Patents

Literature

52results about How to "Increase the degree of vulcanization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of hydro-treatment catalyst

ActiveCN103769125AModerate decrease in viscosityImprove permeabilityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsPtru catalystUltrasonic cavitation

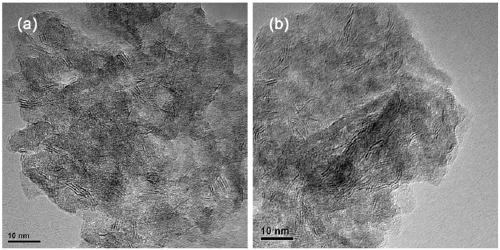

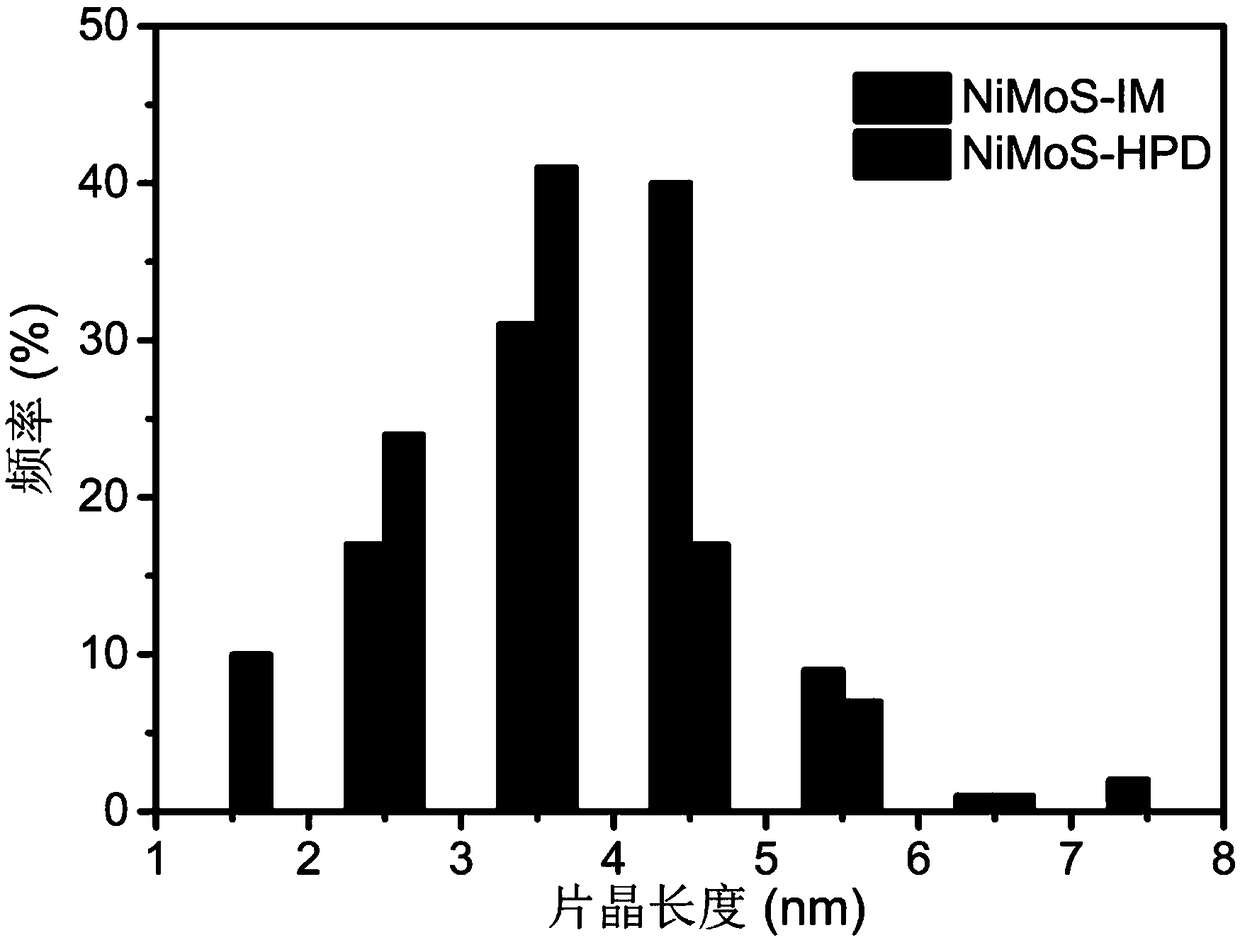

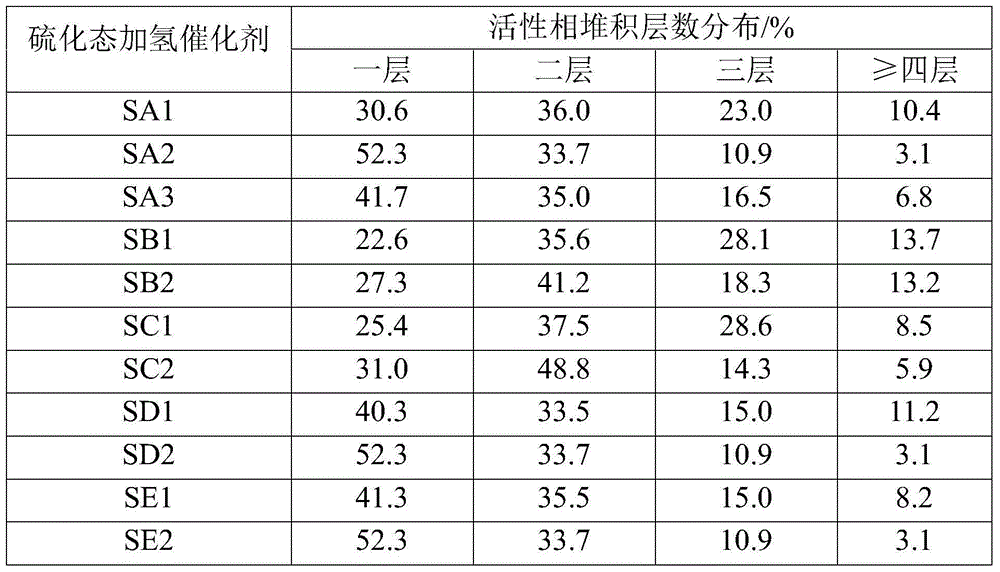

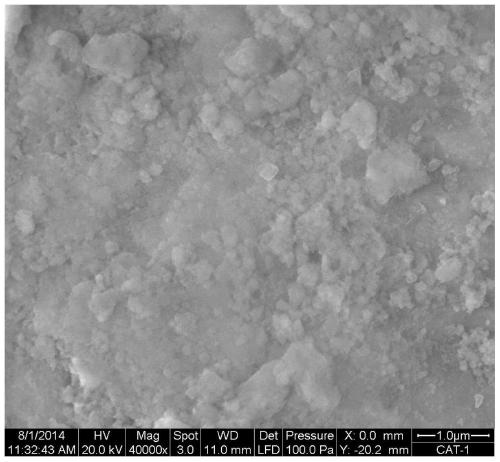

The invention discloses a preparation method of a hydro-treatment catalyst. The preparation method comprises the following steps: preparing an alumina carrier, preparing an impregnation solution containing the VIII group metal and VIB group metal, wherein the impregnation solution comprises a proper amount of an organic auxiliary agent containing chelating ligand, then impregnating the alumina carrier into the impregnation solution under a proper ultrasonic treatment condition, and drying so as to obtain the hydro-treatment catalyst. The preparation method utilizes the ultrasonic cavitation effect to properly reduce the viscosity of the impregnation solution; at the same time the complexing capacity between the chelating ligand in the organic auxiliary agent and nickel / cobalt is improved by the catalytic function of the ultrasonic, the interaction force between the chelating ligand and nickel / cobalt is strengthened, thus the active metal component is promoted to highly disperse on the carrier surface, furthermore, the existing state of the active metal on the catalyst surface is improved at the same time, the sulfurization degree and sulfurization uniformity of the active metal are both improved, so the activity and stability of the catalyst are both improved. The catalyst is especially suitable for being used in the hydro-denitrogenation process and hydro-desulfurization process of heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

