Patents

Literature

96 results about "Hydrazine sulfate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrazine sulfate, more properly hydrazonium hydrogensulfate, is a salt of the cation hydrazinium and the anion bisulfate (hydrogensulfate), with the formula [N₂H⁺₅] [HSO⁻₄] or N₂H₆SO₄. It is a white, water-soluble solid at room temperature.

Synthesis of several metal selenides and tellurides as semiconductor material

InactiveCN1384047AOvercome the problems of high temperature, highly toxic raw materials, complicated process, etc.Low reaction temperatureSemiconductor/solid-state device manufacturingBinary selenium/tellurium compoundsSemiconductor materialsHydroxylamine

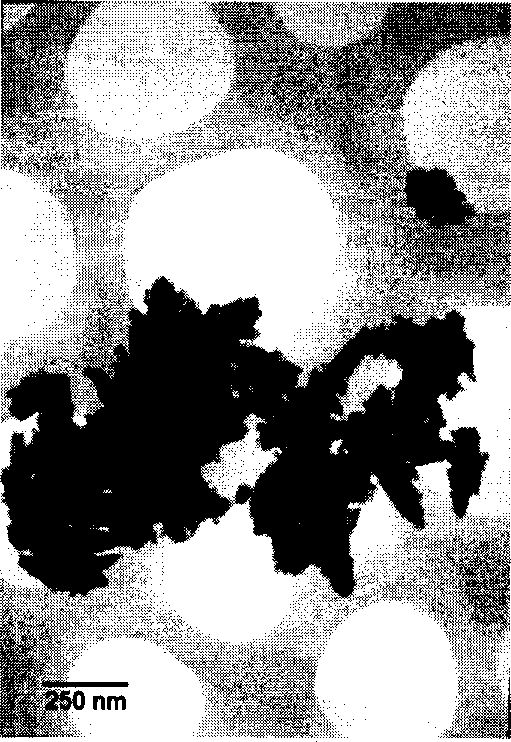

By using the soluble salt of transition metalz Zn, Cd, Pb, Mn, Co, Ni, Cu, Ag, Sb and Bi, selenious acid or its solutl salt, or antimonous acid or its soluble salt as raw material, and hydrazine hydrate, sodium borohydride, potassium borohydride, hydroxylamine or hydrazine sulfate as reductant, and through hydrothermal reduction reaction at 100-200 deg.c in a sealed container for 2 hr to 5 days, selenides or tellurides of the said metals as semiconductor material may be synthesized. Unlike available synthesis process, which needs high temperature, toxic feedstock and complex technological course, the present invention has the advantages of low-cost material, simple apparatus, easy control, good technological reproducibility, stable product quality, etc.

Owner:TSINGHUA UNIV

Novel chemical copper plating method

ActiveCN101979709AImprove reliabilityNo acid fogLiquid/solution decomposition chemical coatingPrinted circuit manufactureCopper platingEtching

The invention discloses a novel chemical copper plating method. The method comprises steps of degreasing and hole finishing, washing, micro etching, pre-impregnation, activation, washing, dispergation, washing and chemical copper plating. The method is characterized in that: in the degreasing and hole finishing step, a circuit board can be degreased, and more important, high negative electricity is carried in the hole and can adsorb more palladium colloid so that the backlight of a copper layer reaches over level 9; salt-based ammonium sulfate and palladium sulfate solution is adopted in the activation step, and acid mist produced by the traditional palladium colloid is not produced, so the method is environment-friendly and has no any injury to the operating personnel; and in the dispergation step, sulfuric acid and hydrazine sulfate are used for removing ammonium radicals, and the hydrazine can reduce palladium metal into palladium atoms, so copper is better deposited.

Owner:江苏矽智半导体科技有限公司

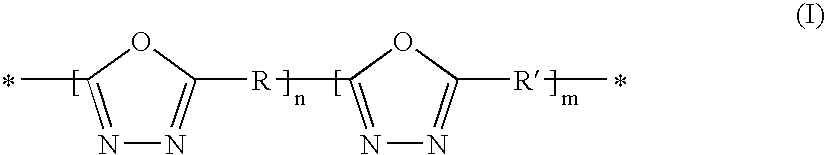

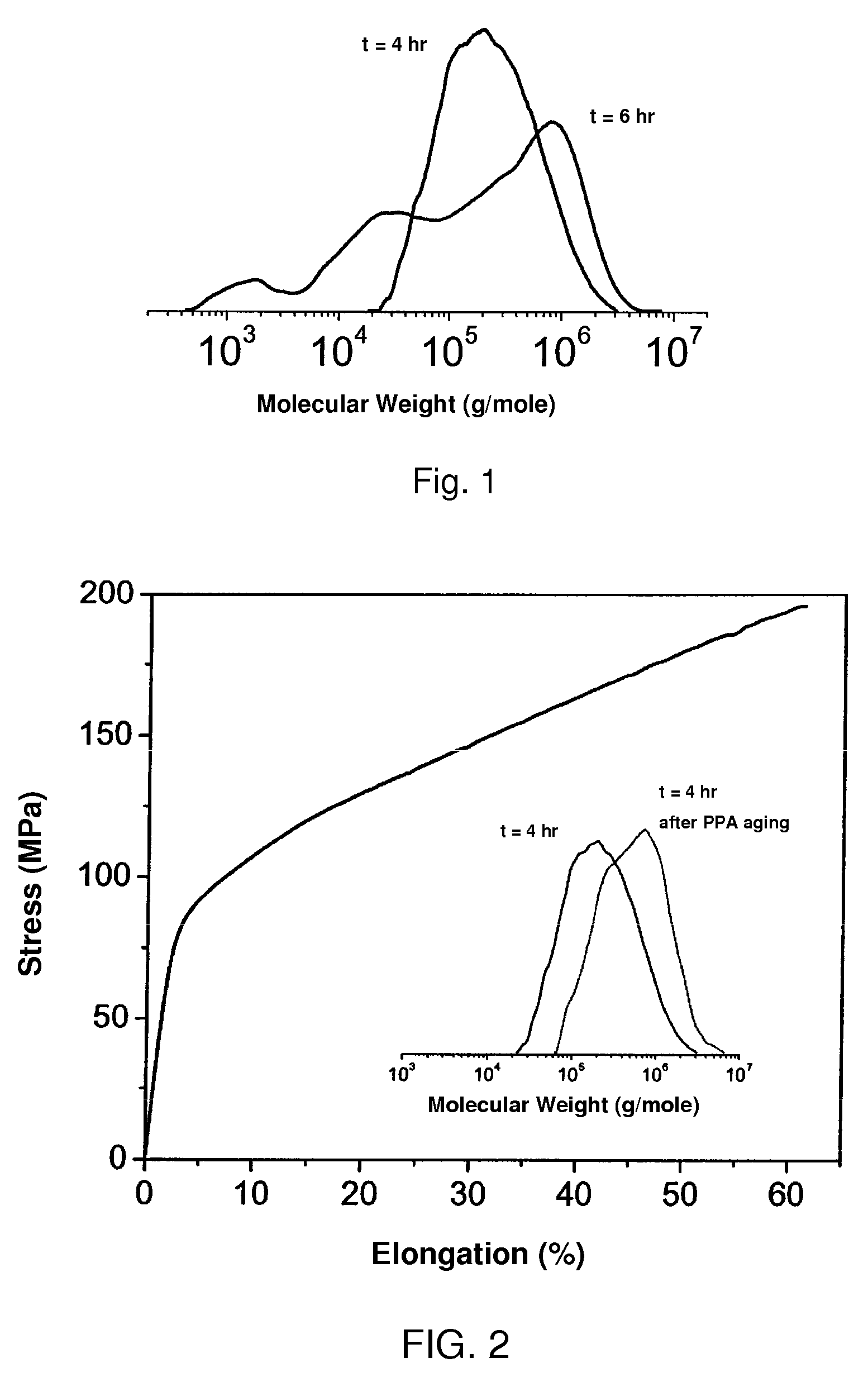

Two step preparation of random polyoxadiazole copolymer and articles resulting therefrom

InactiveUS7582721B2High viscosityExtrusion stabilityMonocomponent synthetic polymer artificial filamentTwo stepCopolymer

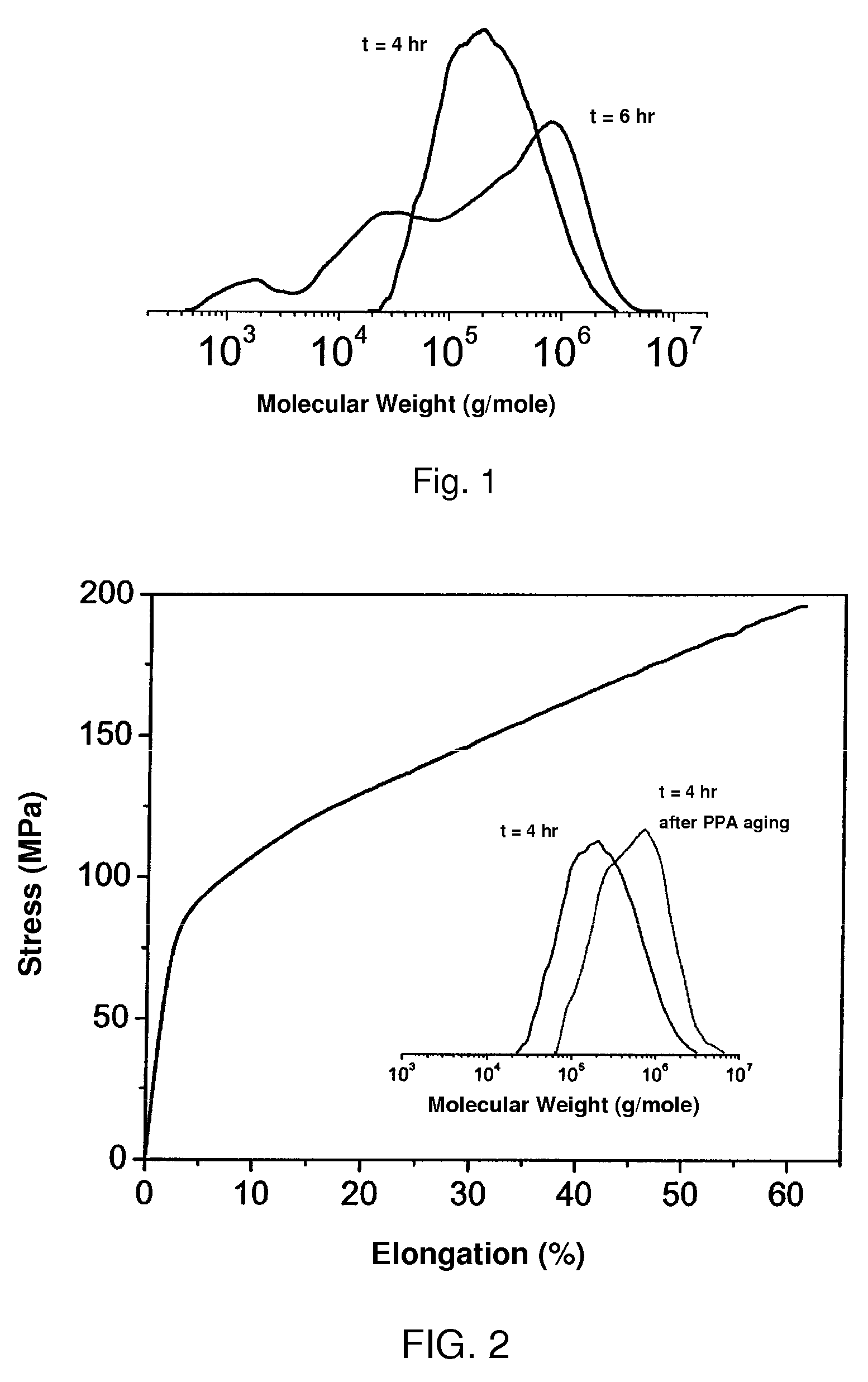

In a preparation of random polyoxadiazole copolymer by reaction of a mixture of oleum, hydrazine sulfate, terephthalic acid, and isophthalic acid, the improvement requires the addition of oleum in more than one step.

