Patents

Literature

42 results about "Polonium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polonium is a chemical element with the symbol Po and atomic number 84. A rare and highly radioactive metal with no stable isotopes, polonium is chemically similar to selenium and tellurium, though its metallic character resembles that of its horizontal neighbors in the periodic table: thallium, lead, and bismuth. Due to the short half-life of all its isotopes, its natural occurrence is limited to tiny traces of the fleeting polonium-210 (with a half-life of 138 days) in uranium ores, as it is the penultimate daughter of natural uranium-238. Though slightly longer-lived isotopes exist, they are much more difficult to produce. Today, polonium is usually produced in milligram quantities by the neutron irradiation of bismuth. Due to its intense radioactivity, which results in the radiolysis of chemical bonds and radioactive self-heating, its chemistry has mostly been investigated on the trace scale only.

Method For The Catalytic Extraction Of Coal

InactiveUS20110044881A1Improve efficiencyImprove productivityCarbon compoundsCoke ovensIridiumHafnium

A method for the production of a carbon material from the extraction of coal, comprising forming a mixture of coal, a solvent and a catalyst selected from the group consisting of molybdenum, tin, titanium, zirconium, hafnium, thorium, selenium, tellurium, polonium, iron, cobalt, nickel, ruthenium, rhodium, palladium, osmium, iridium, platinum, the catalytically-active compounds and coordination compounds containing any of the foregoing, and combinations and mixtures thereof.

Owner:GRAFTECH INT HLDG INC

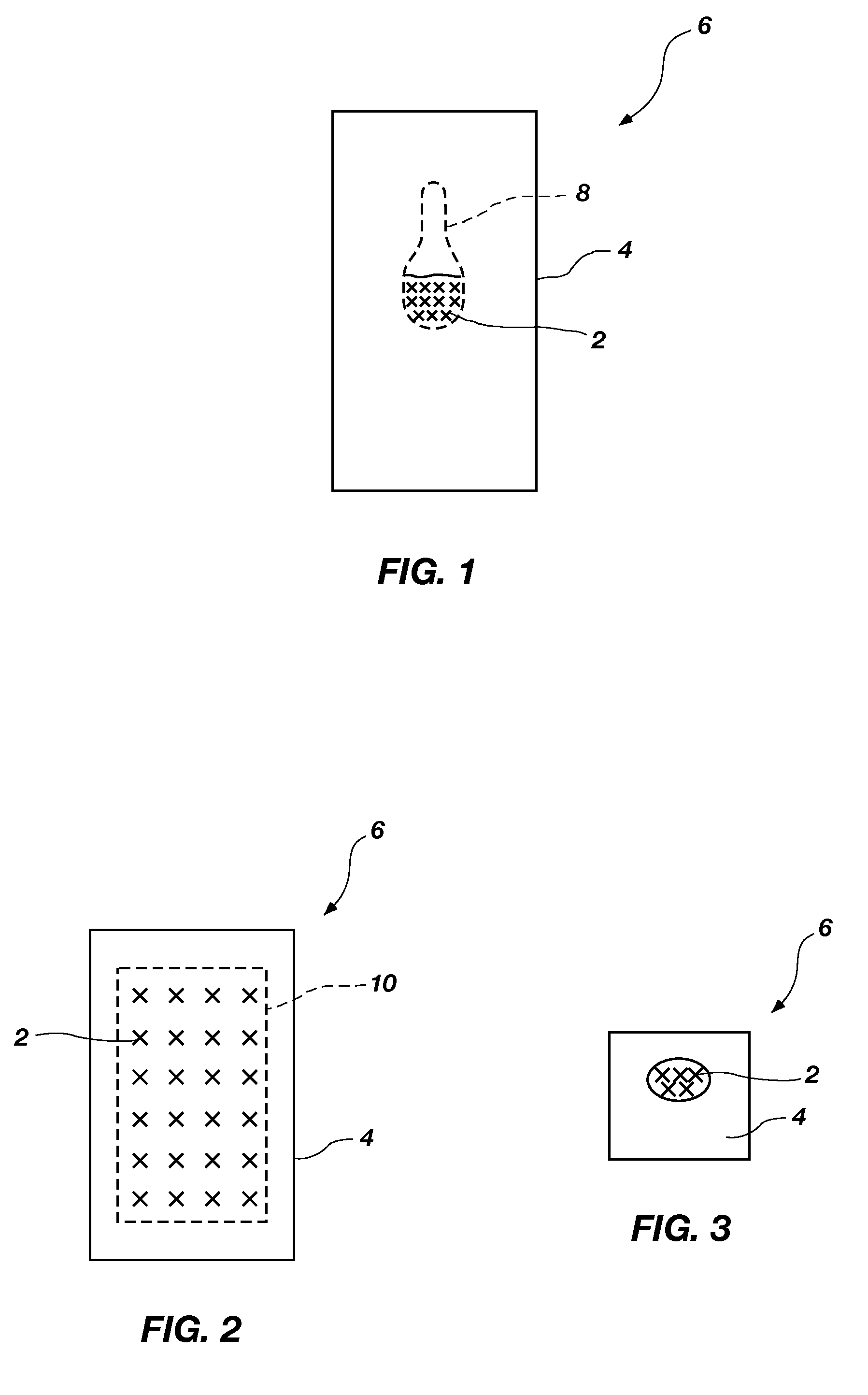

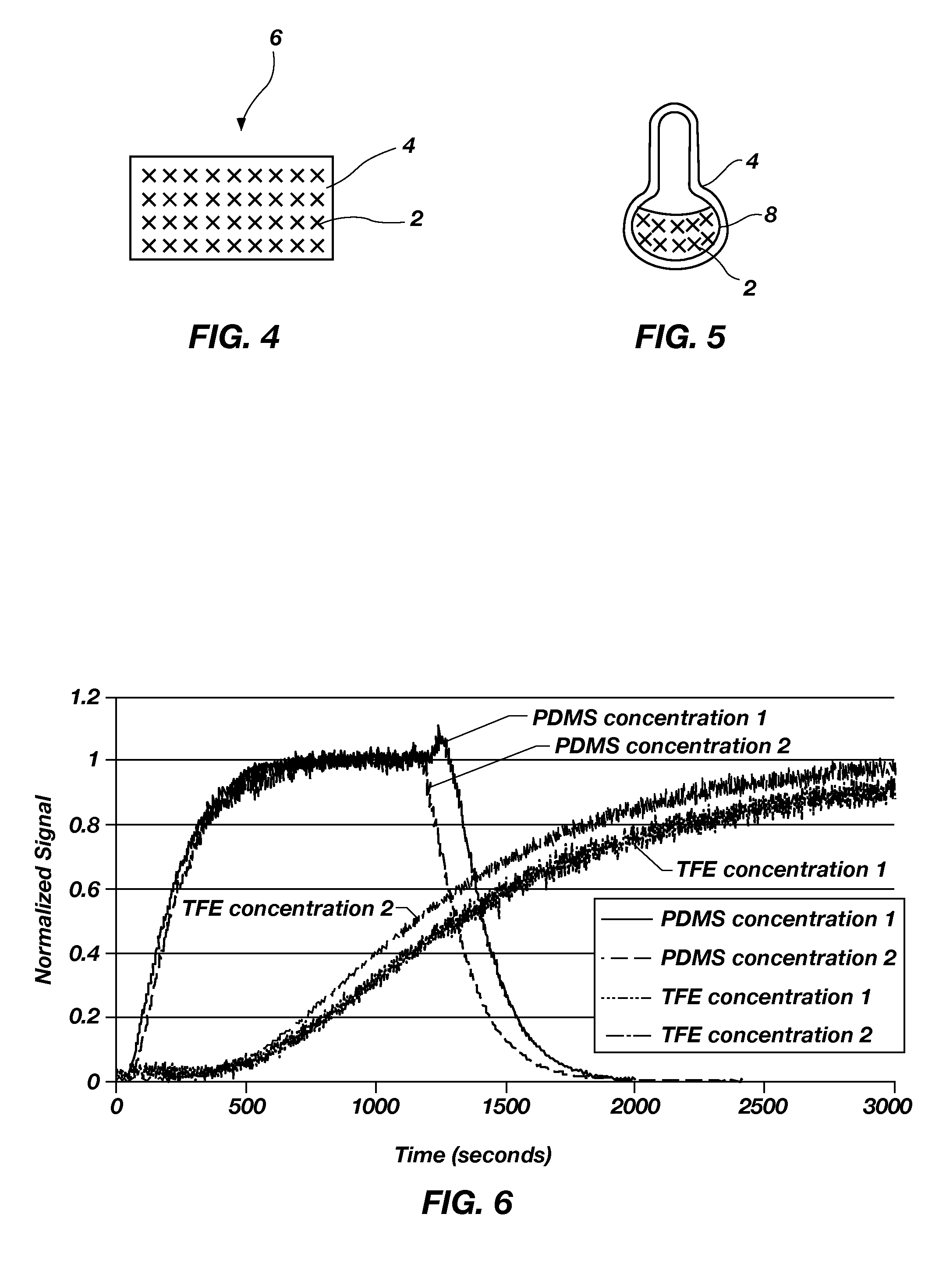

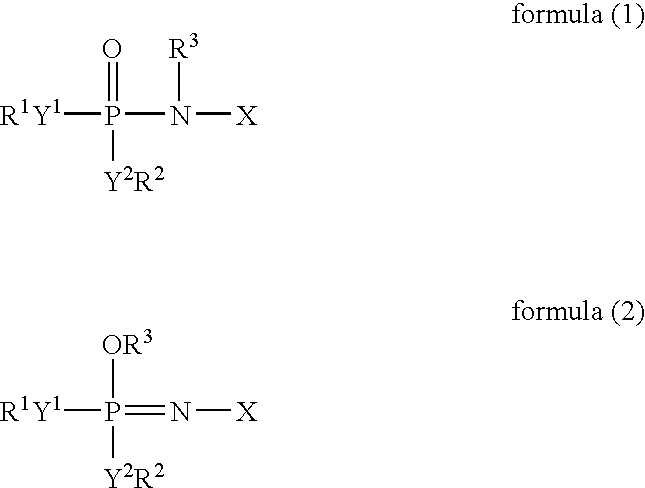

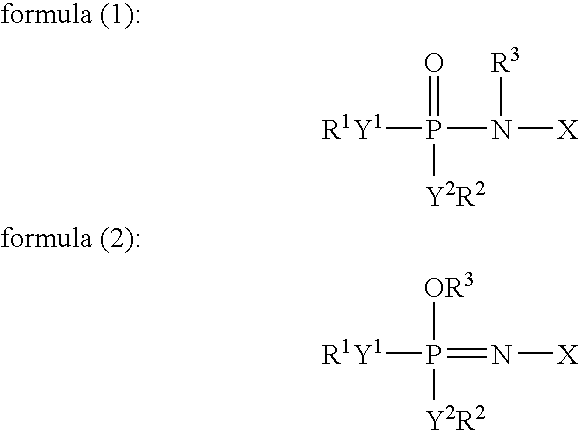

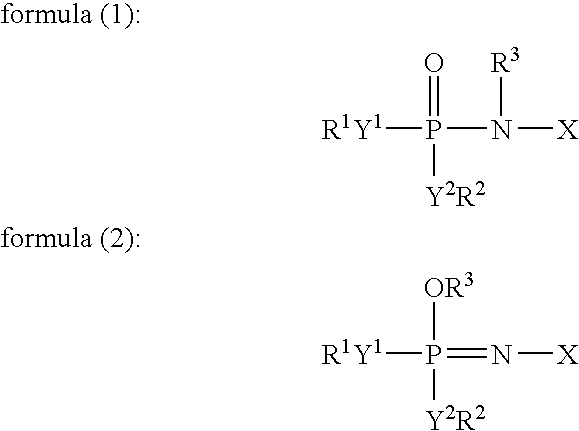

Taggants, method for forming a taggant, and a method for detecting an object

InactiveUS20110100091A1Optical radiation measurementParticle separator tubesChemical structurePolonium

A taggant comprising at least one perfluorocarbon compound surrounded by a polyphosphazene compound. The polyphosphazene compound has the chemical structure:wherein G1 and G2 are pendant groups having different polarities, m is an integer greater than or equal to 100, and each of A and B is independently selected from hydrogen, an alkyl, an alkene, an alkoxide, a polyether, a polythioether, a siloxane, and —X(CH2)nY1(CH2)p1Y2(CH2)p2 . . . Yi(CH2)piCH3, where n ranges from 1 to 6, X and Y are independently selected from oxygen, sulfur, selenium, tellurium, and polonium, and p1 through pi range from 1 to 6. Cyclic polyphosphazene compounds lacking the A and B groups are also disclosed, as are methods of forming the taggant and of detecting an object.

Owner:BATTELLE ENERGY ALLIANCE LLC

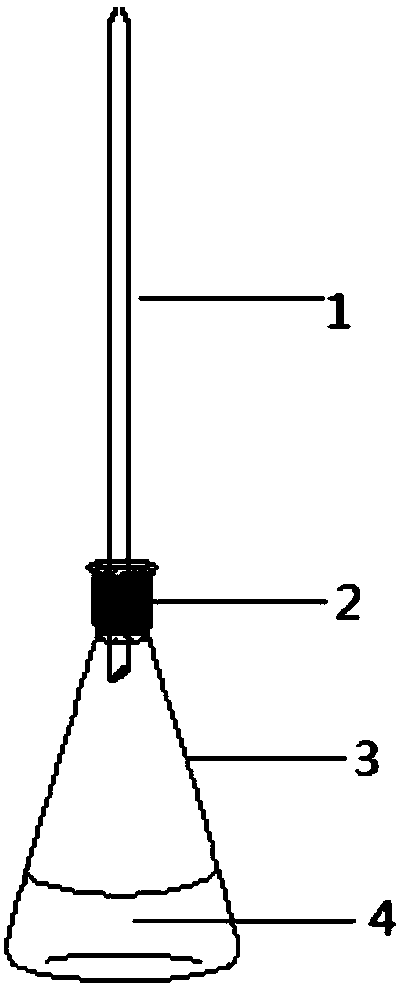

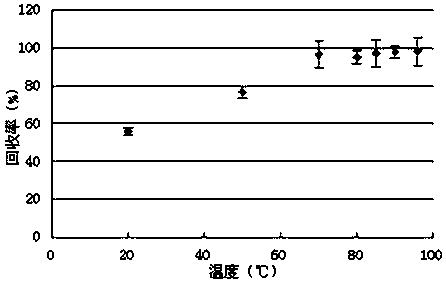

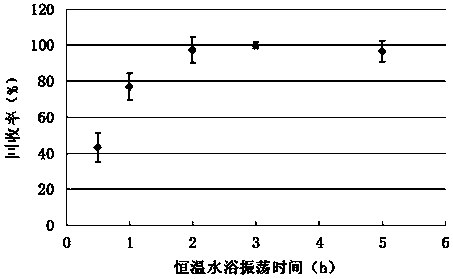

Method for polonium purification and source preparation in aerosol

InactiveCN108020448AImprove accuracyPreparing sample for investigationWater bathsHydroxylamine Hydrochloride

The invention belongs to the technical field of radioactive substance impact assessment, and relates to a method for polonium purification and source preparation in aerosol. The method sequentially comprises: (1) transferring a pre-treated polonium sample to be determined into an erlenmeyer flask, and adding <208>Po(IV) or <209>Po(IV) with a certain activity as a tracer to obtain a polonium sampleto be subjected to purification and source preparation; (2) placing the polonium sample obtained in the step (1) in a water bath, evaporating to remove more than 90% of the liquid, and cooling to a room temperature; (3) adding a hydrochloric acid solution, a hydroxylamine hydrochloride solution and ascorbic acid to the sample solution obtained in the step (2), mixing, and uniformly shaking; (4) adding the sample solution obtained in the step (3), and a polished silver sheet or copper sheet to a device capable of providing a certain sealing effect and a certain condensation recovery effect; (5) after installing the device, placing into an oscillator, and carrying out constant temperature water bath oscillation; and (6) after carrying out oscillation for a certain time, taking the poloniumplated silver sheet or copper sheet out of the device, rinsing with distilled water, and carrying out air drying. With the method of the present invention, the recovery rate of the purification and source preparation can be increased and stabilized so as to improve the accuracy of the <210>Po determination result.