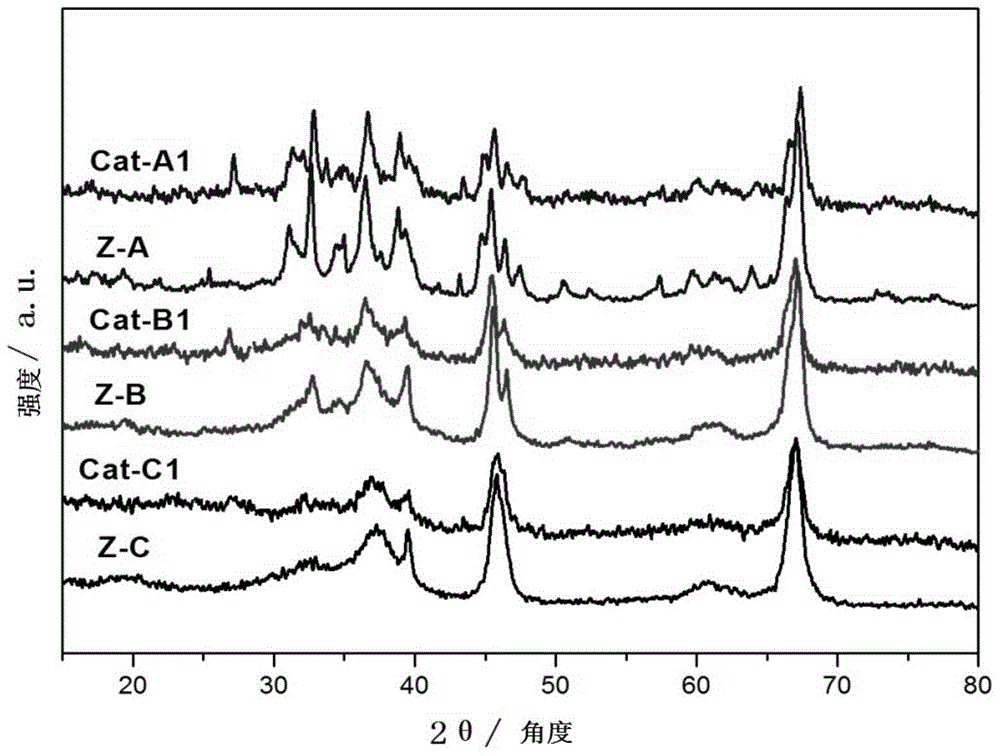

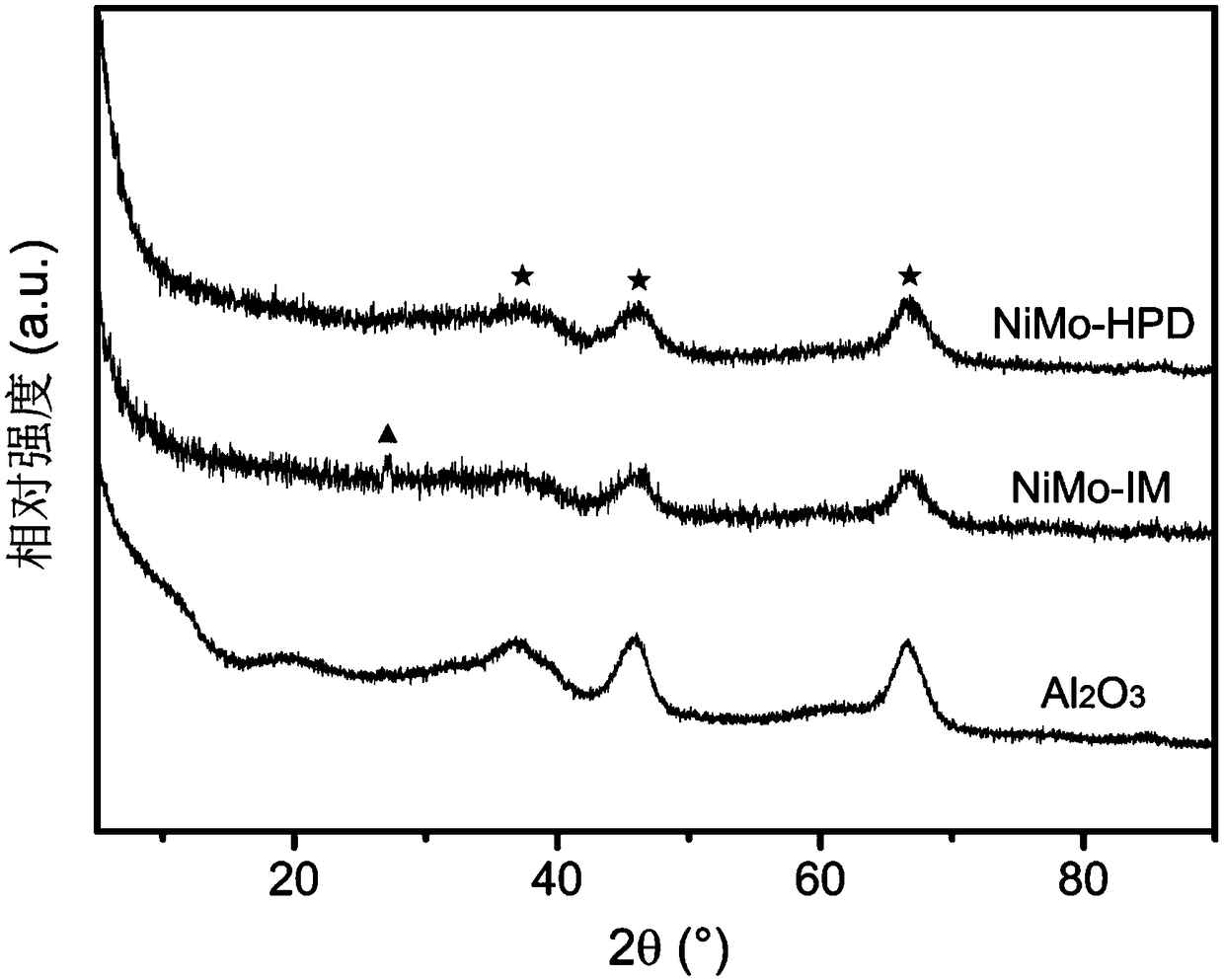

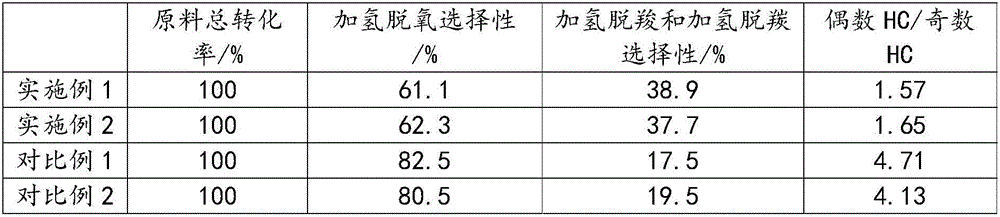

Aluminum oxide based hydrorefining catalyst as well as preparation method and application thereof

ActiveCN104941654AGood dispersionImprove performanceMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsComponent LoadSulfur

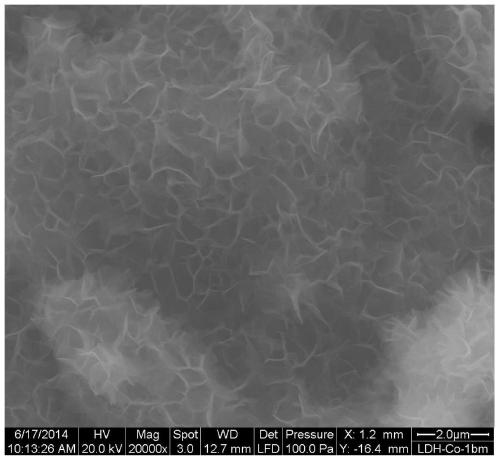

The invention provides an aluminum oxide based hydrorefining catalyst as well as a preparation method and application thereof. The method comprises the following steps: 1, immersing active metal components into an aluminum oxide carrier, and drying and roasting to obtain an active metal component loaded catalyst; and 2, introducing an organic complexing agent into the active metal component loaded catalyst and drying to obtain the aluminum oxide based hydrorefining catalyst, wherein the aluminum oxide carrier comprises delta-Al2O3 or theta-Al2O3. The aluminum oxide based hydrorefining catalyst provided by the invention can be used for FCC diesel oil so that the yield of the FCC diesel oil is higher than 99%, the content of sulfur is lower than 10ppm, and China 5 standard requirements are met.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

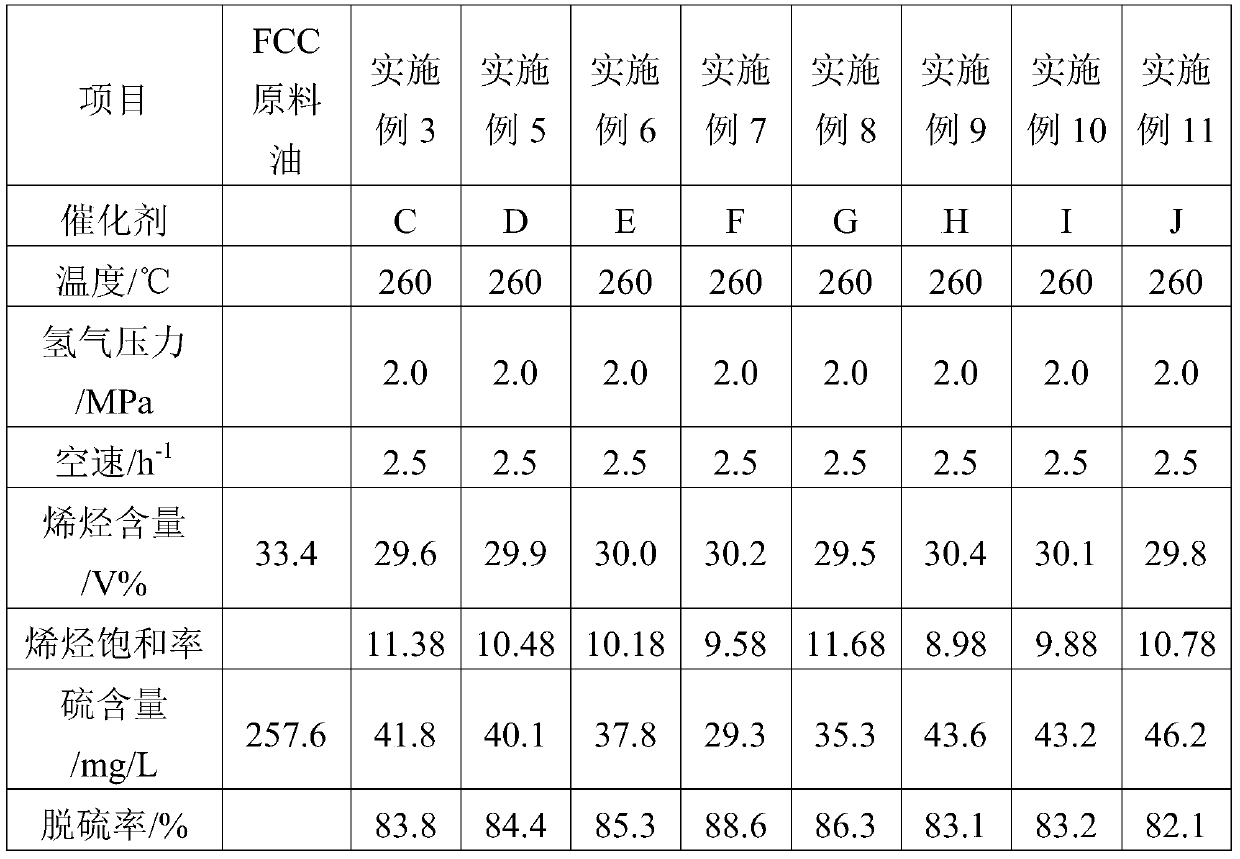

On-site external vulcanization processing method of hydrogenation catalysts

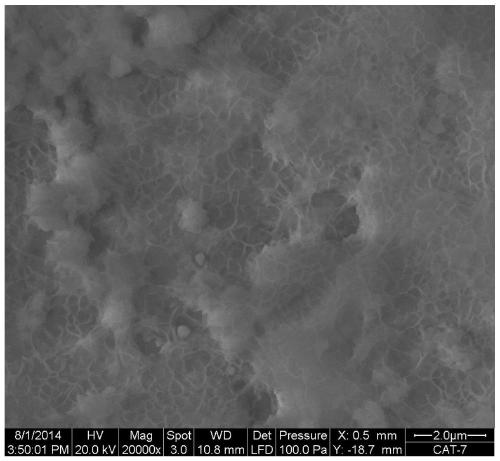

InactiveCN104841493AHigh desulfurization rateReduce saturationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsVulcanizationPolymer science

The invention discloses an on-site external vulcanization processing method of hydrogenation catalysts. According to the processing method, at least one kind of sulfur compounds are added into the hydrogenation catalysts in atmosphere of inert gas; on-site external vulcanization processing is carried out at the normal pressure; the vulcanization temperature is 200 to 500 DEG C; the vulcanization time is 0.5 to 48 hours. Compared with in-device pre-vulcanized catalysts prepared by a conventional method, the vulcanization hydrogenation catalysts prepared and pre-vulcanized by the method have the advantages that the desulfurization rate of the vulcanization hydrogenation catalysts prepared by the method of the invention is high, and the activity is good. The on-site external vulcanization processing method of the catalysts is suitable for being used in the preparing process of various kinds of distillate oil hydrogenation catalysts.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