Owner:DUPONT SAFETY & CONSTR INC

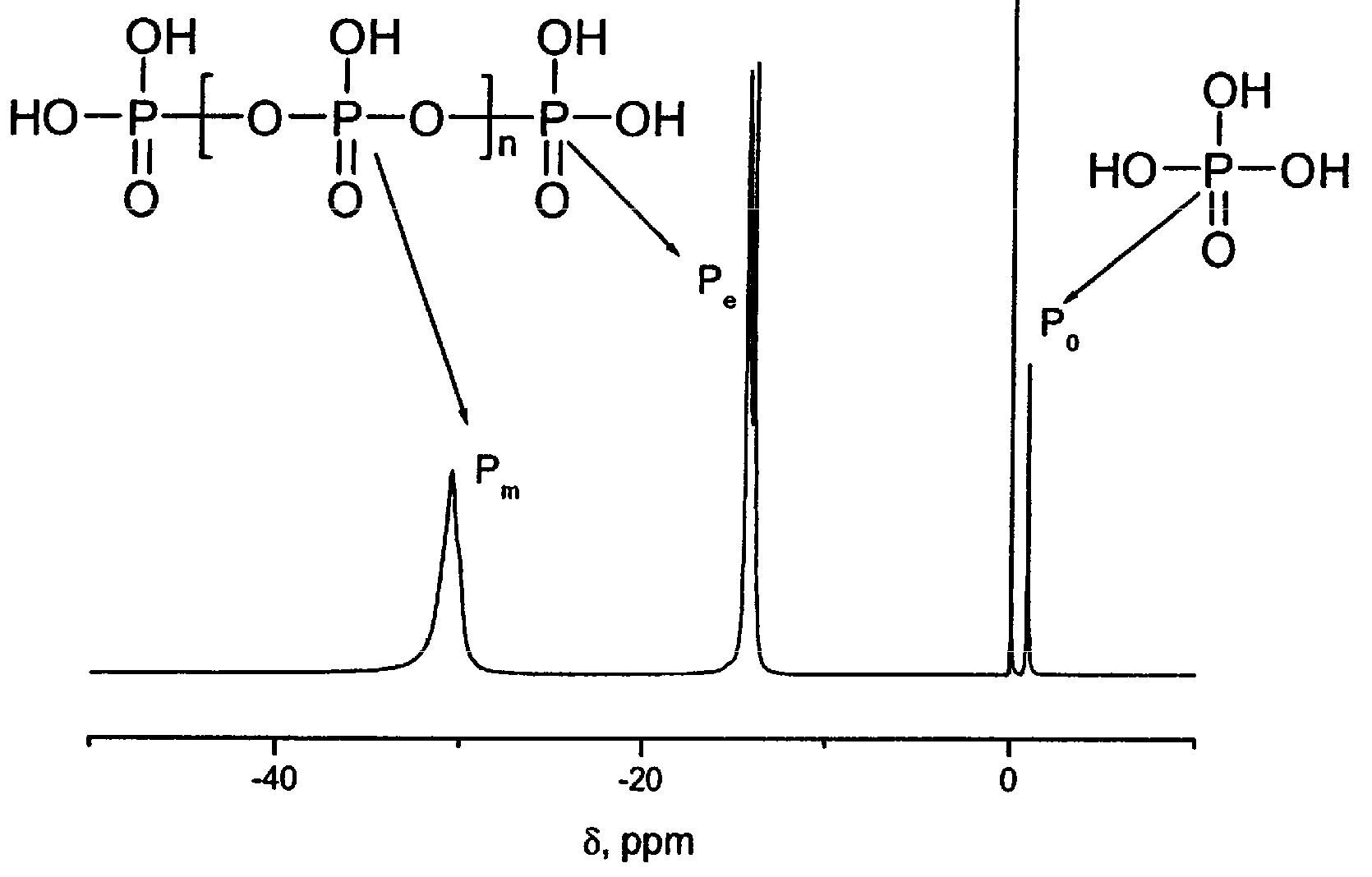

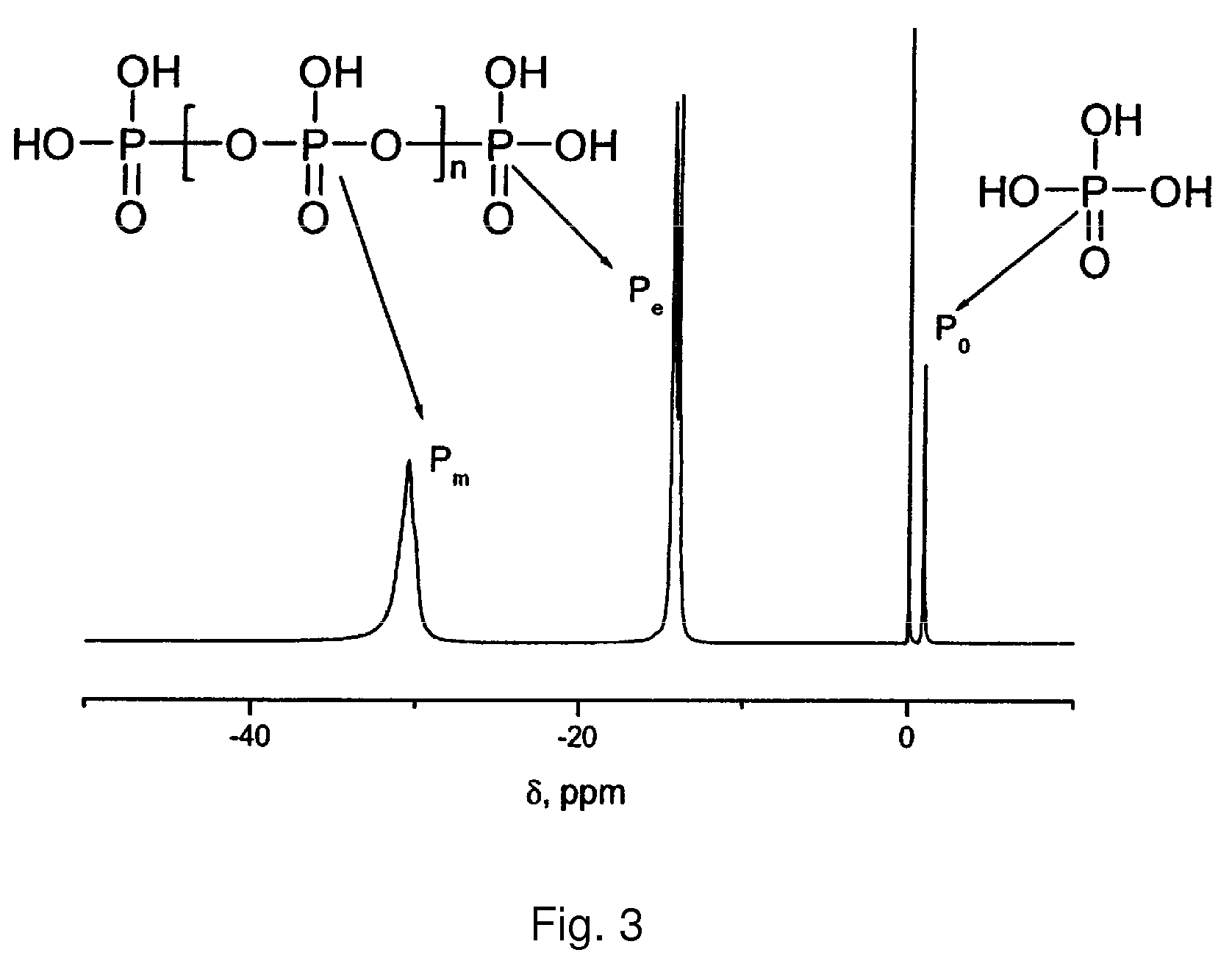

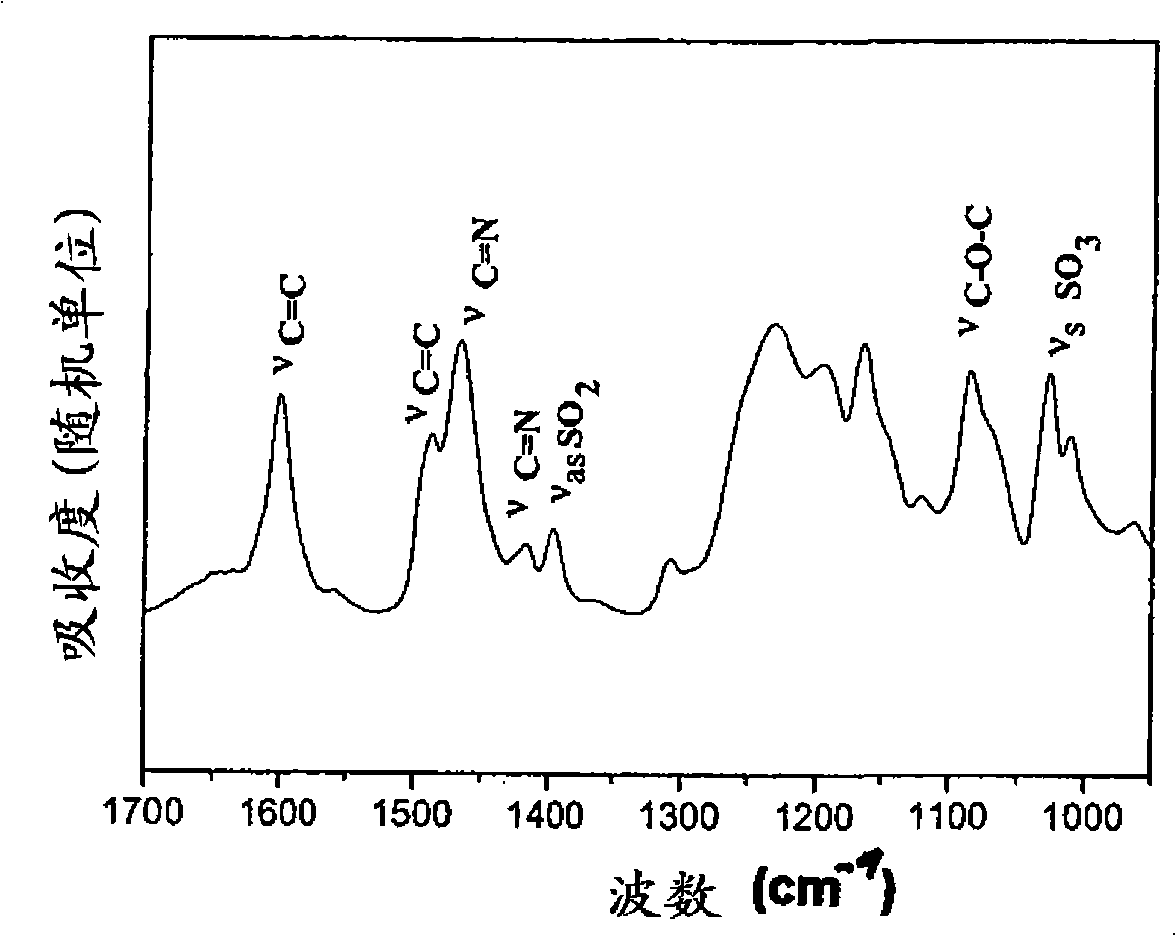

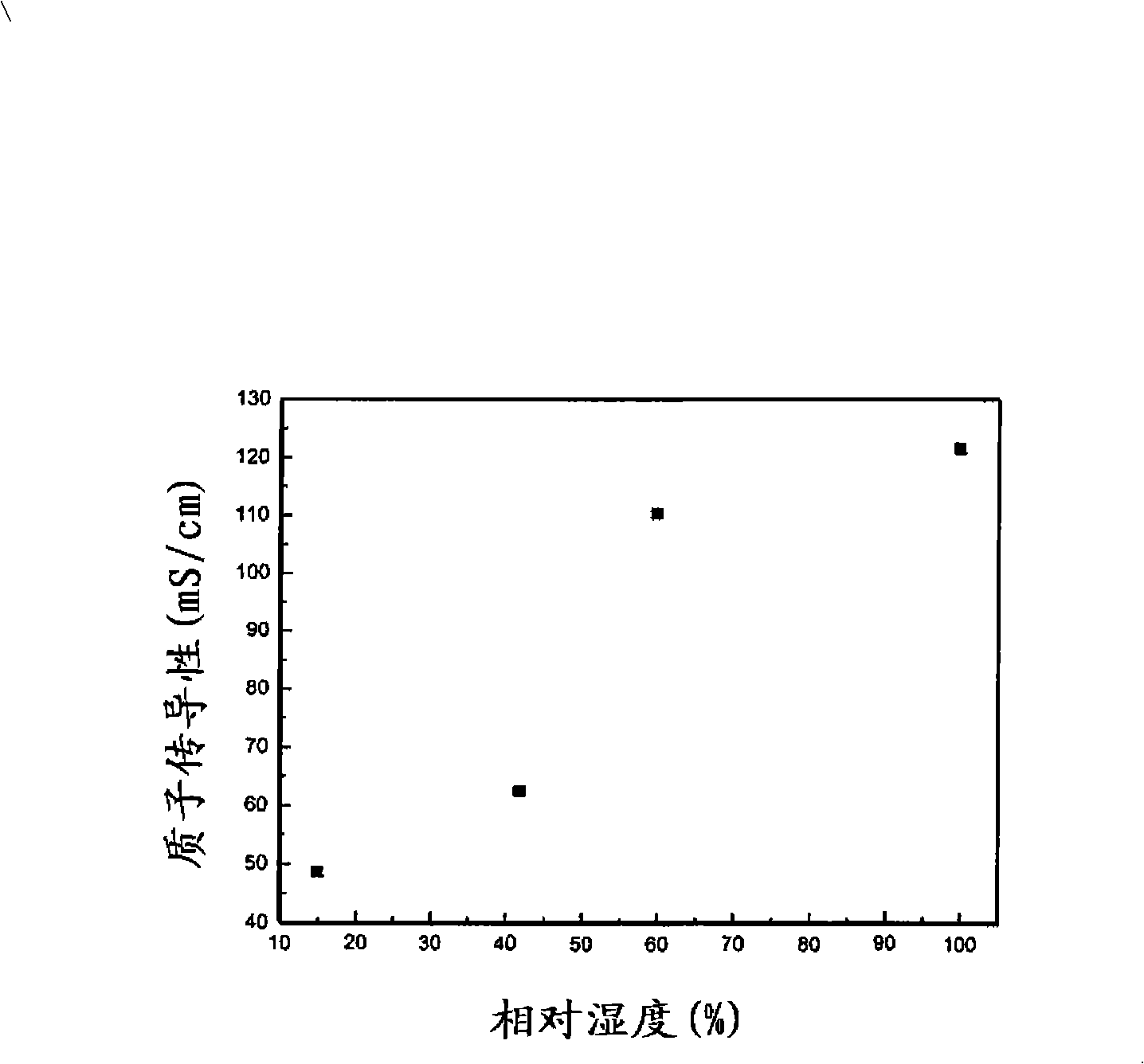

Method for the synthesis of a polyoxadiazole polymer

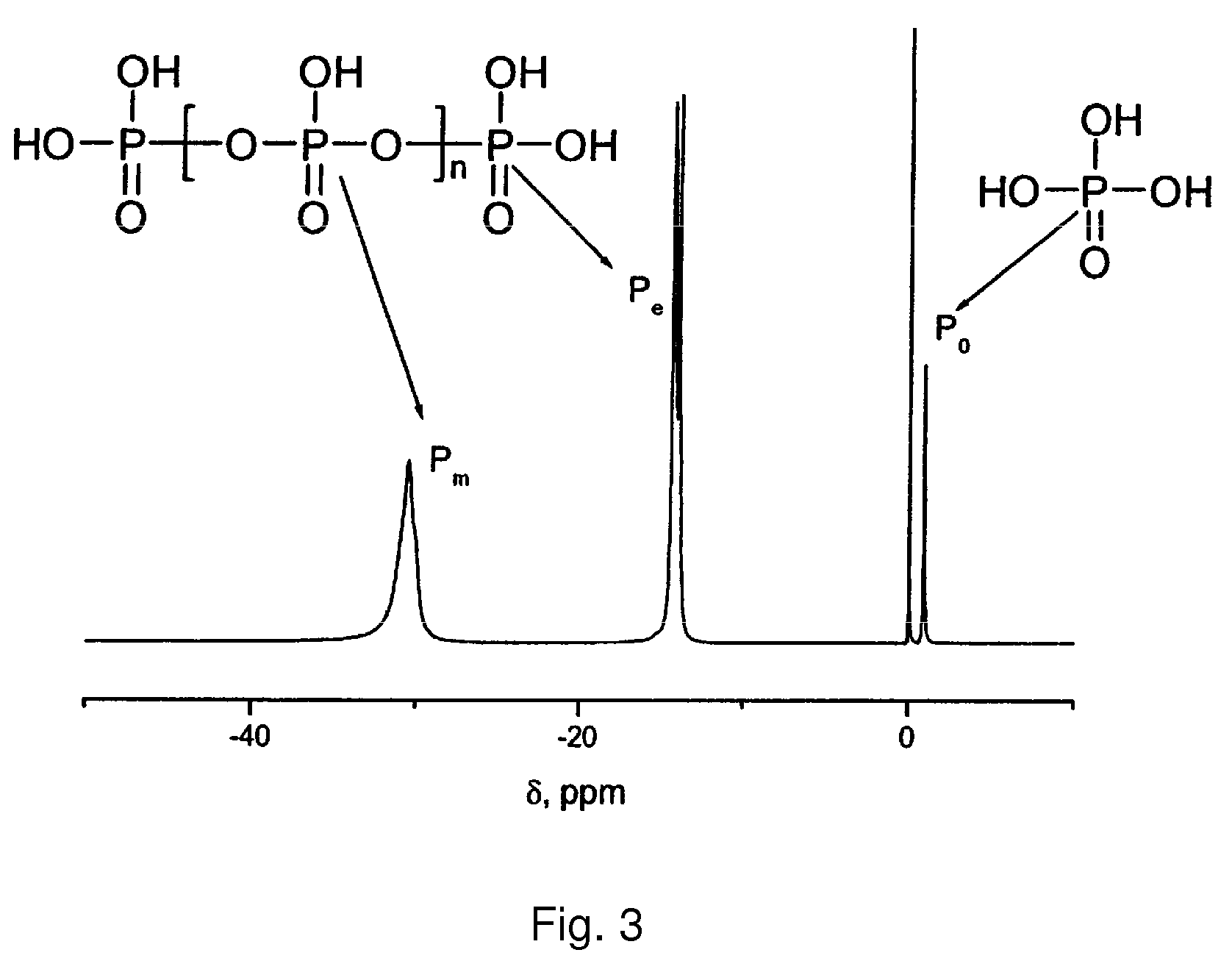

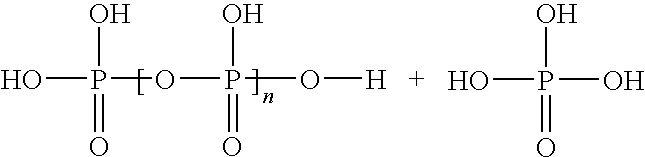

A polyoxadiazole polymer is synthesized by heating polyphosphoric acid to a temperature of at least about 160° C. and making a solution by mixing hydrazine sulfate salt with one or more dicarboxylic acids or their derivatives in the heated polyphosphoric acid. The solution is heated under an inert gas atmosphere and the polymer is precipitated in a basic solution. The polyoxadiazole polymer can be produced as a homopolymer or copolymer, and may be used to produce a membrane or fibers.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