Owner:CHINA INST FOR RADIATION PROTECTION

Additive for nonaqueous-electrolyte secondary battery

InactiveUS7067219B2Improve flame retardant performanceImprove the immunityHybrid capacitor electrolytesProtecting/adjusting hybrid/EDL capacitorOxygenAntimony

Owner:BRIDGESTONE CORP

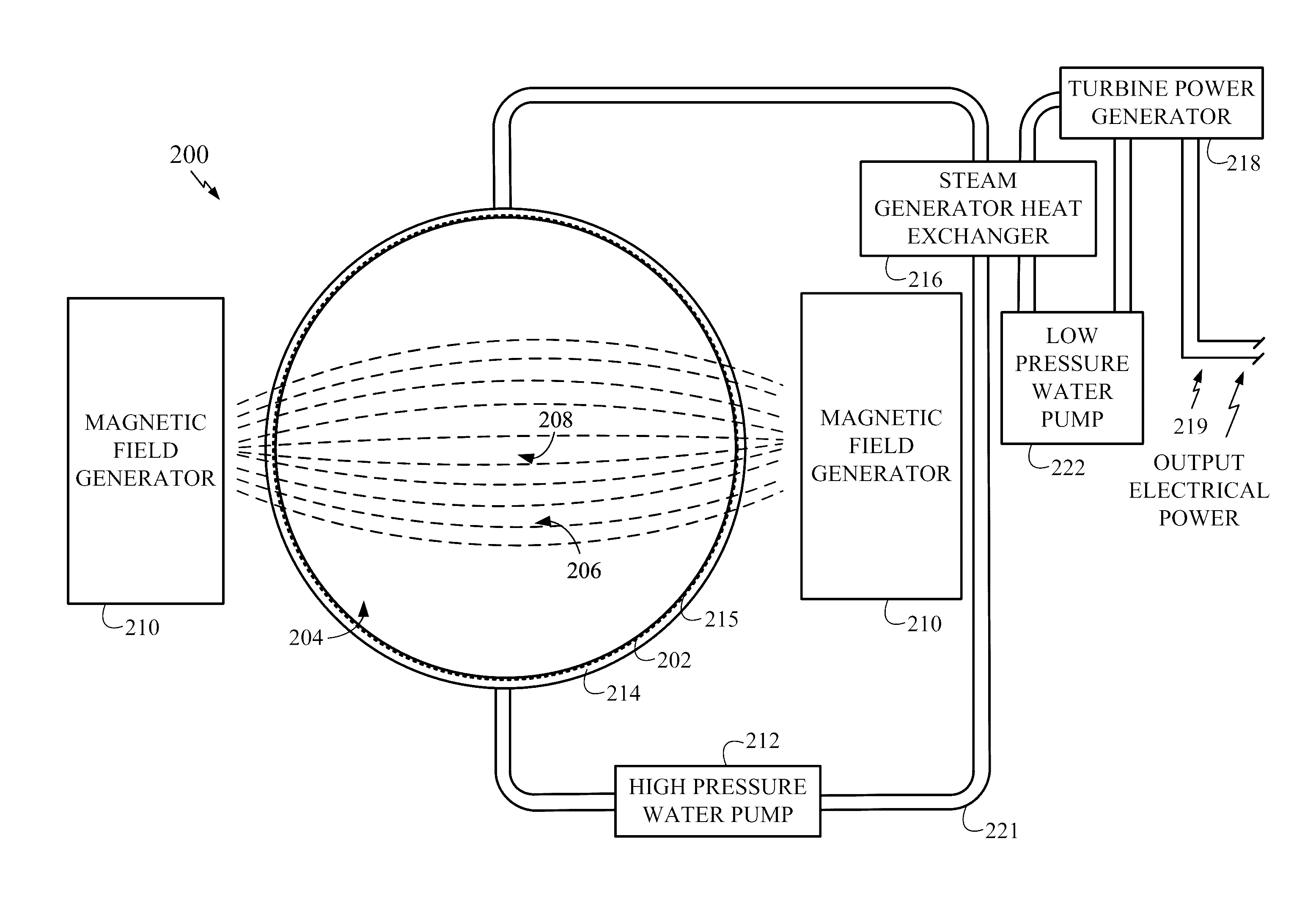

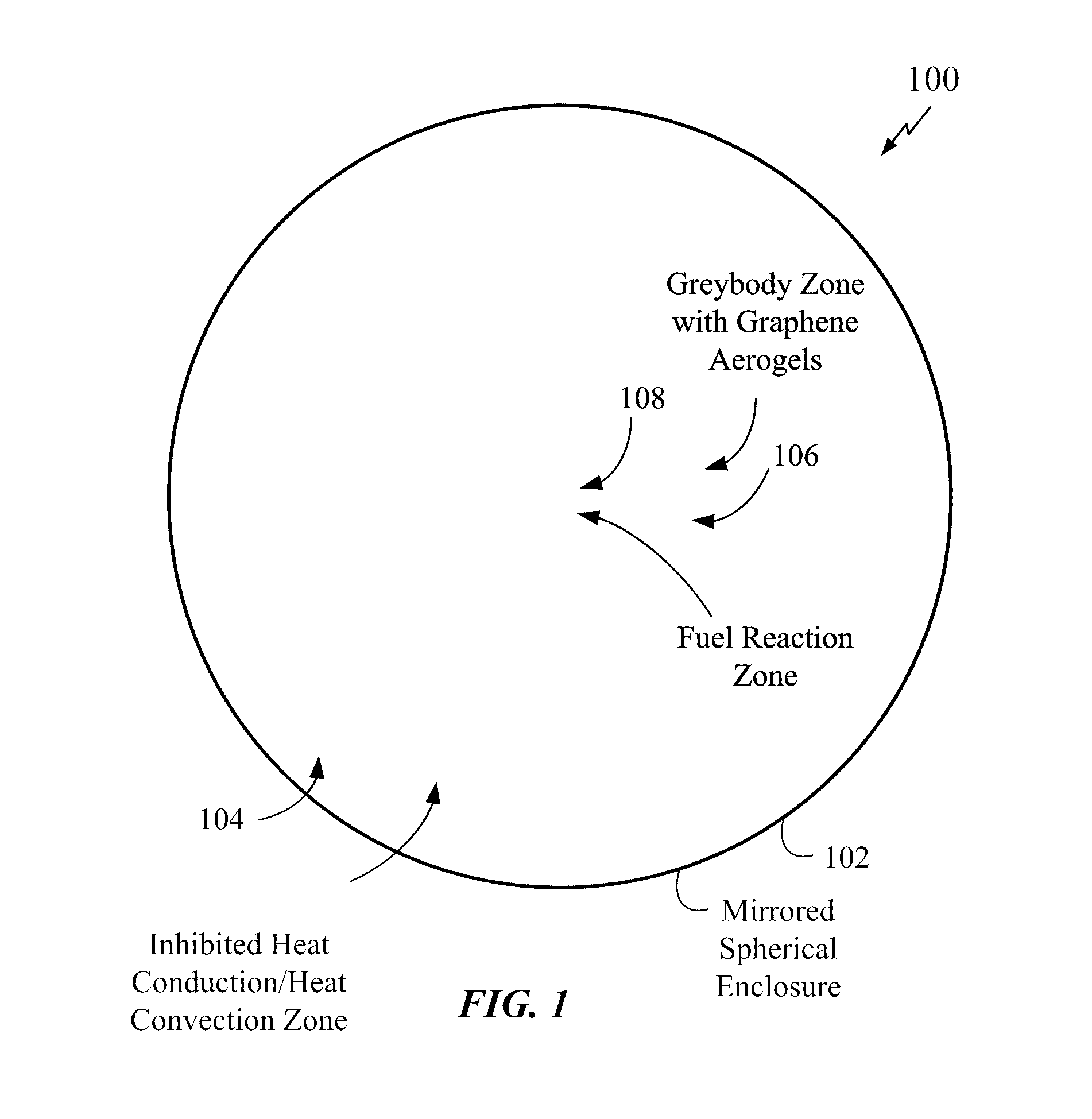

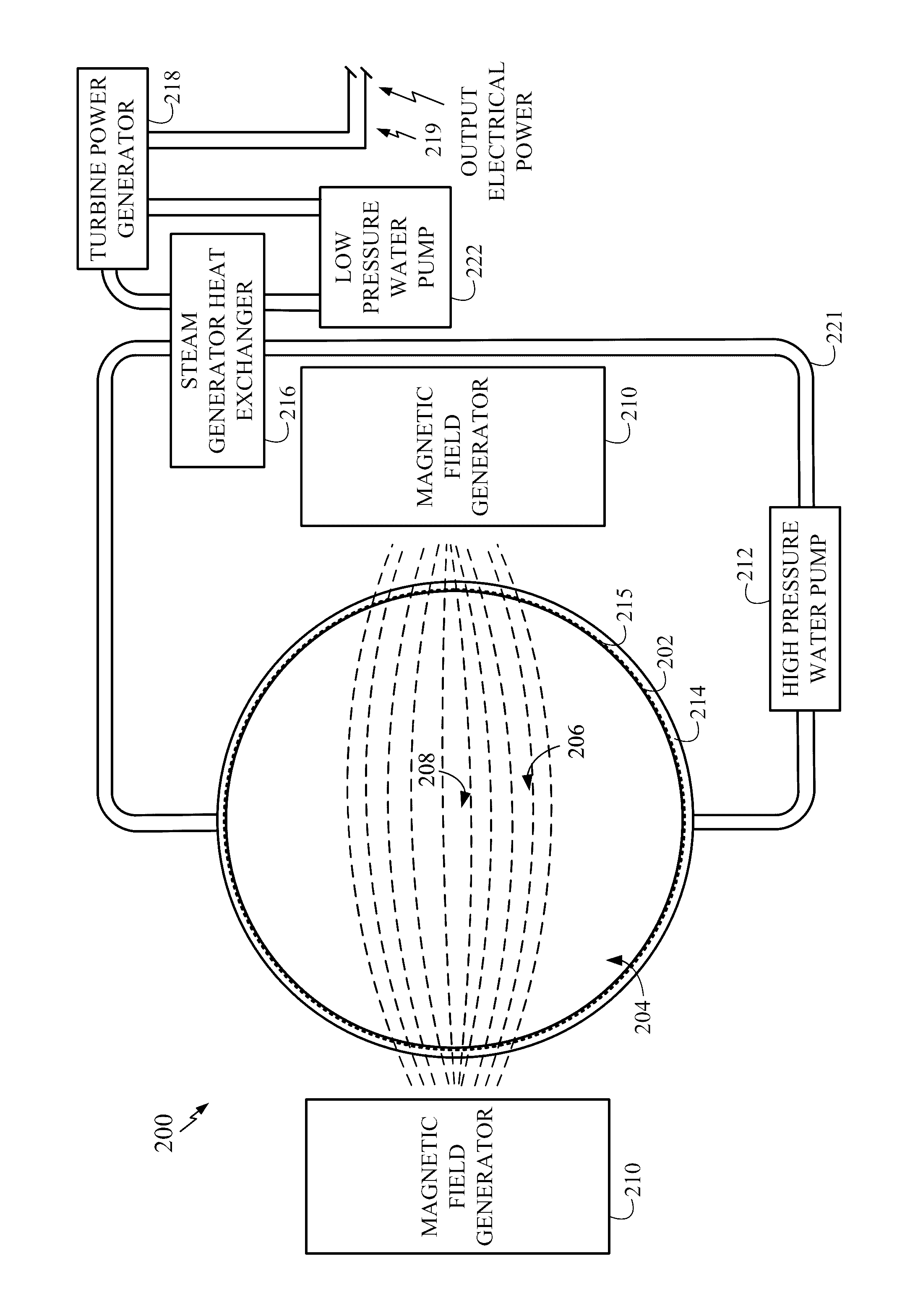

Spherical fusion reactor with aerogel material

InactiveUS20170025190A1Increase flow resistanceImprove faultNuclear energy generationPlasma techniqueKryptonNoble gas

A spherical nuclear fusion reactor machine is provided that uses a graphene aerogel material to enclose a fuel reaction zone. In illustrative examples described herein, the graphene aerogel material functions as a greybody material and includes a heavy noble gas such as xenon, krypton or argon or combinations thereof. The fuel reaction zone includes a radioactive isotope such as polonium-210 in addition to fusion fuel. A component of the heavy noble gas may be a radioactive isotope of xenon, Xe-135. A spherical enclosure with a reflective inner surface surrounds the fuel reaction zone and the graphene aerogel material. Magnetic field generators with rotating permanent magnets or electro-magnets and fixed electro-magnets are also provided. The magnetic field generators are external to the spherical enclosure and are configured to produce magnetic fields within the fuel reaction zone to initiate nuclear fusion and to generate a magnetic “bottle” to contain the fusion materials.

Owner:GIBSON RICHARD ALLEN

Zeolite coated nasal mask and disposable particulate respirator filtration media

InactiveUS20150238784A1Reduce releaseGarment special featuresBreathing filtersParticulatesHazardous substance

A method and use of Zeolite coated nasal mask and disposable particulate respirator filtration media that will absorb air pollutants such as NOx, Ozone, PM2.5 and radioisotopes of cesium, strontium and polonium (the progeny of radon gas) and protect the wearer from inhalation of said deleterious agents.

