2 parts of antioxidants 1010, 1-1.5 parts of antioxidants CA, 10-20 parts of maleic anhydride grafting ethylene-octylene copolymers, 5-10 parts of polysiloxane, 20-30 parts of nano magnesium hydroxide, 13-18 parts of nano clay, 3-7 parts of zinc oxide, 5-10 parts of polyethylene wax and 3-8 parts of calcium stearate. The low-smoke halogen-free flame-retardant cable material can be widely used as insulation and sheathing materials of various electric wires and cables.

Owner:国网山东莒南县供电公司 +2

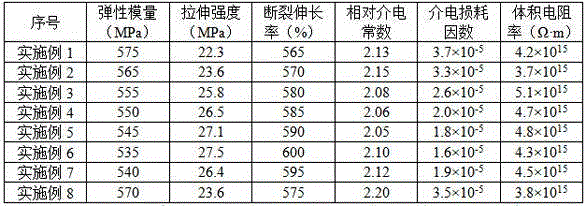

Special insulating material for electrical equipment and preparation method for special insulating material

InactiveCN105348739AGood compatibilityGood dispersionPlastic/resin/waxes insulatorsEpoxyPower equipment

The invention discloses a special insulating material for electrical equipment and a preparation method for the special insulating material. The special insulating material for the electrical equipment comprises the following components in parts by weight: 90-100 parts of epoxy resin, 15-25 parts of methyl vinyl silicone rubber, 20-25 parts of fluorosilicon resin, 15-20 parts of polytetrafluoroethylene, 10-15 parts of glass fiber, 15-20 parts of nano inorganic powders, 0.2-1 part of butyl titanate, 20-40 parts of distilled water, 1-6 parts of a compatilizer, 1-5 parts of a flame retardant, 0.3-1.2 parts of an antioxidant and 1-10 parts of a crosslinking agent. The special insulating material for the electrical equipment prepared by the invention can inhibit the space charge accumulation in the cable insulating material, improve the anti-aging property, the anti-flashover property and the anti-acidic and alkaline water-resistent property of the material, has good mechanical properties, electrical property and thermal property, and is excellent in comprehensive properties.

Owner:国网河南唐河县供电公司

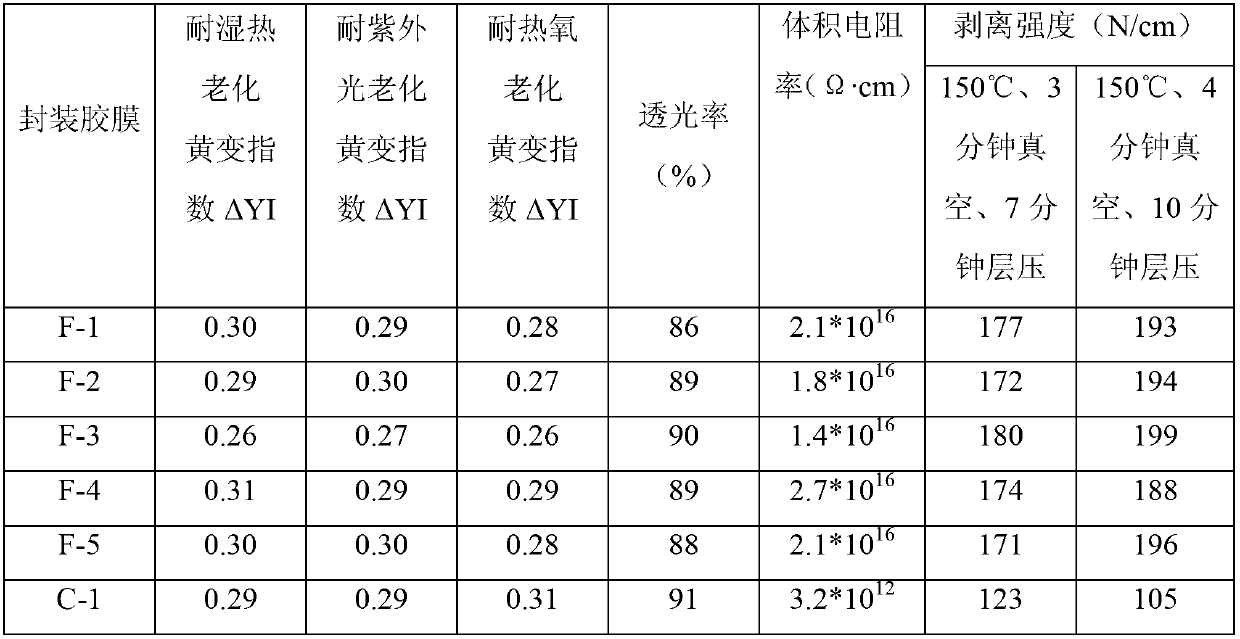

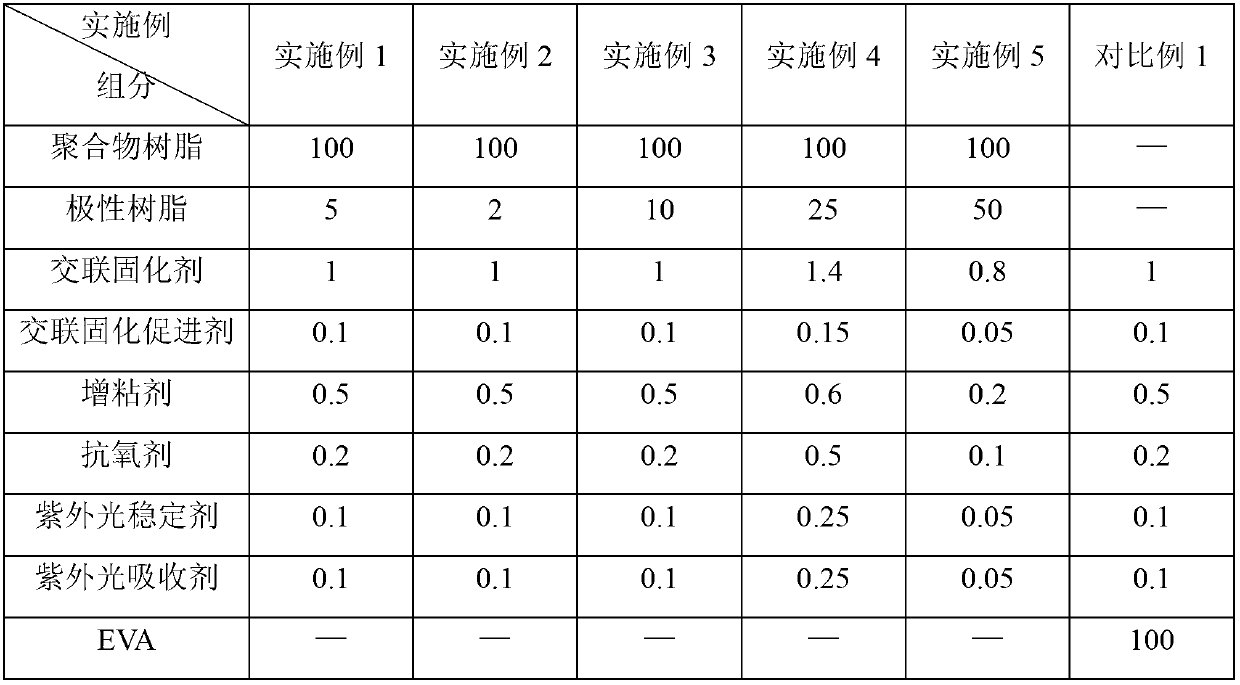

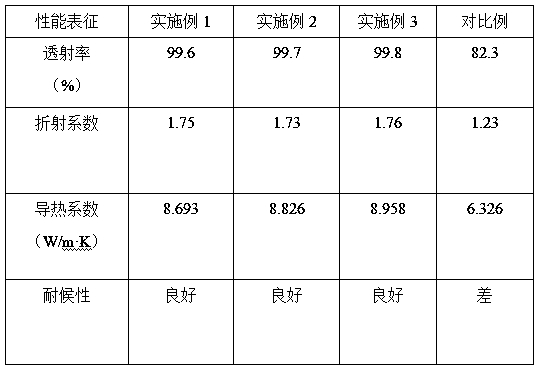

Solar cell packaging rubber film and preparation method thereof

ActiveCN102863914ALow priceRelative density is smallNon-macromolecular adhesive additivesFilm/foil adhesivesCross-linkPolymer science

The invention relates to a solar cell packaging rubber film and a preparation method thereof. The solar cell packaging rubber film comprises the following components in parts by mass: 100 parts of polymer resin, 1-50 parts of polar resin, 0.5-2 parts of cross-linking curing agent, 0.05-0.2 part of cross-linking curing accelerator, 0.2-0.6 part of tackifier, 0.1-0.5 part of antioxidant, 0.05-0.25 part of ultraviolet stabilizer and 0.05-0.25 part of ultraviolet absorber. The preparation method of the solar cell packaging rubber film comprises the following steps of: 1) evenly mixing the raw materials according to proportions to obtain mixture; and 2) pouring the mixture into an extruder for mixing and plasticizing to obtain extruded materials, casting and calendaring the extruded materials to form a film, shaping through cooling and drawing, and finally winding the film. The solar cell packaging rubber film provided by the invention has the advantages that the light transmittance is higher, the film can effectively resist aging and the electric insulating performance is not changed fundamentally after the film is used for a long time; and the preparation method provided by the invention has the advantages that the processing efficiency is high, the cost is low and the large-scale production can be realized.

Owner:宁波威克丽特功能塑料有限公司

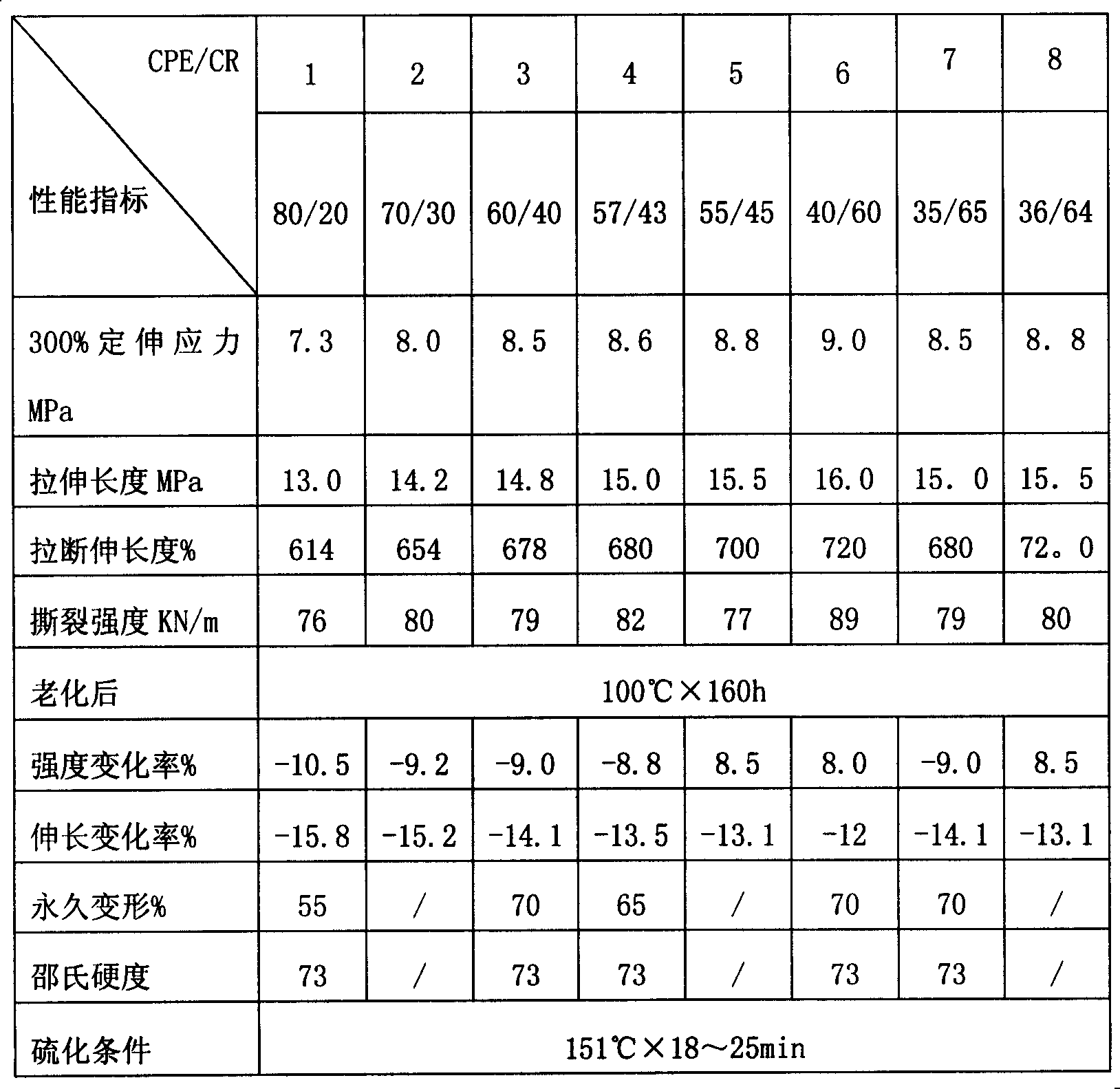

Chlorinated polyethylene-neoprene mixed polymer

The present invention relates to one kind of polymer mixture of chlorinated polyethylene and neoprene. The polymer mixture contains chlorinated polyethylene over 40 wt%, and neoprene, as well as vulcanizing agent, stuffing, promoter, antiager, plasticizer, scorch retarder, stabilizer, etc. The polymer mixture has lowered neoprene consumption, low cost, ozone tolerance, high heat resistance, high weather resistance, high corrosion resistance, and other advantages.

