Halogen-free lead-free soldering paste and soldering flux used by same

A technology of lead-free solder paste and flux, which is applied in the direction of welding medium, welding equipment, welding/cutting medium/material, etc., and can solve the problem of not being able to use electronic products, welding process, not conforming to the world environmental protection trend, and reducing the heating rate of preheating And other problems, to achieve the effect of safe and reliable use, improve printing thixotropy, and reduce interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] (Example 1, halogen-free lead-free solder paste)

[0058] This embodiment is a halogen-free lead-free solder paste, including the following components:

[0059] Ag 2.8%;

[0060] Cu 0.48%;

[0061] Flux 11%;

[0062] Sn 85.72%;

[0063] The flux includes the following components:

[0064] Organic acid activator 1%;

[0065] Hydrazine hydroxycarboxylic acid compound 10%;

[0066] Organic solvent 23%;

[0067] Hydrogenated Castor Oil or Ethylene Bis Stearamide 3%;

[0068] Surfactant 0.5%;

[0069] Water-soluble polymer 62.5%;

[0070] The above percentages are mass percentages;

[0071] The organic acid is malic acid; the hydrazine hydroxycarboxylic acid compound is 2,2'-hydrazine-bis(3-ethylbenzothiazoline-6-sulfonic acid) diamine salt; the surfactant is alkane Base phenol polyoxyethylene ether; the water-soluble polymer is polyethylene glycol with a molecular weight of 200 to 600, and a hydroxyl value of 51 to 64.

[0072] The relevant materials and their p...

Embodiment 2 to Embodiment 3

[0073] (Example 2 to Example 3, halogen-free lead-free solder paste)