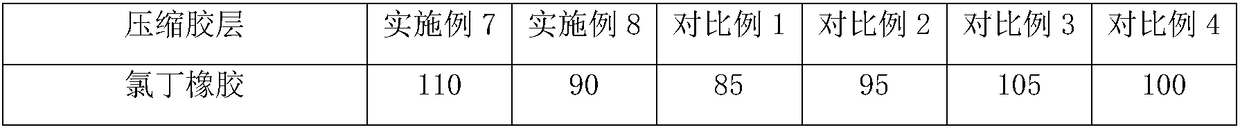

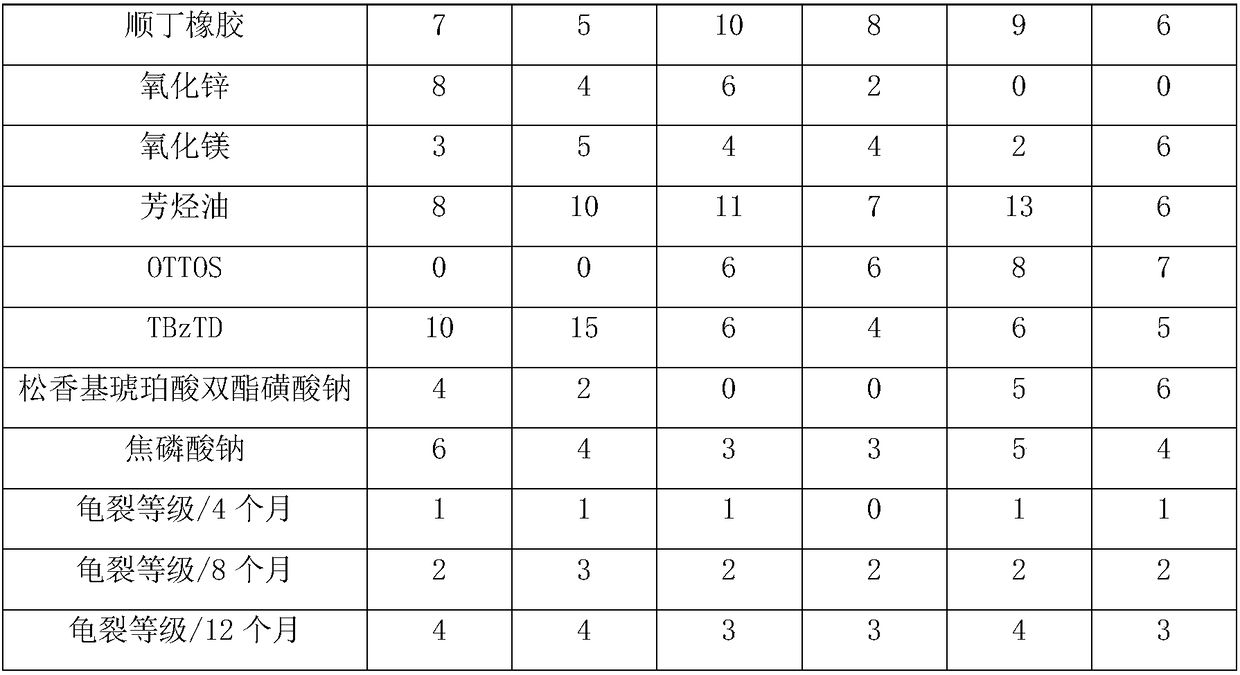

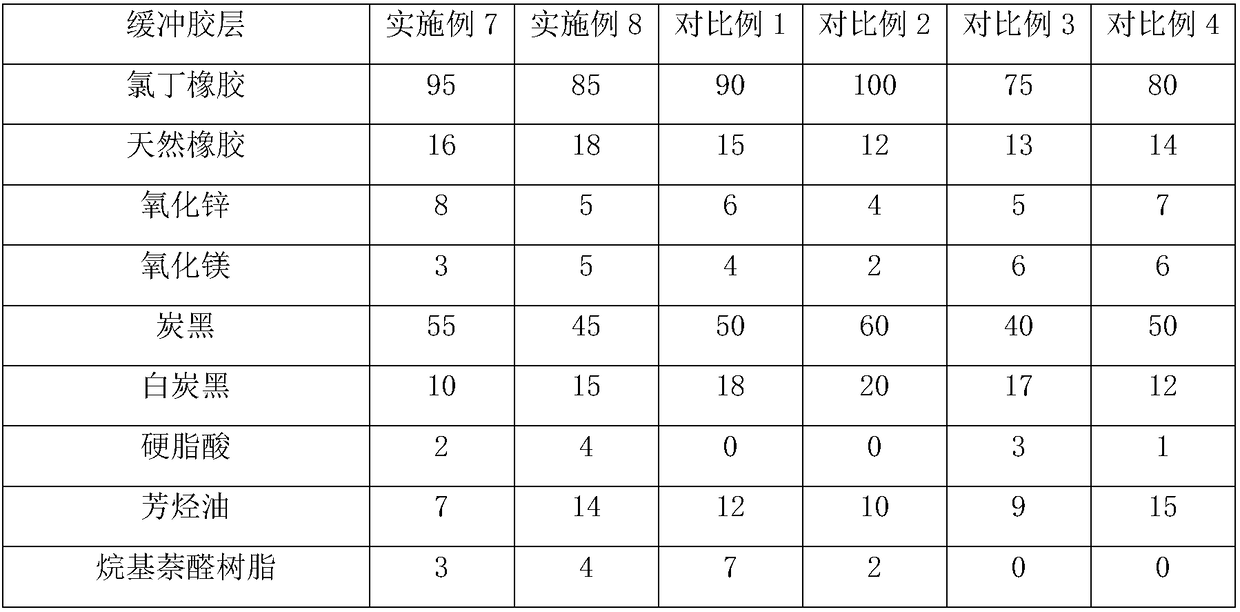

Triangle belt with high tensile strength and high weather resistance and preparation method thereof

The invention discloses a triangle belt with high tensile strength and high weather resistance and a preparation method thereof. The triangle belt comprises a strength layer, a buffer rubber layer, acompressed rubber layer and a coating cloth layer. Raw materials of the compressed rubber layer comprise the following components of chloroprene rubber, cis-polybutadiene rubber, zinc oxide, filler, aromatic oil, a vulcanizing agent and rosin-based sodium sulfosuccinate diester. The rosin-based sodium sulfosuccinate diester has dispersion and emulsification effects and can improve the compatibility and mixing uniformity of the vulcanizing agent, the chloroprene rubber and the cis-polybutadiene rubber , the vulcanizing effect of the vulcanizing agent is improved, and the weather resistance andthe tensile strength of the compressed rubber layer are improved. The zinc oxide has the property of a reinforcing agent and enables the compressed rubber layer to have good tear resistance and elasticity. The zinc oxide has the property of a vulkacit and enhances the vulcanization activity of the compressed rubber layer. The emulsification effect of the rosin-based sodium sulfosuccinate diester can improve the acting force between the zinc oxide, the chloroprene rubber and the cis-polybutadiene rubber and improve the performance enhancement effect of the zinc oxide as the reinforcing agent and the vulkacit on the compressed rubber layer.

Owner:浙江金久胶带股份有限公司

Preparation method for vulcanization type hydrogenation catalyst

ActiveCN102836736AIncrease the degree of vulcanizationMolecular sieve catalystsHydrocarbon oil crackingNickel saltPtru catalyst

The present invention discloses a preparation method for a vulcanization type hydrogenation catalyst. The preparation method comprises: uniformly mixing a carrier precursor, a thiomolybdate and / or thiotungstate, a nickel salt and / or a cobalt salt, adding a binder to carry out kneading, carrying out molding, and then carrying out drying and calcination in the protection of an inert gas to prepare the catalyst. The method of the present invention has characteristics of simple process and high vulcanization degree, wherein the prepared vulcanization type hydrogenation catalyst has high activity and high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

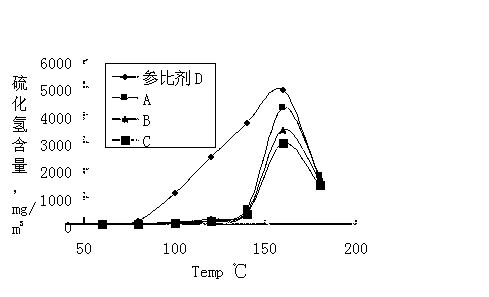

Vulcanization method for hydrogenation catalyst

InactiveCN101260319AEasy to manufactureReduce energy consumptionCatalyst activation/preparationRefining to eliminate hetero atomsCarbon disulfideKerosene