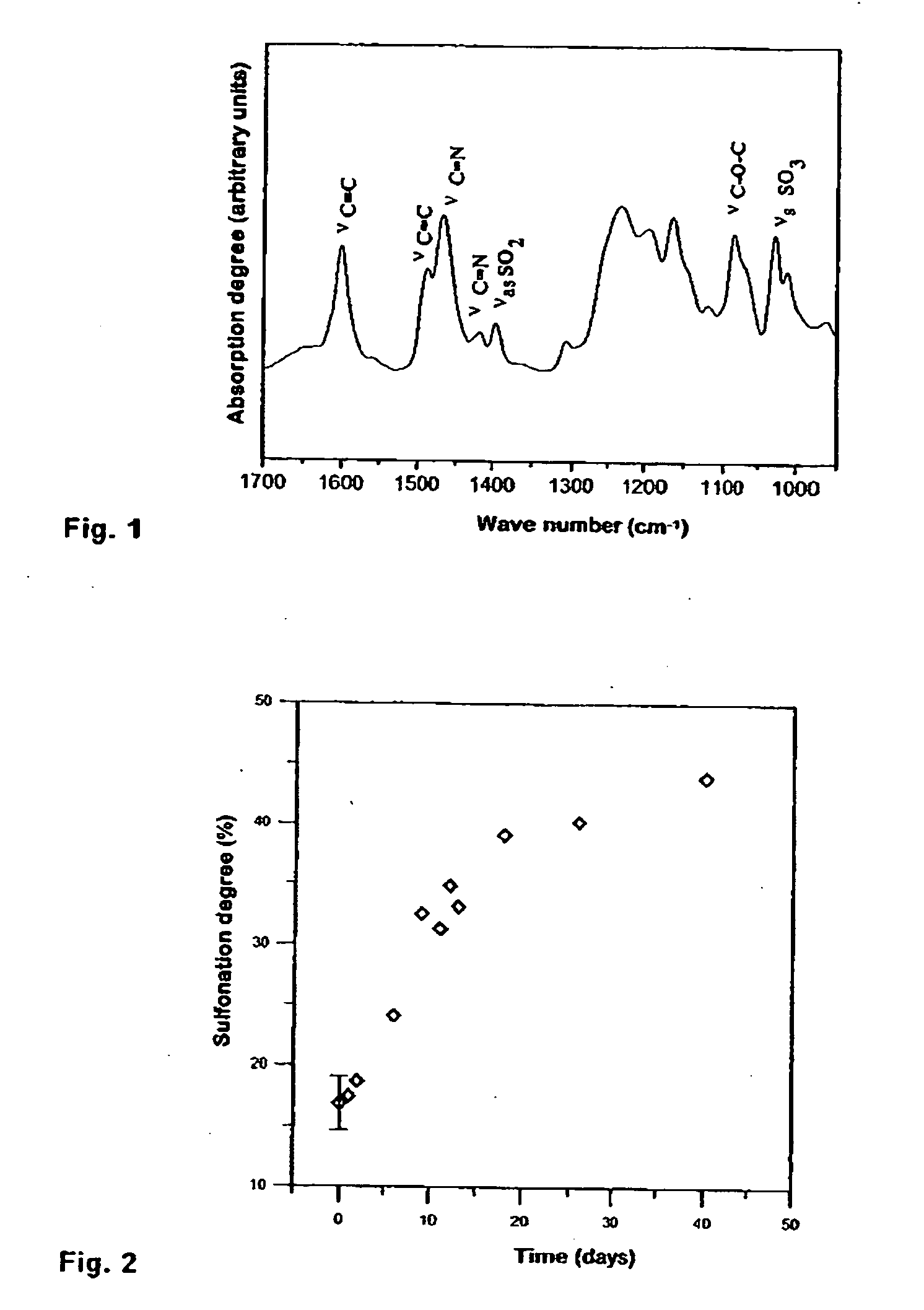

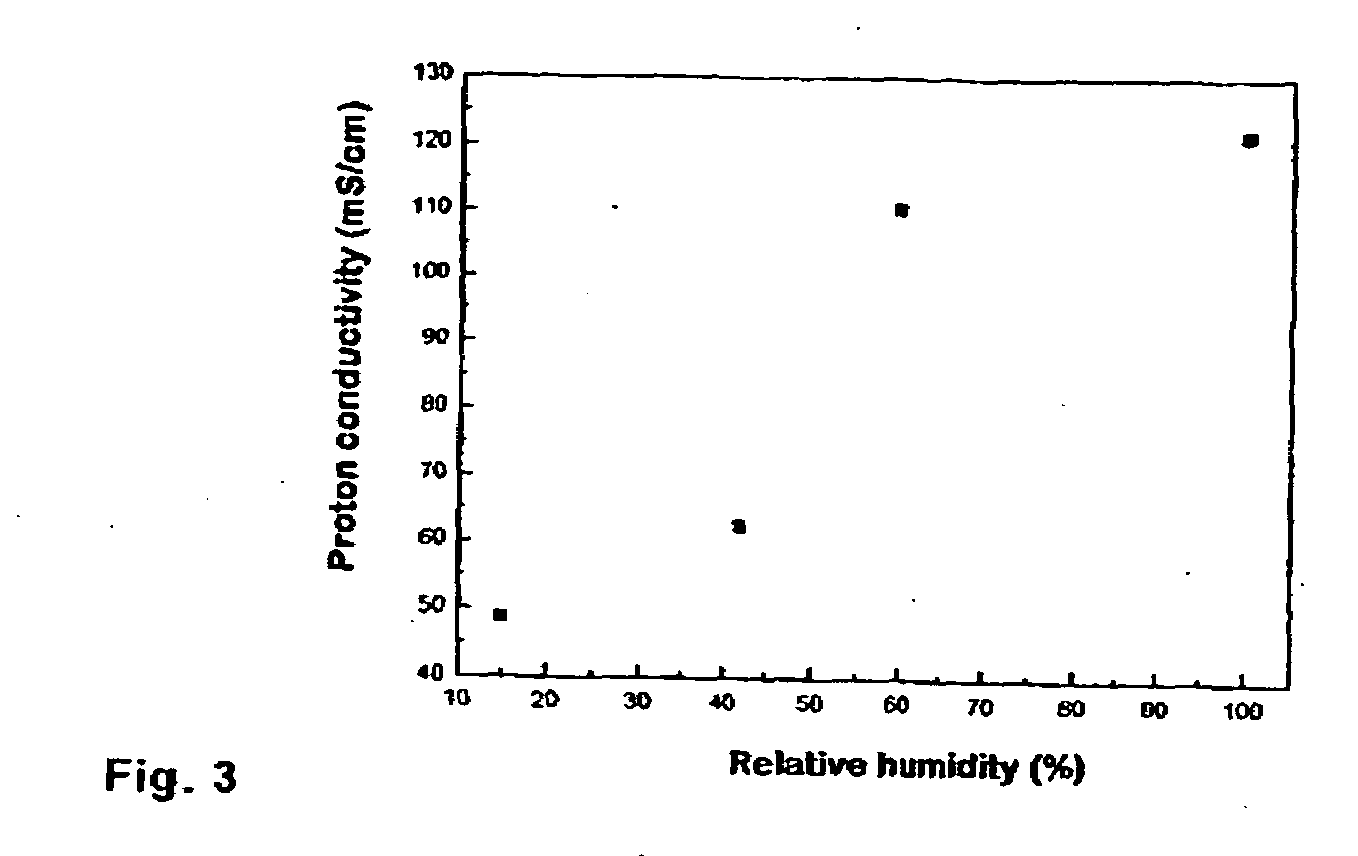

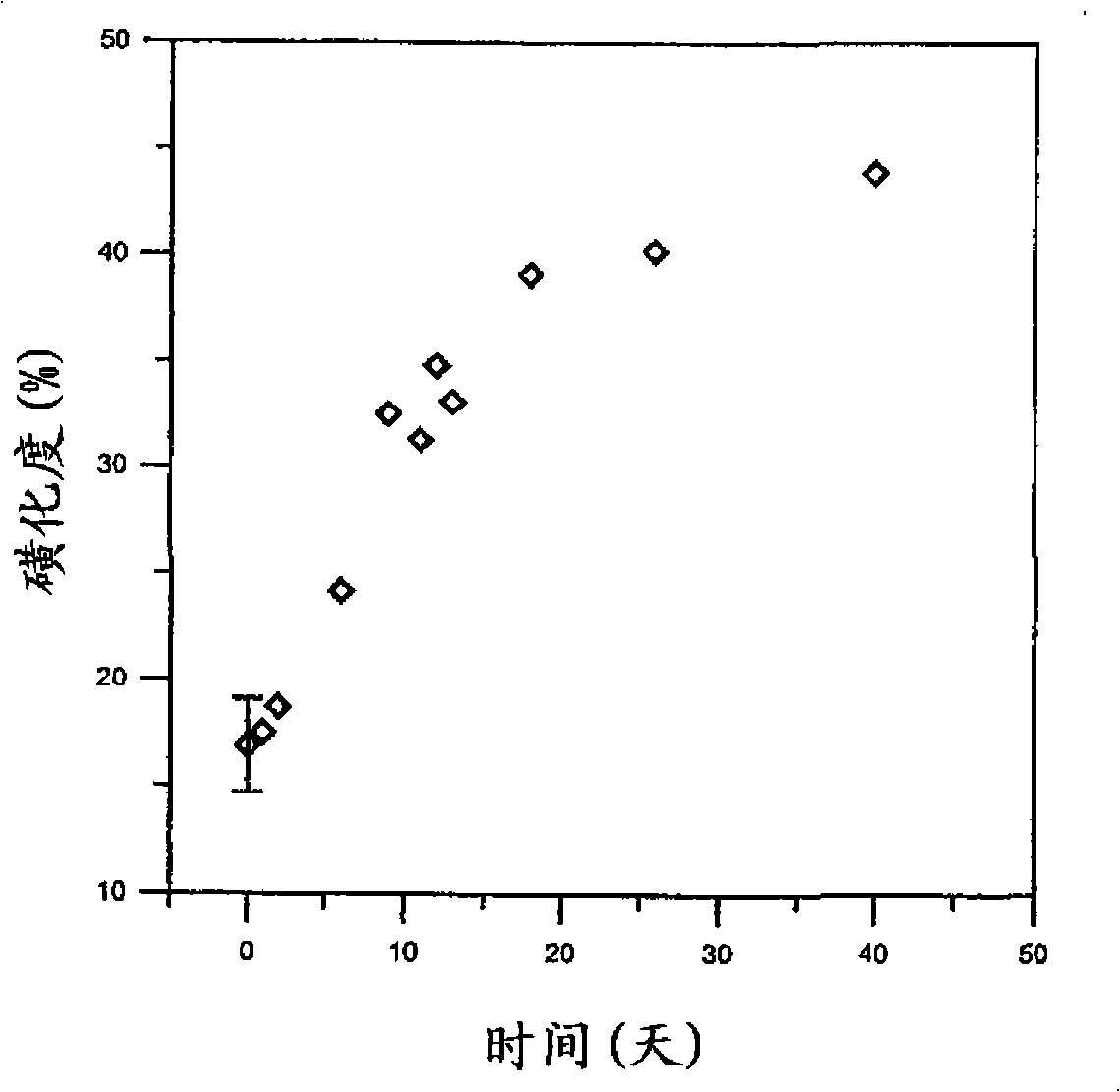

Method for the production of a sulfonated poly (1, 3, 4-oxadiazole) polymer

A sulfonated poly(1,3,4-oxadiazole) polymer is produced by producing of a solution of hydrazine sulfate salt and a non-sulfonated dicarboxylic acid or derivative thereof in polyphosphoric acid; heating the solution under an inert gas atmosphere; and precipitating sulfonated poly(1,3,4-oxadiazole) polymer in a basic solution.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

Method for recycling organic solvents of wastewater generated in synthesis of hydrazine hydrate by ketazine method

InactiveCN104086362AReduce pollutionIncrease added valueOrganic compound preparationOxygen compounds purification/separationAcetone productOrganosolv

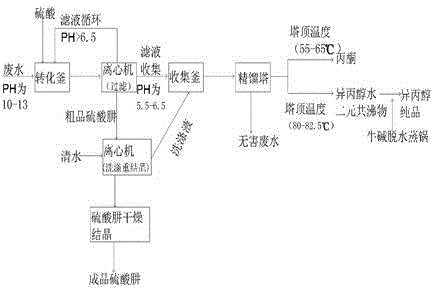

The invention relates to a method for extracting organic solvents and hydrazine sulfate from wastewater generated in synthesis of hydrazine hydrate by a ketazine method. The method comprises the following steps: converting, purifying hydrazine sulfate, rectifying and preparing isopropanol, wherein the step of conversion comprises the following steps: slowly dropping sulfuric acid into a hydrazine hydrate wastewater solution under the condition of 0-15 DEG C so as to precipitate and separate out hydrazine sulfate from the solution, and performing centrifugal filtration to obtain a crude hydrazine sulfate product; the step of purifying hydrazine sulfate comprises the following steps: filtering the crude hydrazine sulfate product, washing for 2-3 times by using cold water, and performing centrifugal filtration and drying crystallization so as to obtain a pure hydrazine sulfate product; the step of rectifying comprises the following steps: collecting filtrate and a washing liquid, feeding into a rectifying tower, rectifying when the tower top temperature is 55-56 DEG C so as to collect a pure acetone product, and rectifying when the tower top temperature is 80-82 DEG C so as to collect binary azeotrope of isopropanol-water; the step of preparing isopropanol comprises the following steps: dehydrating the binary azeotrope of isopropanol-water by using caustic soda flakes, and subsequently distilling, thereby obtaining a pure isopropanol product.

Owner:潍坊蓝海环境保护有限公司

Two step preparation of random polyoxadiazole copolymer and articles resulting therefrom

InactiveUS20070255037A1High viscosityExtrusion stabilityMonocomponent synthetic polymer artificial filamentOrganic chemistryCopolymer

In a preparation of random polyoxadiazole copolymer by reaction of a mixture of oleum, hydrazine sulfate, terephthalic acid, and isophthalic acid, the improvement requires the addition of oleum in more than one step.