Owner:ROBINSON JR WILLIAM L

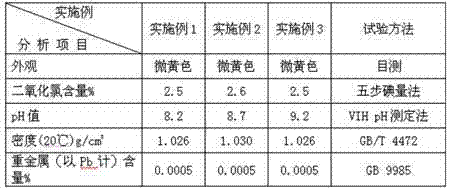

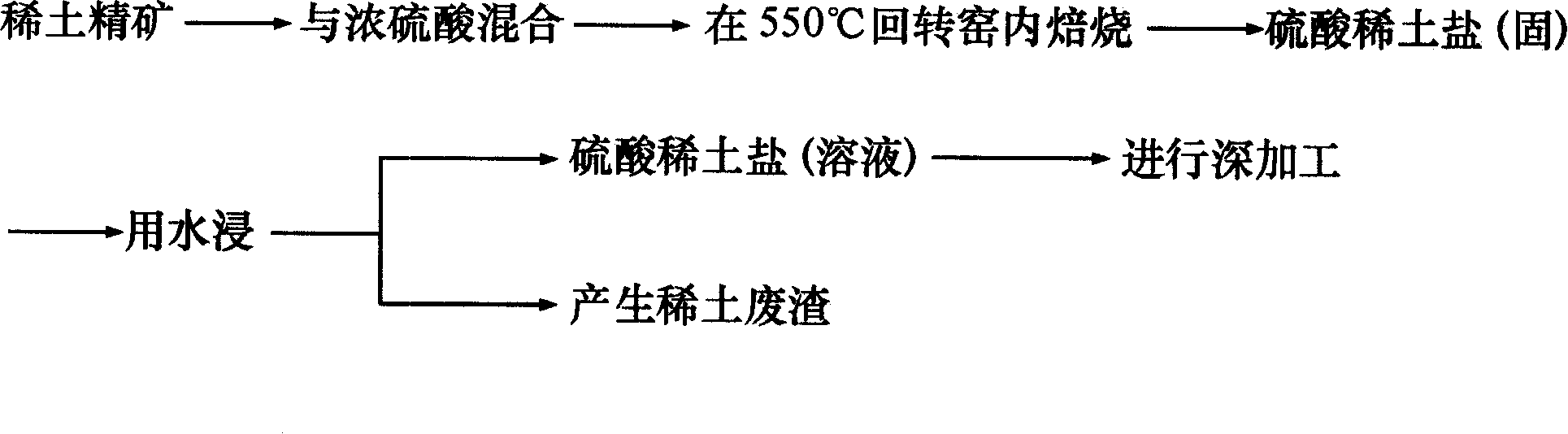

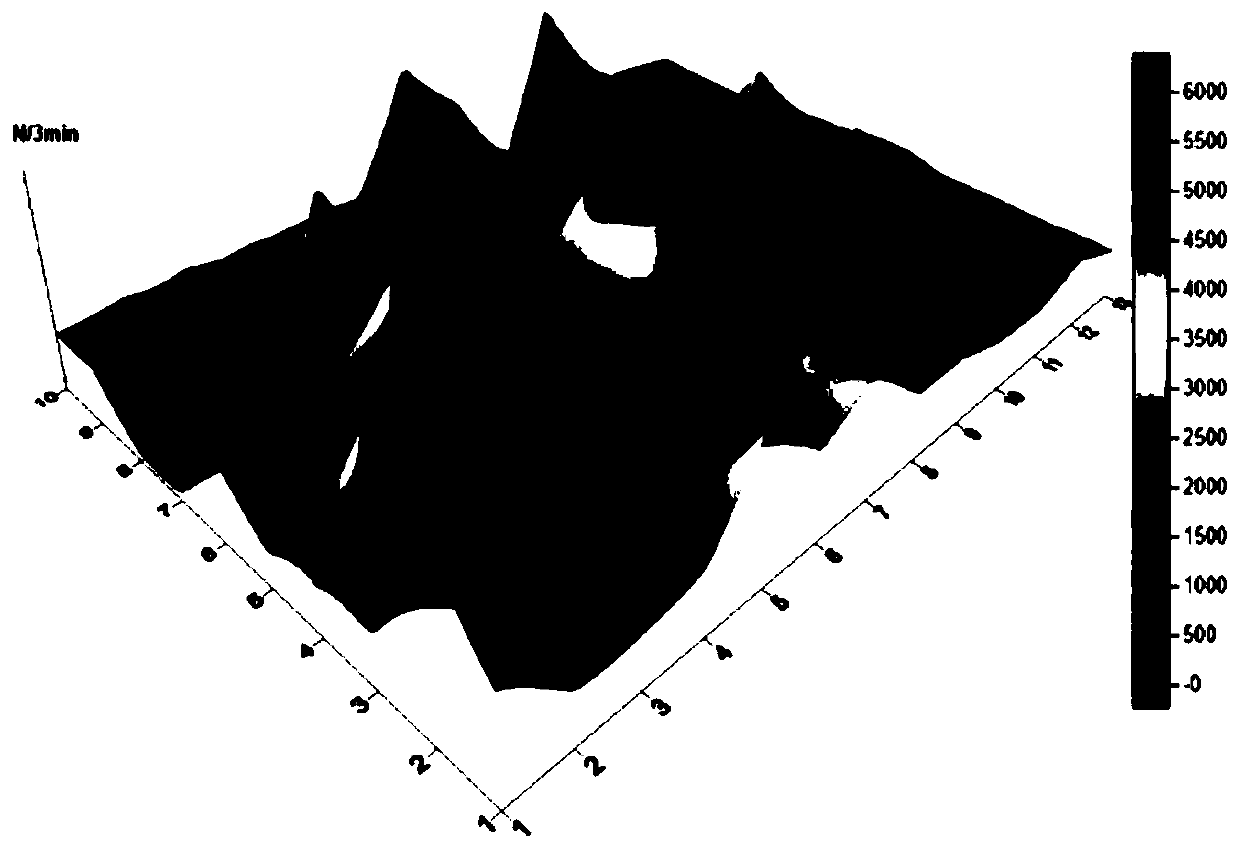

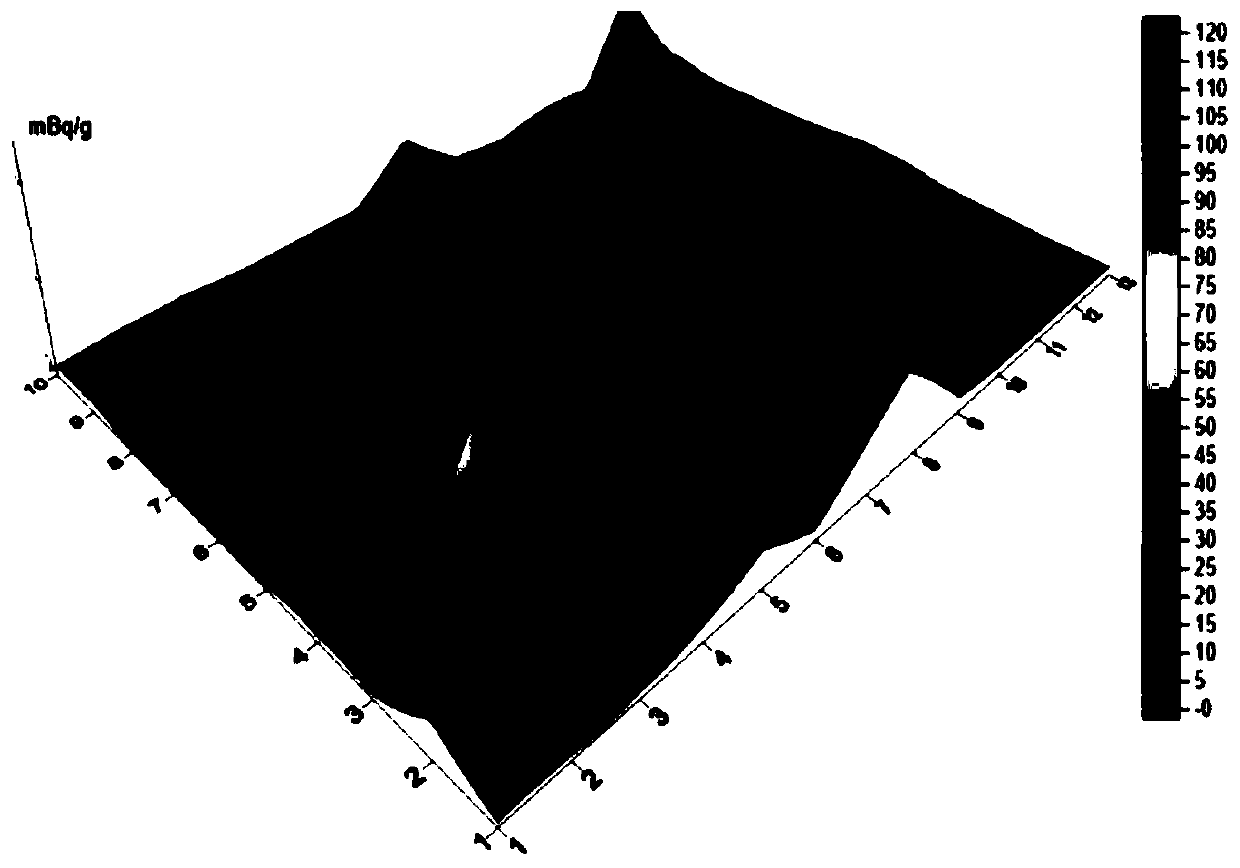

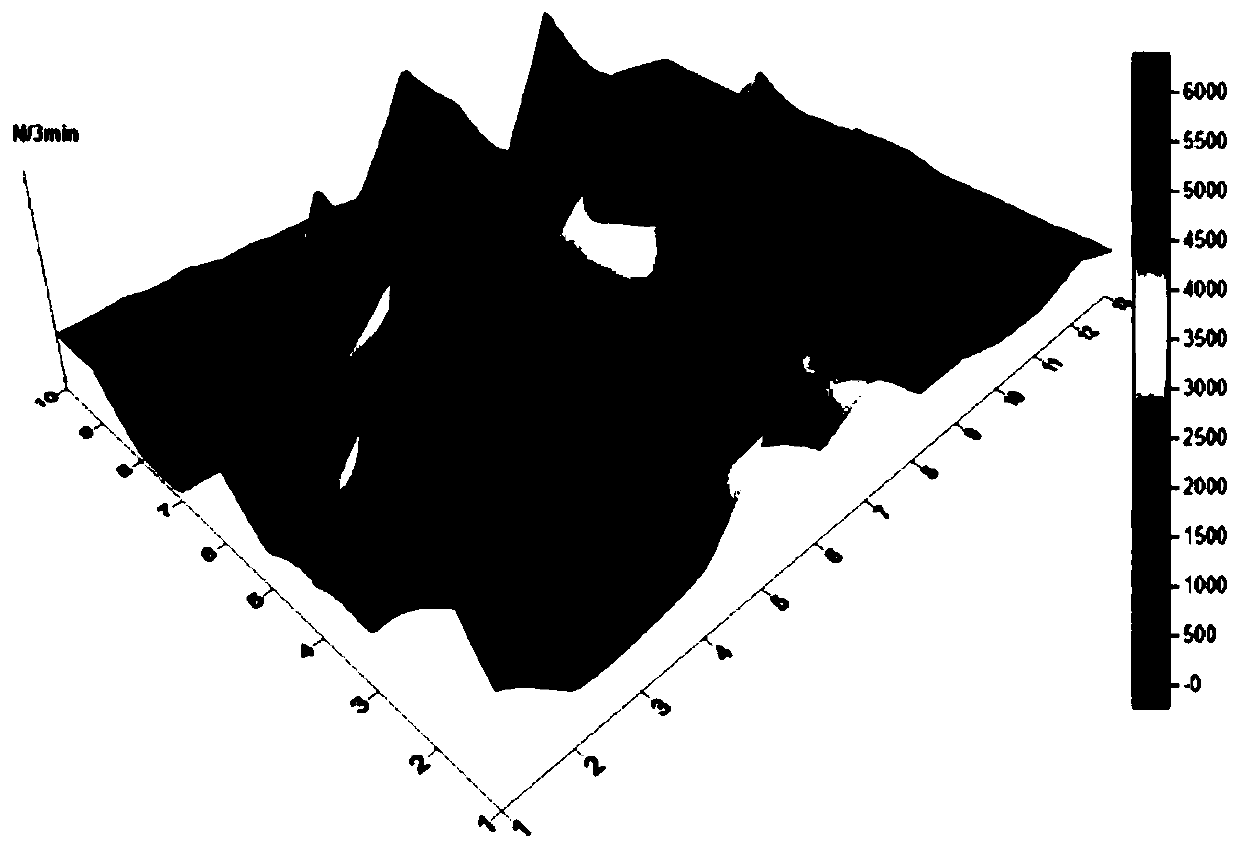

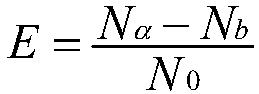

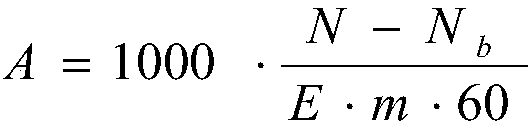

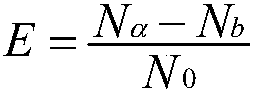

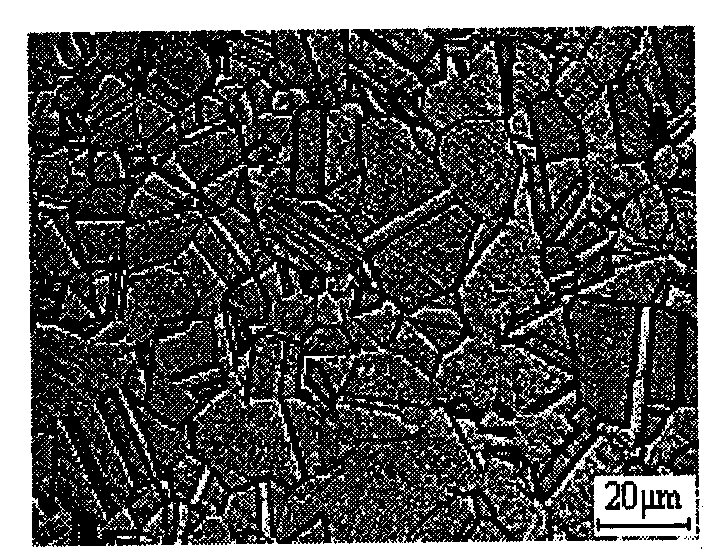

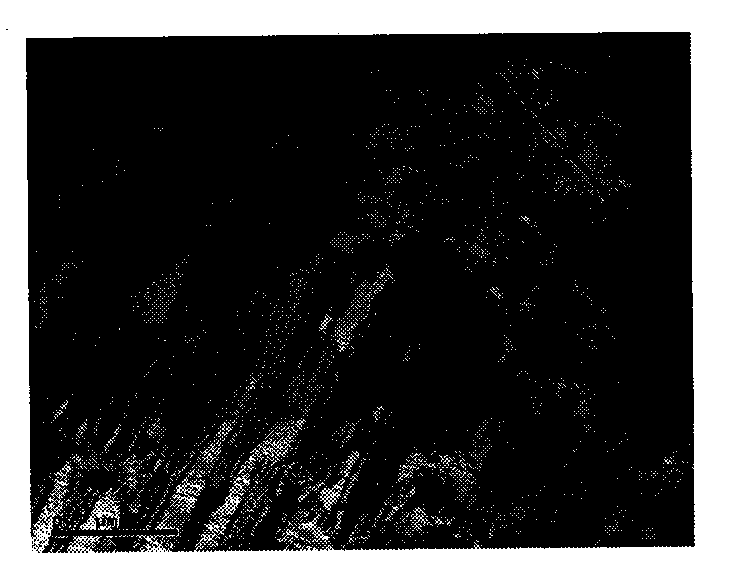

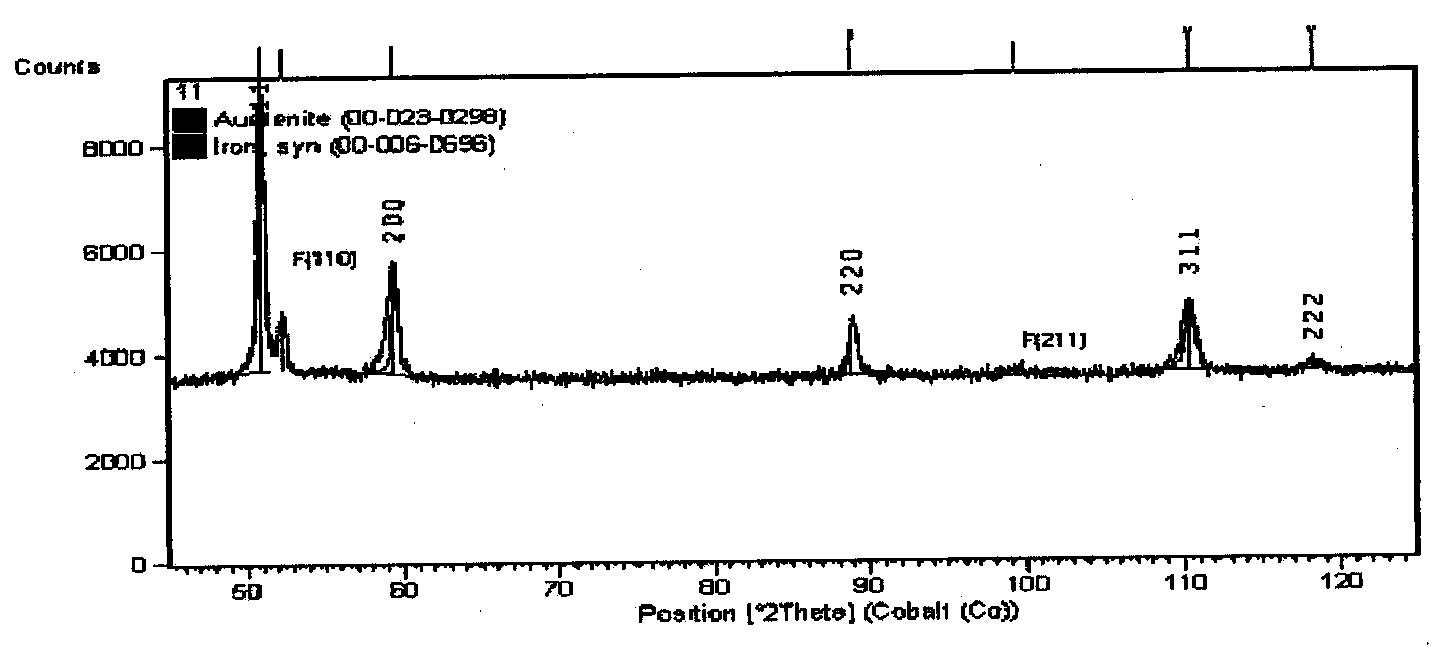

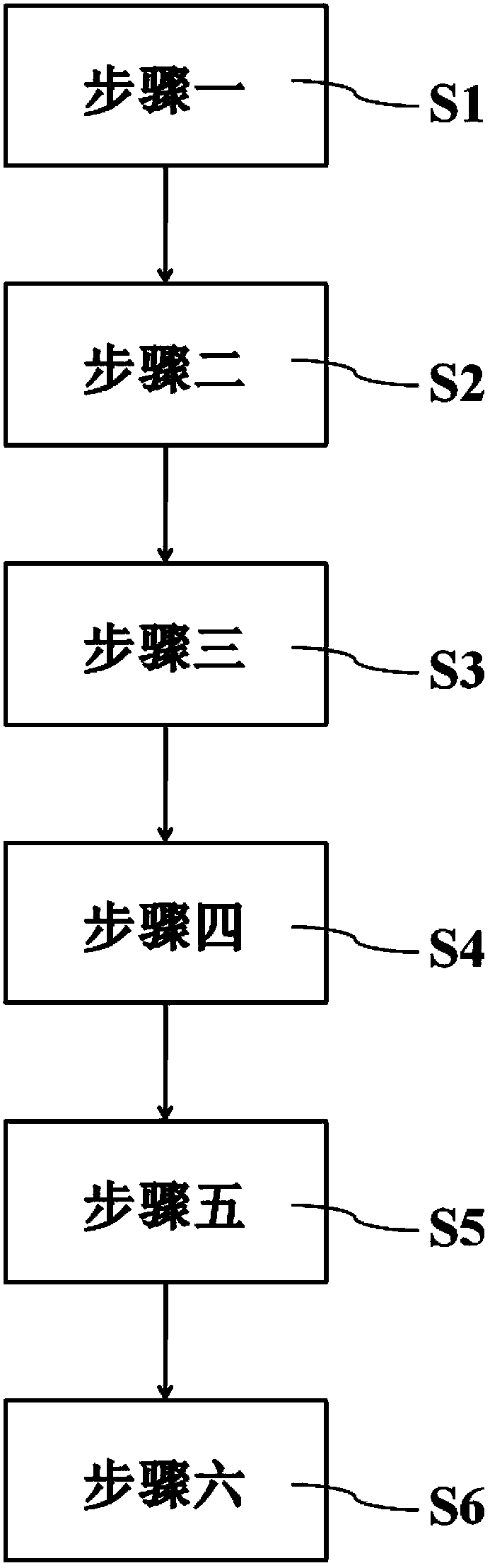

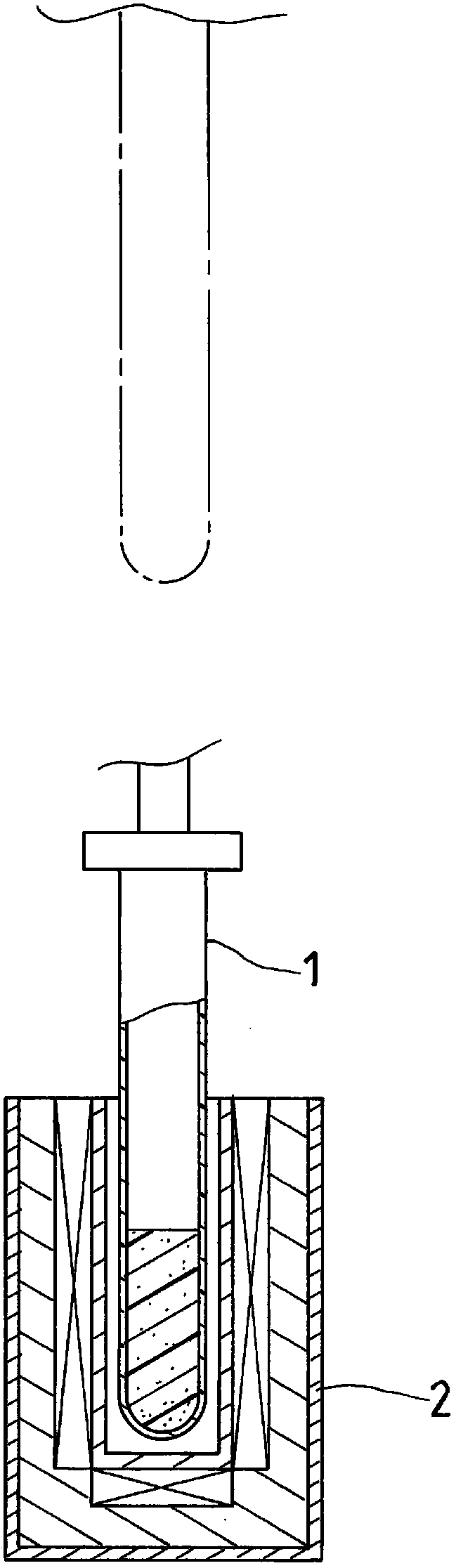

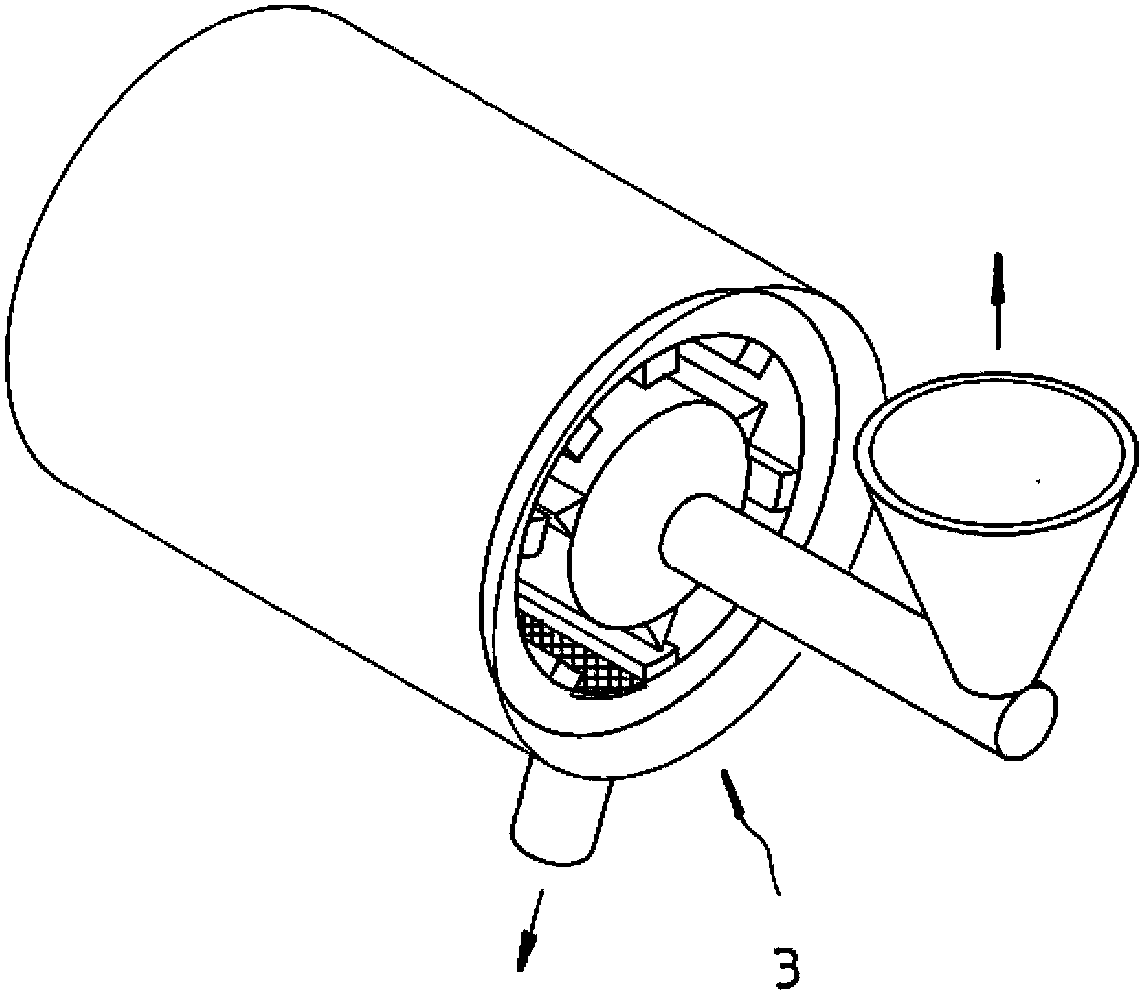

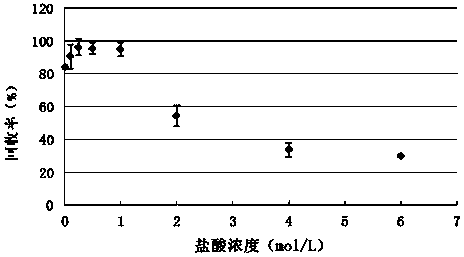

Method for preparing [alpha] measurement source of polonium according to micro precipitation method

ActiveCN108267773AHigh recovery rateShort timeX/gamma/cosmic radiation measurmentSolubilityRadioactive tracer

The invention belongs to the technical field of radioactive substance measurement, and relates to a method for preparing an [alpha] measurement source of polonium according to a micro precipitation method. The method comprises the steps of (1) adding Te(VI) or Te(IV), a polonium-containing sample, a radioactive tracer <209>Po, a reducing substance and an organic solvent capable of being mixed anddissolved with water and reducing the solubility of TeO2 or elementary substance Te into an aqueous solution so as to enable the Te(VI) or Te(IV) to have an oxidation-reduction reaction with the reducing substance, the TeO2 or elementary substance Te obtained by reduction is enabled to serve as a carrier to take down the radioactive polonium and uniformly disperse the radioactive polonium into theaqueous solution under the effect of the organic solvent; and (2) enabling the carrier taking the radioactive polonium to be uniformly dispersed on a filtering membrane through filtering. Compared with the traditional auto precipitation method for preparing the [alpha] measurement source of the polonium, the method for preparing the [alpha] measurement source for the polonium is short in time, simple to operate, easy to perform batch production, low in cost, higher in acid resistance and anti-interference ability and capable of obtaining a polonium recovery rate (85%-100%) which is close to or higher than that of the auto precipitation method.