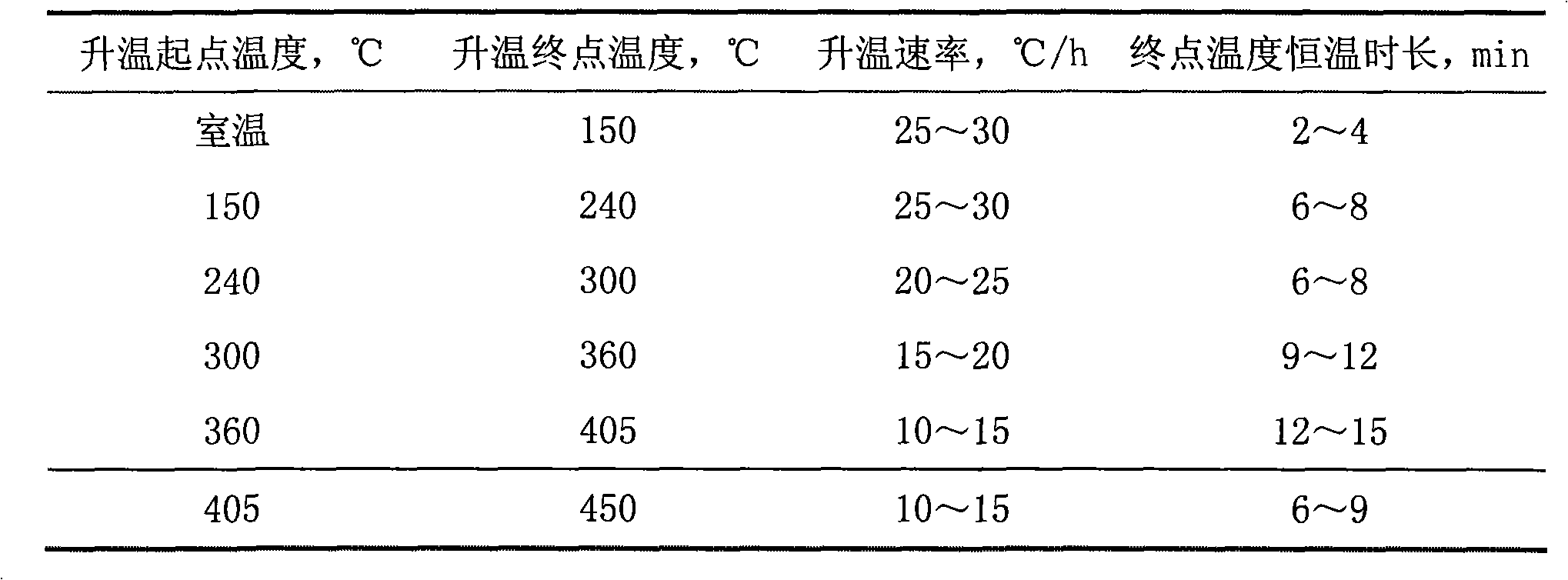

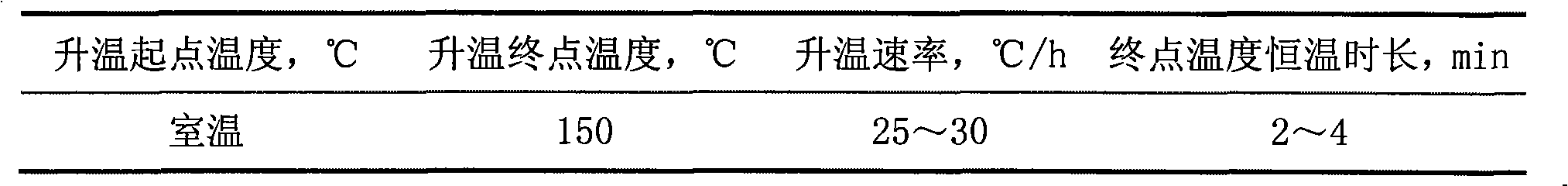

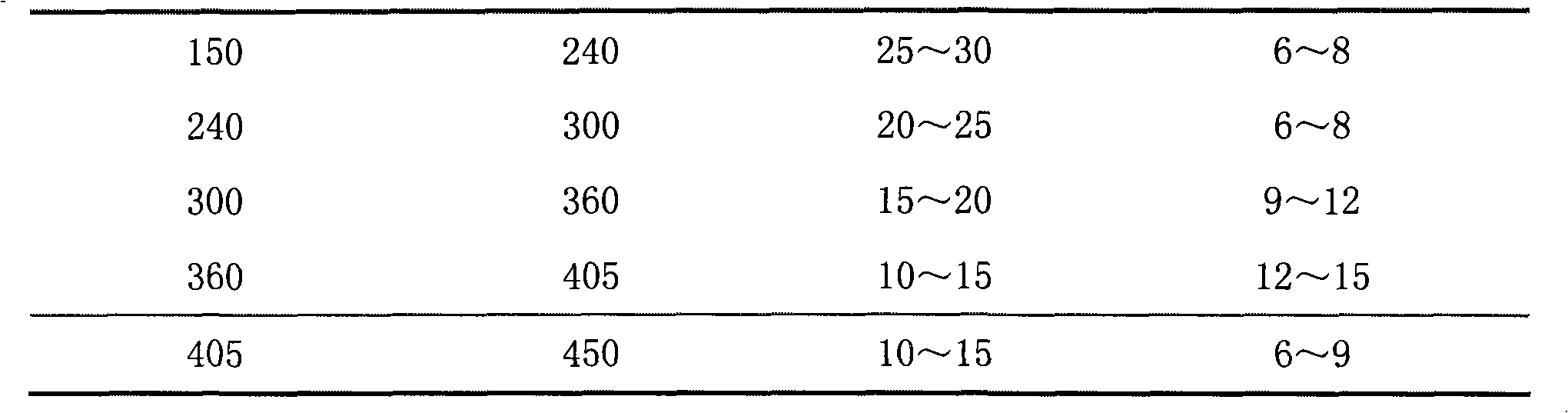

The invention relates to a sulfuration method for a hydrogenation catalyst, comprising the following steps of: after only drying the catalyst which hangs and carries an active component to remove free water in the catalyst, sulfurizing directly in a hydrogenation reactor, that is, straight-distilling naphtha or kerosene, adding carbon bisulfide which occupies 2 percent of the mass of the catalyst to prepare sufurized oil; after mixing the sufurized oil with the hydrogen, entering to a hydrogenation reactor while rising the temperature by a heat exchanger, keeping the temperature of the hydrogenation reactor at the decomposition and sulfuration temperature of the catalyst, controlling strictly the rate of temperature rise and preventing the catalyst bed layer from overheating, wherein the decomposition and sulfuration temperature zone of the catalyst is kept between 150 and 450 DEG C, and the rate of temperature rise is kept between 10 and 30 DEG C / h; after the ending of the decomposition and sulfuration of the catalyst, the system program lowers the temperature so as to control the rate of the temperature fall to be between 25h and 45 DEG C / h, when the temperature is lowered to be the normal reaction temperature of the catalyst, the sufurized oil is shifted into raw material oil which requires the hydrofinishing treatment, thereby beginning the hydrogenation treatment, wherein the treated gasoline is controlled between 180 and 220 DEG C, and the treated diesel oil is controlled between 240 and 290 DEG C. The catalyst sufurized in the method carries out the hydrofinishing for oil products, which has excellent desulfurization effect and less impact upon octane value.

Owner:江苏佳誉信实业有限公司

Ultra-deep desulfurization catalyst, preparation method thereof and application of catalyst

ActiveCN109364957ATightly boundIncrease the level of retouchingCatalyst activation/preparationHydrocarbon oils treatmentWater bathsAcetic acid

The invention provides an ultra-deep desulfurization catalyst, a preparation method thereof and an application of the catalyst. The preparation method of the desulfurization catalyst includes the steps: weighing ammonium paramolybdate and nickel acetate tetrahydrate, dissolving the ammonium paramolybdate and the nickel acetate tetrahydrate in glacial acetic acid and water mixed solution in a stirring manner; adding hydrazine sulfate and dissolving the hydrazine sulfate in a stirring manner; performing stirring reaction in a thermostatic water bath to obtain polyoxometallate after reaction; dispersing the polyoxometallate in water and performing ultrasonic treatment; adding aluminum oxide, uniformly stirring the materials and performing hydro-thermal decentralization loading in an autoclaveto obtain the desulfurization catalyst after reaction. The prepared desulfurization catalyst is good in dispersing performance and high in activity, ultra-deep desulfurization can be achieved, and desulfurization rate reaches up to 93.8%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of vulcanization type catalyst

ActiveCN103100395ASimple production processReduce manufacturing costPhysical/chemical process catalystsRefining to eliminate hetero atomsInorganic saltsVulcanization

The invention discloses a preparation method of a vulcanization type catalyst. The method comprises: adopting a dipping solution containing a sulfide precursor of active metal Mo or W and an inorganic salt of Ni or Co to dip a needed catalyst carrier, and then conducting after-treatment under certain vacuum degree and temperature, thus obtaining the vulcanization type catalyst. The method can control vulcanization of the catalyst under an appropriate temperature in a startup activation process, thus avoiding untimely vulcanization of the active metal, release of a hydrogen sulfide gas and the consequent influence on equipment air tightness. Meanwhile, in the after-treatment process, redundant water in catalyst pores are removed to prevent excess water in recycle hydrogen from influencing the catalyst activity during activation and corroding equipment. The catalyst prepared by the method provided in the invention is applicable to preparation of a petroleum fraction hydrogenation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

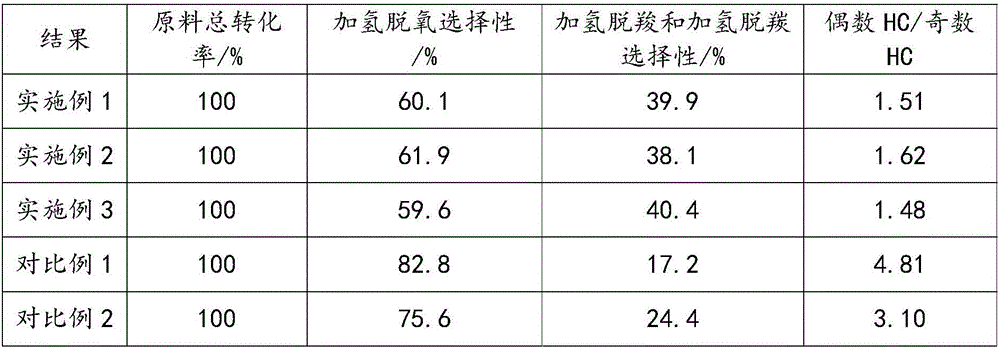

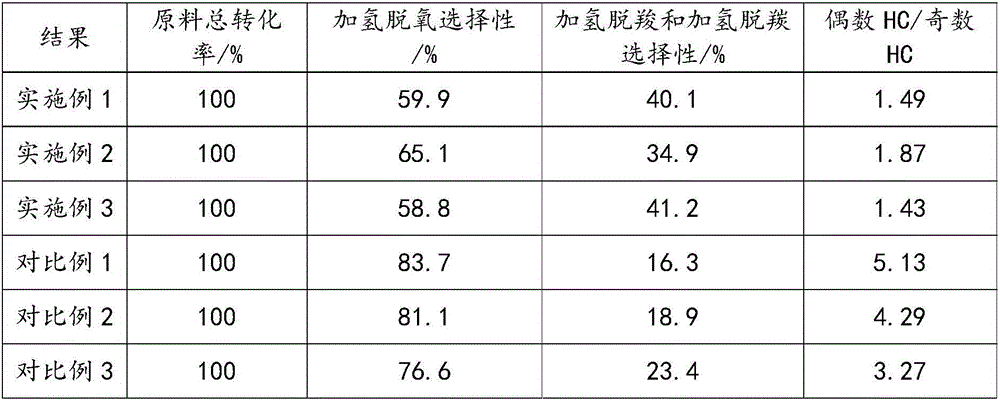

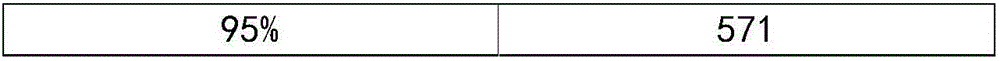

Hydrodeoxygenation method of bio-oil as well as catalyst and preparation method used thereby

ActiveCN105903475AIncrease acidityGood dispersionHeterogenous catalyst chemical elementsCatalyst activation/preparationSulfurActive component

The invention provides a hydrodeoxygenation method of bio-oil as well as a catalyst and a preparation method used thereby. The preparation method comprises: contacting a catalyst carrier dipped with active components with an oxygen-containing organic matter during the process of roasting the catalyst carrier dipped with the active components, completing the roasting to obtain an oxidized catalyst; vulcanizing the oxidized catalyst to obtain the product, wherein the active components comprise at least one or more of VIB group metals, one or more of VIII group metals, and one or more of VB group metals. By preprocessing the catalyst with the oxygen-containing organic matter, the selectivity of hydrogenated decarboxylation and decarbonylation reaction is increased; the sulfur fixation performance and thermal stability of the catalyst are improved.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

Preparation method of roasting-free pre-vulcanized hydrogenation catalyst

InactiveCN107349934AImprove hydrogenation activityGood dispersionHeterogenous catalyst chemical elementsCatalyst activation/preparationDispersityVulcanization

The invention discloses a preparation method of a roasting-free pre-vulcanized hydrogenation catalyst. The method comprises the steps that the environment-friendly dipping technology is adopted for preparing the hydrogenation catalyst, after the dipped catalyst is treated under the temperature of 180-250 DEG C, an organic solvent, elemental sulfur and auxiliaries are added to be mixed to be uniform, and thermal treatment is performed to obtain the roasting-free pre-vulcanized hydrogenation catalyst. The method solves the problems that a conventional catalyst is low in activity, poor in dispersity, long in vulcanization on-stream time and high in operation cost, and meanwhile overcomes the defects that the vulcanized catalyst preparation process is complex and concentrated heat release is easy. The pre-vulcanized hydrogenation catalyst prepared through the method is high in strength, good in activity and short in preparation process flow and has the good application value.