Owner:DUPONT SAFETY & CONSTR INC

Method for recovering hydrazine sulfate and chromium hydroxide from chromium-containing waste acid

InactiveCN102101732AReasonable useEasy to operateMultistage water/sewage treatmentHydrazineChromium(III) hydroxideSulfate

The invention discloses a method for recovering hydrazine sulfate and chromium hydroxide from chromium-containing waste acid, which comprises the following steps of: diluting hydrazine hydrate, slowly adding waste acid into the hydrazine hydrate with stirring, ensuring an acid adding end point when the pH of feed liquid is 0.8-1.2, and reacting hexavalent chromium in the waste acid with the hydrazine hydrate to reduce the hexavalent chromium into trivalent chromium and generate indissoluble hydrazine sulfate crystals; performing solid-liquid separation to obtain crude hydrazine sulfate and acidic chromium sulfate solution; adding alkali into acidic chromium sulfate solution for neutralization to obtain a chromium hydroxide precipitate, performing solid-liquid separation, washing with water, and drying to obtain an industrial product chromium hydroxide meeting quality requirement; and treating wastewater subjected to solid-liquid separation and washing in a wastewater treatment device for up-to-standard emission. The method is easy to operate, and the chromium-containing waste acid is treated for up-to-standard emission; meanwhile, the hydrazine sulfate and chromium hydroxide are recovered, so that the resources are reasonably utilized and the economic benefit is obvious.

Owner:NANJING UNIV

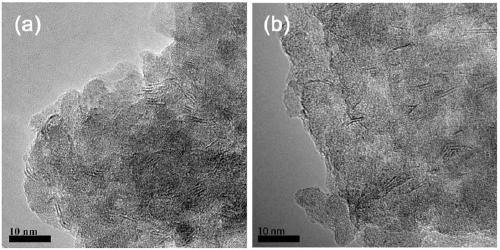

Method for synthesizing catalyst capable of efficiently decomposing hydrazine at room temperature

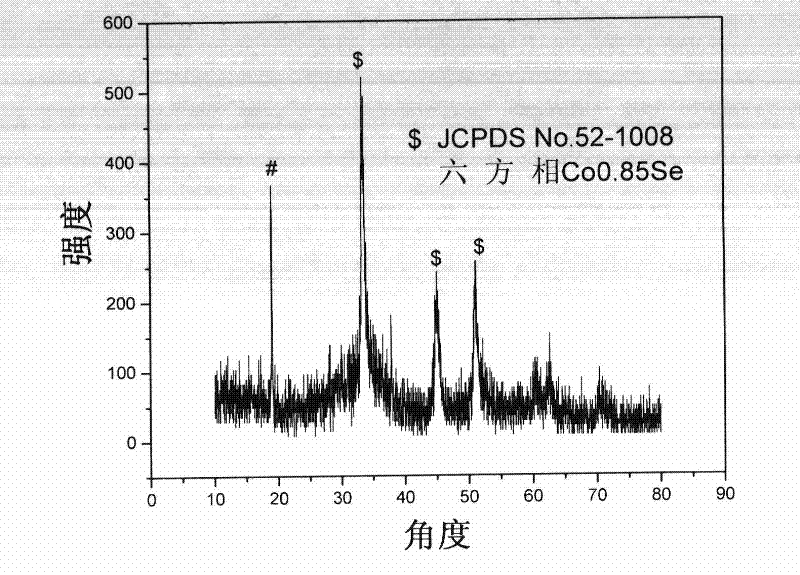

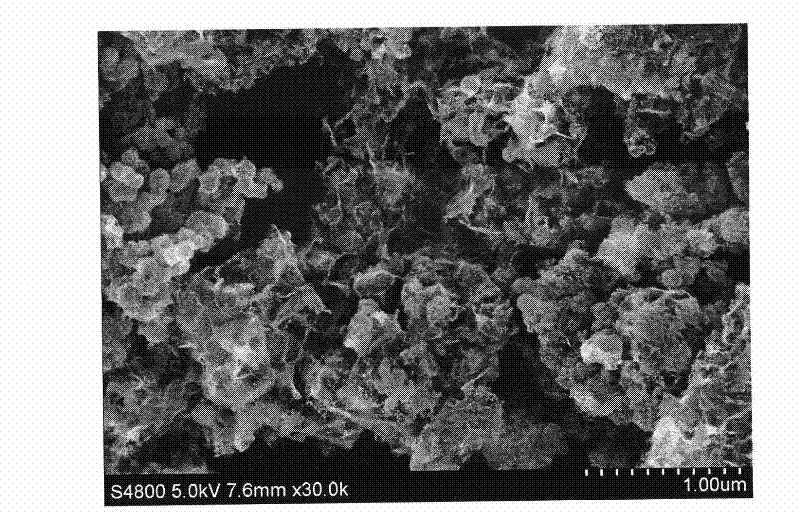

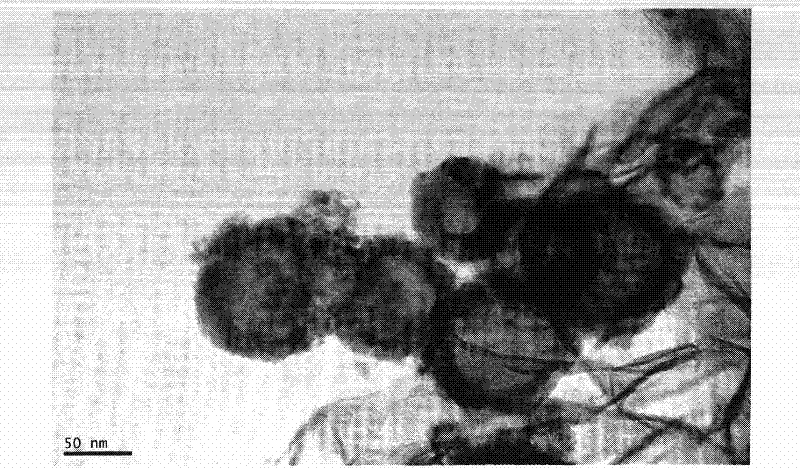

InactiveCN102225340AHigh catalytic activitySmall particlesPhysical/chemical process catalystsWater/sewage treatment by irradiationHydrazine compoundSynthesis methods

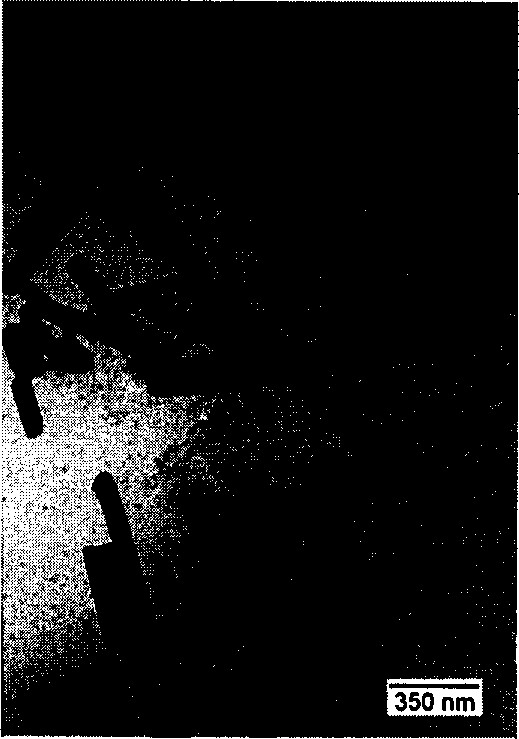

The invention provides a method for preparing a cobaltous selenide nanometer sheet which is a catalyst capable of efficiently decomposing hydrazine compounds. The method belongs to the field of nanometer material synthesis and application. The method comprises the following steps: respectively weighting a certain amount of cobalt source predecessor and selenium source predecessor, taking a solvent and a reducing agent in defined volumes, and putting the weighted and taken materials into a high-pressure reactor; stirring the materials for 20 minutes by using a stirrer; after fully dissolving the materials, sealing the reactor and placing the reactor in an oven at 140 DEG C; after reacting for 24 hours, taking out the reactor and naturally cooling; and using ethanol and distilled water to respectively wash a reaction product for three times, thereby acquiring a sample. According to the method, an organic mould plate and a surface active agent are unnecessary, the cobaltous selenide nanometer sheet is synthesized in one step, the yield is high and the thickness of the cobaltous selenide nanometer sheet is small. The method has simple and energy-saving preparation process and is fit for industrial production. The acquired cobaltous selenide nanometer sheet has the advantages of small thickness, big specific surface area and excellent function for catalyzing and degrading hydrazine compounds, such as hydrazine hydrate, hydrazine chloride, hydrazine sulfate, and the like.

Owner:ANHUI UNIVERSITY

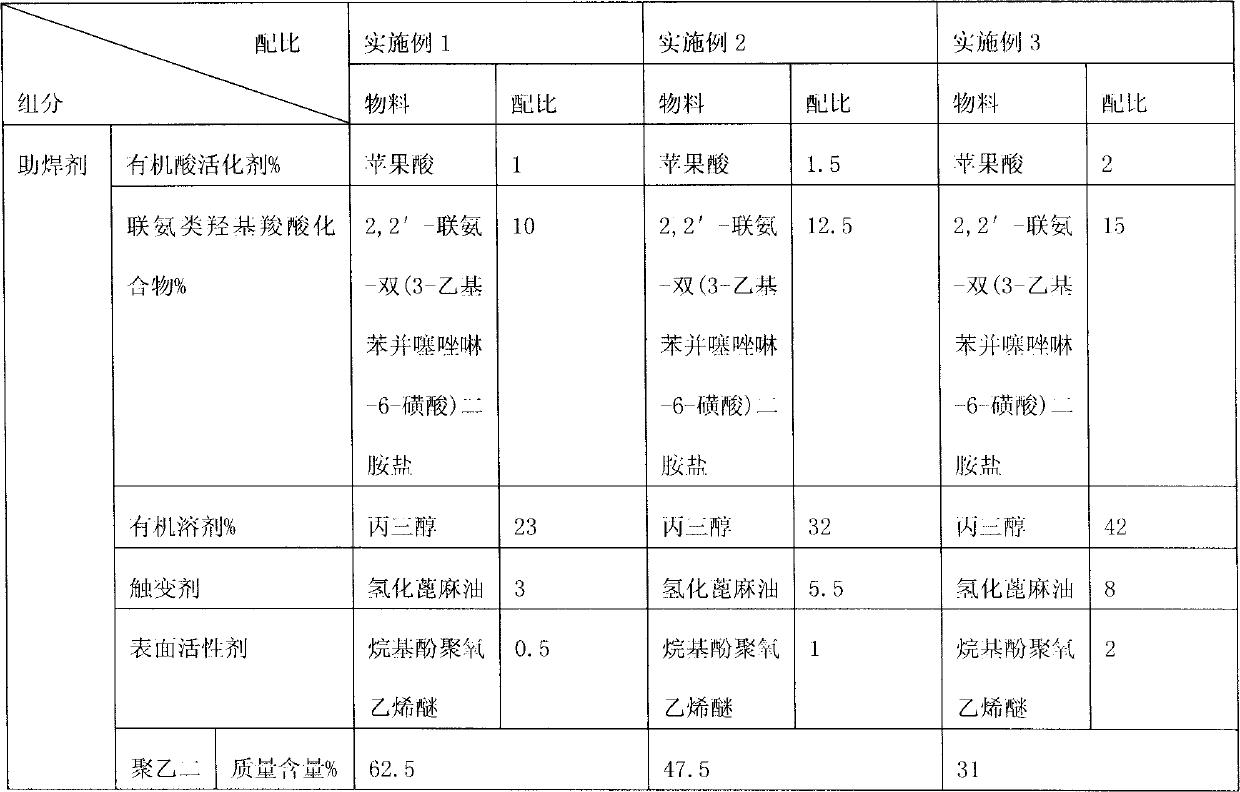

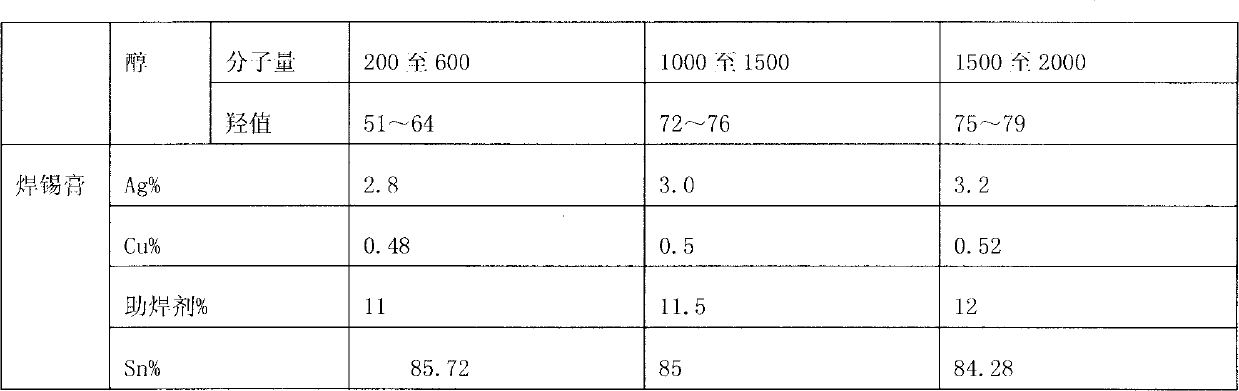

Halogen-free lead-free soldering paste and soldering flux used by same

ActiveCN102166689AHigh insulation resistanceReduce interfacial tensionWelding/cutting media/materialsSoldering mediaSolubilityGlutaric acid

The invention discloses a halogen-free lead-free soldering paste and a soldering flux used by the same. The soldering paste comprises the following components: 2.8-3.2% of Ag, 0.48-0.52% of Cu, 11-12% of soldering flux, and the balance of Sn, wherein the soldering flux comprises the following components: 1-2% of organic acid activating agent, 10-15% of hydrazine hydroxy carboxylic acid compound, 23-42% of organic solvent, 3-8% of thixotropic agent, 0.5-2% of surface active agent, and the balance of water-solubility macromoleclar polymer; and the above percent is mass percent; the organic acidis malic acid, sebacic acid, adipic acid, glutaric acid, or octanedioic acid; the hydrazine hydroxy carboxylic acid compound is 2,2'-azino-bis(3-ethylbenzothiazoline-6-sulfonate) diammonium salt, or 3-hydroxy-2-naphthoic acid, or hydrazine sulfate; the organic solvent is glycerol and glycol; the thixotropic agent is hydrogenated castor oil or ethylene bis stearamide; the surface active agent is alkylphenol ethoxylates or octylphenol ethoxylates; and the water-solubility macromoleclar polymer is polyethylene glycol the molecular weight of which is 200-2000. The soldering paste and the soldering flux used by the same have better welding performance.