Owner:深圳市迅特橡塑技术有限公司

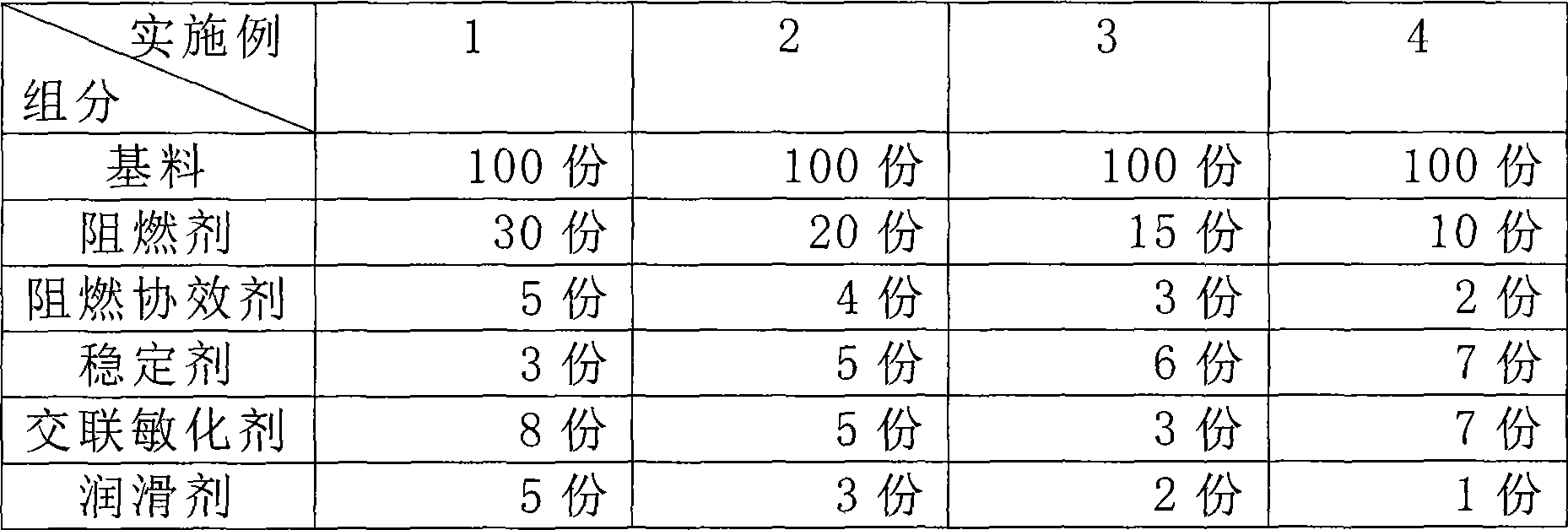

Halogen-free flame retardant insulation material for photovoltaic cable

ActiveCN101456987AImprove aging resistanceGood weather resistancePlastic/resin/waxes insulatorsWeather resistanceEngineering

The invention provides a halogen-free flame retardant insulation material used for a photovoltaic cable, which belongs to a novel cable material technical field and solves the problems exiting in the present halogen-free flame retardant insulation material used for the photovoltaic cable, that is, poor mechanical properties of tensile strength, elongation break and the like, poor heat aging property, shorter service life, and the like. The halogen-free flame retardant insulation material used for the photovoltaic cable comprises the following components according to a weight ratio: a 100 proportion of base material, 8-35 proportion of flame retardant, 2-8 proportion of stabilizer, and 1-10 proportion of crosslinking sensitizer. The halogen-free flame retardant insulation material used for the photovoltaic cable has the advantages of low production cost, good mechanical properties as heat aging property, tensile strength, elongation break and the like, long service life, low temperature tolerance, ozone resistance, weather resistance, direct current voltage resistance, and dynamic penetration resistance, etc.

Owner:临海市亚东特种电缆料厂

High-strength high-flexibility flame-retardant cable sheath rubber and preparation method thereof

InactiveCN102250427AEasy to processHigh strengthInsulated cablesInsulated conductorsEpoxyPlasticizer

The invention discloses a high-strength high-flexibility flame-retardant cable sheath rubber and a preparation method thereof. The sheath rubber comprises 100 parts of chlorosulfonated polyethylene, 15-25 parts of plasticizer, 3-7 parts of compound stabilizer, 40-60 parts of thermal decomposition process carbon black, 15-25 parts of active calcium carbonate, 3-6 parts of antimony trioxide, 2-4 parts of vaseline, 1.5-4.5 parts of antioxidant, 8-10 parts of magnesium oxide and 10-15 parts of epoxy resin. In the cable sheath rubber disclosed by the invention, through the optimal combination of chlorosulfonated polyethylene and other components, the material has the characteristics of high strength, high flexibility and flame retardancy, and at the same time, the material has the advantages of oil resistance, heat resistance, fire resistance, weathering resistance, ozone resistance, acid and base resistance, chemical resistance and the like.

Owner:WUXI MINGZHU CABLE

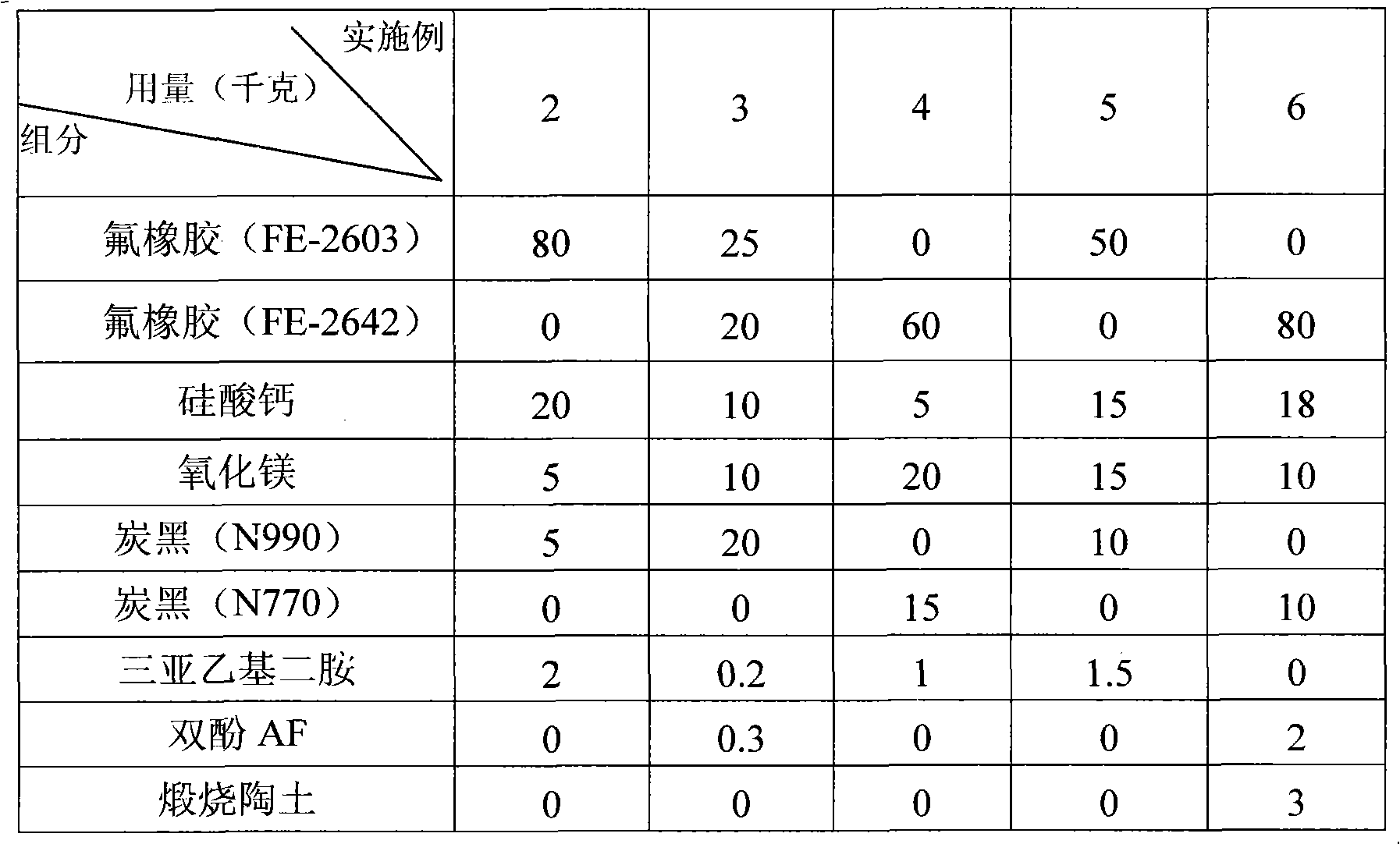

Fluoride rubber and plastic sealing material and preparation method thereof

ActiveCN101838430AHigh temperature resistantOil resistantOther chemical processesCalcium silicateCross-link

The invention discloses a fluoride rubber and plastic sealing material with good performance and low cost, and a preparation method of the rubber. The sealing material comprises the following raw materials in part by weight: 40-80 parts of fluorous rubber, 5-20 parts of calcium silicate, 5-20 parts of carbon black, 5-20 parts of magnesium oxide and 0.5-2 parts of cross-linking agent. The method comprises the steps of arranging the fluorous rubber in an internal mixer at the temperature of 150-160 DEG C with the plasticating time of 4min-10min, adding the carbon black, 1 / 3 of the magnesium oxide and 1 / 3 of the calcium silicate with the plasticating time of 6min-8min, then adding the rest magnesium oxide and calcium silicate, plasticating, stopping, overturning the warehouse to output the materials for spare use, arranging the materials in an open mill, adding the cross-linking agent at the temperature less than or equal to 65 DEG C, thinly introducing four times after material feed, packing with a triangular bag five times, and feeding plates.