Owner:CHINA INST FOR RADIATION PROTECTION

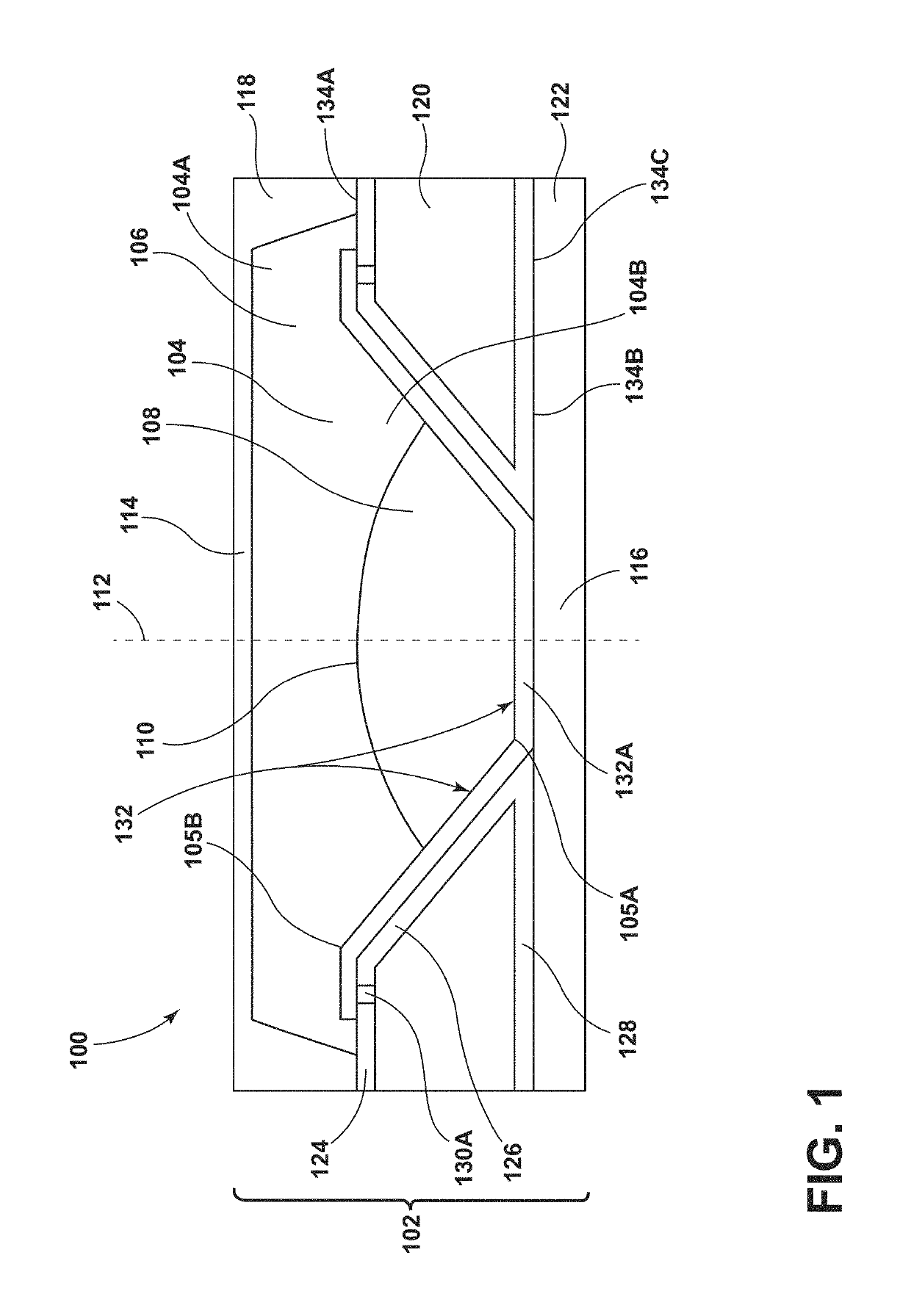

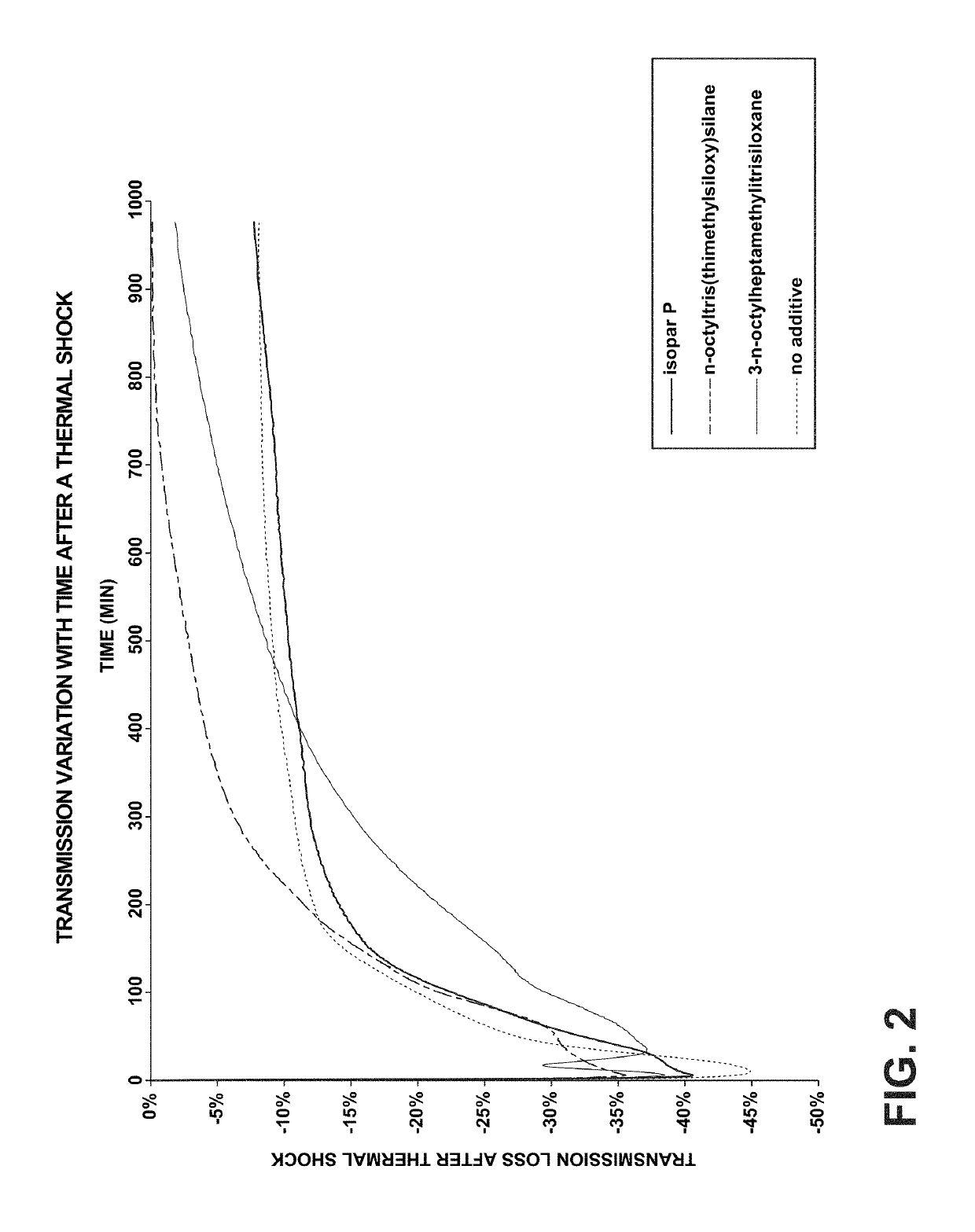

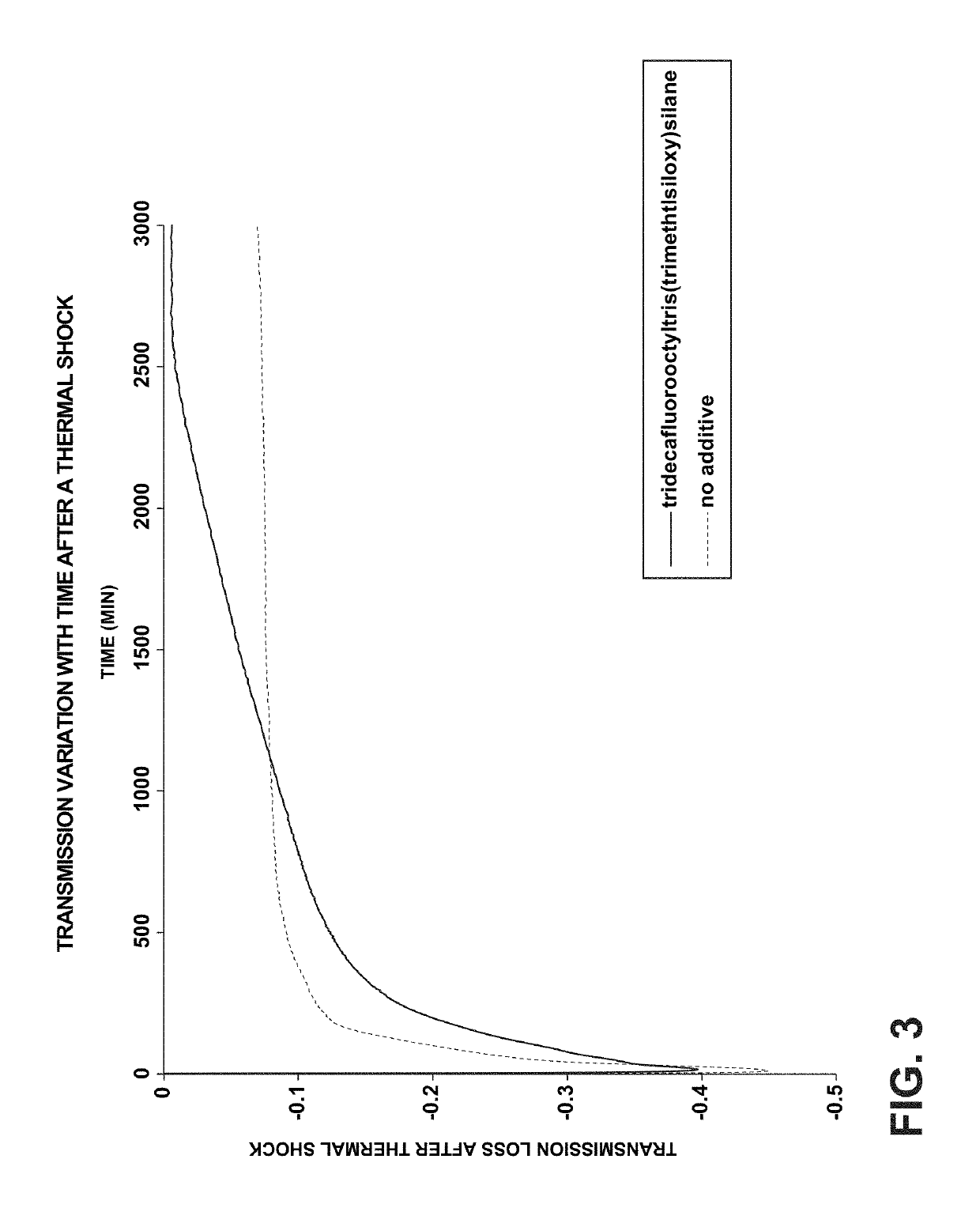

Naphtyl based high index hydrophobic liquids and transmission recovery agents for liquid lens formulations

An electrowetting optical device is provided. The electrowetting optical device includes a conductive liquid and a non-conductive liquid. The non-conductive fluid includes a naphthalene based compound having Formula (I), Formula (II), and / or Formula (III):where R1, R2, and R3 are individually alkyl, aryl, alkoxy, or aryloxy groups; X includes carbon, silicon, germanium, tin, lead, and combinations thereof; and Z includes oxygen, sulfur, selenium, tellurium, polonium, and combinations thereof. The conductive liquid may additionally include a transmission recovery agent having Formula (IV) and / or Formula (V):where R4 is an alkyl, fluoroalkyl, aryl, alkoxy, or aryloxy group. The electrowetting optical device additionally includes a dielectric surface in contact with both the conductive and non-conductive liquids where the conductive and non-conductive liquids are non-miscible.

Owner:CORNING INC

High-strength magnetic core and preparation method thereof

InactiveCN109574647AHigh strengthHigh hardnessInorganic material magnetismManganous-manganic oxideCopper oxide

The invention provides a high-strength magnetic core and a preparation method thereof, and relates to the technical field of magnetic core production. The magnetic core comprises, by weight, 50-54 parts of ferric oxide, 18-22 parts of copper oxide, 12-16 parts of zinc oxide, 6-10 parts of nickel oxide, 14-18 parts of chromium sesquioxide, 12-16 parts of nickel carbonate, 10-14 parts of manganese carbonate, 8-12 parts of cobalt oxide, 6-10 parts of magnesium hydroxide, 14-18 parts of manganous-manganic oxide, 12-16 parts of chromium carbide, 10-14 parts of tungsten carbide, 8-12 parts of polonium oxide, 6-10 parts of aluminum hydroxide, 2-4 parts of coupling agents, 1-3 parts of accelerants and 1-3 parts of defoaming agents. The magnetic core overcomes the shortcomings of the prior art, thestrength of the magnetic core is effectively improved, damage to the magnetic core in the assembly process is prevented, the service life of the magnetic core is greatly prolonged, use effects are good, characteristics such as the impedance, the Curie temperature and magnetic conductivity of the magnetic core are effectively improved, and the magnetic core is small in internal stress, superior inperformance and suitable for popularization.

Owner:安徽精磁电子有限公司

Production and use of supported catalysts

InactiveUS20070173663A1Preventing effective circulation of gasInhibited DiffusionOrganic compound preparationCarboxylic acid esters preparationIndiumReduction treatment

Supported catalysts which allow shortening of the production steps for supported catalysts useful for production of lower aliphatic carboxylic acids from lower olefins and oxygen, and which compared to supported catalysts of the prior art, can inhibit generation of carbon dioxide (CO2) gas by-product during the production of lower aliphatic carboxylic acids. A compound containing at least one element selected from Group 8, 9 and 10 elements of the Periodic Table is loaded on a carrier and then, before reduction treatment of the compound, it is subjected to alkali treatment with an alkaline substance, and a compound containing at least one element selected from gallium, indium, thallium, germanium, tin, lead, phosphorus, arsenic, antimony, bismuth, sulfur, selenium, tellurium and polonium is loaded.