Owner:浙江强力控股有限公司

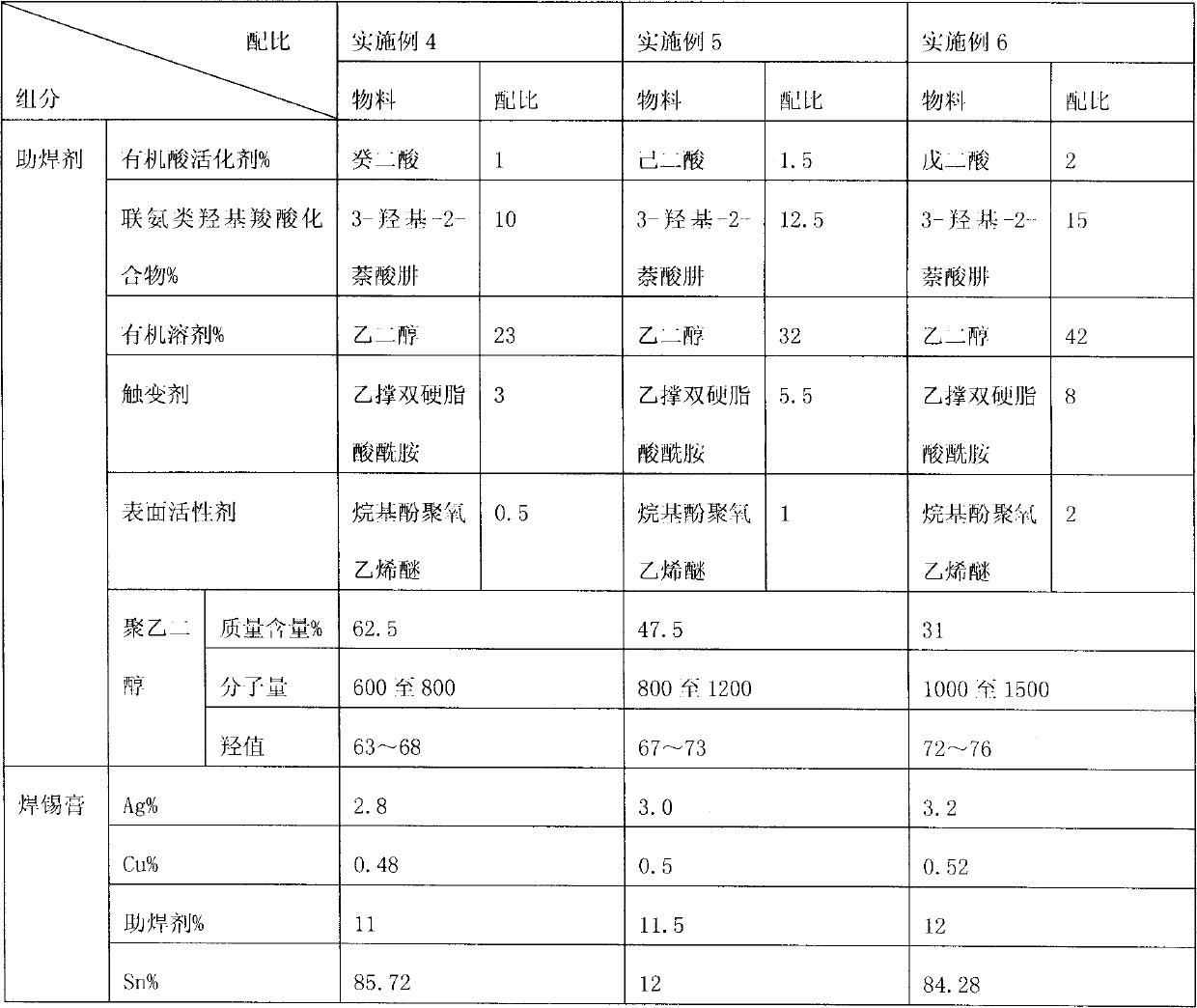

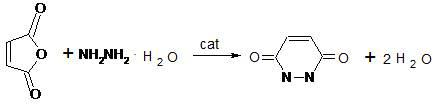

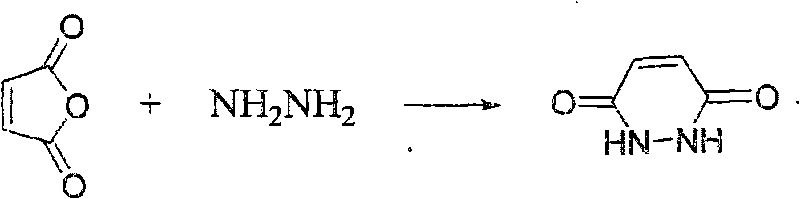

Method for preparing maleic hydrazide

The invention discloses a method for preparing maleic hydrazide. The method is characterized in that after dilute sulfuric acid reacts with hydrazine hydrate to produce a hydrazine sulfate water solution, the hydrazine sulfate water solution conducts cyclization reaction with maleic anhydride under the effect of an organic acid catalyst and is then neutralized to a pH (hydrogen ion concentration) value of 5.0 to 7.0 by using an inorganic base; after the hydrazine sulfate water solution is washed and dried, the maleic hydrazide is acquired; the temperature at which the cyclization reaction is conducted is 70 DEG C to 96 DEG C, and the reaction time is 1.0 hour to 4.0 hours; and the molar ratio of hydrazine hydrate to organic acid catalyst to sulfuric acid to maleic anhydride is 1 to 0.01-0.3 to 1.0-3.0 to 1.0-1.5. The method disclosed by the invention has the advantages that the operation is safe, simple and convenient, the yield is high, the product quality satisfies the international standard, so that the method is very suitable for industrialized production.