Owner:河北鑫科新材料科技有限公司

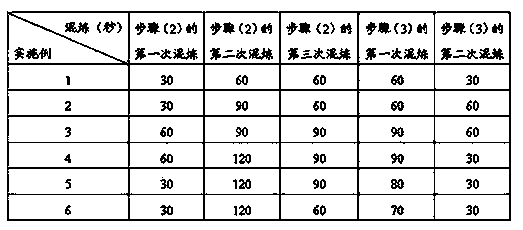

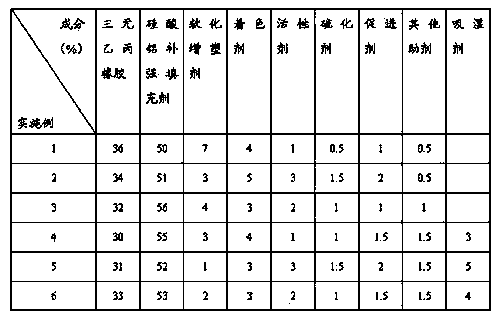

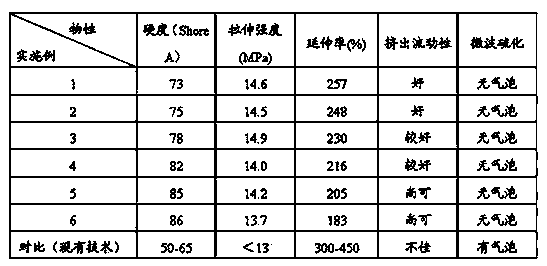

High-hardness color ethylene-propylene-diene monomer (EPDM) suitable for microwave vulcanizing and preparation method thereof

The invention discloses a high-hardness color ethylene-propylene-diene monomer (EPDM) suitable for microwave vulcanizing. The EPDM comprises the following components by weight percent: 30-36% of EPDM, 50-56% of aluminium silicate reinforcing filler, 1-7% of a softening plasticizer, 3-5% of a coloring agent, 1-3% of an activating agent, 0.5-1.5% of a vulcanizing agent and 1-2% of an accelerant. Besides, the invention also discloses a method for preparing the EPDM. The EPDM has the characteristics of heat resistance, low temperature resistance, ozone resistance, weathering aging resistance and insulation, has a long service life, can be suitable for the production process of continuous microwave vulcanizing, does not generate bubbles and has high degree of hardness.

Owner:TAICANG GUANLIAN POLYMERIC MATERIAL

Heat resistant, wear-resistant and tear-resistant cable sheath

InactiveCN105131614AGood dispersionImprove solubilityRubber insulatorsInsulated cablesFiberWear resistant

The invention discloses a heat resistant, wear-resistant and tear-resistant cable sheath. The heat resistant, wear-resistant and tear-resistant cable sheath is prepared, by weight, 20-30 parts of modified phenolic resin, 30-40 parts of epichlorohydrin rubber, 40-50 parts of boron-silicon rubber, 0.4-0.6 part of 3,6,9-triethyl-3,6,9-trimethyl-1,4,7-triperoxynonane, 2-4 parts of sulphur, 1-1.5 parts of accelerant MZ, 0.8-1.3 parts of accelerator TMTD, 3-4 parts of zinc oxide, 0.5-1 part of zinc carbonate, 1-2 parts of magnesium oxide, 20-40 parts of talcum powder, 20-25 parts of montmorillonite, 20-30 parts of kaolin, 2-4 parts of jute fiber, 1-1.5 parts of silane coupling agent, 2-5 parts of chlorinated paraffins, 1-2 parts of dimethyl phthalate, 1-2 parts of antioxidant 8PPD and 0.8-1.4 parts of antioxidant BLE. The heat resistant, wear-resistant and tear-resistant cable sheath has excellent wear resistance, tear resistance, weather resistance and flame resistance.

Owner:ANHUI HONGHAI CABLE

Brake cable for electric vehicle

InactiveCN104613077ASo as not to damageReduce contact surfaceShaft for linear movementCycle brakesFiberCarbon fibers

The invention discloses a brake cable for an electric vehicle, and belongs to the technical field of automobile accessories. The brake cable comprises a rubber tube and a steel cable arranged in the rubber tube, wherein a plurality of radial bulges are arranged on the inner wall of the rubber tube; a gap between the rubber tube and the steel cable is filled with a lubricating substance; the rubber tube is made of chloroprene rubber, ethylene propylene rubber or polyurethane rubber; a sheath is a carbon fiber tube; the lubricating substance adopts lubricating grease or talcum powder. According to the brake cable for the electric vehicle, the problem that the rubber tube is damaged easily due to large friction force between the rubber tube and the steel cable can be solved.

Owner:LIUZHOU YINGHANG AUTO PARTS

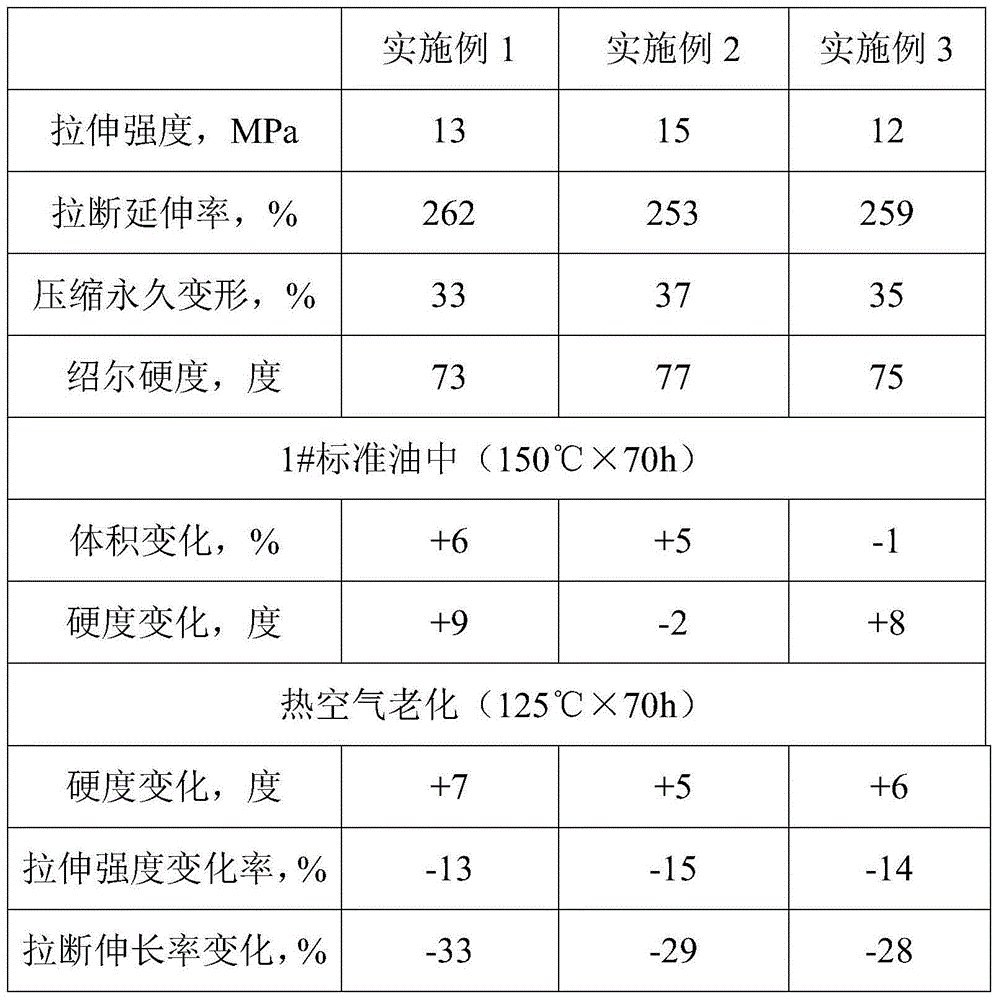

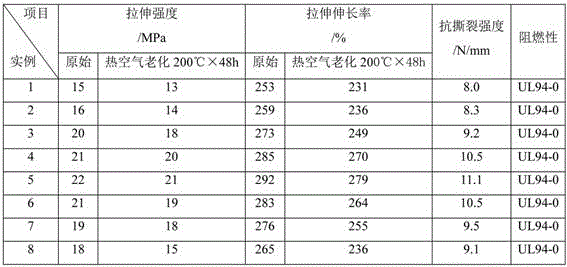

Halogen-free flame retardant insulating material for photovoltaic cables

InactiveCN103756089AHigh tensile strengthHigh elongation at breakPlastic/resin/waxes insulatorsInsulated cablesEngineeringSolar power

The invention relates to a halogen-free flame retardant insulating material for photovoltaic cables, and belongs to the technical field of novel cable materials. The halogen-free flame retardant insulating material for the photovoltaic cables comprises the following components in parts by weight: 100 parts of basic resin, 10-45 parts of a flame retardant, 1-8 parts of a stabilizer and 1-8 parts of a crosslinking sensitizing agent. The halogen-free flame retardant insulating material is used for solving the problems of a conventional cable material that the conventional halogen-free flame retardant insulating material for the photovoltaic cables has relatively poor mechanical performances such as tensile strength and breaking elongation, relatively poor thermal aging resistance and relatively short service life in hostile environments of solar power stations. The production cost of the halogen-free flame retardant insulating material is low, the mechanical property of the halogen-free flame retardant insulating material is improved, and especially the high temperature resistance and the weather fastness of the halogen-free flame retardant insulating material are obviously improved.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI

Special butyronitrile PVC composite cable sheath for aerogenerator

ActiveCN101527186AOptimum service life cycleImprove performanceRubber insulatorsPlastic/resin/waxes insulatorsWeather resistancePlasticizer

The invention belongs to the technical field of wire and cable sheaths, and relates to a special butyronitrile PVC composite cable sheath for an aerogenerator. The sheath is made from the following raw materials in parts by weight: 100 parts of polyvinyl chloride resin; 10-15 parts of nitrile butadiene rubber; 50-60 parts of a plasticizer; 20-40 parts of active calcium carbonate; 6-7 parts of a stabilizer; 0.3-0.4 part of a lubricant; 0.9-3.0 parts of a filler and 0.2-0.6 part of an accelerator. The sheath has the advantages of ozone resistance, weather resistance and aging resistance, large breaking elongation change, high volume index and flow index, good stability and excellent cracking resistance, generally does not crack at the temperature of minus 50 DEG C , has high safety performance and prolongs service life cycle of cables.

Owner:KAIKAI CABLE TECH

Oil-resistant and high-temperature-resistant rubber material for automobiles

The invention discloses an oil-resistant and high-temperature-resistant rubber material for automobiles. The oil-resistant and high-temperature-resistant rubber material comprises the following raw materials in parts by weight: 45-55 parts of butadiene rubber, 20-25 parts of acrylate rubber, 20-35 parts of silicon rubber, 15-20 parts of white carbon black, 10-15 parts of modified nano talcum powder, 2-5 parts of sulfur, 0.5-1.2 parts of zinc oxide, 1-3 parts of tricresyl phosphate, 0.5-2 parts of oxidized polyethylene, 3.5-4.5 parts of a promoter TMDT, 2-5 parts of an anti-aging agent, 0.2-0.5 part of epoxy flaxseed oil, 0.2-0.5 part of triethyl o-acetylcitrate and 1.0-1.5 parts of microcrystalline wax. The rubber material disclosed by the invention is good in wear resistance, heat resistance and oil resistance, and can be applied to automobile fuel tanks.

Owner:安徽宁国尚鼎橡塑制品有限公司

Preparation method of anti-aging silicone material for LED packaging

InactiveCN110016319AImprove aging resistanceHigh hardnessNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceHydrosilylation

The invention relates to a preparation method of an anti-aging silicone material for LED packaging, and belongs to the technical field of silicone products. Polyurethane is adopted to modify siliconerubber so as to obtain a raw material, and through combination with vinyl-terminated methylsilicone oil and a platinum catalyst, a rubber matrix is obtained through hydrosilylation; and the hydrogen-containing methylsilicone oil is adopted as a cross-linking agent, and vulcanization is performed so as to obtain the LED packaging anti-aging silicone material. The anti-aging silicone material has agood refractive index, aging resistance and good mechanical properties, and polyurethane has the advantages of high hardness, high strength, high elasticity, high wear resistance, tear resistance, aging resistance, ozone resistance, radiation resistance, good electrical conductivity and the like, and silicone rubber has excellent heat resistance, cold resistance, dielectric properties, ozone resistance, atmosphere aging resistance and other properties, so that after the silicone rubber is modified by using polyurethane, the tensile strength and tear strength of the modified silicone rubber areimproved, and the aging resistance is also improved.