Owner:SHOWA DENKO KK

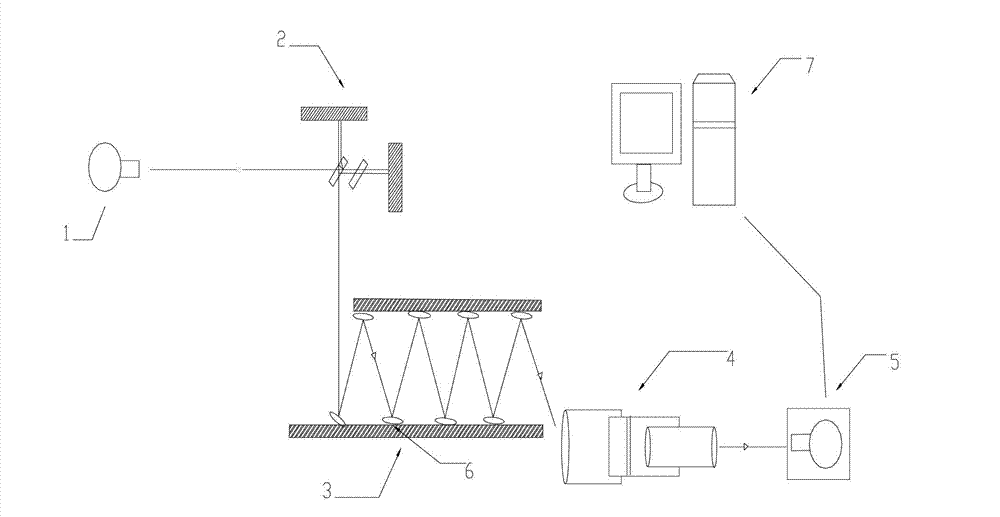

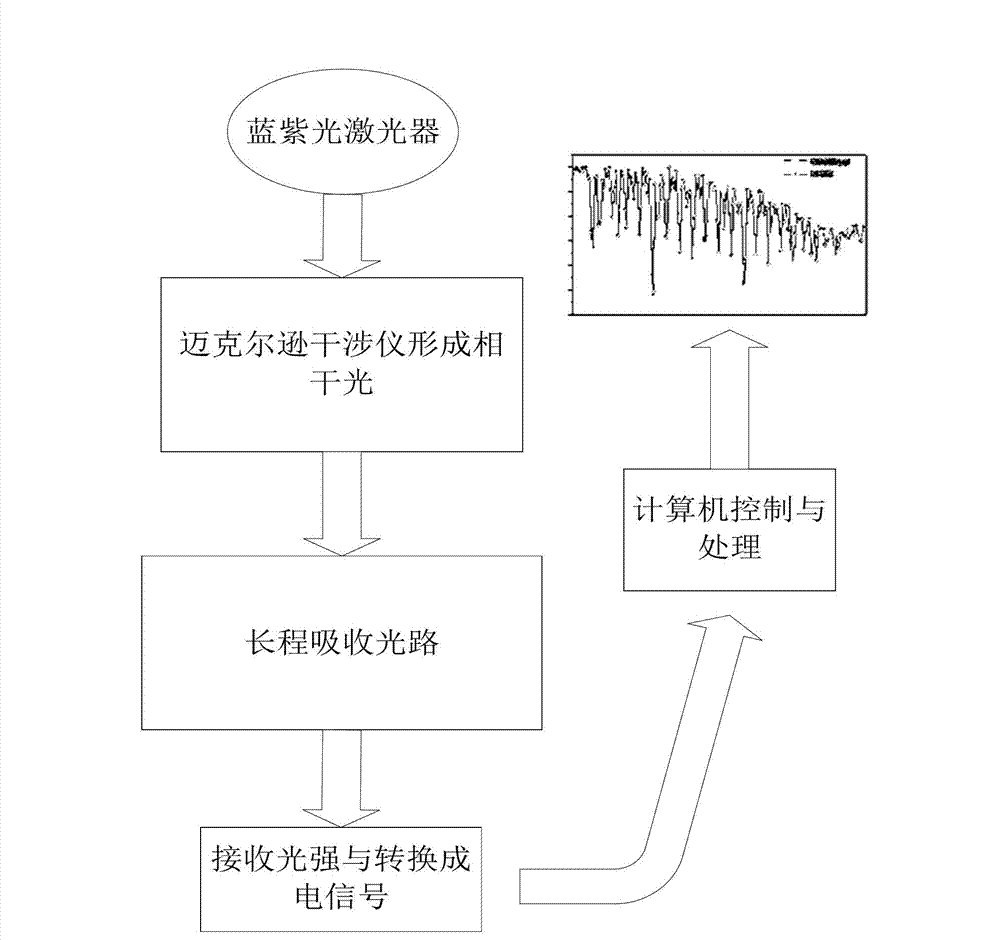

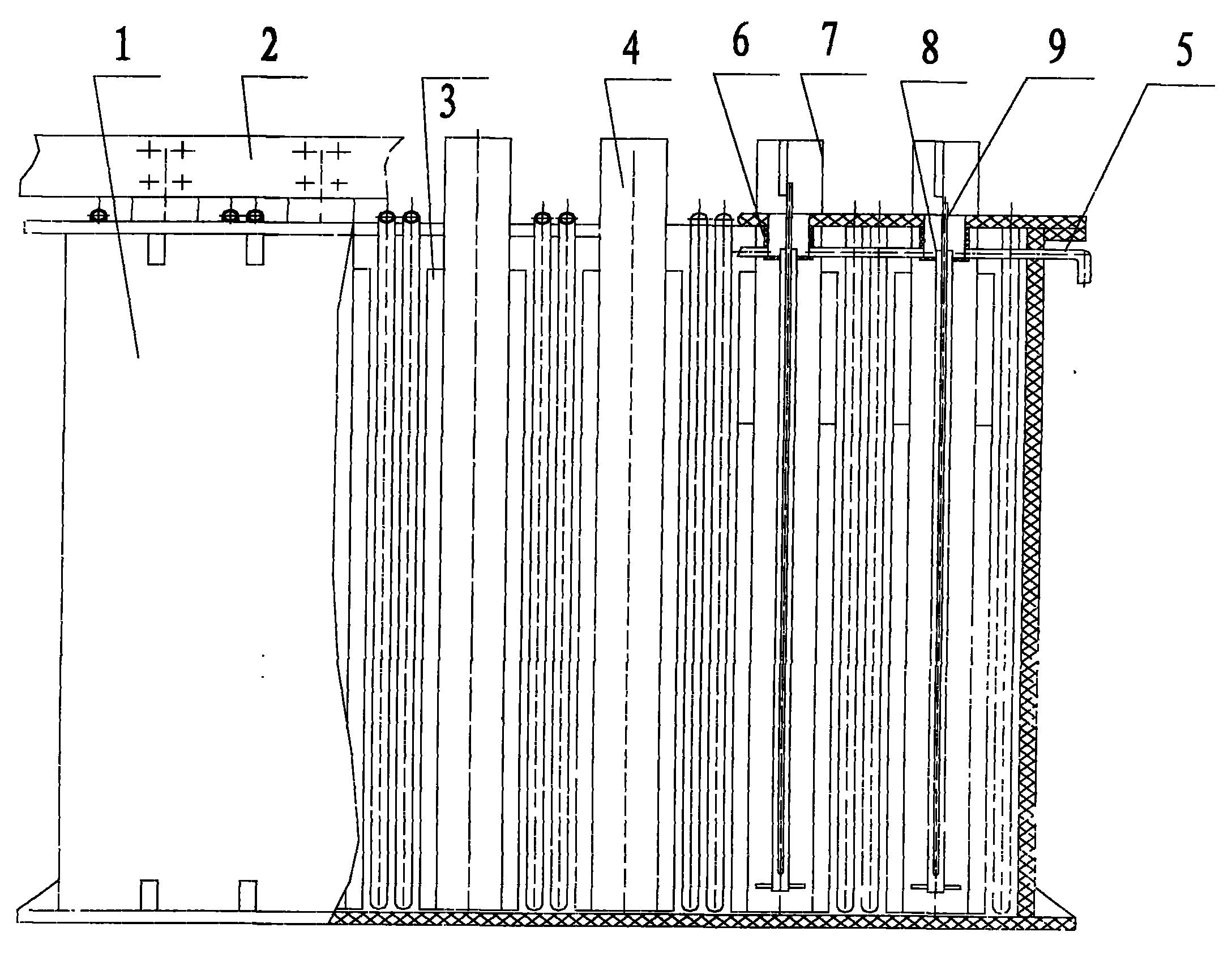

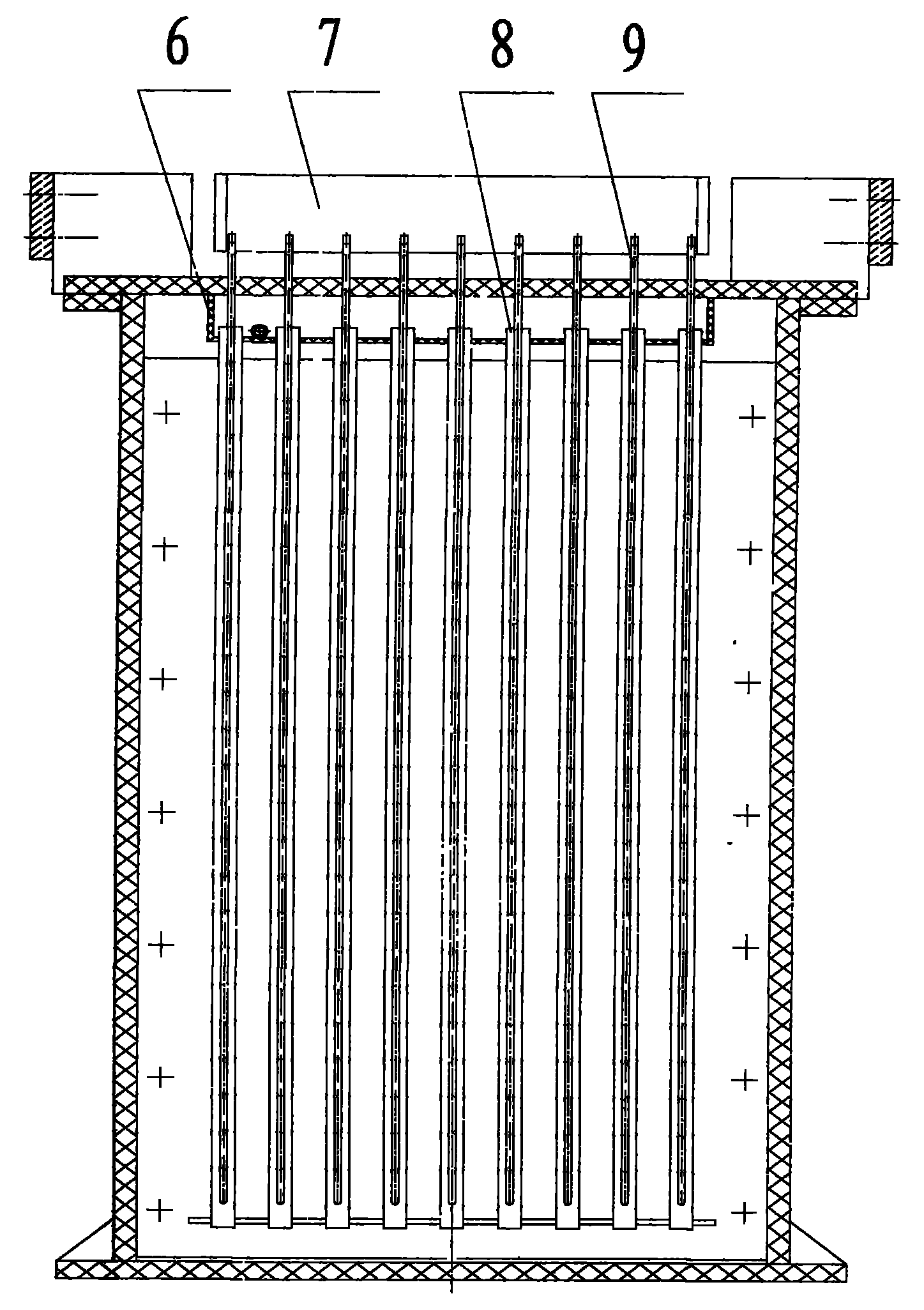

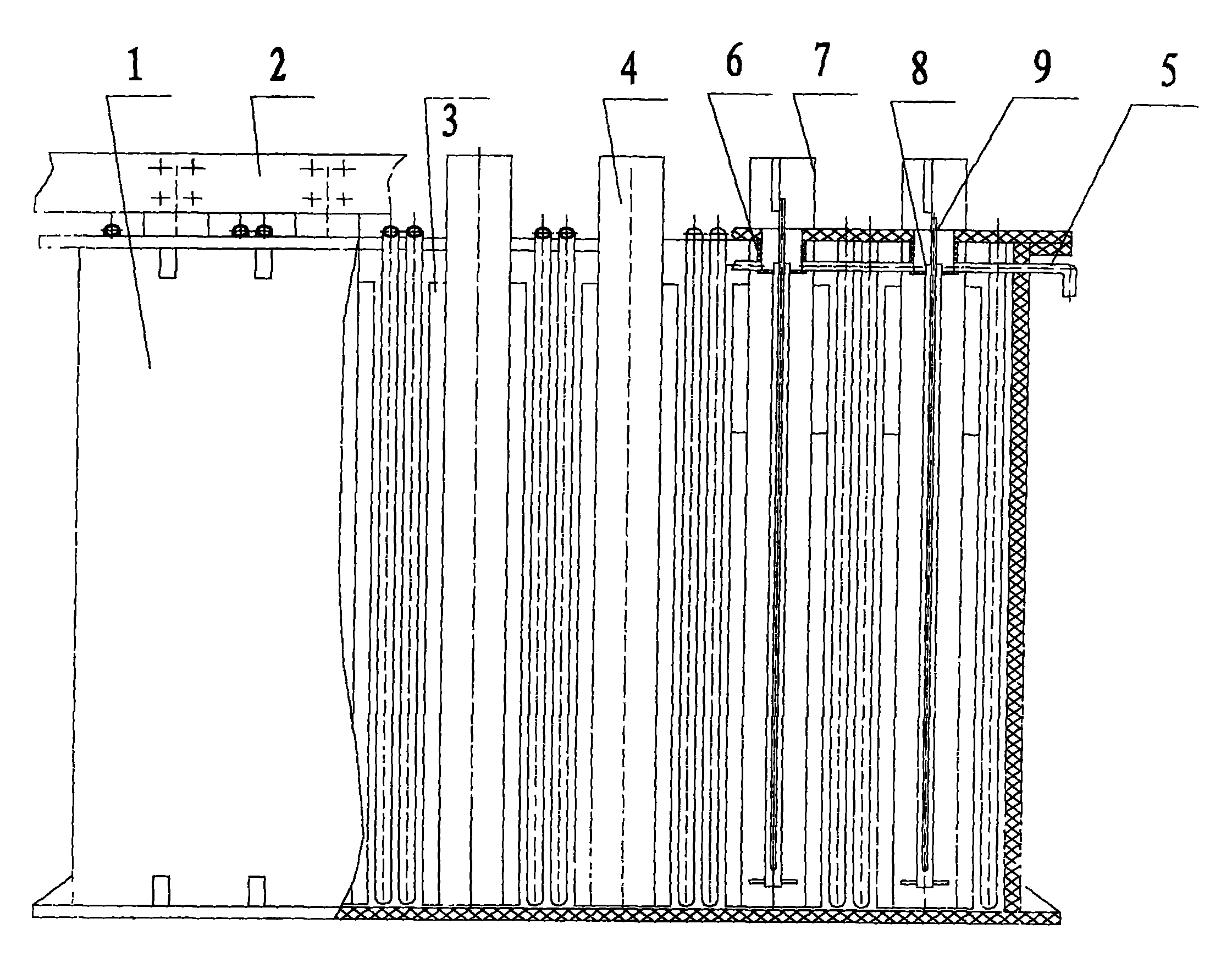

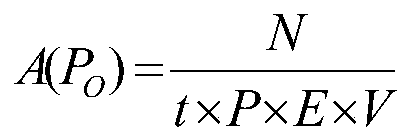

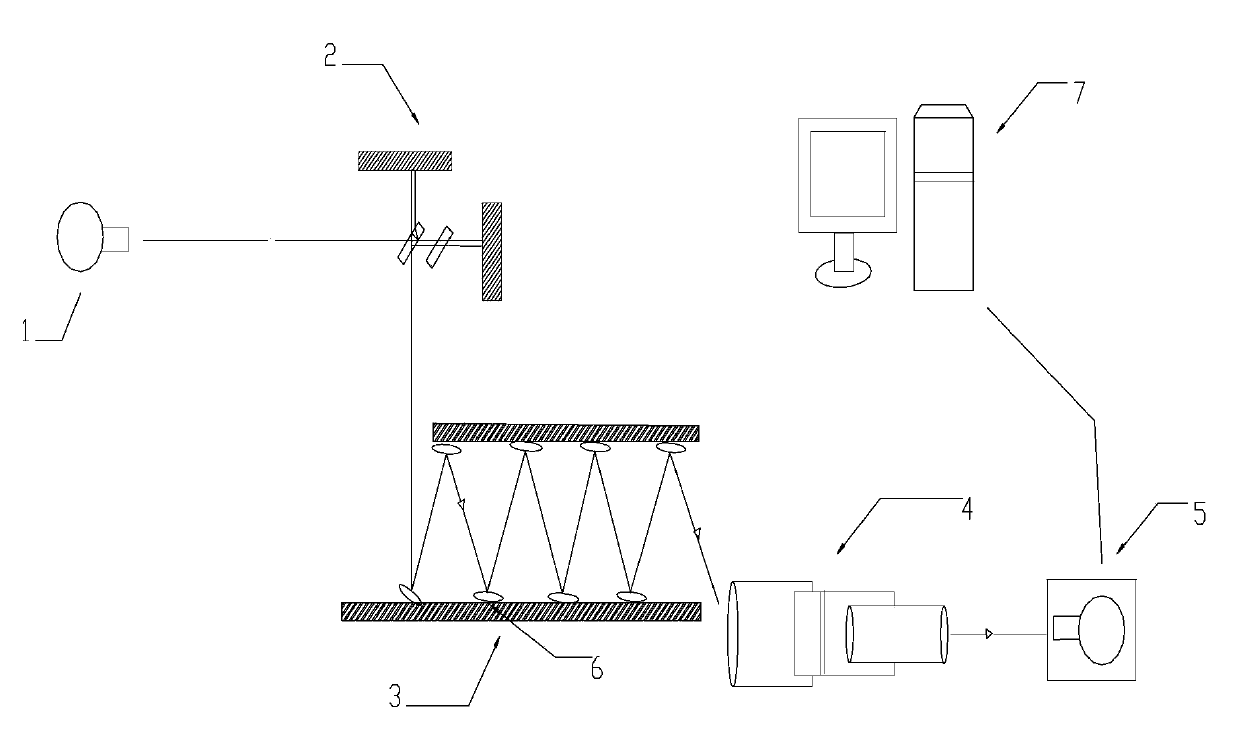

Concentration detection system used for polonium aerosol inside reactor workshop

ActiveCN103163090AHigh resolutionImprove noise immunityColor/spectral properties measurementsPoloniumLaser light