Owner:LIANYUNGANG JINDUN AGROCHEMICAL CO LTD

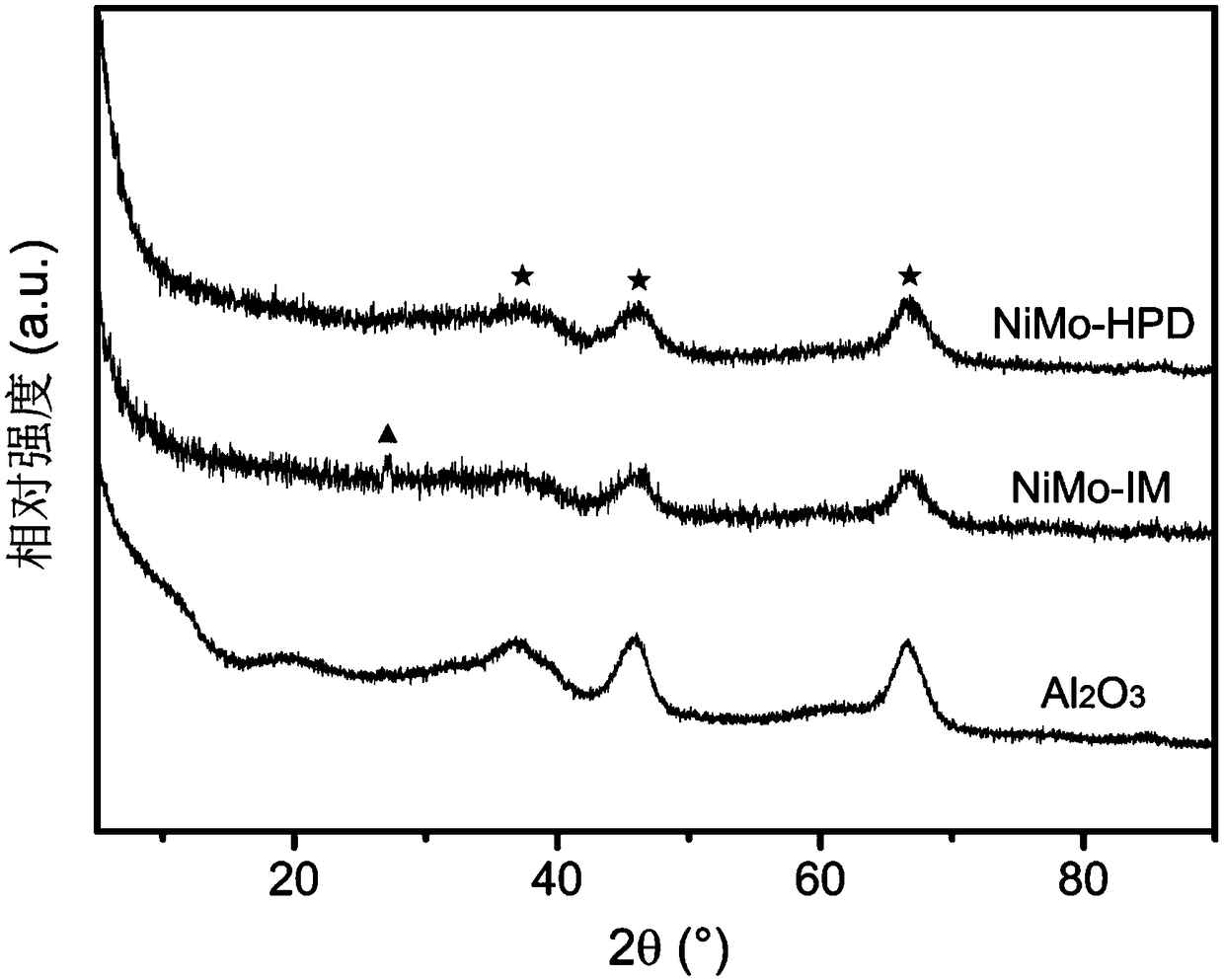

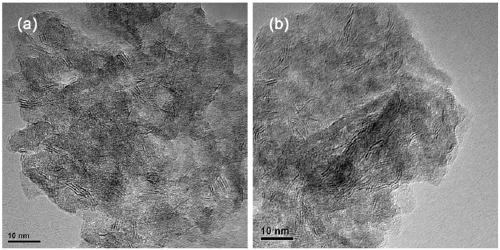

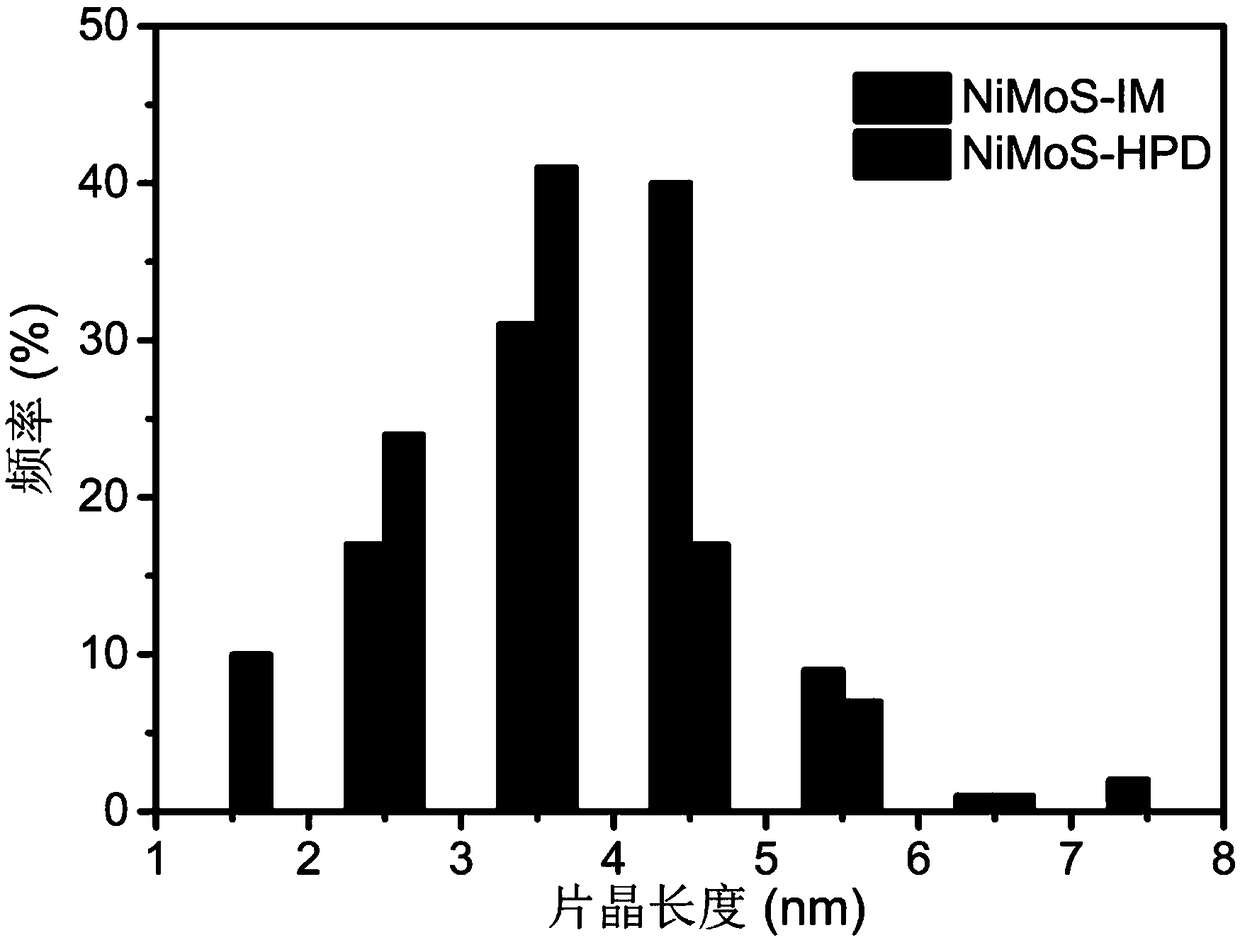

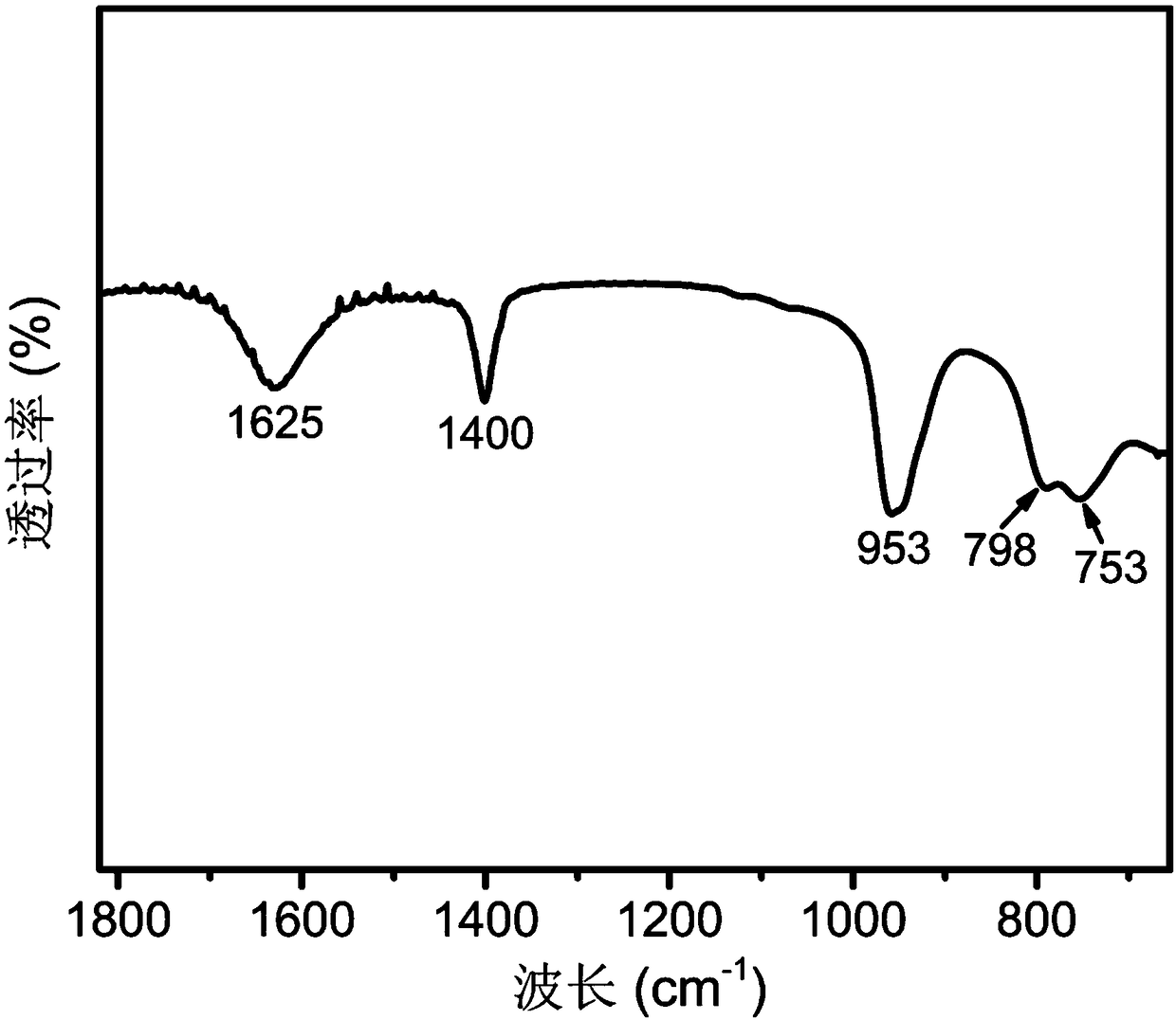

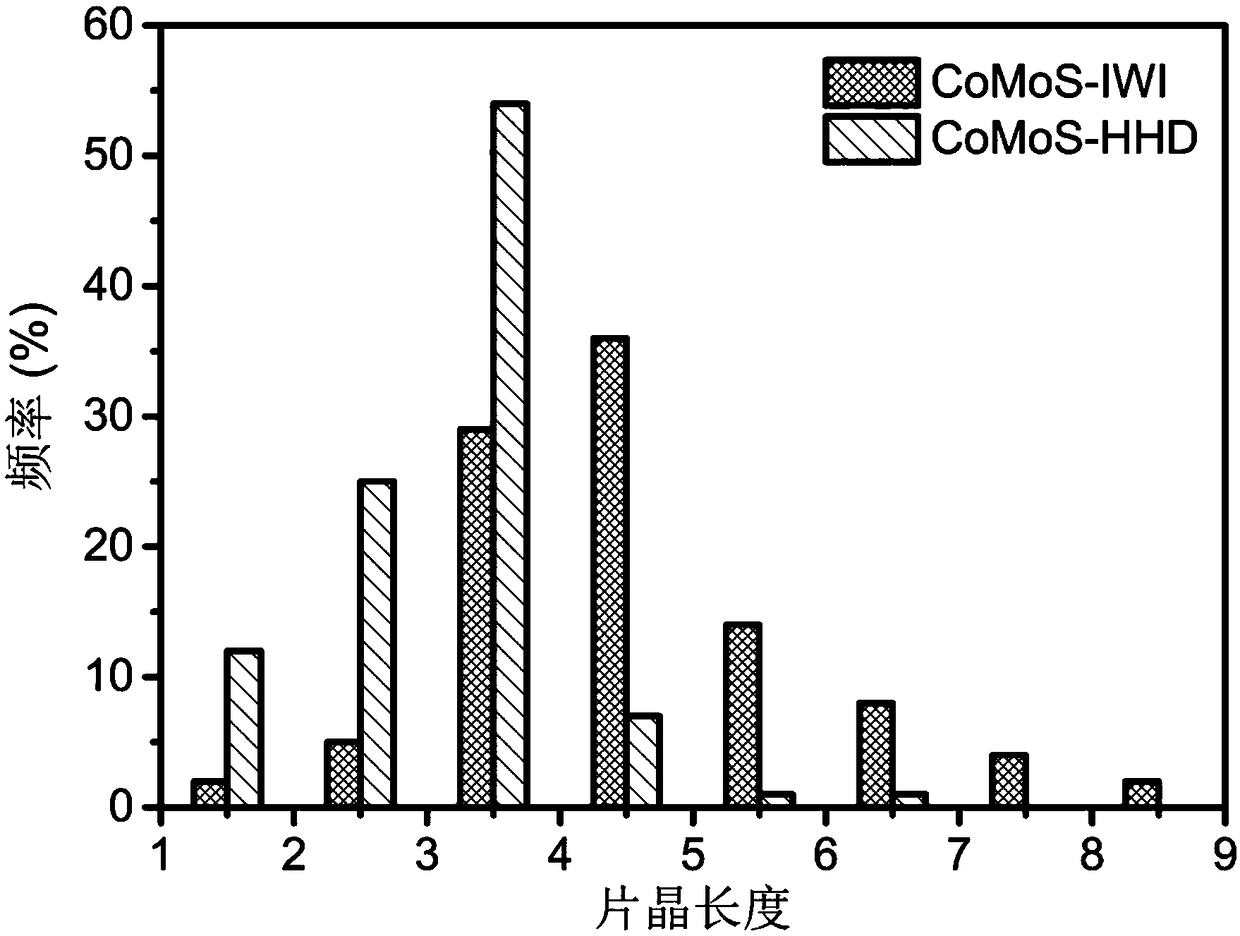

Ultra-deep desulfurization catalyst, preparation method thereof and application of catalyst

ActiveCN109364957ATightly boundIncrease the level of retouchingCatalyst activation/preparationHydrocarbon oils treatmentWater bathsAcetic acid

The invention provides an ultra-deep desulfurization catalyst, a preparation method thereof and an application of the catalyst. The preparation method of the desulfurization catalyst includes the steps: weighing ammonium paramolybdate and nickel acetate tetrahydrate, dissolving the ammonium paramolybdate and the nickel acetate tetrahydrate in glacial acetic acid and water mixed solution in a stirring manner; adding hydrazine sulfate and dissolving the hydrazine sulfate in a stirring manner; performing stirring reaction in a thermostatic water bath to obtain polyoxometallate after reaction; dispersing the polyoxometallate in water and performing ultrasonic treatment; adding aluminum oxide, uniformly stirring the materials and performing hydro-thermal decentralization loading in an autoclaveto obtain the desulfurization catalyst after reaction. The prepared desulfurization catalyst is good in dispersing performance and high in activity, ultra-deep desulfurization can be achieved, and desulfurization rate reaches up to 93.8%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

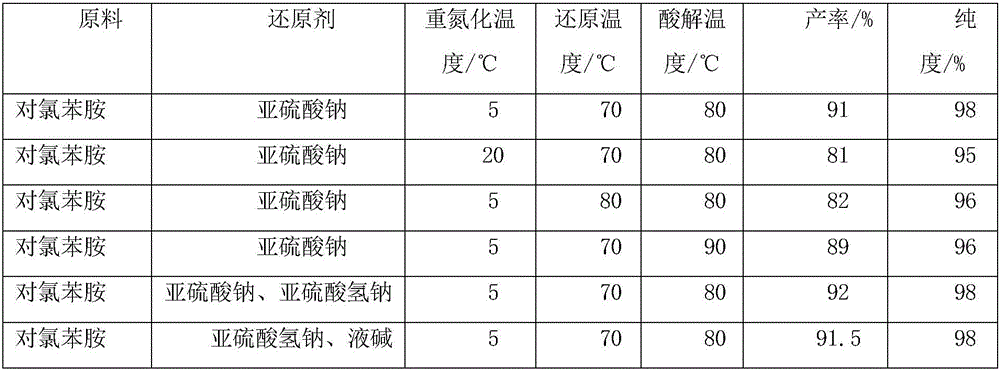

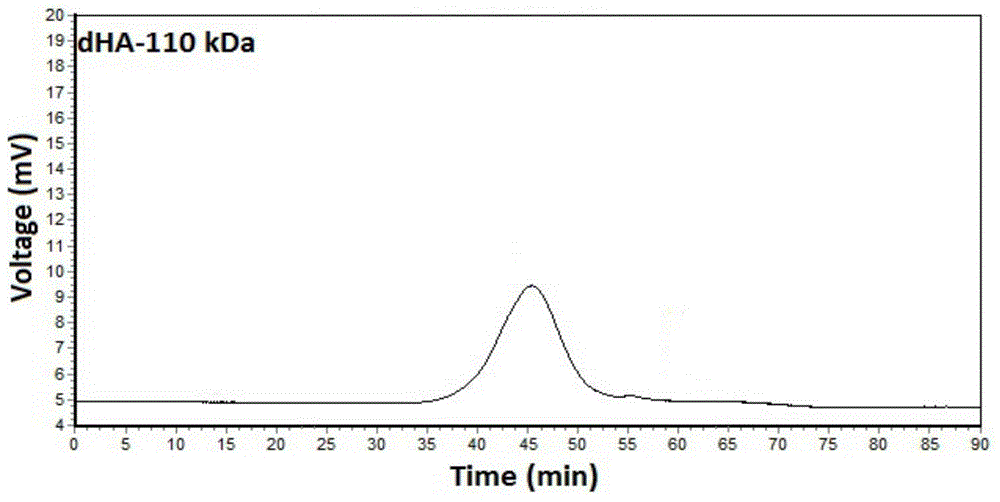

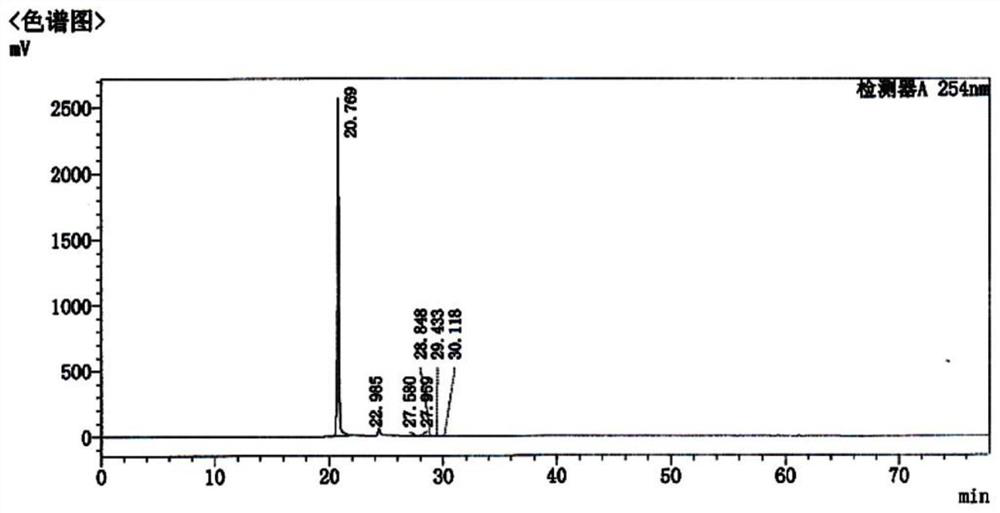

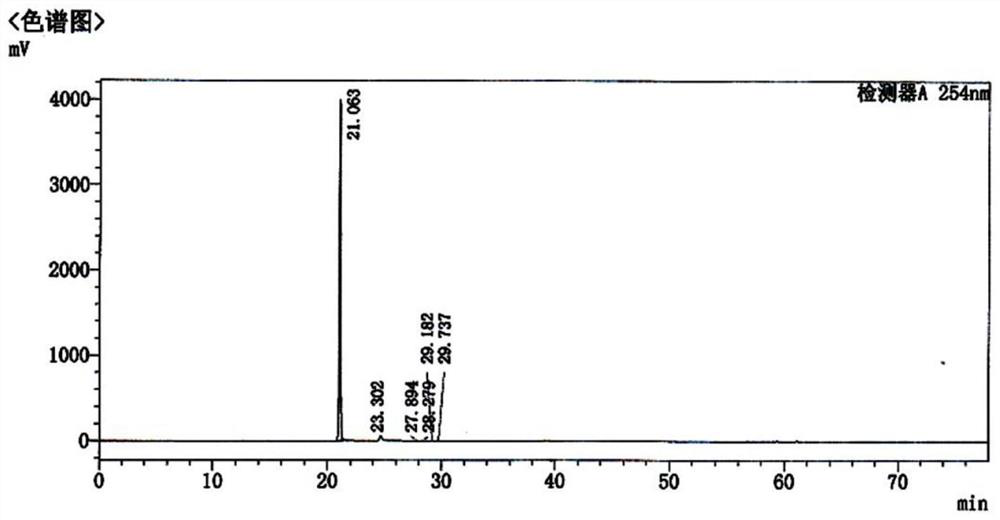

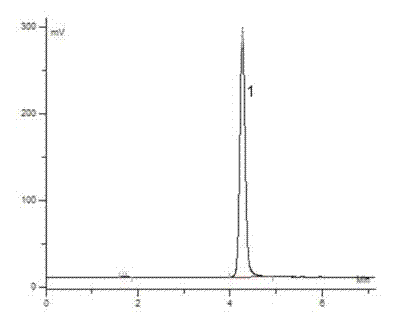

Synthesis method for aromatic hydrazine sulfate

The invention discloses a synthesis method for aromatic hydrazine sulfate. The synthesis method includes the steps that firstly, aromatic amine is added in sulfuric acid with the mass fraction ranging from 15% to 65%, the temperature is lowered to -5-15 DEG C, a diazotization reagent is dropwise added in the reaction liquid, and diazonium salt is obtained after reaction; secondly, a reducing agent is prepared into a solution, a reducing solution is obtained, the diazonium salt obtained in the first step is dropwise added in the reducing solution, heating reduction is conducted after drop-by-drop addition is completed, and reducing material liquid is obtained through filtration; and thirdly, the reducing material liquid obtained in the second step is heated, dilute sulphuric acid is dropwise added in the reducing material liquid to conduct the acidolysis reaction, the temperature is lowered after the reaction is finished, the aromatic hydrazine sulfate is separated out, a filter cake and filtrate are obtained through filtration, the filter cake is washed with dilute sulphuric acid, and an aromatic hydrazine sulfate product is obtained, and sodium sulfate salt is recycled after the filtrate is preprocessed. Compared with a traditional process, the obtained aromatic hydrazine sulfate is high in yield and purity, the purity reaches 97% or above, the yield is higher than 91%, salt in the wastewater obtained through the reaction is the simplex sodium sulfate salt, and the recycling value is high.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

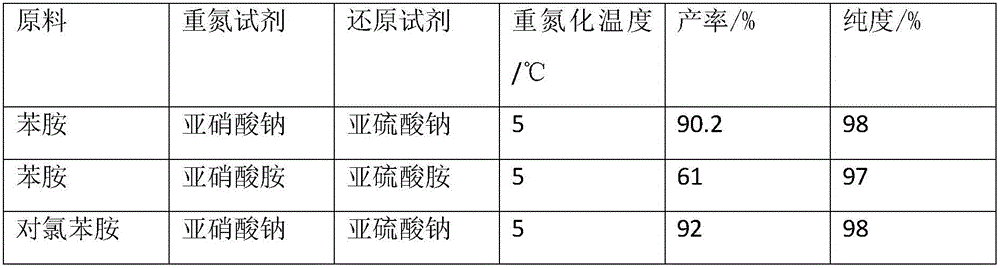

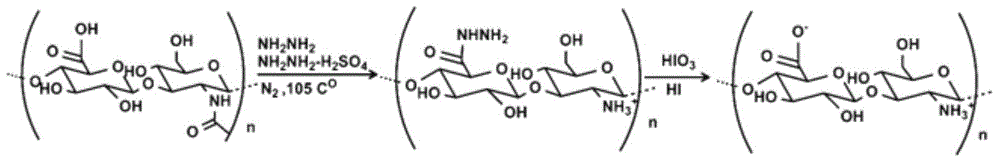

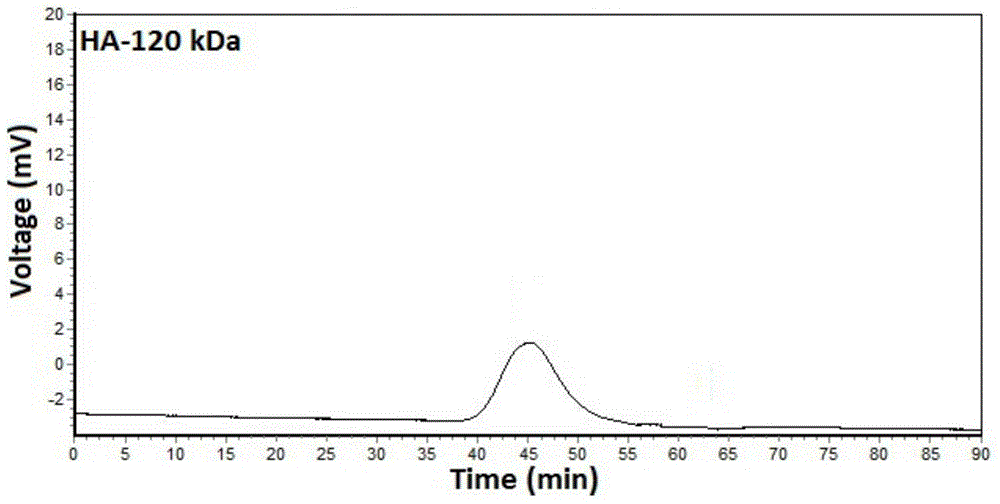

Preparation method and application of high-molecular-weight deacetylated hyaluronic acid

InactiveCN104910294AIncreased degree of deacetylationGood degree of deacetylationImmunological disordersFreeze-dryingIodic acid

The invention discloses a preparation method and application of high-molecular-weight deacetylated hyaluronic acid. The preparation method comprises the following steps: dissolving hyaluronic acid in anhydrous hydrazine containing 1% of hydrazine sulfate, reacting in a deoxidized nitrogen protective atmosphere at 60 DEG C for 72 hours, precipitating the reaction product with cold ethanol, dissolving the precipitate in 5% glacial acetic acid, adding 0.5M of iodic acid, standing at 4 DEG C for 2 hours, and adding excessive iodic acid into 57% hydriodic acid; and carrying out ether extraction to remove generated iodine, neutralizing, and carrying out freeze-drying to obtain the high-molecular-weight deacetylated hyaluronic acid. The zwitterion hyaluronic acid polysaccharide disclosed in the invention is used for immunological diseases, and has the advantages of obvious curative effect and no side effect.