Owner:宁波市海曙果壹电子科技有限公司

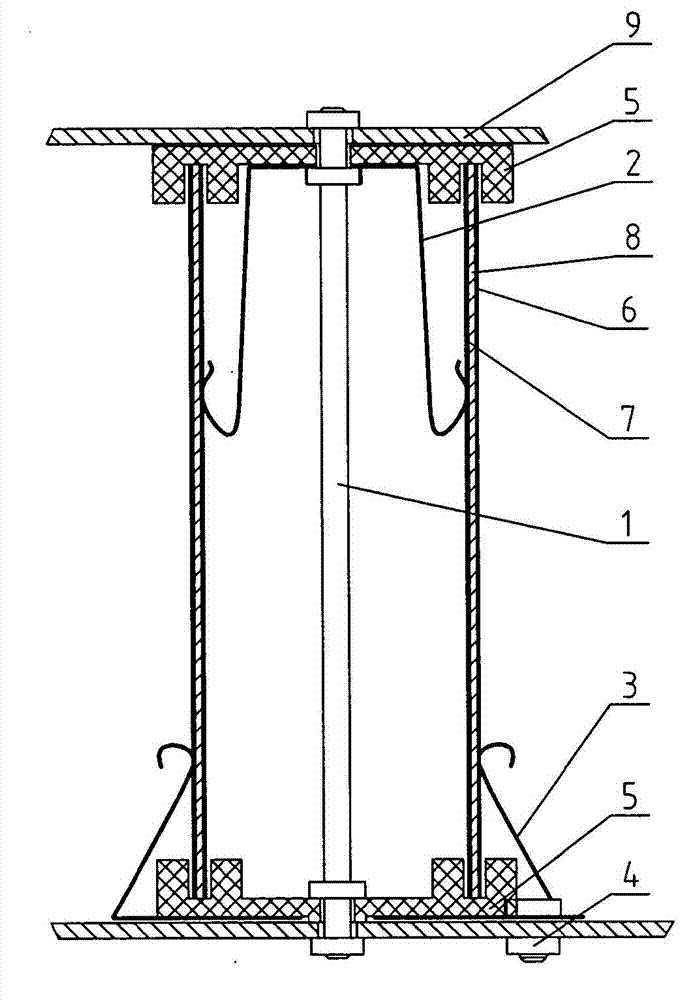

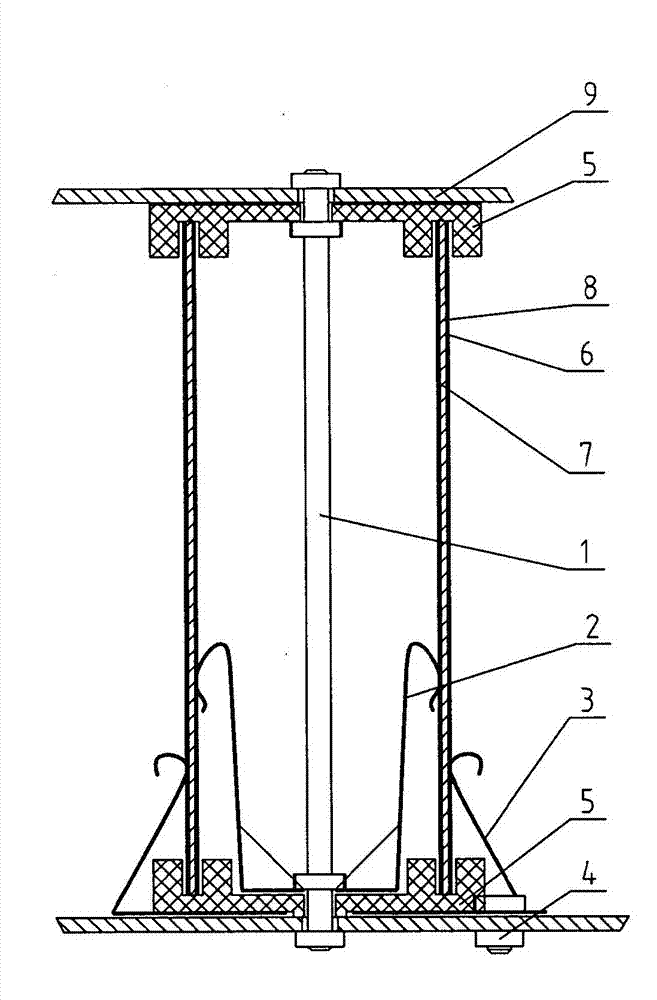

Ion generator

ActiveCN102780161AEfficient removalGood removal effectElectrical apparatusDeodrantsElectricityAir purification

The invention discloses an ion generator and belongs to the technical field of air purification devices. The ion generator comprises a fixed core column, an ion generation tube, an inner reed, an outer reed and an outer electrode connecting column. Insulators are respectively arranged at two ends of the fixed core column, the ion generation tube is embedded in the two insulators, the ion generation tube is composed of an outer electrode, an inner electrode and an isolation insulating layer arranged between the outer electrode and the inner electrode, one end of the inner reed is connected with the inner electrode in butting mode, the other end of the inner reed is electrically connected with the fixed core column, one end of the outer reed is connected with the outer electrode in butting mode, and the other end of the outer reed is electrically connected with the outer electrode connecting column. The ion generator can be used for sterilizing and purifying air, is good in sterilization and purification effects, and cannot generate secondary pollution.

Owner:常州明阳软件科技有限公司 +1

Heat-resistant insulating resin composition

The invention belongs to the technical field of high polymer materials, and particularly discloses a heat-resistant insulating resin composition. The heat-resistant insulating resin composition comprises the following raw materials in parts by weight: 60-80 parts of polypropylene resin, 22-35 parts of polyacrylate rubber, 15-26 parts of polyurethane rubber, 7-15 parts of polyisobutene grafted maleic anhydride, 15-30 parts of plasticizing agent, 5-10 parts of fire retardant, 5-10 parts of antioxidant, 3-6 parts of anti-aging agent, 4-8 parts of crosslinking agent and 1-2 parts of assistant crosslinking agent. The heat-resistant insulating resin composition disclosed by the invention has excellent mechanical property, flame retardant property and high temperature resistance.

Owner:HUANGHE S & T COLLEGE

Formula and preparation method of inner glue in chlorinated polyethylene rubber tube

The invention relates to a formula of inner glue in a chlorinated polyethylene oil-resisting and low-temperature-resisting rubber tube. The formula comprises the following components in parts by weight: 60-80 parts of chlorinated polyethylene (CM), 0-20 parts of alloy glue 4, 1-2 parts of an antiager, 60-90 parts of semi-reinforced furnace black, 40-60 parts of modified nano kaolin, 1-2 parts of wax, 30-45 parts of a cold-resistant plasticizer, 5-8 parts of magnesium oxide, 2-4 parts of fatty acid amide and 2-4 parts of a disulfydryl thiazole derivative. Compared with conventional formula, the formula provided by the invention has the advantages that the cost is lower, the liquid resisting performances of the prepared inner glue completely reach HG / T3037-2008 standard and the prepared inner glue can be used for a long time in a working environment at -50 DEG C.

Owner:DANDONG DECHENG PLASTIC SCI & TECH

Low-hardness NBR (nitrile-butadiene rubber) sealing element material for automobile transmission converters and preparation method thereof