Owner:湖北润驰环保科技有限公司

Vulcanized hydrogenation catalyst, preparation method therefor and application thereof

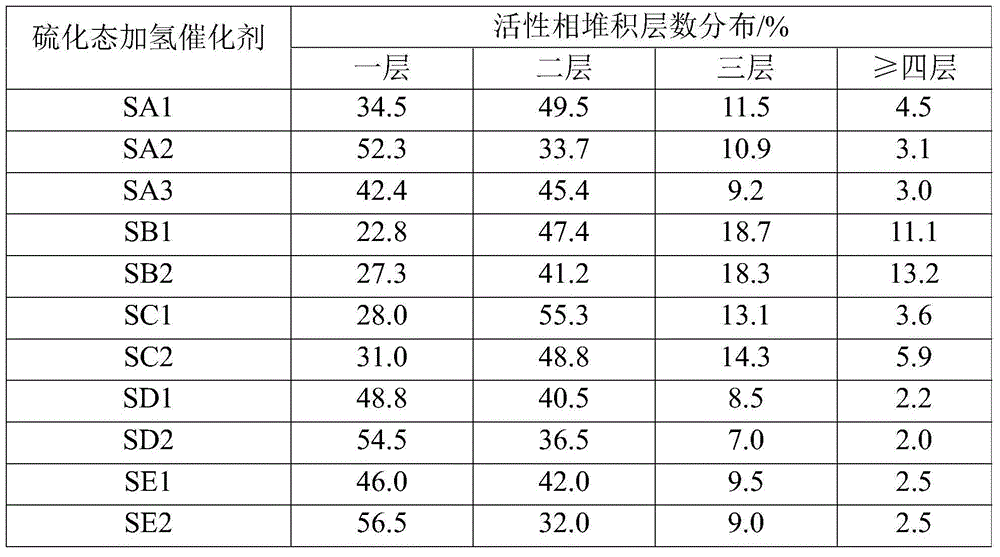

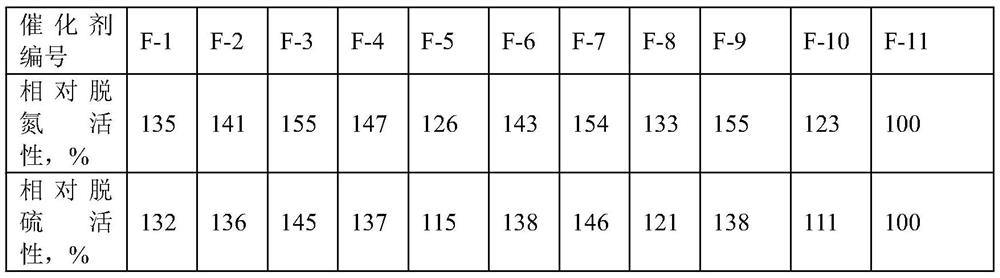

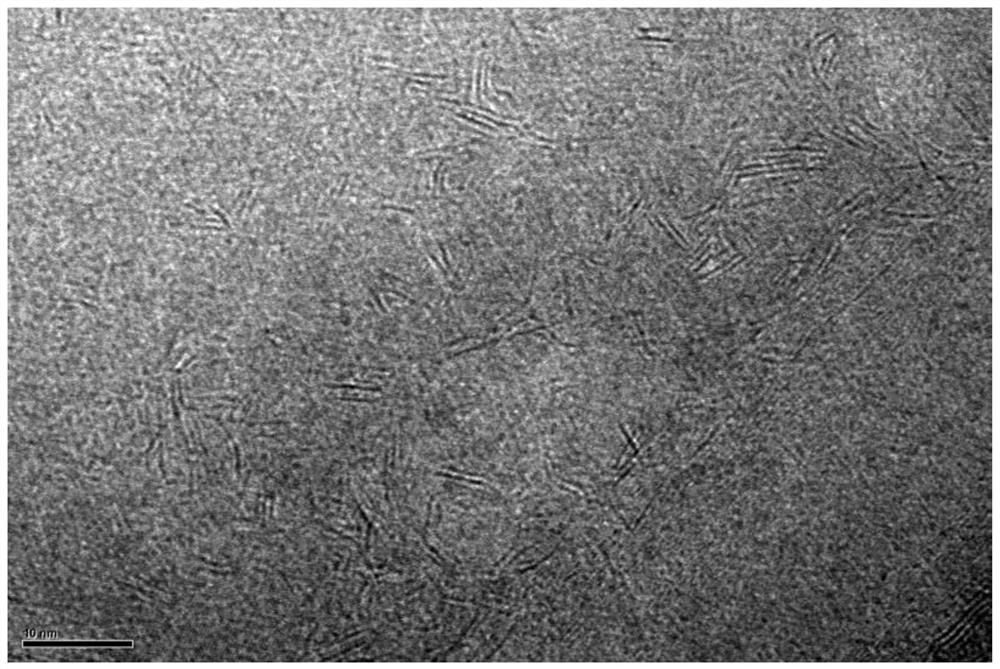

ActiveCN105080621AOvercome the defect of low degree of vulcanizationIncrease the degree of vulcanizationCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsAlcoholVulcanization

The invention provides a vulcanized hydrogenation catalyst, a preparation method therefor and application thereof. The preparation method for the vulcanized hydrogenation catalyst comprises the following steps: (1) preparing an oxidized hydrogenation catalyst, wherein the oxidized hydrogenation catalyst comprises a carrier, and a nitrogenous organic compound and an active metal oxide loaded on the carrier; the nitrogenous organic compound has at least one exothermic peak at 200-400 DEG C; and (2)in the presence of a curing media, successively increasing the temperature of the oxidized hydrogenation catalyst from a room temperature to the temperature corresponding to each exothermic peak of the organic alcohol compound at 200-400 DEG C at a rate of 1-20 DEG C / h; performing a constant temperature vulcanization for 1-5 hours; and finally increasing the temperature by 20-80 DEG C from the temperature corresponding to the highest temperature exothermic peak of a nitrogenous organic compound at 200-400 DEG C at the rate of 1-20 DEG C / h; and performing the constant temperature vulcanization for 1-5 hours. By adopting the preparation method provided by the invention, the degree of vulcanization of metals in the catalyst and the proportion of a two-layer-packed structure are improved, thus facilitating the improvement of the catalyst on hydrodesulfurization and hydrodearomatization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

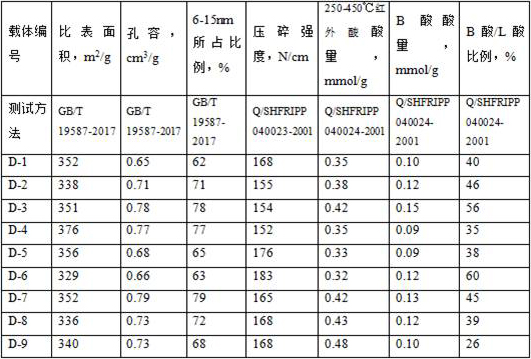

Modified alumina carrier and preparation method thereof

ActiveCN112619632AGood pore propertiesHigh strengthCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNaphthaHydrogenation reaction

The invention discloses a modified alumina carrier and a preparation method thereof. Based on the weight of the modified alumina carrier, the modifier A accounts for 2wt%-10wt% by element, the modifier B accounts for 3wt%-15wt% by oxide, and a group VIII metal sulfide accounts for 2wt%-10wt%; and the infrared acid amount at a temperature of 250-450DEG C is 0.18-0.55mmol / g. The preparation method comprises the following steps: (1) adding an aluminum source and a precipitant into a precursor aqueous solution containing a modifier A in parallel, carrying out precipitation reaction, carrying out hydrothermal treatment, and then performing filtering and drying to obtain modified pseudo-boehmite; (2) uniformly mixing the modified pseudo-boehmite with a peptizing agent and an extrusion aid, carrying out extrusion molding, and performing drying and roasting to obtain an alumina carrier; and (3) loading a VIII group metal onto the alumina carrier, and carrying out vulcanization treatment to obtain the modified alumina carrier. The modified alumina carrier has the characteristics of appropriate medium-strength acid amount, high B acid content, low L acid content, large pore size, centralized pore size and pore distribution and the like, and is suitable for the hydrogenation reaction process of aviation kerosene, diesel oil and coker naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrotreating catalyst, preparation method and applications thereof

InactiveCN110090654AImprove propertiesIncrease the degree of vulcanizationPhysical/chemical process catalystsHydrocarbon oils treatmentDispersityOrganic compound

The invention relates to the field of hydrotreating catalysts, and discloses a hydrotreating catalyst, a preparation method and applications thereof. The preparation method comprises: 1) impregnatingan alumina carrier with a sulfur-nitrogen-containing organic compound solution to obtain an impregnated product; 2) carrying out low-temperature drying treatment on the impregnated product obtained inthe step 1); and 3) impregnating the alumina carrier treated in the step 2) with an active component solution, and carrying out heat treatment, wherein the temperature of the low-temperature drying treatment is 15-180 DEG C, and the temperature of the heat treatment is 180-550 DEG C. According to the present invention, the catalyst prepared by the method has good matching between the dispersion degree and the sulfurization, and more active sites are generated, such that the intrinsic activity of the catalyst is easily improved; and the preparation method is simple, and the production cost islow.

Owner:CHINA PETROLEUM & CHEM CORP +1

Presulfurized sulfur-tolerant shift catalyst and preparation method

ActiveCN105233867BUniform vulcanizationIncrease the degree of vulcanizationOrganic-compounds/hydrides/coordination-complexes catalystsActive componentSulfidation