Owner:NORTHWEST A & F UNIV

Method for preparing 3, 3 ', 4, 4'-biphenyltetracarboxylic dianhydride

ActiveCN111620769AEase of industrial productionAvoid residueOrganic compound preparationMetal/metal-oxides/metal-hydroxide catalystsMethanol waterPtru catalyst

The invention discloses a method for preparing 3, 3 ', 4, 4'-biphenyltetracarboxylic dianhydride. The method comprises the following steps: 1) coupling and acid precipitation: reducing a chlorinated phthalate monosodium salt mixture by a hydrazine reducing agent under the catalysis of a palladium-copper carbon supported catalyst by taking water as a solvent, carrying out a dechlorination couplingreaction to obtain 3, 3 ', 4, 4'-biphenyltetracarboxylic acid, adding filtrate after the catalyst is filtered into dilute sulfuric acid, and carrying out cooling crystallization to obtain a 3, 3 ', 4,4'-biphenyltetracarboxylic acid crude product; 2) refining: refining with a methanol aqueous solution to obtain a 3, 3 ', 4, 4'-biphenyltetracarboxylic acid refined product; and 3) anhydrous treatment: heating and dehydrating the 3, 3 ', 4, 4'-biphenyltetracarboxylic acid fine product to obtain the 3, 3 ', 4, 4'-biphenyltetracarboxylic dianhydride. The raw materials are easy to obtain, the palladium-copper carbon supported catalyst is adopted, and a proper dechlorination coupling reducing agent hydrazine sulfate is preferably selected, so that the conversion rate of the chlorinated sodium phthalate mixture reaches 100%; a proper solvent system is selected, a product is finally obtained, the content is larger than 99.7%, the yield is 81%-87%, and metal ions are smaller than 2 ppM.

Owner:河北东丽新材料有限公司

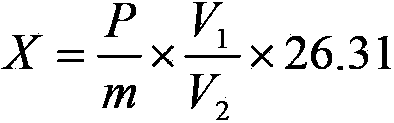

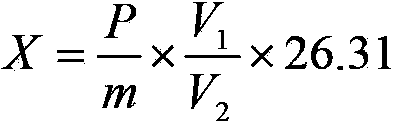

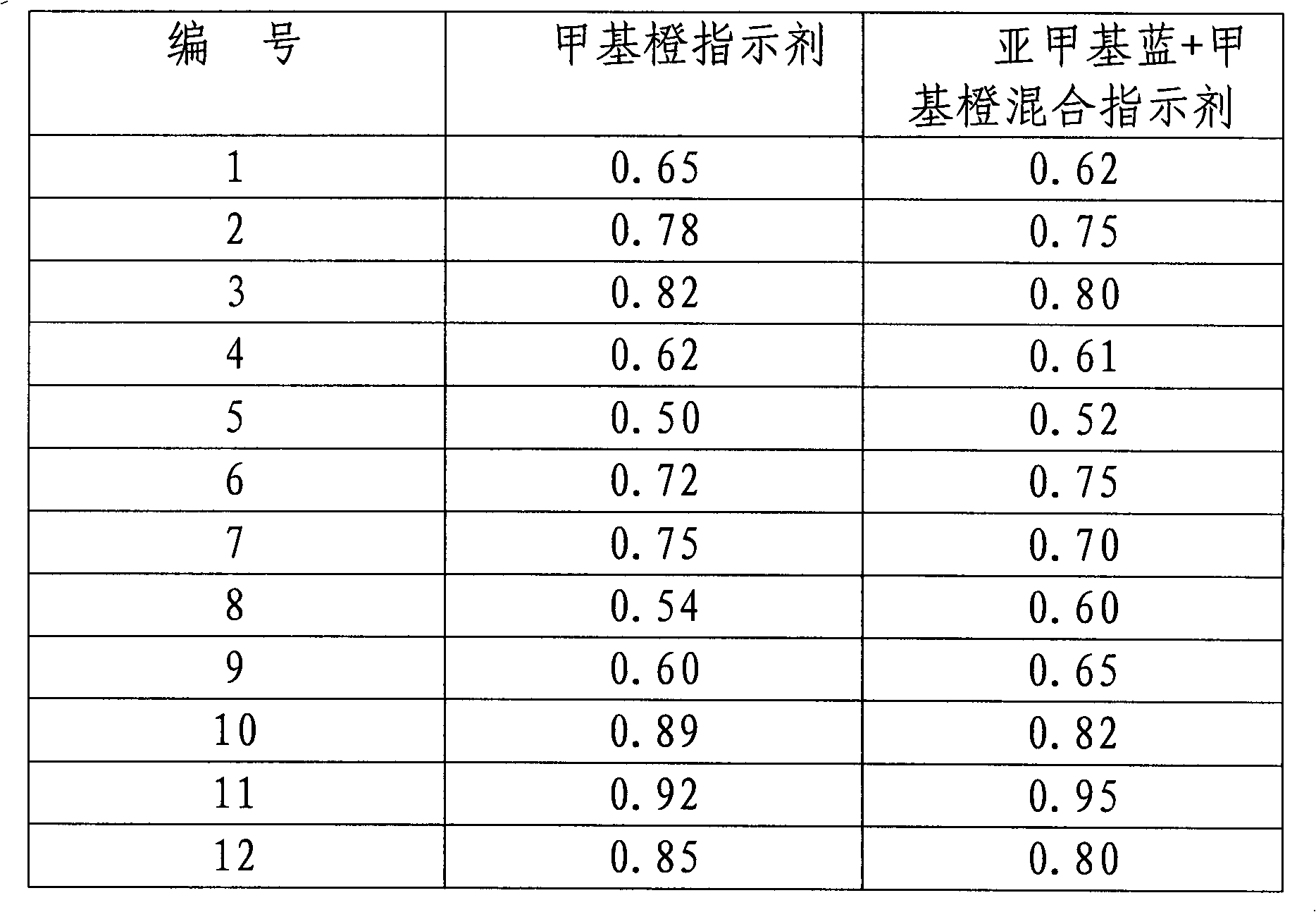

Microwave digestion method for the determination of phosphorus / phosphatide content in oil

InactiveCN103969248AMeet testing needsShort analysis timePreparing sample for investigationAnalysis by subjecting material to chemical reactionPhosphateDigestion

The invention relates to a microwave digestion method for the determination of phosphorus / phosphatide content in oil. The method is as below: adding 4-8mL of nitric acid and 1-3mL of hydrogen peroxide into 0.2g of a sample, digesting the sample in a microwave digestion instrument, setting the digestion liquid to a determined volume in a volumetric flask and shaking uniformly; preparing a hydrazine sulfate solution and an ammonium molybdate sulfuric acid solution; drawing a standard curve to form a curve equation; preparing a phosphate standard solution for the standard curve; adding the hydrazine sulfate solution and the ammonium molybdate sulfuric acid solution into the digestion solution in the volumetric flask; diluting with deionized water to the scale, shaking uniformly, standing, and measuring the absorbance at the wave length of 650nm by using deionized water as the blank; and checking the amount of phosphorus from the standard curve according to the absorbance of the measured solution, and calculating the phosphatide content according to a formula as below. According to the method, nitric acid and hydrogen peroxide are added into the sample, which is digested in a micro wave digestion furnace; and the method can substitute a phosphatide dry ashing determination method, and has the advantages of greatly shortened analysis time, direct volume setting of the digestion liquid, convenience for the following operations and accurate and reliable determination results.

Owner:PETROCHINA CO LTD

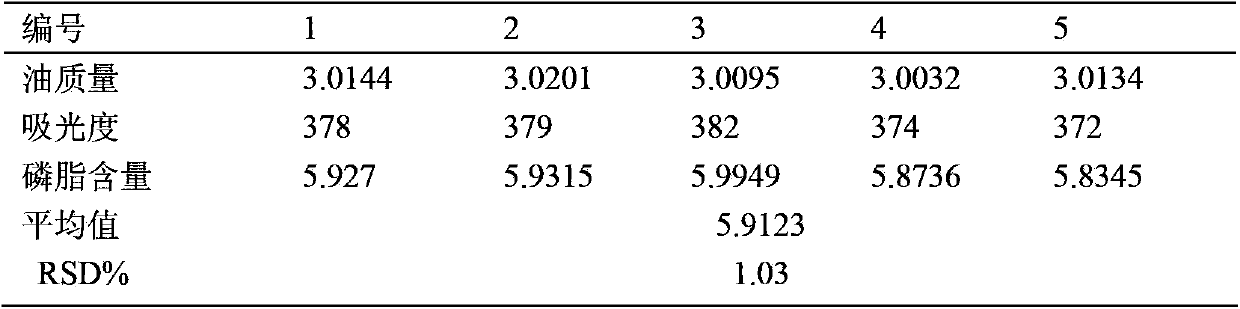

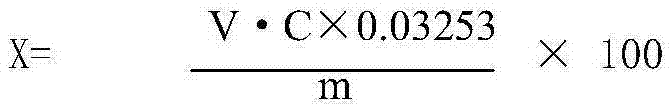

Method for determination of antimony content in smelting slag

InactiveCN102914618AEasy to operateReal reaction real tasteChemical analysis using titrationPreparing sample for investigationPotassium fluorideDecomposition

The present invention discloses a method for determination of the antimony content in a smelting slag, which comprises the following steps: (1) weighing a certain amount of a slag sample, and placing in a conical flask; (2) adding a certain amount of potassium sulfate, potassium fluoride dehydrate, and a sulfuric acid solution to dissolve the sample, and then heating the test sample on an electric hot plate for decomposition; and after most of the sulfur is expelled, covering by a watch glass, and further heating on the electric hot plate, so that the sample was dissolved completely; (3) taking down the test sample and cooling a little, adding a certain amount of hydrazine sulfate and heating continuedly for 10-15 minutes; (4) taking down and cooling the test sample; adding a certain amount of water, and hydrochloric acid, mixing uniformly; adding a certain amount of phosphoric acid, and mixing uniformly in on the electric hot plate for continue heating, temperature controlled at 80 DEG C to 90 DEG C; (5) taking down the test sample, adding a little methylene blue and a little methyl orange, mixing as an indicator; titrating with the cerium sulfate standard solution; and calculating the content of antimony ions according to the consumption of the cerium sulfate standard solution. By using the method, the result is easy to judge, and the determination is rapid and accurate.

Owner:湖南东港锑品有限公司

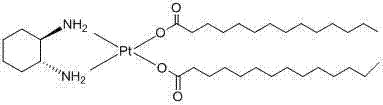

New method for synthesizing anti-tumor drug miboplatin

The invention relates to a preparation method of anti-tumor drug miboplatin, which comprises the process flow: based on K4PtC14 as a starting material, reacting K4PtC14 with sodium nitrite to generate a K4Pt(NO2)4 solution; reacting with (1R, 2R)-1, 2-cyclohexanediamine to generate cis-dinitroso-(1R, 2R)-1, 2-cyclohexanediamine platinum (II); and reducing NO2<-> using hydrazine sulfate, and reacting the obtained solution with n-butanol solution of sodium n-tetradecyl carbonate to generate miboplatin. In the method, silver ions are not introduced and toxic solvents such as chloroform are not used.

Owner:KUNMING GUIYAN PHARMA

Method for preparing maleichydrazide

InactiveCN101735154AHigh yieldQuality improvementOrganic chemistryHydrazine compoundRoom temperature

The invention relates to a method for preparing maleichydrazide of a plant growth inhibitor, which is characterized by comprising the following steps of: reacting concentrated sulfuric acid with hydrazine hydrate to form a hydrazine sulfate aqueous solution; then adding organic aromatic acid as a catalyzer to react with maleic anhydride under refluxing under the condition of temperature rise; adding inorganic base to neutralize until the pH is 5.0-7.0; and rinsing with water at room temperature to remove hydrazine residues to obtain the maleichydrazide. The invention has safe and convenient operation and high yield, and the product quality meets the international standards, and thereby, the invention is extremely suitable for industrial production.