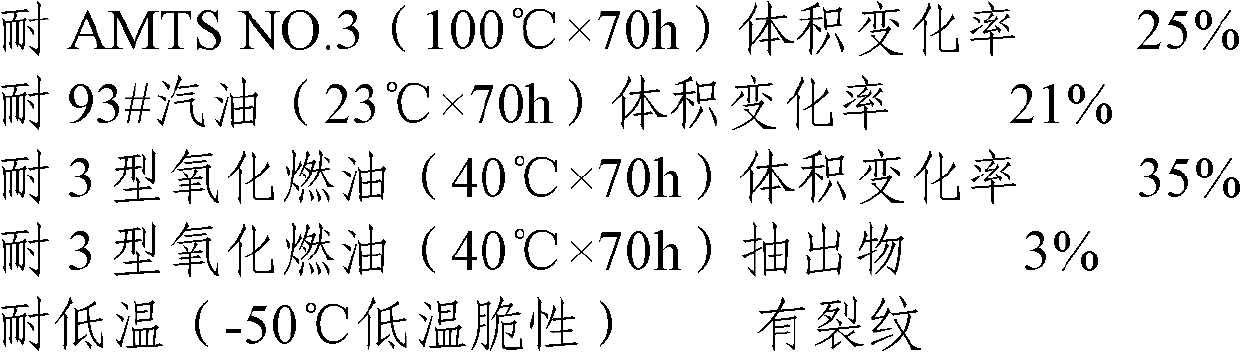

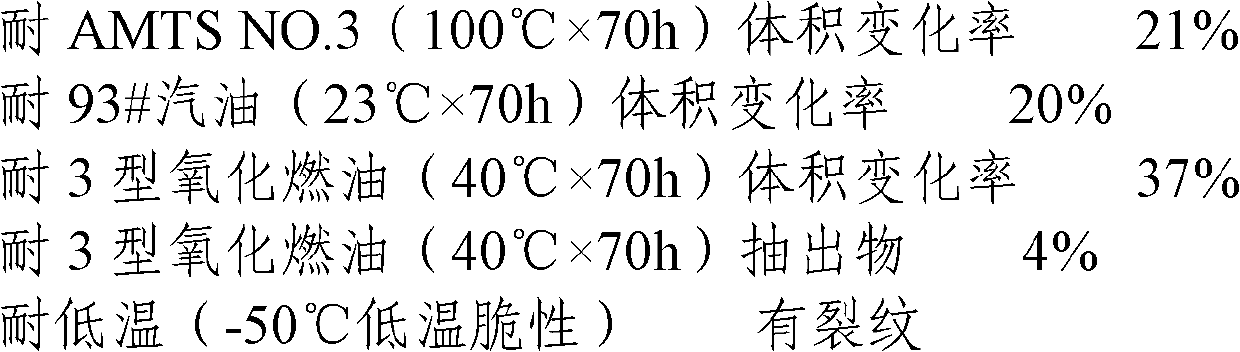

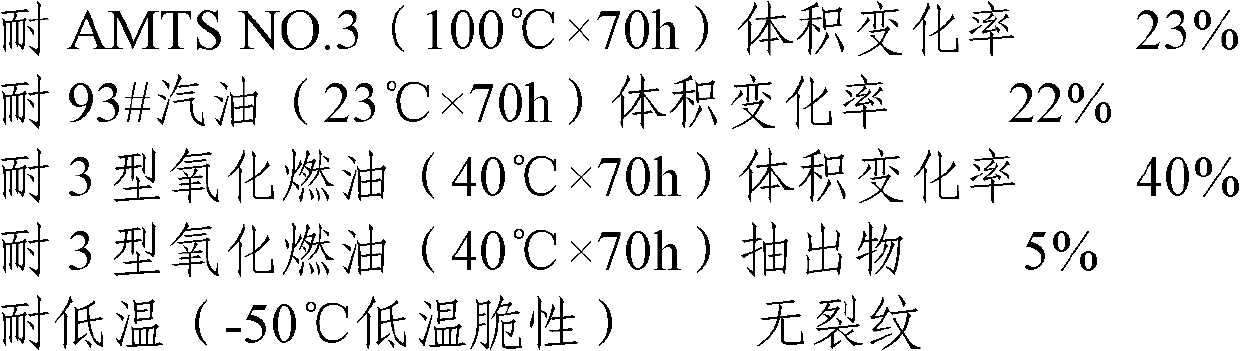

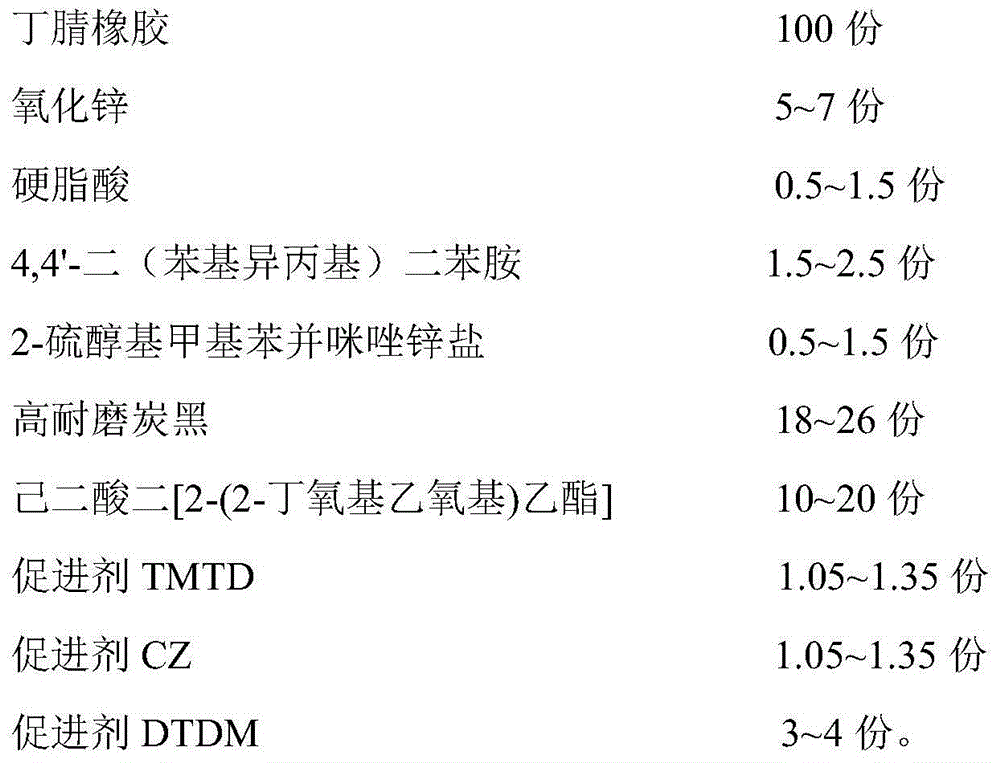

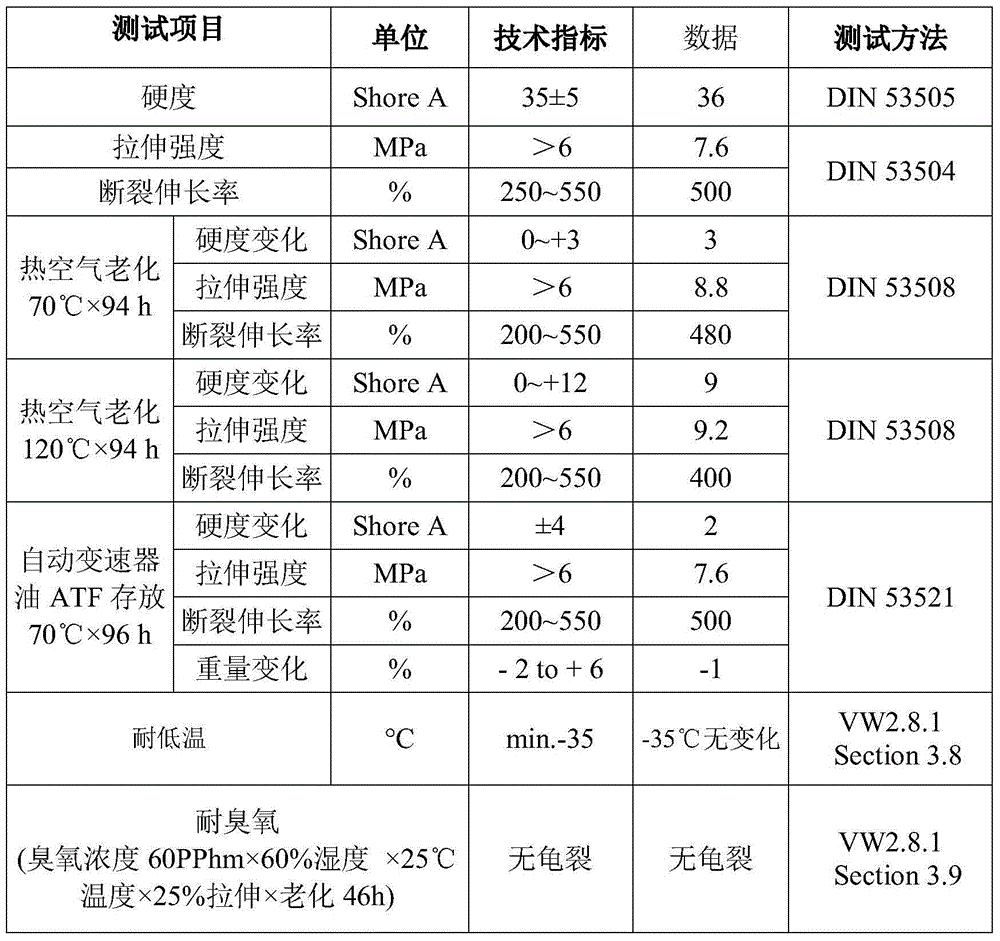

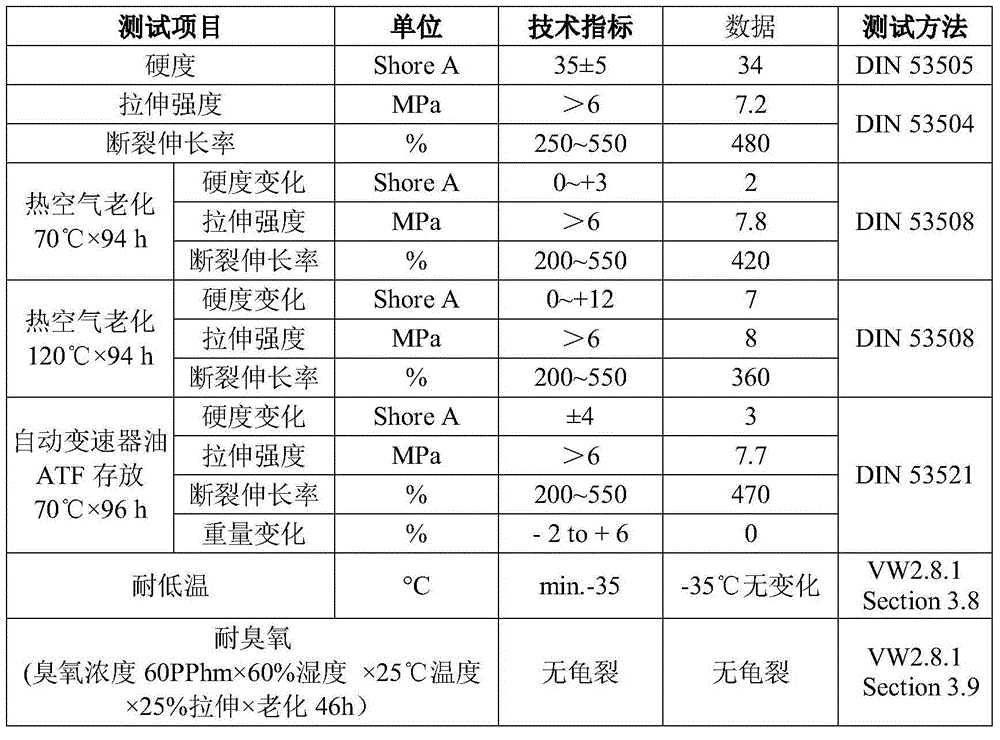

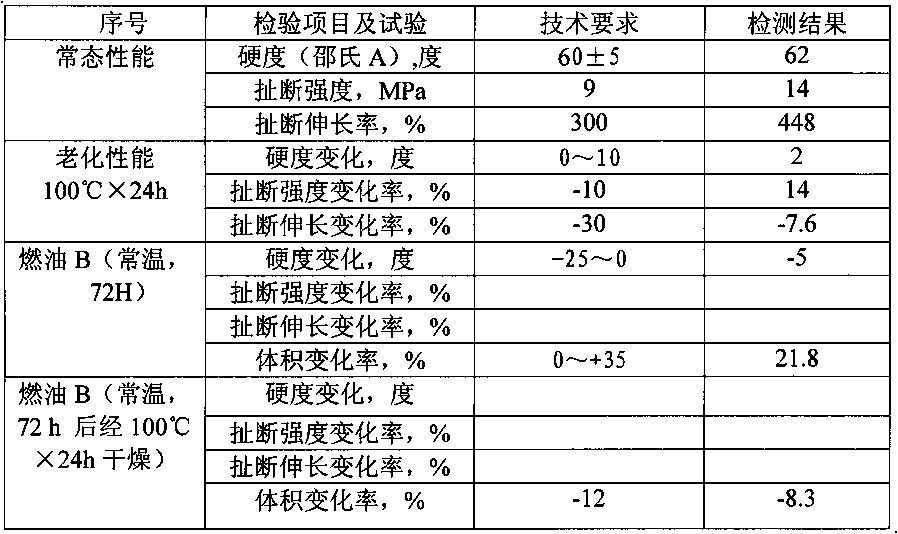

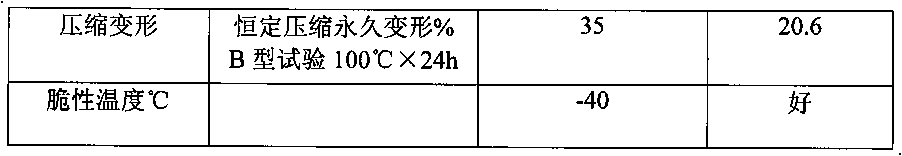

The invention discloses a low-hardness NBR (nitrile-butadiene rubber) sealing element material for automobile transmission converters and a preparation method thereof, belonging to the technical field of rubber sealing elements. The low-hardness NBR sealing element material for automobile transmission converters comprises 100 parts of NBR, 5-7 parts of zinc oxide, 0.5-1.5 parts of stearic acid, 1.5-2.5 parts of 4,4'-di(phenylisopropyl)diphenylamine, 0.5-1.5 parts of 2-thiomethylbenzimidazole zinc salt, 18-26 parts of high-wear-resistance carbon black, 10-20 parts of ethyl di[2-(2-butoxyethoxy)]adipate, 1.05-1.35 parts of accelerator TMTD (tetramethyl thiuram disulfide), 1.05-1.35 parts of accelerator CZ and 3-4 parts of accelerator DTDM. The preparation method comprises the following steps: compounding a master batch; carrying out two-stage sulfurization on the master batch; and vulcanizing. The hardness of the NBR sealing element material can be lowered to 30-40 Shaw A, thereby satisfying the Volkswagen VW2.8.1_P35 Standard. The NBR sealing element material has the advantages of favorable temperature resistance, transmission ATF oil resistance, ozone resistance and high resilience.

Owner:南京金三力高分子科技有限公司

Neoprene material for air conditioner motor damping rings

The invention discloses a neoprene material for air conditioner motor damping rings, which is prepared from the following raw materials in parts by weight: 40-90 parts of neoprene, 10-60 parts of natural rubber, 5-15 parts of rubber composite vulcanizing agent and 1-5 parts of rubber anti-aging agent. The rubber composite vulcanizing agent is composed of sulfur and one or more of zinc oxide, magnesium oxide, rubber accelerator M, rubber accelerator DM, rubber accelerator TT and rubber accelerator CZ. The neoprene material has the advantages of low cost, favorable high-temperature resistance, small variation in hardness after aging, and favorable damping effect.

Owner:王强

Fuel oil resistant rubber and O-shaped rubber sealing ring

The invention relates to a fuel oil resistant and oxygen-contain ethanol gasoline resistant rubber sealing series product for a vehicular fuel oil pump assembly. The fuel oil resistant rubber comprises the following basic components in parts by mass: 100 parts of rubber alloy, 4-8 parts of activating agent, 2-3 parts of chemical protection agent, 1.5-3 parts of physical protecting agent, 0.3-1 part of vulcanizing agent, 2.5-3.5 parts of vulcanizing accelerator, 30-70 parts of carbon black, 15-40 parts of filling agent, 18-25 parts of plasticizer, 1.5-5 parts of lubricating agent, 1-2 parts of cream inhibiting gel and 0.1-0.5 part of antiscorching agent. According to the rubber obtained according to the technical scheme provided by the invention, the rubber alloy is used as a body material, so that the cost of a formula is far lower than that of fluororubber. Meanwhile, under the conditions that no rubber exists and special processing equipment is used, the rubber material with fuel oil resistance, ozone resistance, high physical and mechanical performance, favorable elasticity, favorable processing process performance and the like is obtained by reasonably configuring a special assistant. The rubber material is suitable for O-shaped rubber sealing materials and relevant parts of automobiles and motorcycles.

