Halogen-free flame retardant insulation material for photovoltaic cable

A photovoltaic cable and insulating material technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of short service life, poor heat aging resistance, tensile strength, poor mechanical properties of elongation at break, etc. Achieve the effects of improving weather resistance, aging resistance and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The preparation method of the halogen-free flame-retardant insulating material for photovoltaic cables is as follows: select the components by weight as shown in Example 1 in Table 1 as components, put them into a mixer and mix them thoroughly for 10 minutes, then put them into a double-stage twin-screw extruder The granulator (Nanjing Chengmeng CM-80 / 150 type) is extruded and granulated to make the halogen-free flame-retardant insulating material for photovoltaic cables.

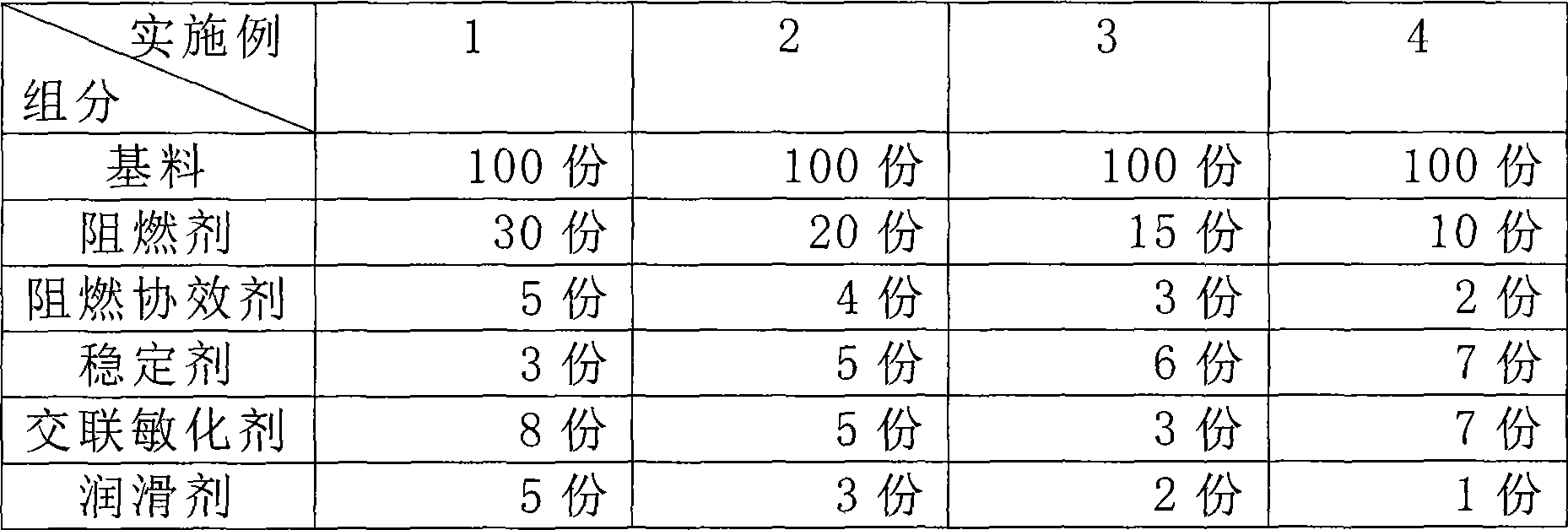

[0036] Table 1: Components (parts by weight) of the halogen-free flame-retardant insulating material for this photovoltaic cable

[0037]

[0038] Wherein the base material described in embodiment 1 is made up of the composition of following parts by weight; Described base material is made up of the composition of following parts by weight; High-density polyethylene: 85 parts; Ethylene-methyl methacrylate copolymer: 15 parts parts; the flame retardant is composed of the following parts by weight; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com