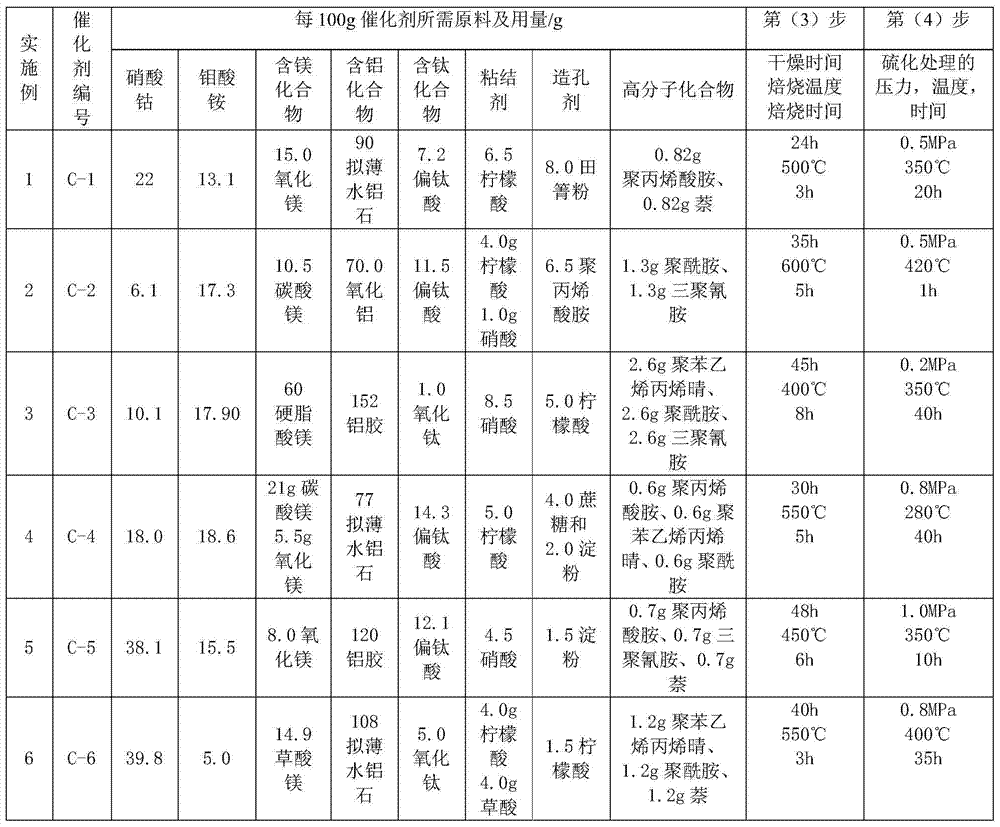

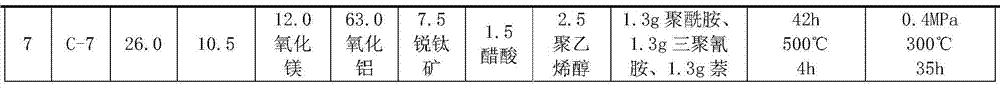

The invention relates to a presulfided sulfur-tolerant shift catalyst and a preparation method, belonging to the technical field of presulfurization treatment of sulfur-tolerant shift catalysts. The presulfided sulfur-tolerant shift catalyst prepared by using the method in the invention comprises an active component which is a binary component of a cobalt-contained compound and a molybdenum-contained compound, and carrier raw materials which are a magnesium-contained powdery compound, an aluminum-contained powdery compound, a titanium-contained powdery compound, and an external surface wrappage material composed of a macromolecular compound. The preparation method for the presulfided sulfur-tolerant shift catalyst provided by the invention comprises the following steps: preparation of an active component solution, molding of the catalyst, drying, roasting, presulfurization treatment, and aftertreatment of the catalyst. The presulfided sulfur-tolerant shift catalyst prepared by using the method in the invention is easy to activate when in use, has short activation time and high shift activity, and is convenient for transportation and storage; and the preparation method for the presulfided sulfur-tolerant shift catalyst provided by the invention is simple in process and facilitates realization of industrialization.

Owner:CHINA PETROLEUM & CHEM CORP

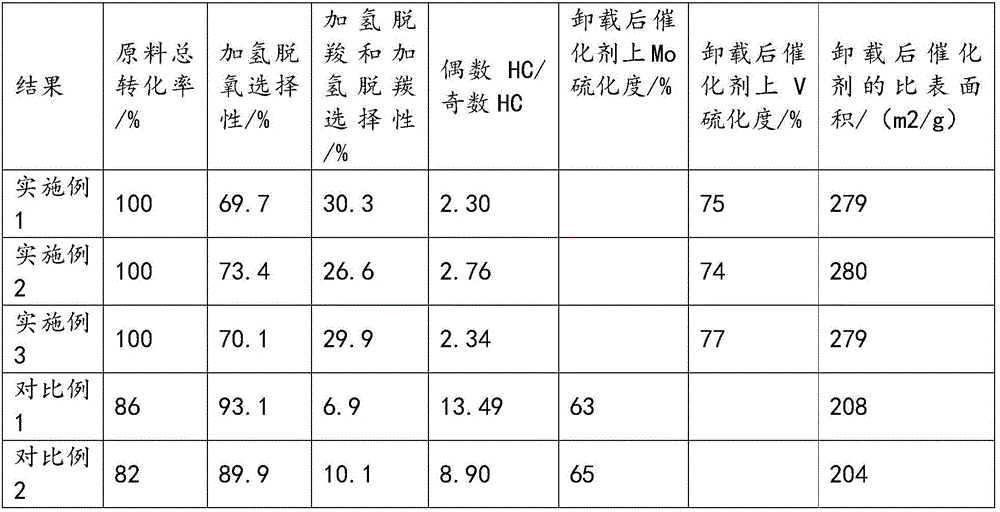

Bio-oil hydrodeoxygenation method

ActiveCN105885911AIncrease acidityGood dispersionPhysical/chemical process catalystsLiquid hydrocarbon mixture productionVulcanizationOxygen

The invention provides a bio-oil hydrodeoxygenation method, which comprises the following steps that a hydrodeoxygenation catalyst is used as a reaction catalyst; bio-oil is subjected to hydrodeoxygenation treatment. A preparation method of the hydrodeoxygenation catalyst comprises the following steps of taking roasted catalyst carriers soaked with active ingredients; absorbing oxygen inorganic acid by the catalyst carriers; then performing vulcanization treatment to obtain a product, wherein the active ingredients are mainly formed by one or a plurality of kinds of VB group metals and one or a plurality of kinds of VIIB group metals. The inorganic acid is used for performing pre-treatment on the catalyst, so that the selectivity of the hydrogenation decarboxylation and decarbonylation reaction is improved; the sulfur fixation performance and the thermal stability of the catalyst are improved.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

Regeneration method of deactivated hydrogenation catalyst

PendingCN111729689AReduce utilizationIncrease profitOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst regeneration/reactivationCarboxyl radicalPtru catalyst

The invention provides a regeneration method of an deactivated hydrogenation catalyst. The regeneration method comprises the following steps: carrying out charking treatment on the inactivated hydrogenation catalyst; dipping the charked deactivated hydrogenation catalyst in a solution containing a hydroxyl and / or carboxyl chelated ligand compound; and carrying out microwave vacuum drying on the catalyst subjected to dipping treatment so that the deactivated hydrogenation catalyst then recovers the activity. According to the technical scheme, microwave vacuum drying is adopted, due to the factthat operation is carried out under the condition of air isolation, oxygenolysis cannot occur in the drying process even if the decomposition temperature of an organic additive is high, and the utilization rate of the organic additive is remarkably increased.

Owner:湖北中超化工科技有限公司

Vulcanized hydrogenation catalyst, preparation method therefor and application thereof

ActiveCN105080555AOvercome the defect of low degree of vulcanizationIncrease the degree of vulcanizationMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsVulcanizationAlcohol

The invention provides a vulcanized hydrogenation catalyst, a preparation method therefor and an application thereof. The preparation method of the vulcanized hydrogenation catalyst comprises the following steps: (1) preparing an oxidized hydrogenation catalyst, wherein the oxidized hydrogenation catalyst comprises a carrier and an organic alcohol compound and an active metal oxide loaded on the carrier; the organic alcohol compound has at least one exothermic peak at 200-400 DEG C; and (2) in the presence of a curing media, successively increasing the temperature of the oxidized hydrogenation catalyst from the room temperature to a temperature corresponding to each exothermic peak of the organic alcohol compound at 200-400 DEG C at a rate of 1-20 DEG C / h; performing a constant temperature vulcanization for 1-5 hours; then increasing the temperature by 20-150 DEG C from atemperature corresponding to the highest temperature exothermic peak of the organic alcohol compound at 200-400 DEG C at the rate of 1-20 DEG C / h; and performing the constant temperature vulcanization for 1-5 hours. By adopting the preperation method provided by the invention, the degree of vulcanization of metals in the catalyst and the proportion of a three-layer-packed structure are improved, thus facilitating the improvement of the catalyst on hydrodearomatization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sulfuration type hydrodesulfurization catalyst as well as preparation method and application thereof

PendingCN114073970AIncrease the degree of vulcanizationReduce interactionCatalyst activation/preparationHydrocarbon oils treatmentPtru catalystHydrodesulfurization

The invention provides a sulfuration type hydrodesulfurization catalyst and a preparation method and application thereof. The catalyst comprises a carrier, active metal and auxiliary metal. The preparation method comprises the following steps: 1, adding a compound containing the active metal and a sulfurizing agent into a first solvent, and carrying out heating reflux to obtain active metal sulfide; and 2, dispersing the active metal sulfide on the carrier, then dipping the carrier in a compound solution containing the auxiliary metal, and carrying out roasting to obtain the sulfuration type hydrodesulfurization catalyst. According to the invention, the catalyst obtained by the method can be directly used for hydrodesulfurization of oil product without a sulfuration process, and strong interaction between the active metal and the carrier can be avoided; and the active metal in the prepared catalyst has high sulfuration degree and high dispersion degree, so the catalyst has high removal activity for thiophene sulfur-containing compounds.

Owner:PETROCHINA CO LTD +1

A kind of preparation method of sulfurized hydrogenation catalyst

ActiveCN102836736BIncrease the degree of vulcanizationMolecular sieve catalystsNickel saltVulcanization

The present invention discloses a preparation method for a vulcanization type hydrogenation catalyst. The preparation method comprises: uniformly mixing a carrier precursor, a thiomolybdate and / or thiotungstate, a nickel salt and / or a cobalt salt, adding a binder to carry out kneading, carrying out molding, and then carrying out drying and calcination in the protection of an inert gas to prepare the catalyst. The method of the present invention has characteristics of simple process and high vulcanization degree, wherein the prepared vulcanization type hydrogenation catalyst has high activity and high selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrodeoxygenation method of bio-oil

ActiveCN105861038AIncrease acidity and active phase dispersibilityImprove sulfur fixation effectHeterogenous catalyst chemical elementsCatalyst activation/preparationOxidation stateHeat stability

The invention provides a hydrodeoxygenation method of bio-oil. The method includes the steps that a hydrodeoxygenation catalyst serves as a reaction catalyst, and hydrodeoxygenation treatment is conducted on the bio-oil; the preparation method of the hydrodeoxygenation catalyst includes the steps that in the process of calcinating a catalyst carrier soaked with active components, the catalyst carrier soaked with the active components is made to make contact with organic matter containing oxygen, and calcination is completed, so that a catalyst in an oxidation state is obtained; the catalyst in the oxidation state adsorbs inorganic acid, then sulfidizing is conducted, and a product is obtained; the active components are mainly composed of one of more types of VIB metal and one or more types of VIII metal. According to the method, the organic matter containing oxygen and inorganic acid are utilized to conduct pretreatment on the catalyst, selectivity of a hydrogenation decarboxylation decarbonylation reaction is increased, and sulfur fixation performance and heat stability of the catalyst are improved, so that the operation cycle of a device is prolonged.

Owner:GUANGHAN TIANZHOU AERO ENGINE FUEL TECH CO LTD

Pre-sulfurization method of hydrogenation catalyst

ActiveCN106925356AIncrease concentrationIncrease partial pressureCatalyst activation/preparationInternal pressureSulfur

The invention discloses a pre-sulfurization method of a hydrogenation catalyst, comprising the specific steps of mixing the hydrogenation catalyst with one or more sulfur-bearing compounds, adding the mixture into a reactor, introducing hydrogenation active gas into the reactor, maintaining the inner pressure of the reactor to 1.5-4 MPa, sealing the reactor, and pre-sulfurizing at 220-380 DEG C for 1-6 hours. The pre-sulfurization process is performed in the sealed reactor, the sulfur-bearing compounds may be released massively and instantly during heating, the formed H2S gas has high pressure and concentration, sulfurization can be finished within a short time, and sulfurization degree is high; in addition, by controlling the usage of the catalyst and sulfur-bearing compounds in the reactor, it is possible to achieve controllable pre-sulfurization degree; all the sulfur-bearing materials are nearly consumed, and no pollutant is produced.