Owner:重庆建兴橡胶制品有限公司

Irradiation crosslinking flame-retardant cable material and its preparation method

ActiveCN102977465AImprove flame retardant performanceExcellent non-flammabilityInsulated cablesInsulated conductorsOcteneAntimony trioxide

The invention provides an irradiation crosslinking flame-retardant cable material. The cable material is prepared from the following raw materials, by weight, 20-30 part of chlorhydrin, 60-80 parts of ethylene propylene diene monomer, 8-10 parts of chlorinated polyethylene, 8-10 parts of an ethylene-octylene copolymer POE, 0.5-1.0 part of stearic acid, 1-3 parts of magnesium oxide, 20-30 parts of tributyl citrate, 4-6 parts of iron oxide, 0.5-1.0 part of ammonium trimolybdate, 30-50 parts of semi-reinforced furnace black N765, 10-13 parts of modified argil, 1-3 parts of a silane coupling agent KH570, 0.2-0.5 parts of an antioxidant 4040, 0.5-1.5 parts of a promoter TMTD, 0.2-0.5 parts of sulfur, 8-10 parts of decabromodiphenylethane, 12-15 parts of antimony (III) oxide and 6-8 parts of zinc borate. The cable material has the advantages of excellent flame retardation, very less smoke in combustion, no generation of toxic gases or corrosive gases, good high and low temperature resistances, good abrasion resistance, good water resistance, good ozone resistance, and good ageing resistance.

Owner:东莞市悦来光电科技有限公司

Low smoke weather resistant electric wire and cable silane crosslinked polyethylene cable material and manufacturing method thereof

InactiveCN104829913AReasonable formulaImprove wear resistancePlastic/resin/waxes insulatorsWeather resistancePOLYETHYLENE WAX

The invention discloses a low smoke weather resistant electric wire and cable silane crosslinked polyethylene cable material which is characterized by comprising the following raw materials by weight: 65-75 parts of high density polyethylene, 20-25 parts of ethylene-propylene-diene monomer, 16-22 parts of nylon 6, 6-10 parts of PET fiber, 2-4 parts of polyethylene wax, 3-5 parts of dilauryl thiodipropionate, 0.2-0.3 part of sulfur, 15-20 parts of silane coupling agent G-570, 6-9 parts of epoxy soybean oil, 40-45 parts of vinyl acetate-acrylic emulsion, 17-20 parts of brown corundum ash, 0.3-0.6 part of zinc borate, 0.4-0.7 part of benzotriazole and right amount of water; the low smoke weather resistant electric wire and cable silane crosslinked polyethylene cable material is reasonable in formula, by addition of the PET fiber, the wear resistance of the cable material is improved, by addition of the silane coupling agent G-570 for crosslinking with polyethylene complex, the formed mesh structure can effectively prevent oil substances from penetrating and diffusing into blend material molecules, the cable material shows good barrier performance, and by addition of other effective auxiliary, the cable material has cracking resistance, weather resistance, low smoke and ozone resistance and other advantages, and is suitable for mines or high security occasions in special working environment.

Owner:BENGBU TRIUMPH ENG TECH CO LTD

Heat-resistant acrylic ester rubber

InactiveCN101445575AGood comprehensive physical propertiesGood post-processing performanceEthyl esterEthyl fumarate

The invention relates to a heat-resistant acrylic ester rubber which is made by copolymerization of methyl acrylate, ethyl acrylate, vinyl monochloroacetate and regulating agent. Calculating by mass percentage, the detailed mixture ratio is: methyl acrylate, 5-40%; ethyl acrylate, 50-94%; vinyl monochloroacetate, 1-10%; and regulating agent, 0.0001-1%; batch process emulsion polymerization technique is used in the process of synthesis; the initiation temperature in the process of polymerization is 10-50 DEG C and the condensation temperature is 40-70 DEG C. The invention has very excellent physical and mechanical properties and post-processing property, thus meeting requirements of the motorcycles and oil-resistant and heat-resistant rubber tubes on material, the formed product of the invention has the advantages of excellent heat-resistance and oil resistance and high tensile-strength, the application of the product ranges from leakproof material of motorcycles, oil-resistant and heat-resistant tubes to protecting jackets and the like.

Owner:JIUJIANG SHILONG RUBBER

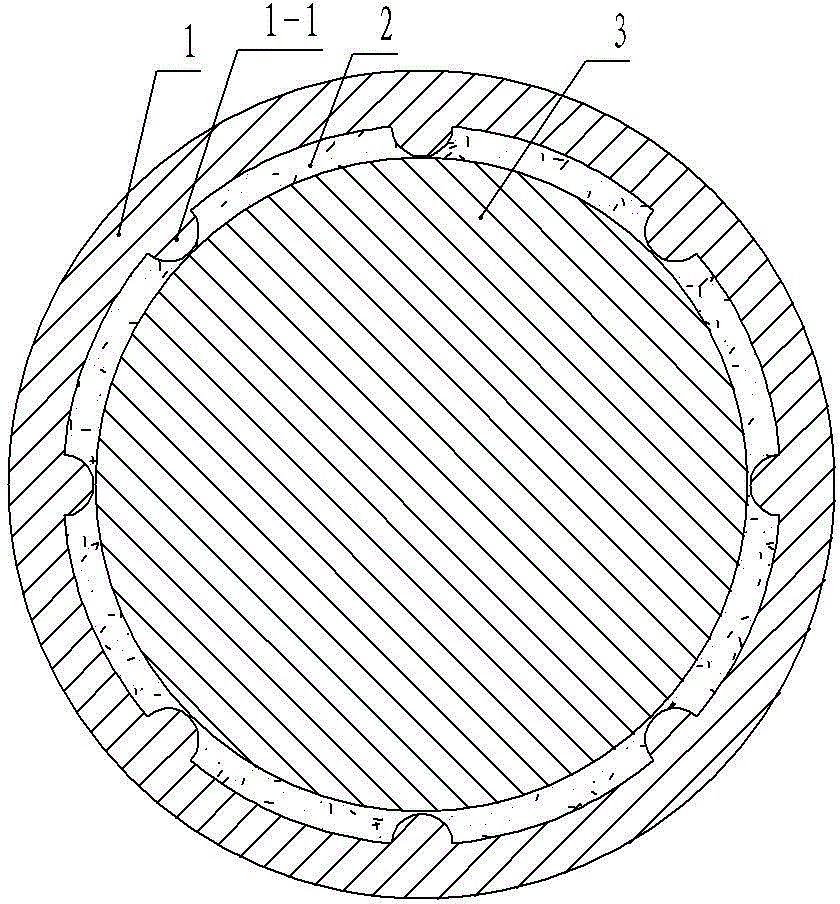

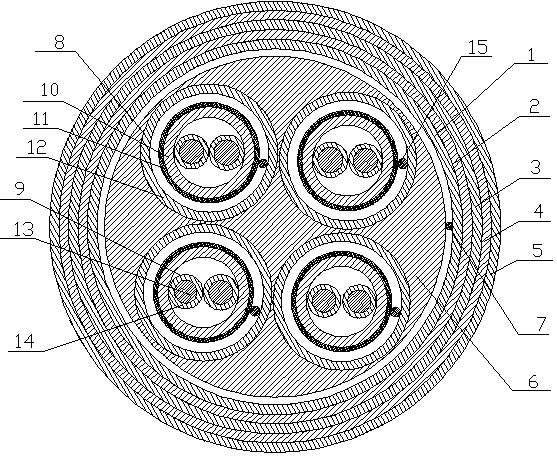

Flexible cable for intrinsic safety DCS

InactiveCN104240802AReduce capacitanceReduce inductanceFlexible cablesFlexible conductorsCapacitanceIntrinsic safety

The invention relates to the technical field of cable manufacturing, in particular to a flexible cable for an intrinsic safety DCS. The flexible cable comprises a cable core, and a lapping cabling layer, a main shielding layer, a lining layer, an armor layer and an outer sheath layer are arranged on the outer side of the cable core in sequence. A filling layer is arranged between the cable core and the lapping cabling layer. A first drainage wire is arranged between the lapping cabling layer and the main shielding layer. The cable core comprises a plurality of strands of stranded wire cores, each wire core comprises a set of insulation conductors twisted in pair, and colored tape layers, belting layers and split-phase shielding layers are sequentially arranged on the outer side of the insulation conductors twisted in pair. Second drainage wires are arranged between the belting layers and the split-phase shielding layers. Each insulation conductor comprises a tinned copper wire bunch stranded conductor, and the tinned copper wire bunch stranded conductors are coated with insulation layers. The flexible cable is reasonable and novel in structure, scientific and particular in material and low in capacitance and inductance, electric sparks are not prone to being generated, and intrinsic safety is achieved. Meanwhile, the excellent properties of flame retardance, interference resistance, oil resistance, ozone resistance and the like are achieved.

