Heat-resistant, ozone-resistant and pressure-change-resistant rubber sealing member and preparation method thereof

A rubber seal, ozone-resistant technology, applied in the field of seals, can solve the problems of low permanent compression deformation resistance, failure to meet the use requirements, poor ozone resistance, etc., to improve comprehensive physical properties, improve scorch time, vulcanization high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

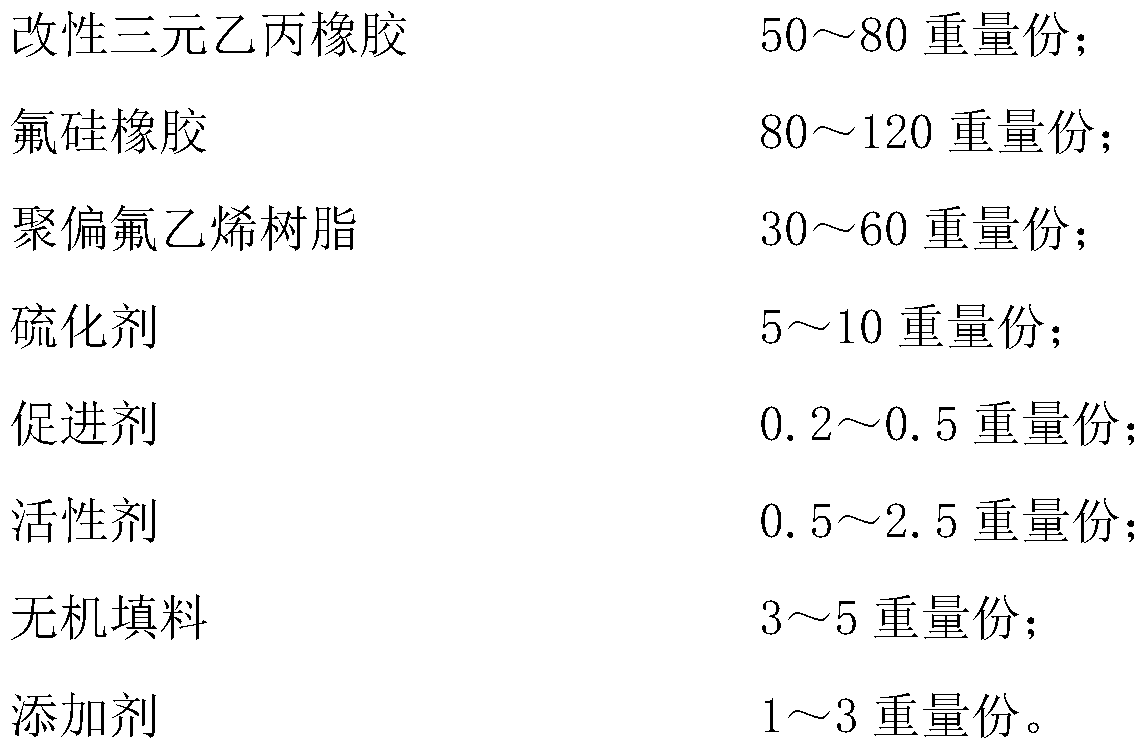

[0043] A heat-resistant, ozone-resistant and pressure-resistant rubber seal, the rubber seal is composed of the following raw materials in parts by weight:

[0044] 60 parts by weight of modified EPDM rubber;

[0045] 100 parts by weight of fluorosilicone rubber;

[0046] 45 parts by weight of polyvinylidene fluoride resin;

[0047] 7 parts by weight of vulcanizing agent;

[0048] Accelerator 0.4 parts by weight;

[0049] Active agent 1.5 parts by weight;

[0050] 4 parts by weight of inorganic filler;

[0051] Additive 2 parts by weight.

[0052] The Mooney viscosity range of the EPDM rubber is 40.

[0053] The modified EPDM rubber is cage-type silsesquioxane modified EPDM rubber.

[0054] The cage silsesquioxane is octavinyl cage silsesquioxane.

[0055] The vulcanizing agent is composed of platinum vulcanizing agent, N,N'-m-phenylene bismaleimide and bis(trimethylsilyl) peroxide with a mass ratio of 1:0.6:1.5.

[0056] The accelerator is composed of tetramethylthiura...

Embodiment 2

[0066] A heat-resistant, ozone-resistant and pressure-resistant rubber seal, the rubber seal is composed of the following raw materials in parts by weight:

[0067] Modified EPDM rubber 50 parts by weight;

[0068] Fluorosilicone rubber 80 parts by weight;

[0069] 30 parts by weight of polyvinylidene fluoride resin;

[0070] 5 parts by weight of vulcanizing agent;

[0071] Accelerator 0.2 parts by weight;

[0072] Active agent 0.5 parts by weight;

[0073] 3 parts by weight of inorganic filler;

[0074] Additive 1 part by weight.

[0075] The Mooney viscosity range of the EPDM rubber is 35.

[0076] The modified EPDM rubber is cage-type silsesquioxane modified EPDM rubber.

[0077] The cage silsesquioxane is octavinyl cage silsesquioxane.

[0078] The vulcanizing agent is composed of platinum vulcanizing agent, N,N'-m-phenylene bismaleimide and bis(trimethylsilyl) peroxide in a mass ratio of 1:0.5:1.

[0079] The accelerator is composed of tetramethylthiuram disulfid...

Embodiment 3

[0089] A heat-resistant, ozone-resistant and pressure-resistant rubber seal, the rubber seal is composed of the following raw materials in parts by weight:

[0090] Modified EPDM rubber 80 parts by weight;

[0091] Fluorosilicone rubber 120 parts by weight;

[0092] 60 parts by weight of polyvinylidene fluoride resin;

[0093] 10 parts by weight of vulcanizing agent;

[0094] Accelerator 0.5 parts by weight;

[0095] Activator 2.5 parts by weight;

[0096] 5 parts by weight of inorganic filler;

[0097] Additive 3 parts by weight.

[0098] The Mooney viscosity range of the EPDM rubber is 45.

[0099] The modified EPDM rubber is cage-type silsesquioxane modified EPDM rubber.

[0100] The cage silsesquioxane is octavinyl cage silsesquioxane.

[0101] The vulcanizing agent is composed of platinum vulcanizing agent, N, N'-m-phenylene bismaleimide and bis(trimethylsilyl) peroxide with a mass ratio of 1:0.8:2.

[0102] The accelerator is composed of tetramethylthiuram disul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com