Owner:PETROCHINA CO LTD

A kind of sulfurized hydrogenation catalyst and its preparation method and application

ActiveCN107971034BImprove hydrogenation performanceEnsure safetyOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbon oils treatmentPtru catalystOrganosolv

The invention relates to the field of hydrorefining, and discloses a vulcanization type hydrogenation catalyst, a preparation method and applications thereof. The method comprises: (1) mixing a dispersing agent and a solution A containing a group VIB metal salt, a group VIII metal salt and a sulfur source, wherein the solution A is acidic, the dispersing agent is a water-soluble organic solvent with a boiling point of 15-90 DEG C, and the sulfur source is a sulfur-containing material capable of being hydrolyzed at 50-100 DEG C under an acidic condition; (2) making the mixture obtained in the step (1) contact a catalyst carrier for 5-30 h at a temperature of 60-150 DEG C under a sealed condition; and (3) calcining the solid material obtained in the step (2) in an inert or reducing atmosphere. With the method of the present invention, the main agent component and the auxiliary agent component are introduced in one step, and the active component of the prepared catalyst is highly dispersed and fully vulcanized so as to significantly improve the hydrogenation performance of the catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of sulfur-loaded hydrogenation catalyst

ActiveCN103801333BEvenly dispersedSimple processPhysical/chemical process catalystsRefining to eliminate hetero atomsAmmonium heptamolybdateCobalt

The invention discloses a preparation method of a sulfur-loaded hydrogenation catalyst. The method comprises the following steps: firstly pulping a hydrated alumina precursor, adding a nickel nitrate or cobalt nitrate solution, then slowly adding a carbonate precipitating agent solution drop by drop to form composite nickel carbonate or composite cobalt carbonate precipitates, aging, filtering, washing to obtain a wet filter cake, pulping in a closed container, orderly adding an ammonium heptamolybdate aqueous solution and an ammonium sulphide aqueous solution, slowly adding dilute nitric acid drop by drop into the solution to generate a molybdenum sulfide MoS3 paste precipitate, filtering the precipitate, drying, molding, and drying to obtain the sulfur-loaded catalyst. The sulfur-loaded catalyst prepared by the method of the invention is high in sulfidity, and the production process is simple, and easy to carry out technically; the catalyst has high hydrorefining performance. The method of the invention simplifies the preparation process of the catalyst, saves resources, and increases benefits.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of presulfurization method of hydrogenation catalyst

ActiveCN106925356BIncrease concentrationIncrease partial pressureCatalyst activation/preparationPtru catalystPhysical chemistry

The invention discloses a pre-sulfurization method of a hydrogenation catalyst, comprising the specific steps of mixing the hydrogenation catalyst with one or more sulfur-bearing compounds, adding the mixture into a reactor, introducing hydrogenation active gas into the reactor, maintaining the inner pressure of the reactor to 1.5-4 MPa, sealing the reactor, and pre-sulfurizing at 220-380 DEG C for 1-6 hours. The pre-sulfurization process is performed in the sealed reactor, the sulfur-bearing compounds may be released massively and instantly during heating, the formed H2S gas has high pressure and concentration, sulfurization can be finished within a short time, and sulfurization degree is high; in addition, by controlling the usage of the catalyst and sulfur-bearing compounds in the reactor, it is possible to achieve controllable pre-sulfurization degree; all the sulfur-bearing materials are nearly consumed, and no pollutant is produced.

Owner:PETROCHINA CO LTD

A kind of alumina-based hydrorefining catalyst and its preparation method and application

ActiveCN104941654BIncrease the degree of vulcanizationMultiple hydrogenation active sitesMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsComponent LoadSulfur

The invention provides an aluminum oxide based hydrorefining catalyst as well as a preparation method and application thereof. The method comprises the following steps: 1, immersing active metal components into an aluminum oxide carrier, and drying and roasting to obtain an active metal component loaded catalyst; and 2, introducing an organic complexing agent into the active metal component loaded catalyst and drying to obtain the aluminum oxide based hydrorefining catalyst, wherein the aluminum oxide carrier comprises delta-Al2O3 or theta-Al2O3. The aluminum oxide based hydrorefining catalyst provided by the invention can be used for FCC diesel oil so that the yield of the FCC diesel oil is higher than 99%, the content of sulfur is lower than 10ppm, and China 5 standard requirements are met.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Bulk phase hydrogenation catalyst and preparation method thereof

PendingCN112705221APromote generationHigh activityCatalyst activation/preparationHydrocarbon oils treatmentPtru catalystSulfidation

The invention discloses a bulk phase hydrogenation catalyst and a preparation method thereof. The catalyst comprises a VIB group metal sulfide, a VIII group metal oxide, Al2O3 and an auxiliary agent. The VIB group metal sulfide is distributed in the bulk phase and the surface phase of the catalyst, and the ratio of the weight content of the VIB group metal sulfide in the surface phase to the weight content of the VIB group metal sulfide in the bulk phase is 3: 1-7.5: 1. The preparation method comprises the following steps: (1) preparing a mixed solution A containing VIB group metal and an aluminum source, and carrying out parallel flow gelatinization with a precipitant to generate slurry I; (2) uniformly mixing the slurry I and an auxiliary agent precursor, and molding to obtain a precursor I; (3) drying and roasting the precursor I, and carrying out vulcanization treatment to obtain a precursor II; and (4) impregnating the precursor II with an impregnation liquid containing a group VIII metal, and drying and roasting the impregnated precursor II in an inert atmosphere to obtain the bulk phase hydrogenation catalyst. The catalyst provided by the invention has high vulcanization degree and high II type active center number, and is especially suitable for a diesel oil hydrofining process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrofining catalyst and preparation method thereof

ActiveCN112619676AAvoid generatingIncrease the degree of vulcanizationPhysical/chemical process catalystsBio-feedstockPolycyclic aromatic hydrocarbonPtru catalyst

The invention discloses a hydrofining catalyst and a preparation method thereof, the hydrofining catalyst comprises a modified alumina carrier and a hydrogenation active component, the modified alumina carrier comprises phosphorus and a modifier A, the modifier A is magnesium oxide, calcium oxide or zirconium oxide, the phosphorus accounts for 0.1wt%-5wt% of the elements, and the modifier A accounts for 3wt%-15wt% of the elements; based on the total weight of the catalyst, a VIB group metal accounts for 2.0%-30% of the total weight of the catalyst in terms of oxide, and a VIII group metal accounts for 0.1%-10% of the total weight of the catalyst in terms of oxide. The preparation method comprises the following steps: (1) adding an aluminum source and a precipitant into an aqueous solution containing a phosphate type anionic surfactant for precipitation reaction to obtain pseudo-boehmite powder, and molding the powder to obtain a carrier; and (2) impregnating the carrier with a modifier A precursor aqueous solution, mixing the impregnated carrier with a urea solution, carrying out hydrothermal treatment to obtain a modified alumina carrier, and loading an active component to obtain the catalyst. The catalyst provided by the invention has the characteristics of appropriate acid amount and mesoporous aperture, uniform active metal dispersion, low price and the like, and has good hydrodesulfurization and polycyclic aromatic hydrocarbon hydrogenation saturation activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

High-strength alumina-based hydrogenation catalyst as well as preparation method and application thereof

ActiveCN114433134AHigh crystallinityRefine grain sizeCatalyst activation/preparationBulk chemical productionPtru catalystBiodiesel

The invention provides a high-strength alumina-based hydrogenation catalyst, which comprises a carrier and an active component, the carrier comprises alumina, a modifier A selected from at least one of zirconia, titanium oxide and silicon oxide, and a modifier B selected from at least one of magnesium oxide, potassium oxide and calcium oxide; the active component is a VIB group metal sulfide and a VIII group metal oxide. The catalyst is prepared by adopting a coprecipitation method and comprises the following steps: firstly, preparing a mixture of aluminum oxide and a modifier A, adding group VIB metal salt and precursor salt of a modifier B in an aging process after precipitation is completed, vulcanizing, forming, dipping group VIII metal salt, and drying to obtain the catalyst. The catalyst has high mechanical strength and hydrogenation activity, the application range of the catalyst is widened, and the catalyst is especially suitable for the hydrogenation process of water-containing raw materials such as coal tar and biodiesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of hydrotreating catalyst

ActiveCN103769125BImprove complexation abilityRaise the vulcanization temperatureMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsUltrasonic cavitationPtru catalyst

The invention discloses a preparation method of a hydro-treatment catalyst. The preparation method comprises the following steps: preparing an alumina carrier, preparing an impregnation solution containing the VIII group metal and VIB group metal, wherein the impregnation solution comprises a proper amount of an organic auxiliary agent containing chelating ligand, then impregnating the alumina carrier into the impregnation solution under a proper ultrasonic treatment condition, and drying so as to obtain the hydro-treatment catalyst. The preparation method utilizes the ultrasonic cavitation effect to properly reduce the viscosity of the impregnation solution; at the same time the complexing capacity between the chelating ligand in the organic auxiliary agent and nickel / cobalt is improved by the catalytic function of the ultrasonic, the interaction force between the chelating ligand and nickel / cobalt is strengthened, thus the active metal component is promoted to highly disperse on the carrier surface, furthermore, the existing state of the active metal on the catalyst surface is improved at the same time, the sulfurization degree and sulfurization uniformity of the active metal are both improved, so the activity and stability of the catalyst are both improved. The catalyst is especially suitable for being used in the hydro-denitrogenation process and hydro-desulfurization process of heavy distillate oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrodesulfurization and dearomatization catalyst and system, preparation method thereof, and method for hydrodesulfurization and dearomatization of diesel oil

ActiveCN105478145BHigh desulfurization activityImprove performancePhysical/chemical process catalystsHydrocarbon oils treatmentVulcanizationHydrodesulfurization