Owner:扬州市金阳光电缆有限公司

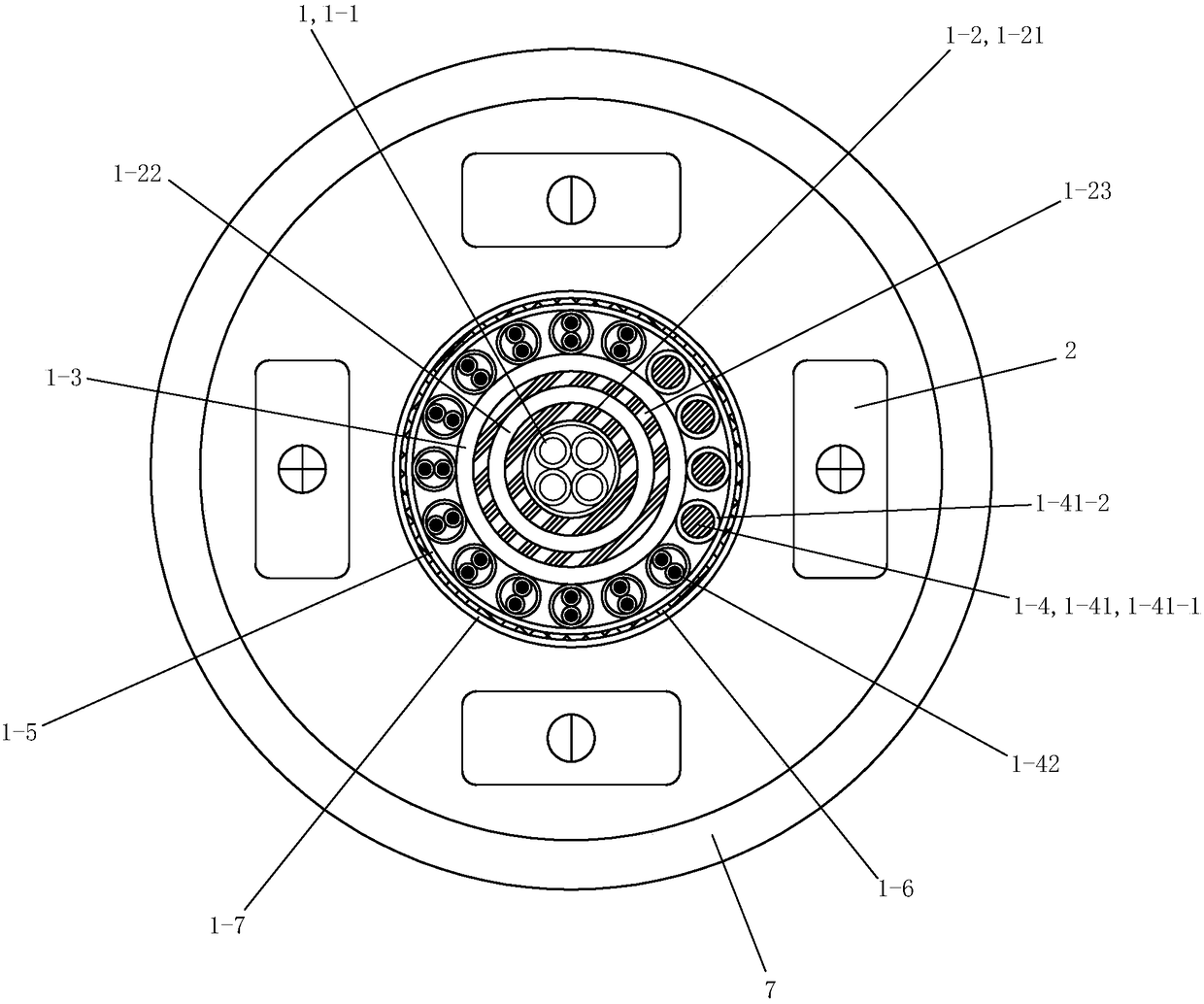

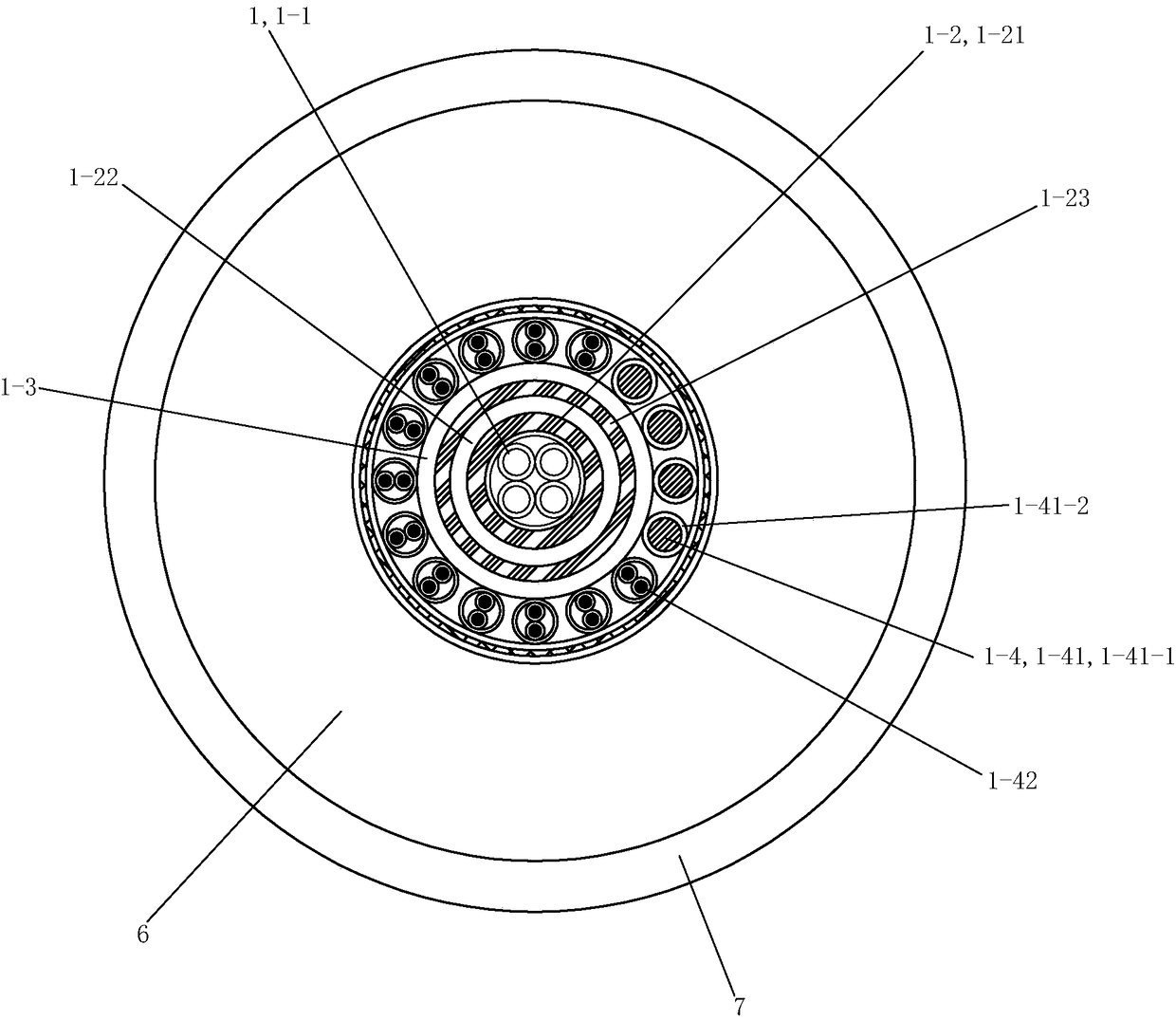

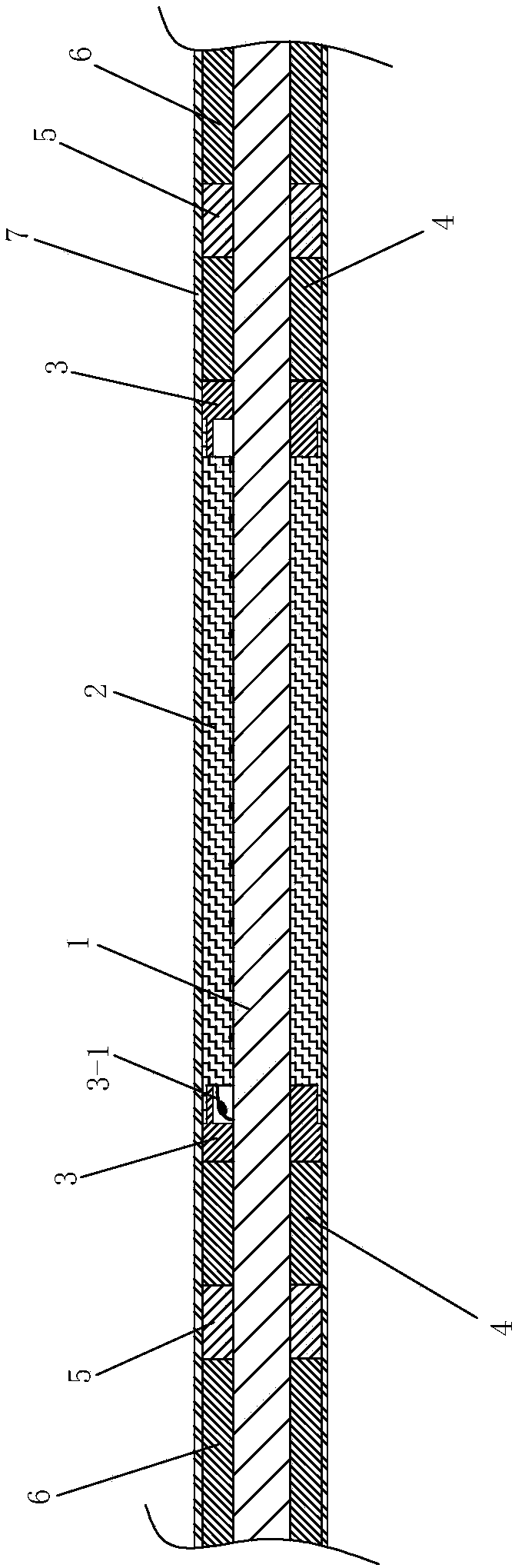

Solid towline with good dragging performance for marine seismic exploration

InactiveCN108447591AMaintain pressure resistanceWith impact resistanceNon-insulated conductorsFloating cablesYarnRubber material

The invention discloses a solid towline with good dragging performance for marine seismic exploration. The solid towline is characterized in that the solid towline comprises a main cable, hydrophones,buoyancy sleeves and an outer sheath. The hydrophones are fixedly arranged on the main cable with an equal interval. The hydrophones are electrically connected to corresponding wire cores in the maincable. Each of the buoyancy sleeves is made of a foamed polyethylene material, and foamed polyethylene is extruded on the main cable. The main cable includes the transmission wire cores, a tensile fiber layer and a conductive wire layer. The tensile fiber layer is formed by weaving aramid yarn and / or polyester yarn outside the transmission wire cores. The conductive wire layer includes a set of power lines and a set of signal lines. The power lines and the signal lines are orderly arranged with an equal interval along the circumferential direction of the main cable outside the tensile fiber layer to form the corresponding wire layer. The buoyancy sleeves are fixedly arranged on the main cable with an equal interval, and each of the buoyancy sleeves is between two adjacent hydrophones. Theouter sheath is made of a thermoplastic polyurethane elastomer rubber material and is extruded outside the hydrophones, positioning ends and the buoyancy sleeves, and the outer sheath is seamlessly bonded to the hydrophones.

Owner:CHANGZHOU MARINE CABLE

Recycled ethylene propylene diene monomer/reclaimed isobutylene-isoprene rubber (REPDM/RIIR) elastomer and preparation method thereof

The invention discloses a recycled ethylene propylene diene monomer / reclaimed isobutylene-isoprene rubber (REPDM / RIIR) elastomer and a preparation method thereof, and relates to an elastomer material and the preparation method thereof. The waterproof material is prepared from the following components in parts by mass: 100 parts of combined REPDM and RIIR, 1-2 parts of brimstone, 0.9-2 parts of accelerant, 2.5-8 parts of vulcanizing activator, and 0-20 parts of carbon black. The material has good process compatibility by combination of the EPDM and the IIR; better combination property can be obtained. Blend rubber can be vulcanized by the brimstone, peroxide, esters and resin; the vulcanization rates of the brimstone, the peroxide, the esters and the resin are approximate; a co-vulcanization material is easily formed. According to the REPDM / RIIR elastomer, the EPDM and the IIR are completely replaced by the REPDM and the RIIR; the cost of the waterproof material is reduced by matching with a fortifier and a vulcanizing agent; the waterproof material is easily formed; the adhesiveness between the waterproof material and a matrix is improved. An experiment research proves that the REPDM / RIIR waterproof material with excellent ozone resistance, weather fastness, low temperature resistance, resistance to chemical mediator and hot air aging resistance is prepared.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

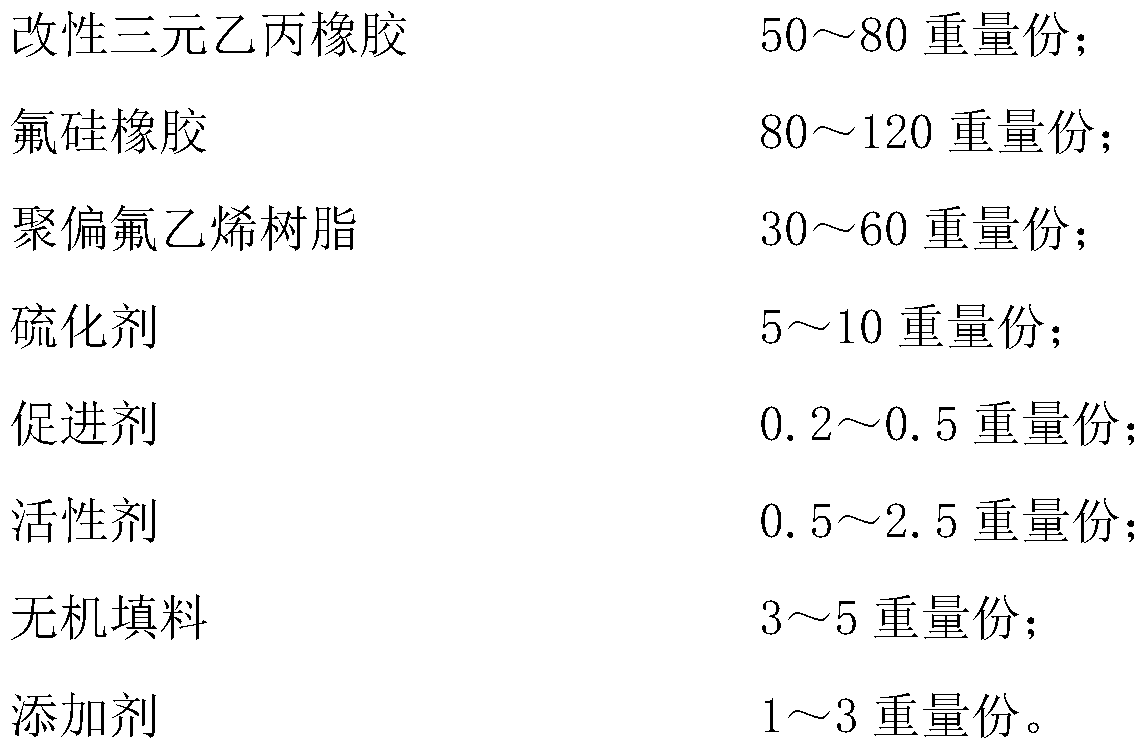

Heat-resistant, ozone-resistant and pressure-change-resistant rubber sealing member and preparation method thereof

