Preparation method for super-grade pure hydrazine sulfate

A hydrazine sulfate, excellent grade pure technology, applied in the directions of hydrazine, nitrogen and non-metallic compounds, can solve the problem of unsatisfactory purity of hydrazine sulfate, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

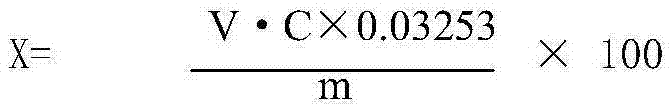

Image

Examples

Embodiment 1

[0014] A kind of preparation method of superior grade pure hydrazine sulfate, concrete preparation steps are as follows:

[0015] (1) Add 100kg of pure water to a 300L glass-lined reactor, stir and slowly add 100kg of 98% sulfuric acid under cooling.

[0016] (2) The filtrate was adjusted to PH = 4-5 with sulfuric acid or hydrazine hydrate, stirred for 30 minutes, and cooled to 25°C for crystallization when the pH remained unchanged. The crystallization was separated by centrifugation, washed with 10 kg of absolute ethanol, and air-dried at room temperature to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com