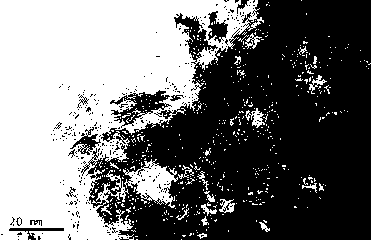

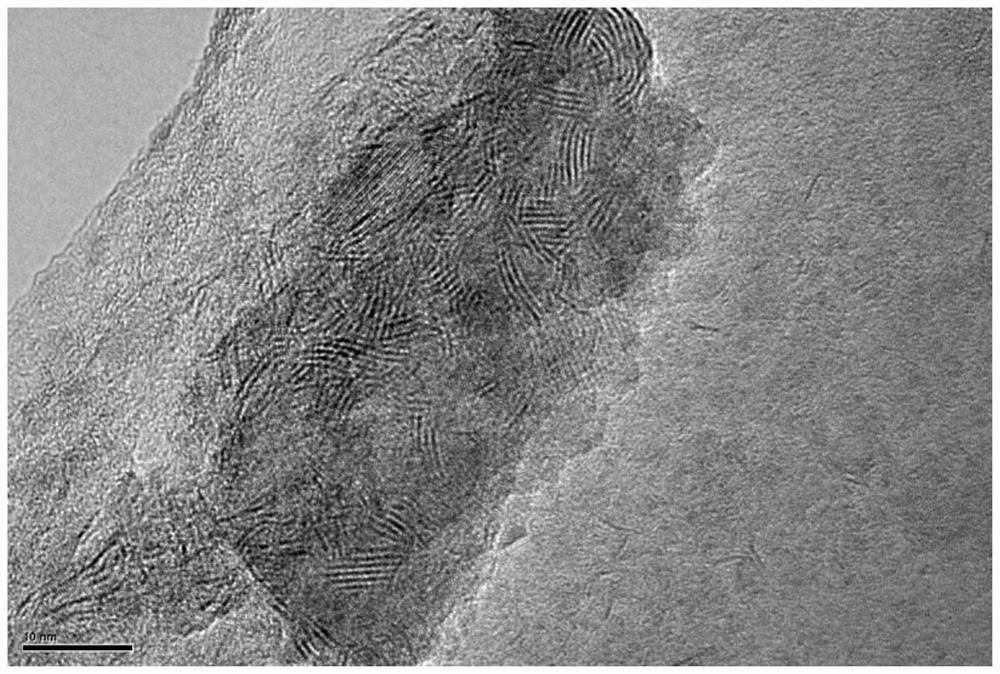

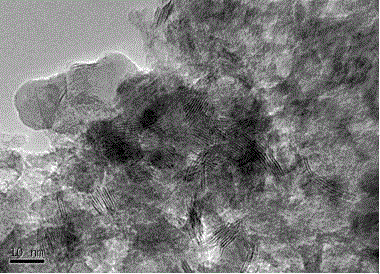

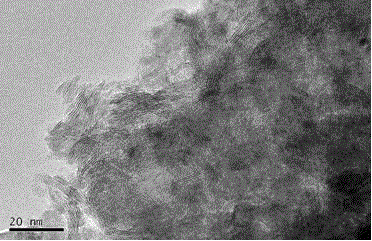

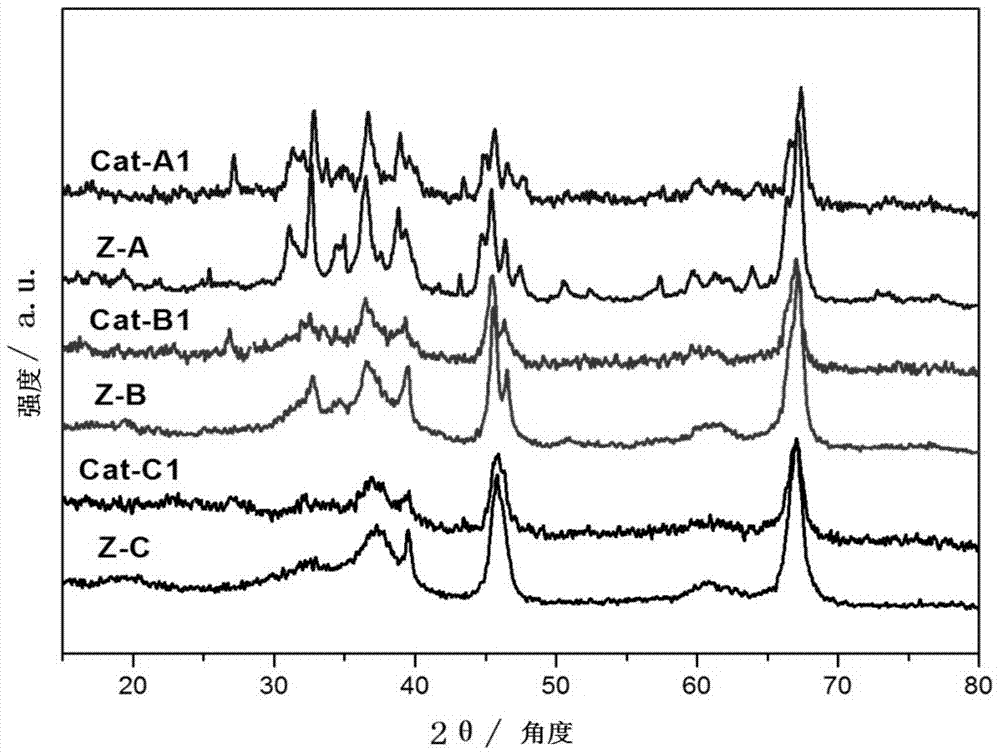

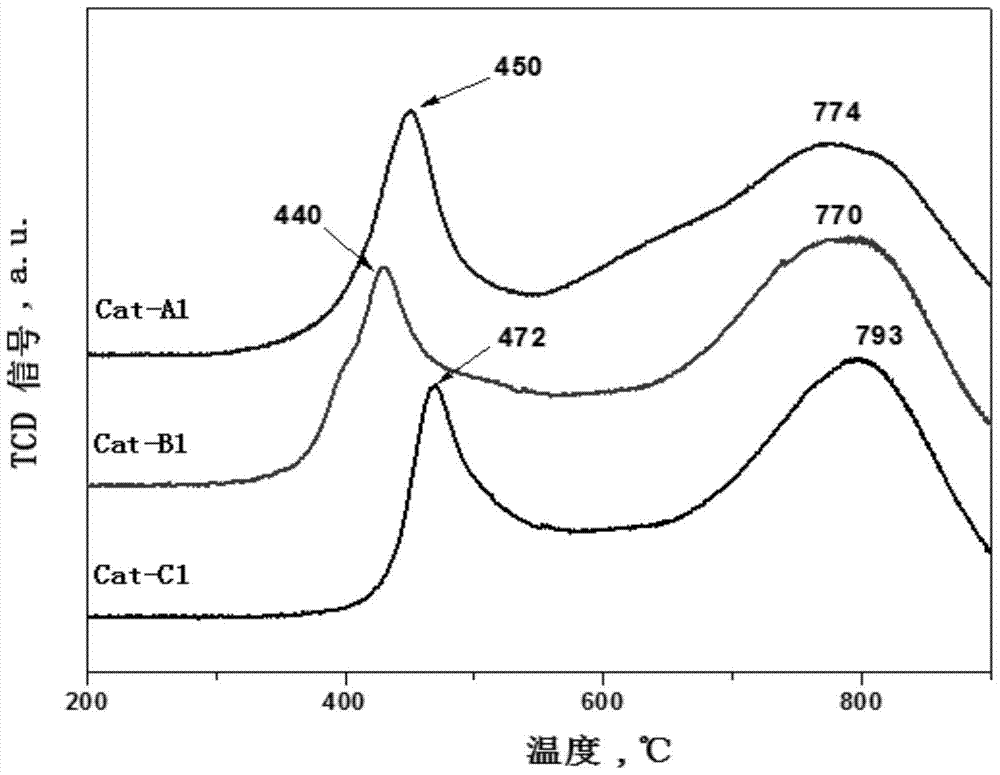

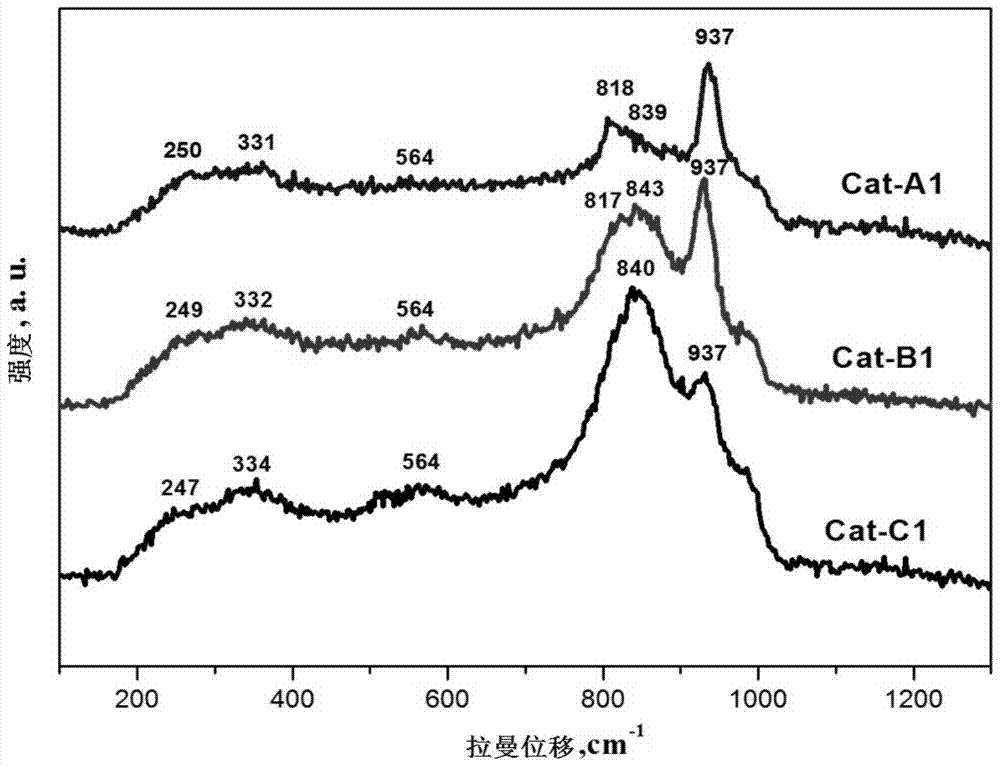

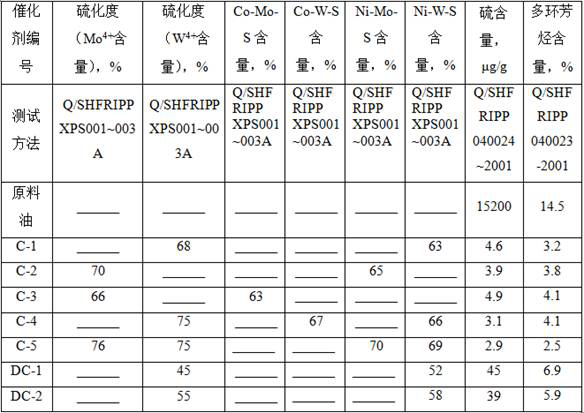

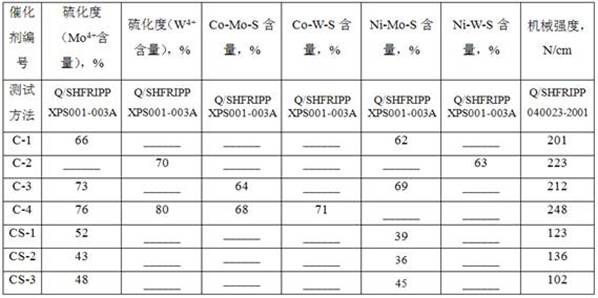

The invention relates to a hydrogenation desulfurization and dearomatization catalyst, a preparation method thereof, a hydrogenation desulfurization and dearomatization catalyst system, and a diesel hydrogenation desulfurization and dearomatization method. The hydrogenation desulfurization and dearomatization catalyst comprises a carrier and sulfide-state metal active components and trace elements loaded on the carrier. The trace elements are one or more selected from P, F, Si, B and Mg. The metal active components comprise Group VIII and Group VIB metal elements. The catalyst is characterized in that, tested with XPS, the vulcanization degree of the Group VIII metal elements in the catalyst is no lower than 70%, and the vulcanization degree of the Group VIB metal elements in the catalyst is no lower than 70%; and counted with TEM, an active phase ratio of a three-layer stack of the catalyst is no lower than 30%. With the hydrogenation desulfurization and dearomatization catalyst provided by the invention, both the desulfurization effect and the dearomatization effect are taken into account.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com