Preparation method of anti-aging silicone material for LED packaging

A LED packaging and anti-aging technology, applied in adhesives, adhesive additives, electrical components, etc., can solve the problems of poor aging resistance, low refractive index, poor formability, etc., and achieve high elasticity, good flexibility, and tear resistance The effect of increasing the crack strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

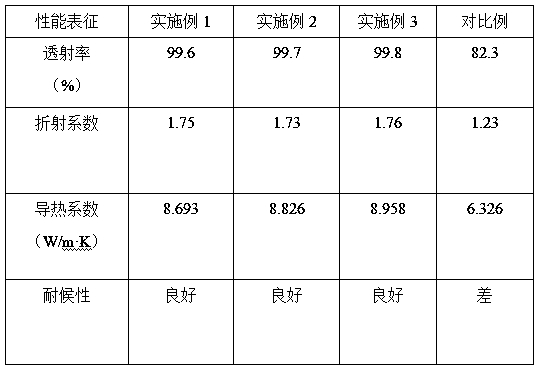

Examples

Embodiment Construction

[0032] In parts by weight, weigh 40-50 parts of silicone rubber, 20-30 parts of polyurethane, 5-15 parts of white carbon black, 1-3 parts of hexamethyldisilazane, 1-3 parts of diphenylsilane Glycol, 1-3 parts of bis-pentasulfurizing agent, mix white carbon black and hexamethyldisilazane in a mixer, and knead for 10-20 minutes at a stirring speed of 200-300r / min, that is To obtain a kneaded product, place the kneaded product in an oven at a temperature of 80-90°C and dry for 1-2 hours to obtain a dry kneaded product. Add diphenylsilanediol, silicone rubber and polyurethane to the dried kneaded product. Blend at a speed of 400-500r / min for 1-2 hours to obtain the blended rubber. Add bis-dipentasulfurizing agent to the blended rubber, thin it out and take out the sheet to obtain a sample. Put the sample in a flat vulcanizing machine In the process, vulcanize at a pressure of 15-20MPa and a temperature of 170-180°C for 5-10 minutes, take it out and dry it in an oven at a temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com