The invention relates to a concentration detection system used for polonium aerosol inside a reactor workshop. The concentration detection system used for the polonium aerosol inside the reactor workshop is composed of a laser light source (1), an interferometer (2), reactor workshop walls (3), a receiving telescope (4), a photoelectric conversion device (5), corner reflectors (6) and a computer processing system (7). In measurement, lasers sent by the light source are modulated through the interferometer (2) at first, and then are shot into a long-range absorbing light path and reflected and transmitted through a plurality of corner reflectors (6) on the reactor workshop walls (3), and finally are received by the receiving telescope (4), wherein he number of the corner reflectors is determined by the structure of the reactor workshop and the length of the absorbing light path. The photoelectric conversion device (5) converts received optical signals into electrical signals and sends the electrical signals to the computer processing system (7) to generate the Fourier spectrum, and concentration of the polonium aerosol is obtained through calculation. According to the concentration detection system used for the polonium aerosol inside the reactor workshop, rapid and accurate measurement of the polonium aerosol inside the reactor workshop becomes possible, and safety of the inside of the reactor and areas around the reactor is ensured.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

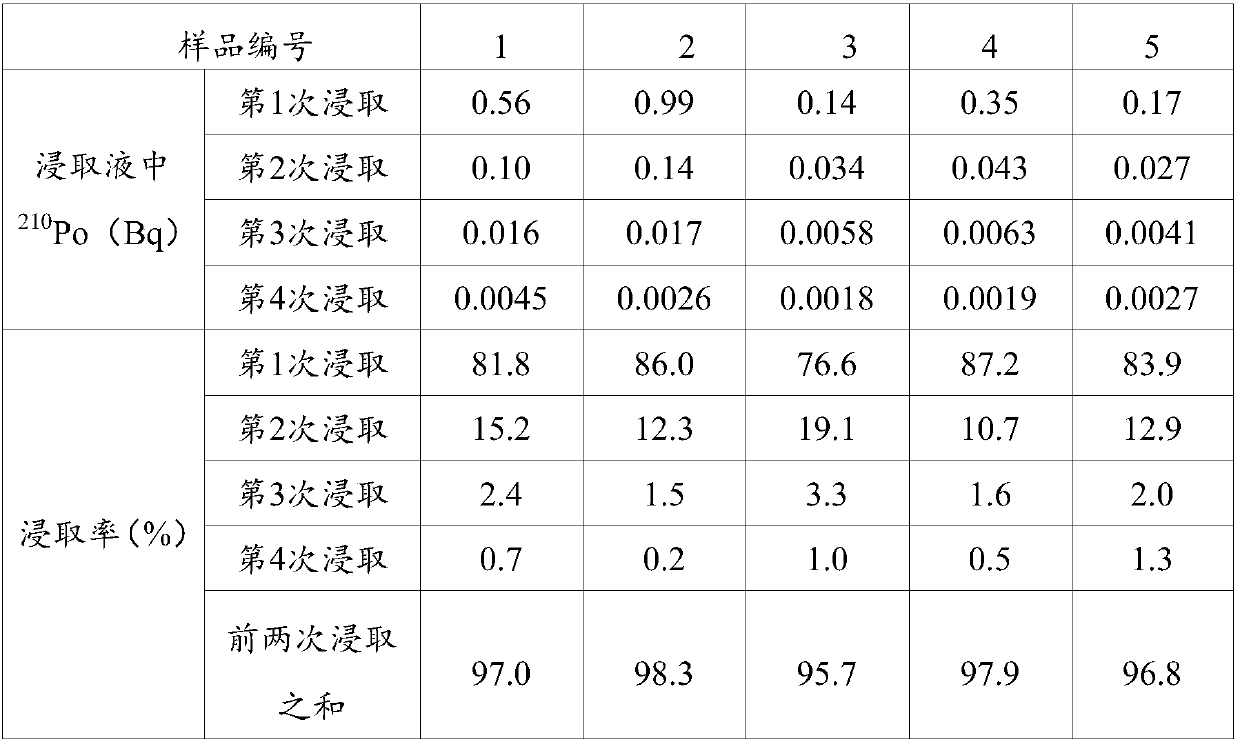

Method for polonium leaching in aerosol

PendingCN108020857AHigh extraction rateReduce volatile lossX/gamma/cosmic radiation measurmentWater bathsPolonium

The invention relates to the technical field of radioactive substance impact assessment, and relates to a method for polonium leaching in an aerosol. The method sequentially comprises the steps of (1)filtering by a filtering membrane to obtain a tested aerosol sample; (2) adding the filtering membrane, which obtains the tested aerosol sample, into a leaching device; (3) adding <209>Po(IV) with certain activity into the leaching device to serve as a tracer agent; (4) adding hydrochloric acid into the leaching device, enabling the solution to completely immerse the filtering membrane, and theninstalling the leaching device; (5) heating the leaching device so as to enable the solution in the leaching device to be at a slight boiling state, keeping the state, leaching <210>Po on the filtering membrane, and filtering to respectively collect a filtrate and leaching residues; (6) transferring the leaching residues to the leaching device, adding the hydrochloric acid again, then leaching andfiltering by using a method identical to that in the step (5), and carrying out the step for 1-5 times; (7) combining the filtrates of multiple times of leaching; and (8) heating the combined filtrate in a water bath to evaporate more than 90% of the liquid, cooling to obtain a filtrate dry product containing the <210>Po and the tracer agent <209>Po. According to the method, the recovery rate ofpolonium leaching can be improved and stabilized, and thus the accuracy of a <210>Po measurement result is improved.

Owner:CHINA INST FOR RADIATION PROTECTION

Production method of food-grade stabilized chlorine dioxide disinfectant

The invention relates to a production method of a food-grade stabilized chlorine dioxide disinfectant. The production method comprises the following steps: taking sodium chlorate as an oxidant as well as methanol in an acid medium as a reducing agent; preparing the methanol into acid reaction liquid of polonium chloride, potassium chloride, acetic acid and sulphuric acid solution; continuously dripping the acid reaction liquid into a saturated aqueous solution of sodium chlorate; keeping the system in negative pressure during the reaction process; and generating chlorine dioxide gas and then absorbing the chlorine dioxide gas by absorption liquid prepared with water, solid and flake caustic soda, solid borax and hydrogen peroxide, and finally obtaining the stabilized chlorine dioxide disinfectant. The production method can improve the utilization ratio of raw materials and the purity (up to 99 percent) of the chlorine dioxide gas, and is simple in process and low in production cost, and the obtained food-grade stabilized chlorine dioxide disinfectant is colorless, tasteless, non-irritating, non-toxic, non-corrosive and the like and is a safe and efficient food-grade disinfection product.

Owner:苏州久泰集团有限公司

Novel device for production of ammonium persulfate

InactiveCN102011137AImprove corrosion resistanceSolve pollutionElectrolysis componentsPoloniumElectrolysis

The invention provides a novel device for the production of ammonium persulfate, comprising an electrolytic bath, an anode copper bar, a cathode copper bar, an anode and a cathode. The electrolytic bath is made of plastic plates; the anode copper bar and the cathode copper bar are arranged above the electrolytic bath; the anode is connected with the anode copper bar; and the cathode is connected with the cathode cooper bar. The production device is characterized in that the cathode comprises a plurality of graphite cathode plates; and the anode is formed by spirally winding a polonium wire outside a titanium bar and carrying out spot welding. In the invention, the novel device for the production of the ammonium persulfate is environment-friendly, efficient and energy-saving.

Owner:NANTONG LANTIAN GRAPHITE EQUIPS

Anti-abrasive contact temperature measurement probe and treatment process thereof

The invention discloses an anti-abrasive contact temperature measurement probe and a treatment process thereof. An anti-abrasive metal coating comprises the following components in percentage by mass: 0.03%-0.05% of carbon, 0.12%-0.15% of boron, 2.5%-2.8% of chrome, 1.2%-1.5% of manganese, 2.5%-2.8% of sodium, 6.5%-6.8% of magnesium, 4.2%-4.5% of niobium, 3.4%-3.6% of polonium, 0.52%-0.54% of barium, 0.26%-0.28% of tungsten, 1.2%-1.5% of iodine, 2.5%-2.8% of cerium, 3.82%-3.87% of neodymium, 0.73%-0.75% of promethium, 0.62%-0.64% of europium, 9.2%-9.5% of gadolinium, 6.4%-6.6% of an assistant and the balance of iron.

Owner:JIANGSU JINDI ELECTRONICS TECH

Large-section H-shaped steel and production process thereof

The invention discloses large-section H-shaped steel and a production process thereof. The large-section H-shaped steel comprises the following chemical components in percentage by mass: 0.08-0.13% ofcarbon, 0.15-0.35% of silicon, 1.25-1.45% of manganese, 0.10-0.20% of vanadium, nitrogen not more than 0.012%, phosphorus not more than 0.01%, sulfur not more than 0.010%, 0.03-0.05% of niobium, 0.03-0.05% of thallium, 0.03-0.05% of polonium, 0.02-0.04% of terbium, 0.01-0.02% of nickel, and the balance of iron and impurity elements. The produced large-section H-shaped steel is lower in alloy content and high in final rolling temperature, reduces the load and the energy consumption of a rolling mill, and improves the production efficiency.

Owner:ANHUI KINGYOUNG STRUCTURAL METAL WORK

Scaling powder special modified rosin and preparation method thereof

ActiveCN102974957AHas non-corrosion base metalImprove liquidityWelding/cutting media/materialsSoldering mediaPoloniumAntioxidant

The invention discloses scaling powder special modified rosin and a preparation method thereof. The scaling powder special modified rosin is made through compound, by weight, rosin 90.4%-94.8%, acrylic acid 4%-6%, fumaric acid 1%-3%, antioxidant 0.1%-0.3% and additive polonium (PO) 0.1%-0.3%. The preparation method of the scaling powder special modified rosin includes adding the rosin into a reaction still for reaction, slowly adding the fumaric acid, adding the antioxidant and the acrylic acid after the reaction is finished, sampling and detecting an acid value, cooling when the acid value is qualified, adding the additive, evenly mixing and then cooling, packaging and then obtaining the rosin. The scaling powder obtained made from the modified rosin has the advantages of not corroding base materials, so under a welding temperature, fluidity of welding flux is increased, an oxidation film on the surface of metal is eliminated, and soldering flux residues are easy to clean. Meanwhile, poisonous gas and foul smell can not be generated, and human bodies can not be damaged, and environment can not be polluted.

Owner:GUANGXI ZHONGCHANG RESIN

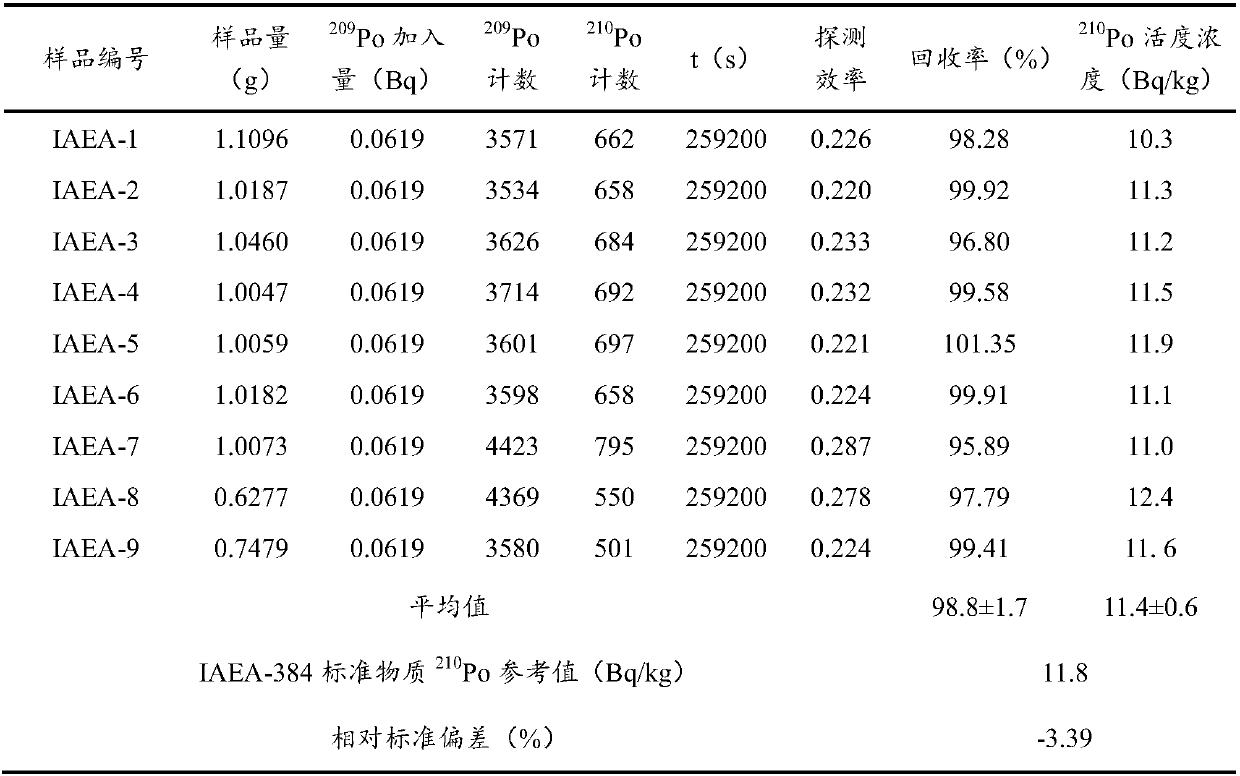

Rapid analysis method of polonium-210 in aerosol

PendingCN110988962AImprove measurement rateX/gamma/cosmic radiation measurmentPoloniumAnalytical chemistry

The invention discloses a rapid analysis method of polonium-210 in aerosol. The method comprises the steps of aerosol sample treatment, polonium-210 chemical analysis, polonium-210 activity concentration calculation in an aerosol sample and the like. According to the method disclosed by the invention, the sample treatment process only needs 4 hours, so that the measurement rate of polonium-210 inaerosol is greatly improved.