Owner:亚邦投资控股集团有限公司

Deep desulfurization catalyst and preparation method and application thereof

ActiveCN109289876ATightly boundIncrease the level of retouchingCatalyst activation/preparationHydrocarbon oils treatmentWater bathsAcetic acid

The invention provides a deep desulfurization catalyst and a preparation method and application thereof. The preparation method of the deep desulfurization catalyst includes: weighing ammonium paramolybdate and cobalt acetate tetrahydrate, dissolving into glacial acetic acid and water mixed solution, stirring to dissolve, adding hydrazine sulfate, stirring to dissolve, performing stirring reactionin a constant-temperature water bath to obtain a cobalt-molybdenum heteropoly compound after reaction is finished; dispersing the cobalt-molybdenum heteropoly compound into water, ultrasonically treating, adding aluminum oxide, well stirring, and performing hydrothermal load dispersion in an autoclave to obtain the desulfurization catalyst after reaction is finished. The desulfurization catalystis high in dispersion performance and activity, deep desulfurization can be realized, and the desulfurization rate is up to 94.1%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for manufacturing a sulfonated poly(1,3,4-oxadiazol) polymer

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

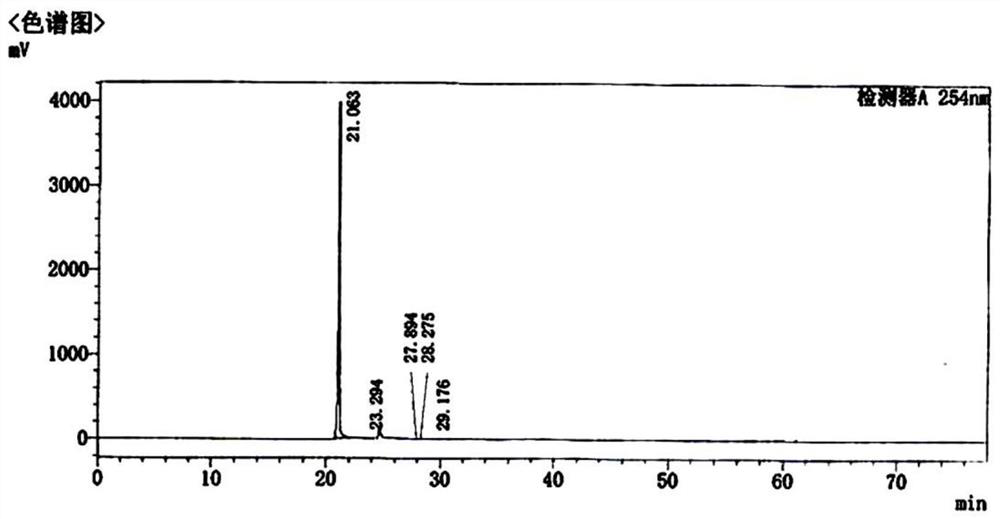

Preparation method of HA/RGD double-receptor multi-target-point drug administration system

InactiveCN105688221AImprove bindingGrowth inhibitionOrganic active ingredientsMacromolecular non-active ingredientsDrug administrationDrug resistance

The invention discloses a preparation method of a HA / RGD double-receptor multi-target-point drug administration system.The method includes the following steps that hyaluronic acid and hydrazine sulfate are dissolved in hydrazine, reaction is performed for 1-12 h under the protection of inert gas at the temperature of 60-115 DEG C so that deacetylated HA can be obtained; RGD is dissolved in water, an EDC / NHS solution is activated, pH of the solution is adjusted to be 3.5-6.5, the deacetylated HA aqueous solution is dropwise added, reaction is performed for 1-12 h at 4-38 DEG C, and HA-RGD is obtained; a CLB-ADH aqueous solution is dropwise added into the HA-RGD aqueous solution, reaction is performed for 1-12 h under the condition of stirring, and the double-receptor multi-target-point drug administration system is obtained.HA and RGD can more effectively enhance combination of drugs and tumor cells, effective concentration on the tumor parts is improved, an effect-enhancing and toxicity reducing effect is achieved, meanwhile tumor cells are killed, growth of tumor microvasculature is inhibited, the effect that one drug is multipurpose is achieved, and tumor drug resistance can be effectively reversed.

Owner:WUHAN UNIV OF TECH

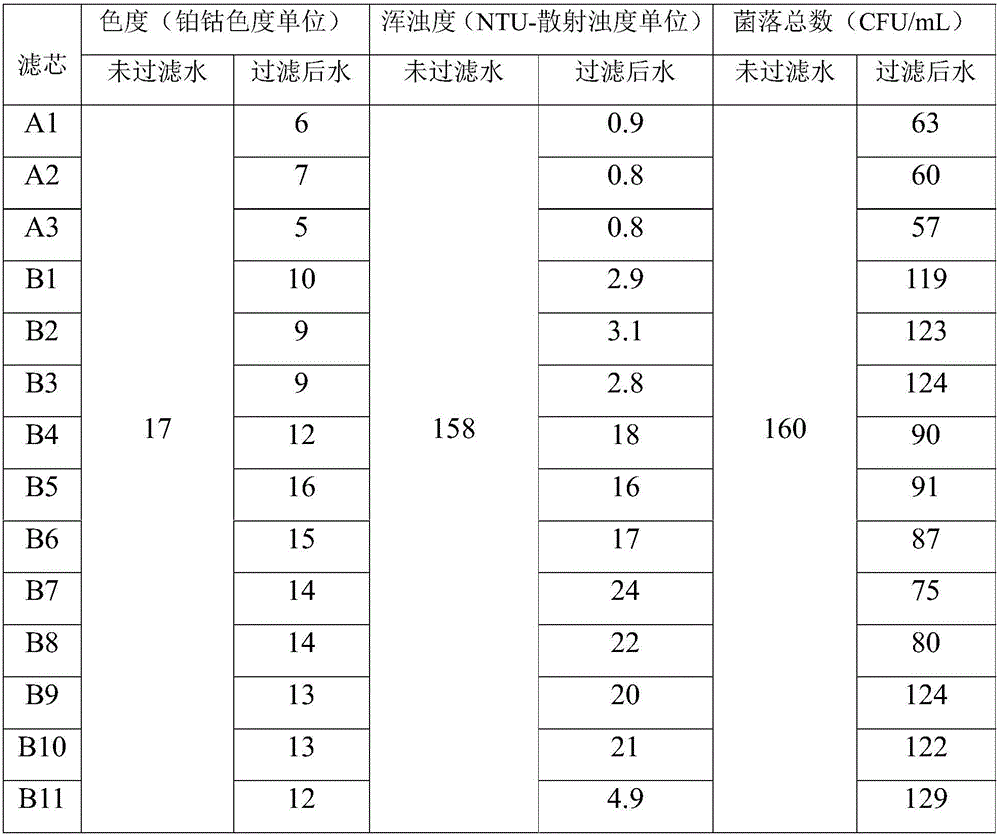

Attapulgite modification based PP (polypropylene) melt-blown filter cartridge and preparation method thereof

InactiveCN106310786AImprove filtering effectImprove antibacterial propertiesMembrane filtersFiltration separationActivated attapulgiteShielding gas

The invention discloses an attapulgite modification based PP (polypropylene) melt-blown filter cartridge and a preparation method thereof. The method includes: 1) coating the surface of attapulgite with polymer paint, drying, soaking in dilute sulphuric acid, and filtering to obtain activated attapulgite; 2) simultaneously spraying silver nitrate solution and hydrazine sulfate solution to the surface of attapulgite, and standing to obtain silver modified attapulgite; 3) decocting Chinese herbal medicines in water, and filtering to obtain Chinese herbal medicine extract liquor and a Chinese herbal medicine filter cake; 4) in existence of shielding gas, calcining the silver modified attapulgite, impregnating calcination products in the Chinese herbal medicine extract liquor, and filtering to obtain Chinese herbal medicine modified attapulgite; 5) mixing PP, AES, methyl methacrylate, alkyl glycoside, paraffin, polyhexamethyl guanidine phosphate, expanded vermiculite, D-glyceraldehyde, maltose, chloroplatinic acid, the Chinese herbal medicine modified attapulgite and the Chinese herbal medicine filter cake, and performing melt blowing to obtain the PP melt-blown filter cartridge. The PP melt-blown filter cartridge has excellent filtration and antibacterial effects.

Owner:WUHU CHENGDELONG FILTER EQUIP CO LTD

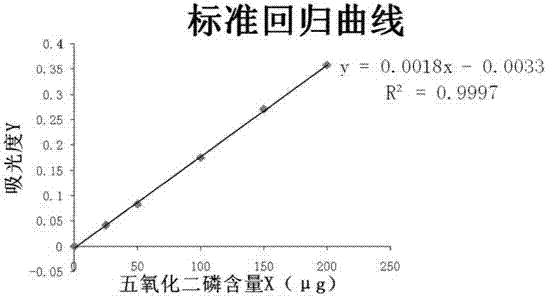

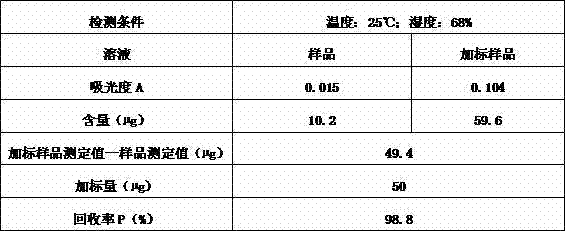

Improved spectrophotometry for phosphorus pentoxide ammonium molybdate

InactiveCN104777113ASimple stepsHigh sensitivityColor/spectral properties measurementsWater bathsPhysical chemistry

The invention relates to an improved spectrophotometry for phosphorus pentoxide ammonium molybdate. With the adoption of the improved spectrophotometry, the problem of low sensitivity of the existing determination method for the phosphorus pentoxide is mainly solved. The improved spectrophotometry is characterized by comprising the following measures: firstly, preparing standard phosphorus-pentoxide solution; secondly, taking six 50ml color-comparison tubes with stoppers, respectively adding the standard phosphorus pentoxide solution into the color-comparison tubes by 0.0ml, 2.5ml, 5.0ml, 10.0ml, 15.0ml and 20.0ml, adding 0.5ml sulfuric acid solution, 0.5ml ammonium molybdate solution and 2.0ml hydrazine sulfate solution, putting in a boiling water bath for 10 minutes, then taking out, and cooling to the room temperature; measuring the absorbancy under the 680nm wavelength, drawing a standard curve, and calculating a linear regression equation thereof; and then determining the absorbancy of the sample and calculating the recovery rate of standard addition. The improved spectrophotometry has the advantages of wide application range, simple steps, high sensitivity and good reproducibility.

Owner:ZHEJIANG ZHENGAN DETECTION TECH CO LTD

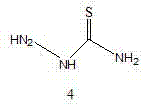

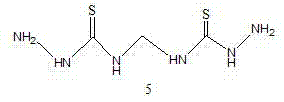

Synthesis method of bismerthiazol

ActiveCN102924403ASuitable for industrial productionOrganic chemistryAromatic solventSynthesis methods

The invention discloses a synthesis method of bismerthiazol. The method comprises the steps that firstly, hydrazine hydrate and sulphuric acid are reacted, so as to produce hydrazine sulfate; the produce hydrazine sulfate is reacted with aliphatic ketone solution of ammonium thiocyanate, so as to obtain thiosemicarbazide, and the aliphatic ketone adopts acetone or butanone; then the thiosemicarbazide is reacted with formaldehyde or paraformal-dehyde under hydrochloric acid and the effect of catalyst, so as to obtain conteben, and the catalyst adopts one or more of dimethyl sulfoxide, dimethyl formamide and pyridine; and finally, the conteben is reacted with carbon disulfide in aromatic solvent, so as to obtain the bismerthiazol. The invention further discloses an optimal enforcement mode. The synthesis method has the advantages that the yield in each step is more than 80 percent, the purity of the final product bismerthiazol is more than 90 percent, the reaction condition is mild, wastewater and waste gas are hardly produced, and the synthesis method is environmentally friendly and suitable for industrial production.

Owner:JIANGXI HEYI CHEM

Thiocarbazide production wastewater treatment technology

InactiveCN108862217AThe amount of COD and ammonia nitrogen decreasedSimple methodSulfur preparation/purificationHydrazineChemical treatmentChemical oxygen demand

The invention discloses a thiocarbazide production wastewater treatment technology. The thiocarbazide production wastewater treatment technology comprises the following steps: sucking about 1100kg of40 percent of diluted sulfuric acid in a high-order dropwise adding tank, sucking 4000kg (a batch of materials) of thiocarbazide waste liquid into a reaction kettle, starting tail gas absorption, dropwise adding diluted sulfuric acid, controlling the temperature of the reaction kettle, regulating PH (Potential of Hydrogen) value to an appropriate numerical value, cooling the reaction kettle, carrying out discharging and suction filtration, sucking filtrate into a receiving tank, utilizing 40 percent of industrial waste diluted sulfuric acid to react with the filtrate, removing hydrazine hydrate and a sulfur-containing compound in the filtrate, and generating hydrazine sulfate and sulfur. According to the thiocarbazide production wastewater treatment technology disclosed by the invention, the COD (Chemical Oxygen Demand) content and the ammonia content are greatly reduced, and the removal rate of COD and ammonia is up to 95 percent. A method disclosed by the invention is simple and easyand is energy-saving and environment-friendly, high-COD thiocarbazide wastewater can be degraded, the treatment difficulty and the treatment cost fornext chemical treatment on wastewater can be reduced, byproducts of 99 percent of hydrazine sulfate and sulfur can be sold, and certain economic benefit is generated.

Owner:郭秦

Preparation method of hydrazine sulfate

InactiveCN107381523ASimple processSuitable for the needs of large-scale industrial productionHydrazineNitrogenButanone

The invention provides a preparation method of hydrazine sulfate and relates to a preparation method of a chemical reagent. The method comprises the following steps: taking butanone and ammonia as raw materials and air as an oxidizing agent and synthesizing butazone by using PdC12 and CuC12 as catalysts, and formamide and sodium bromide as co-catalysts; synthesizing hydrazine hydrate by utilizing the butazone; finally adding concentrated sulfuric acid into the hydrazine hydrate to prepare the hydrazine sulfate. The hydrazine sulfate prepared by the preparation method provided by the invention is high in purity.

Owner:盐城顺恒化工有限公司

Preparation method for super-grade pure hydrazine sulfate

InactiveCN106865511ASimple processSuitable for the needs of large-scale industrial productionHydrazineAlcoholHydrazine compound

The invention provides a kind of preparation method of high-grade pure hydrazine sulfate, and concrete preparation steps are as follows: (1) add pure water in glass-lined reactor, stir, slowly add 98% sulfuric acid under cooling, add, at 70- Add 80% hydrazine hydrate at 80°C and filter while hot, wherein the mass ratio of pure water, 98% sulfuric acid and 80% hydrazine hydrate is 10:10:4; (2) use sulfuric acid or hydrazine hydrate to adjust the pH of the filtrate to 4- 5. Stir for 20-60 minutes, wait for no change in pH, cool and crystallize to 25°C, centrifuge to separate the crystals, wash with absolute ethanol, and air-dry at room temperature to obtain the finished product; the preparation method is simple in process, and has developed a The preparation method of the chemical reagent hydrazine sulfate, the product quality reaches the high-grade pure standard, and is suitable for the needs of large-scale industrial production.

Owner:TIANJIN KERMEL CHEM REAGENT

Method for the synthesis of a polyoxadiazole polymer

A polyoxadiazole polymer is synthesized by heating polyphosphoric acid to a temperature of at least about 160° C. and making a solution by mixing hydrazine sulfate salt with one or more dicarboxylic acids or their derivatives in the heated polyphosphoric acid. The solution is heated under an inert gas atmosphere and the polymer is precipitated in a basic solution. The polyoxadiazole polymer can be produced as a homopolymer or copolymer, and may be used to produce a membrane or fibers.

Owner:GKSS FORSCHUNGSZENTRUM GEESTHACHT GMBH

A new method for preparing biuret by utilizing ketazine

The present invention relates to a new method for preparing biurea by using ketazine. First, sulfuric acid or hydrochloric acid with a molar ratio of 1:1 to ketazine is added to ketazine to generate pure hydrazine sulfate or hydrazine hydrochloride. Then add solid urea at one time, and rapidly raise the temperature to 105-120°C to generate biurea. Advantages of the present invention are: 1, adopt ketazine and sulfuric acid (hydrochloric acid) to generate hydrazine sulfate (hydrazine hydrochloride), avoid the hydrolysis and concentration process that ketazine is longer in the traditional technique, the method reacts rapidly, and the hydrazine sulfate obtained The purity is high, and the yield of biurea is high. 2. Using hydrazine sulfate and urea to react, the heating speed is fast, the product purity is high, and the yield of the obtained biuret is more than 85%. 3. The by-product ammonium salt can be recycled through the quicklime ammonia distillation process and returned to the ketazine synthesis device to realize the full recycling of materials.

Owner:HANGZHOU HI TECH FINE CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com