The invention discloses a heat-resistant, ozone-resistant and pressure-change-resistant rubber sealing member, which comprises the following raw materials by weight: 50-80 parts of modified ethylene propylene diene monomer, 80-120 parts of a fluorosilicone rubber, 30-60 parts of a polyvinylidene fluoride resin, 5-10 parts of a vulcanizing agent, 0.2-0.5 part of an accelerant, 0.5-2.5 parts of an active agent, 3-5 parts of an inorganic filler, and 1-3 parts of an additive. According to the invention, the heat-resistant, ozone-resistant and pressure-change-resistant rubber sealing member has advantages of good heat resistance, good ozone resistance, small permanent compression deformation and good machinability, and can satisfy the use occasions under severe conditions. The invention furtherdiscloses a preparation method of the heat-resistant, ozone-resistant and pressure-change-resistant rubber sealing member, wherein the vulcanization speed is high in the preparation process, the scorching time is long, and the production process is safe.

Owner:宁波泰意德过滤技术有限公司

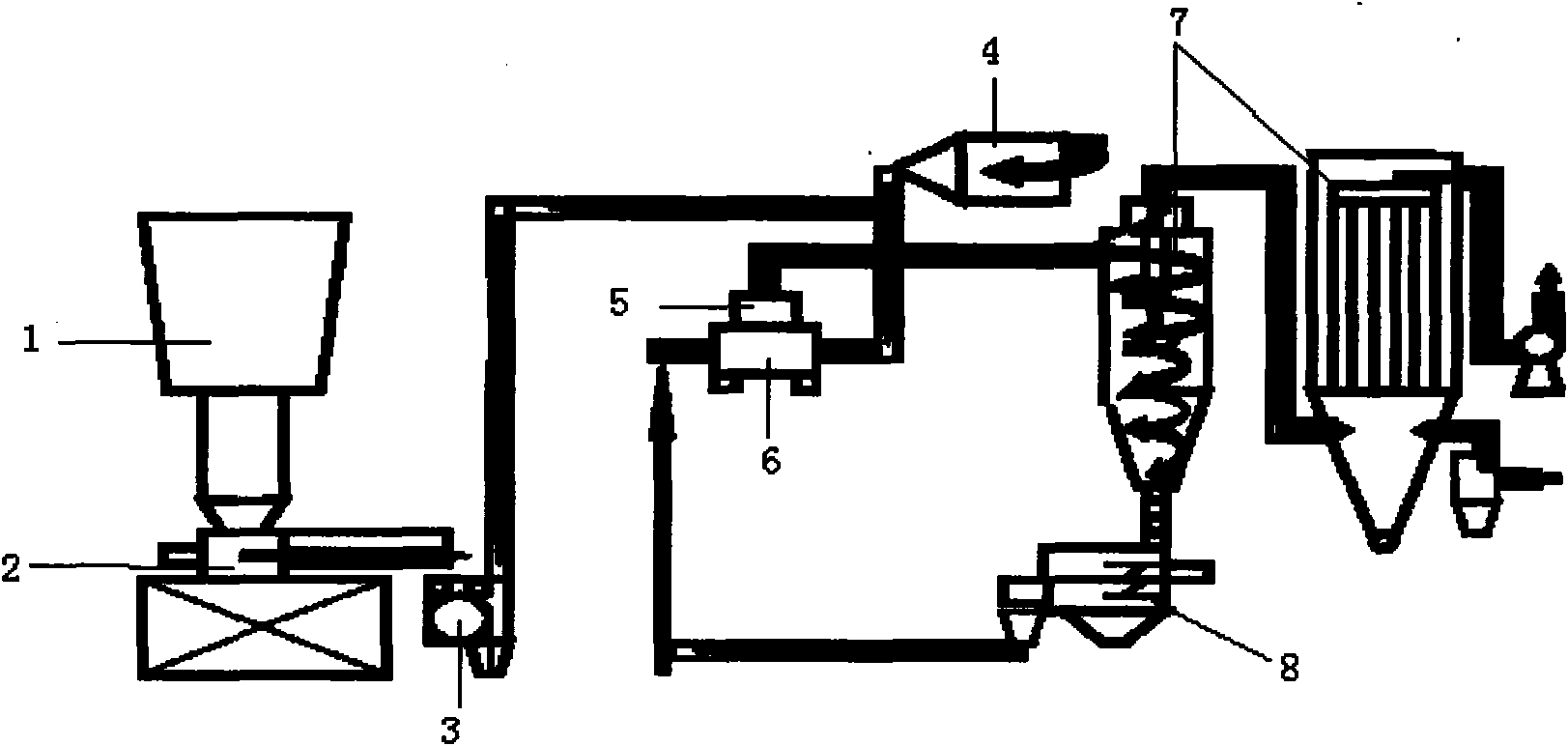

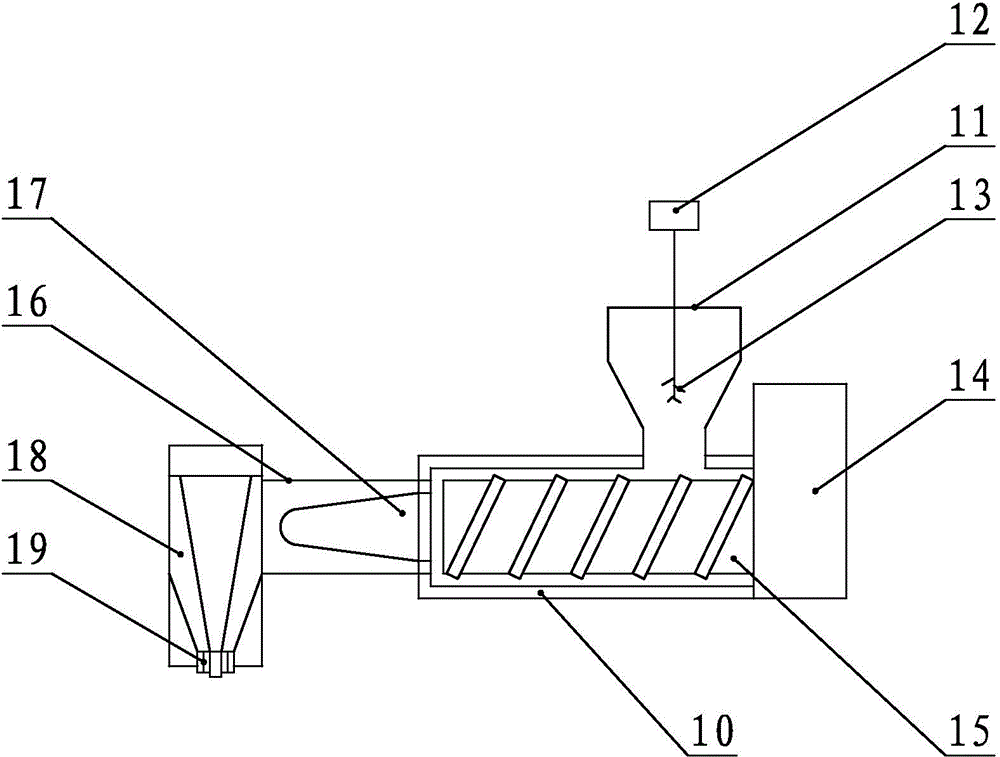

Domestic gas hose, processing process thereof and special-purposed production device thereof

The invention discloses a domestic gas hose composed of the following components, by weight: 35-45 parts of NBR, 50-65 parts of PVC, 0.3-0.8 parts of a crosslinking agent, 3-8 parts of a stabilizer, 20-40 parts of a plasticizer, and 30-50 parts of a reinforcing filler. According to the invention, NBR is subjected to mixing, pre-crosslinking and pulverizing, and is mixed with kneaded and plasticized PVC; and the mixture is preheated and is subjected to extrusion molding. The hose has the characteristics of good strength, good oil resistance, good elasticity and good low-temperature resistance of NBR, as well as the characteristics of good ozone resistance, good weather resistance, good flame retarding property and good tear resistance of PVC. The product has higher density, better performances such as strength and air tightness, and excellent comprehensive performances. The hose is especially suitable to be used in oil-resistant product exposed to air.

Owner:SUZHOU XINDISI GAS SEALING MATERIAL

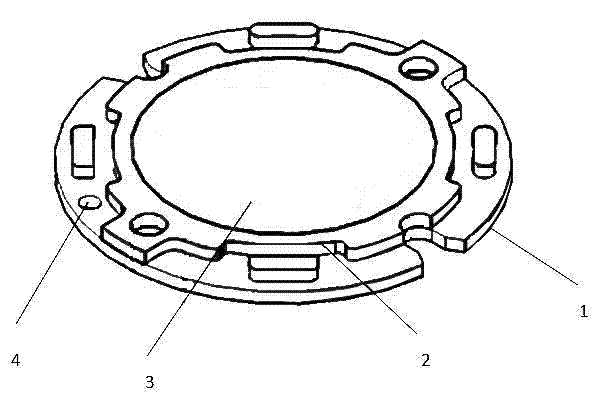

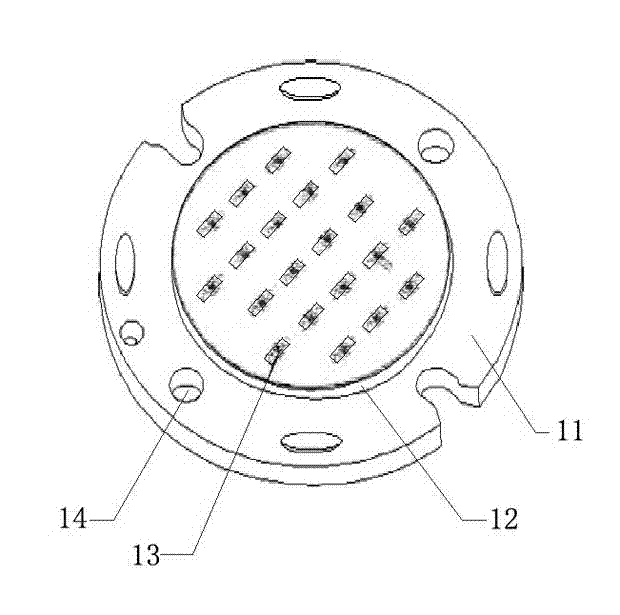

Novel LED (light emitting diode) integrated light source module and preparation method thereof

InactiveCN102738372AControl Volume and Thickness UniformityControl the light effectSemiconductor devicesEngineeringLight-emitting diode

The invention discloses a novel LED integrated light source module. The novel LED integrated light source module comprises a substrate body, and LED chips arranged on the substrate body, wherein rubber barrier walls are arranged on the substrate body to enclose an LED chip fixing region on the substrate body to at least one closed region; the LED chips are arranged in the closed region; the rubber barrier walls can stop a phosphor powder glue mixed layer in the LED chip region from flowing out of the light emitting region due to fluid dynamics and can also improve the light emitting efficiency and light uniformity of the LED chip. The invention also discloses a processing method of the above LED integrated light source module.

Owner:FOSHAN EVERCORE OPTOELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com