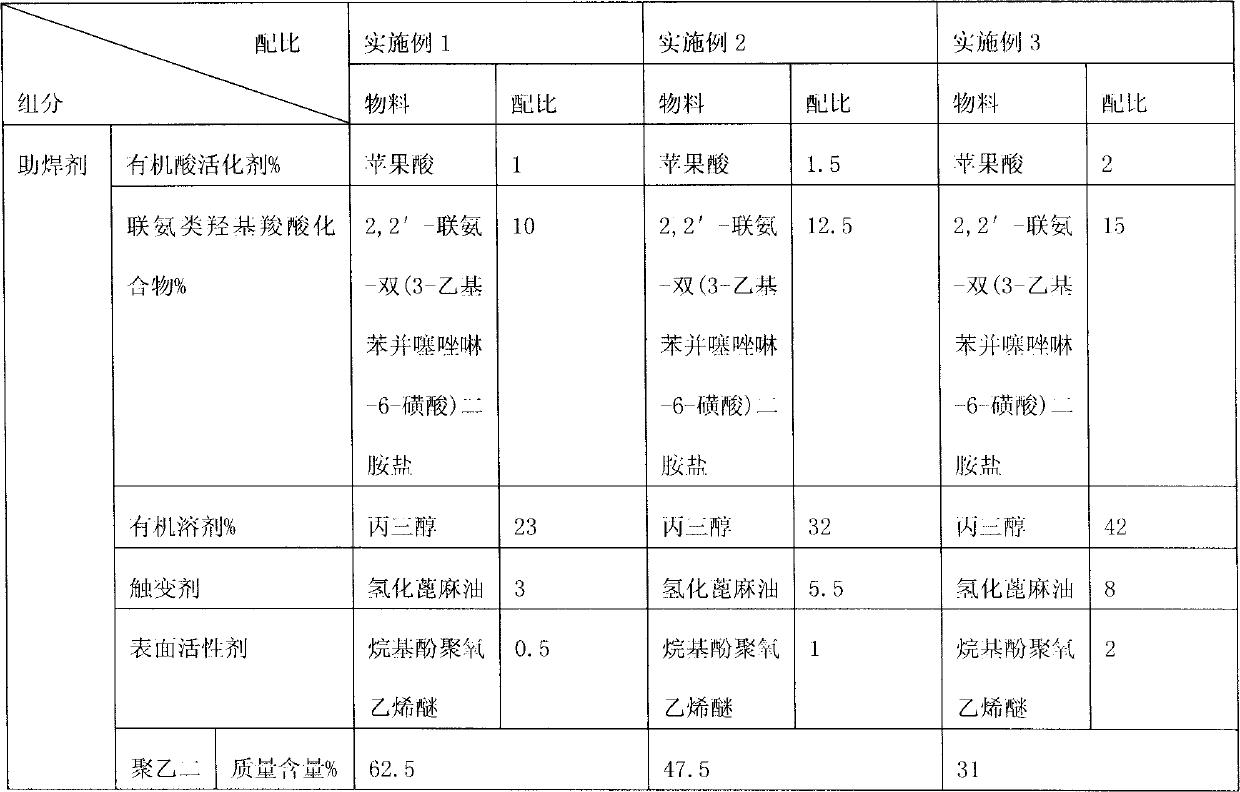

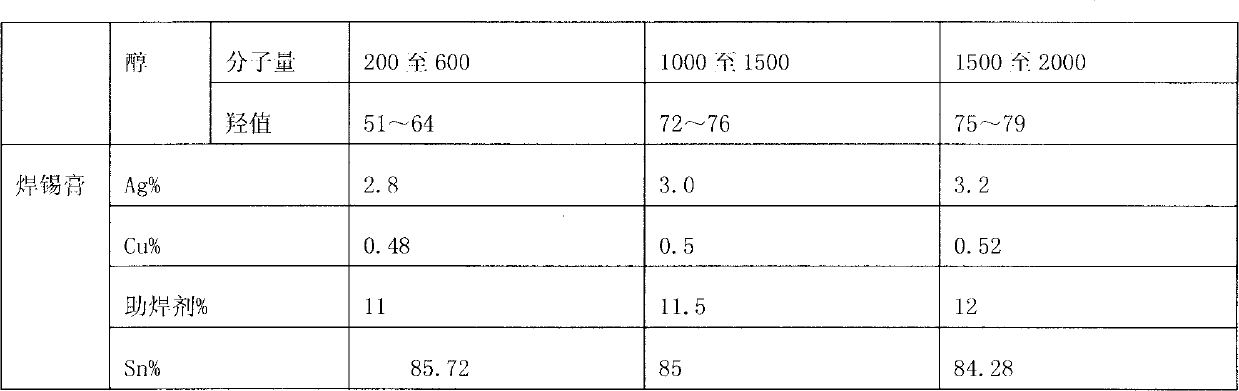

[0074] Embodiment 2 to embodiment 3 are basically the same as embodiment 1, the difference is: the component distribution ratio of the solder paste in this embodiment is different from that of embodiment 1; in addition, the flux used in embodiment 2 to embodiment 3 Proportioning is different from Example 1; See Table 1 for relevant parameters in Example 2 to Example 3.

[0075] Table 1

[0076]

[0077]

Embodiment 4 to Embodiment 6

[0078] (Example 4 to Example 6, halogen-free lead-free solder paste)

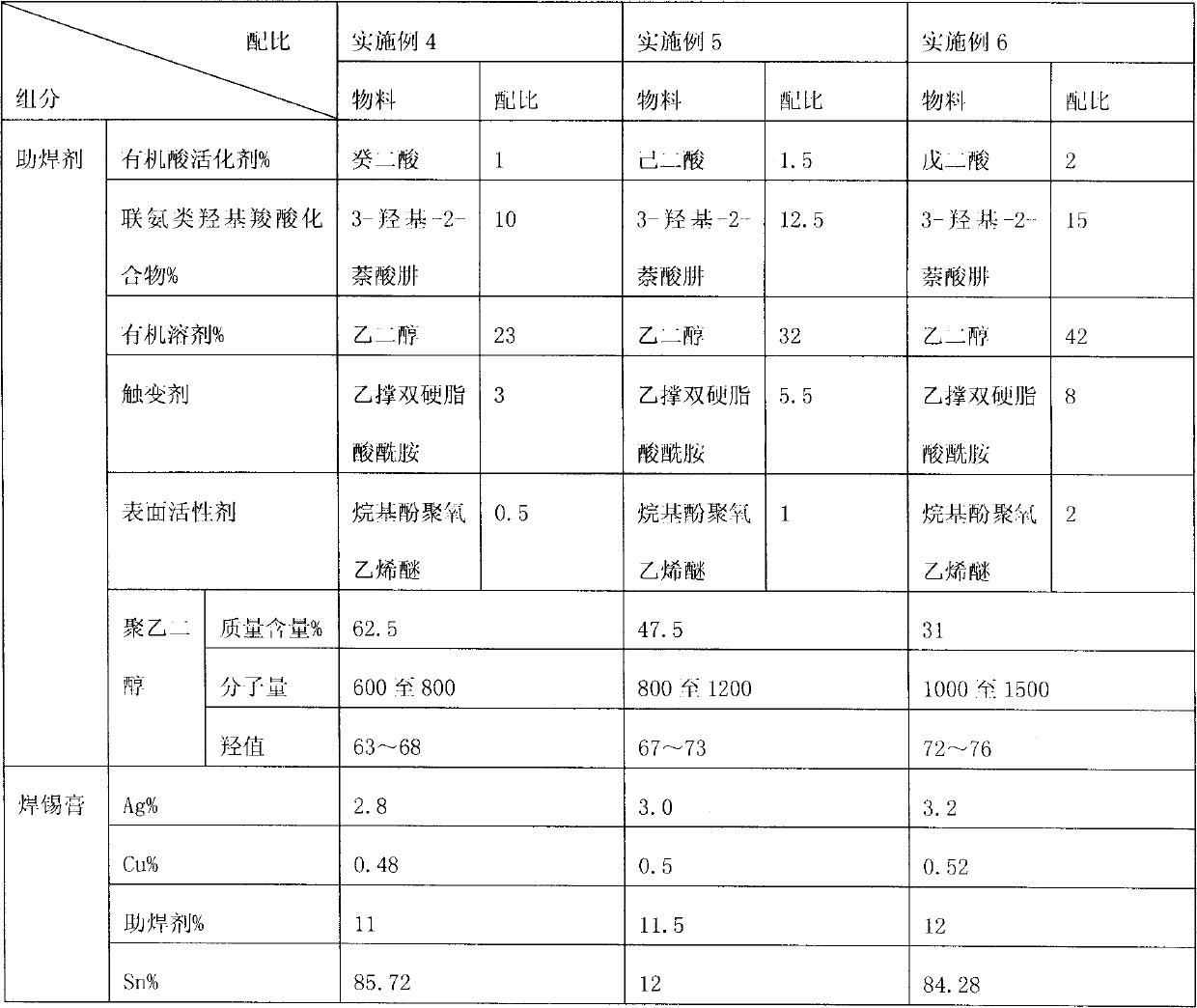

[0079]Embodiment 4 to embodiment 6 are basically the same as embodiment 1, the difference is: the component distribution ratio of the solder paste in this embodiment is different from that of embodiment 1; in addition, the flux used in embodiment 4 to embodiment 6 Proportioning is different from Example 1; See Table 2 for relevant parameters in Example 4 to Example 6.

[0080] Table 2

[0081]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com