Owner:CHINA INST FOR RADIATION PROTECTION

Concentration detection system used for polonium aerosol inside reactor workshop

ActiveCN103163090BHigh resolutionImprove noise immunityColor/spectral properties measurementsPoloniumLaser light

The invention relates to a concentration detection system used for polonium aerosol inside a reactor workshop. The concentration detection system used for the polonium aerosol inside the reactor workshop is composed of a laser light source (1), an interferometer (2), reactor workshop walls (3), a receiving telescope (4), a photoelectric conversion device (5), corner reflectors (6) and a computer processing system (7). In measurement, lasers sent by the light source are modulated through the interferometer (2) at first, and then are shot into a long-range absorbing light path and reflected and transmitted through a plurality of corner reflectors (6) on the reactor workshop walls (3), and finally are received by the receiving telescope (4), wherein he number of the corner reflectors is determined by the structure of the reactor workshop and the length of the absorbing light path. The photoelectric conversion device (5) converts received optical signals into electrical signals and sends the electrical signals to the computer processing system (7) to generate the Fourier spectrum, and concentration of the polonium aerosol is obtained through calculation. According to the concentration detection system used for the polonium aerosol inside the reactor workshop, rapid and accurate measurement of the polonium aerosol inside the reactor workshop becomes possible, and safety of the inside of the reactor and areas around the reactor is ensured.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Alloy steel nut connecting piece and preparation method thereof

InactiveCN106048452ALess impuritiesHigh purityFoundry mouldsMetallic material coating processesNiobiumSlag

The invention discloses an alloy steel nut connecting piece. The alloy steel nut connecting piece is characterized by being prepared from, by weight percent, 0.55%-0.65% of magnesium, 1.25%-1.3% of manganese, 2.1%-2.2% of chromium, 0.7%-0.75% of silicon, 1.22%-1.35% of carbon, 0.4%-0.45% of copper, 0.02%-0.06% of titanium, 0.15%-0.20% of tungsten, 0.6%-0.9% of molybdenum, 0.4%-0.6% of niobium, 0.03%-0.05% of cobalt, 0.02%-0.05% of scandium, 0.002%-0.006% of polonium and 20%-25% of a refining slag regulating agent. According to the alloy steel nut connecting piece, casting quality is improved, and mechanical performance, corrosion resistance and oxidation resistance are good.

Owner:MAANSHAN WANXIN CASTING

Hard alloy cutting tool blade

The invention relates to a hard alloy cutting tool blade, and belongs to the technical field of blade materials. The hard alloy cutting tool blade is characterized by comprising the following components of, by weight, 1-2 parts of chromium carbide, 1-3 parts of silicon carbide, 2-4 parts of tantalum carbide, 1-5 parts of lanthanum, 2-4 parts of praseodymium, 1-2 parts of caesium, 1-3 parts of cadmium, 2-5 parts of polonium, 1-2 parts of scandium, 1-3 parts of francium, 1-5 parts of antimony and the balance tungsten carbide. According to the hard alloy cutting tool blade, cutter materials are reasonably selected and are reasonably proportioned, so that the problem that the harness and the wear resistance of an existing cutter which are kept at a high temperature are low is solved.

Owner:江苏切剀刀具有限公司

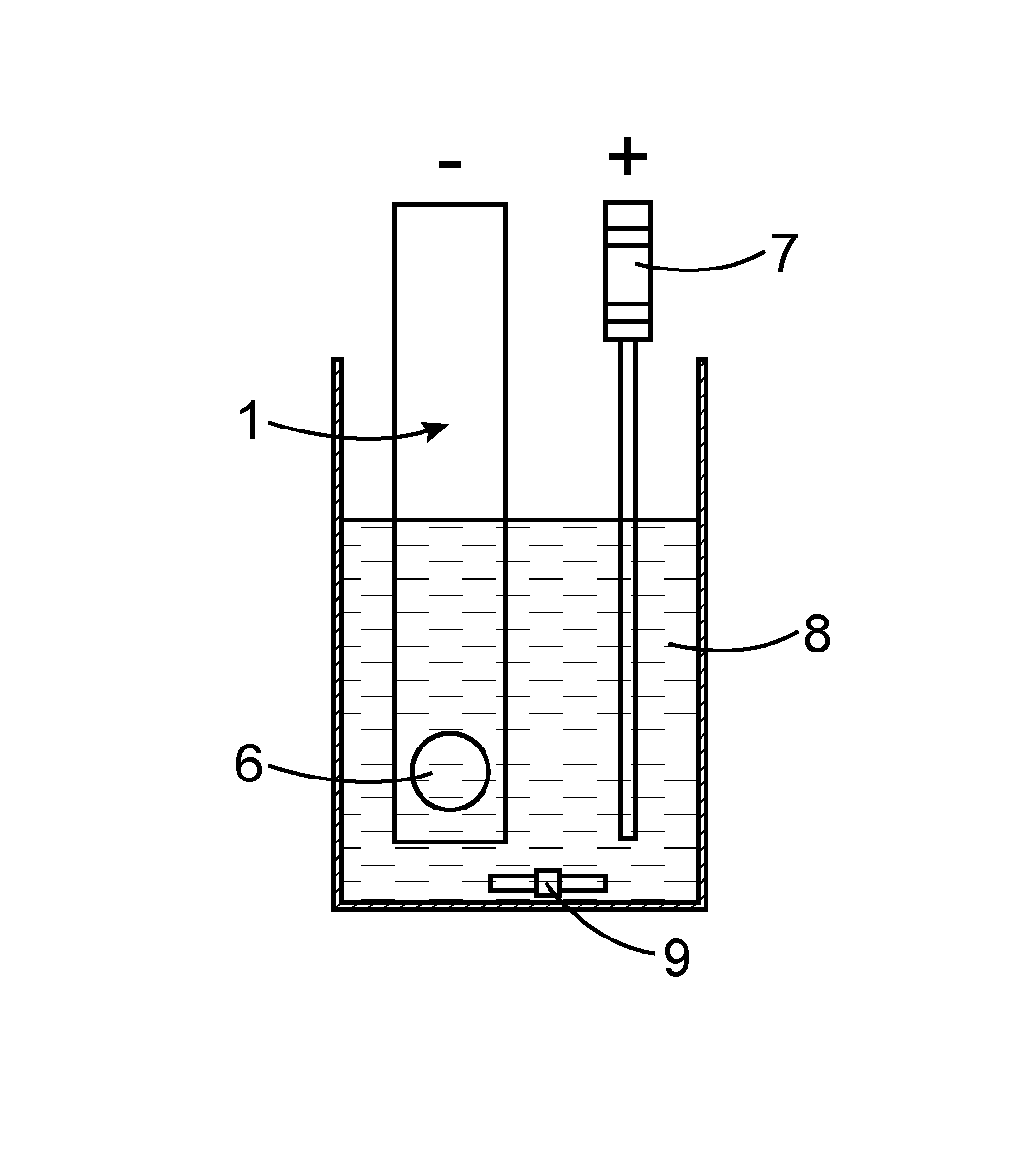

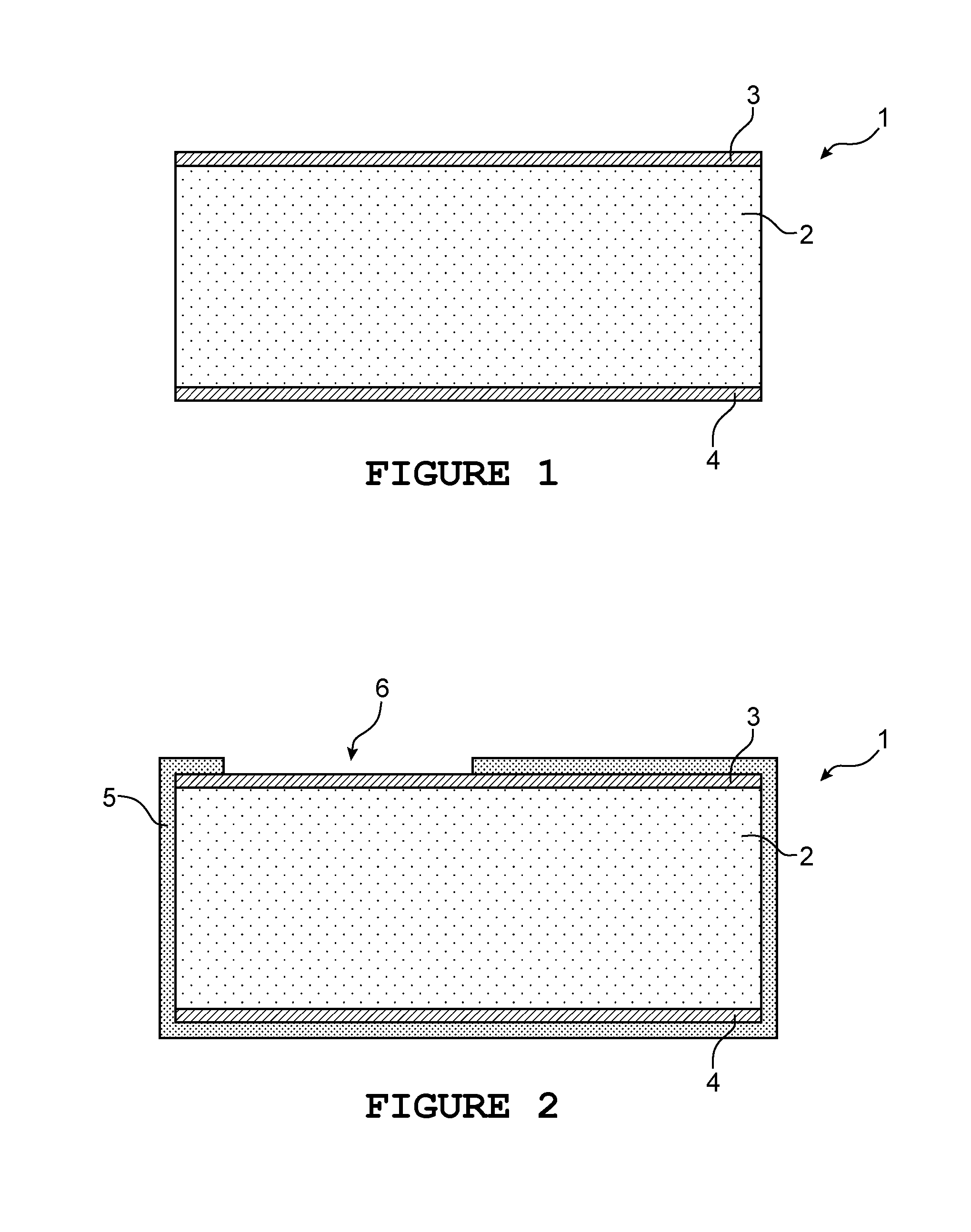

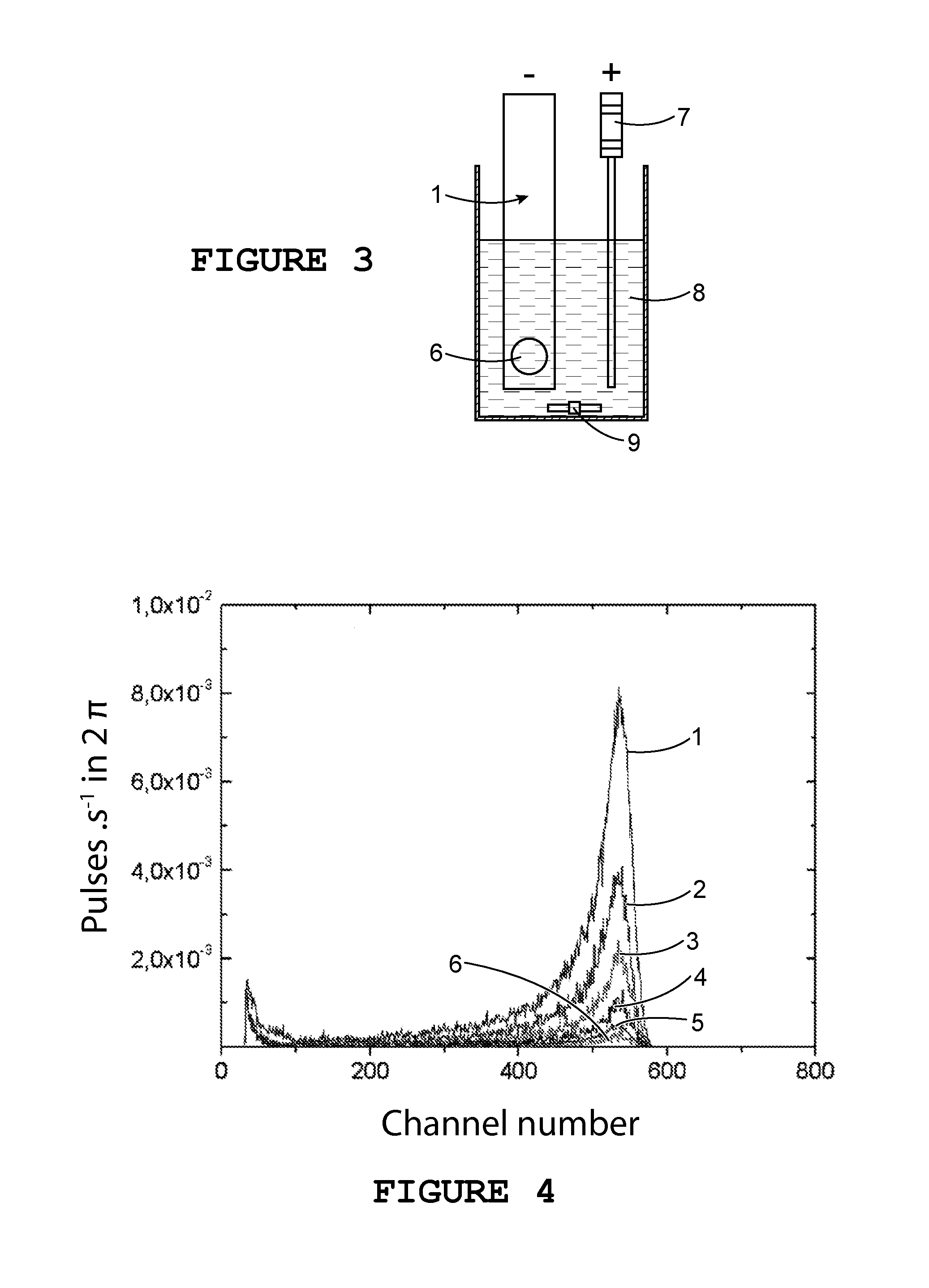

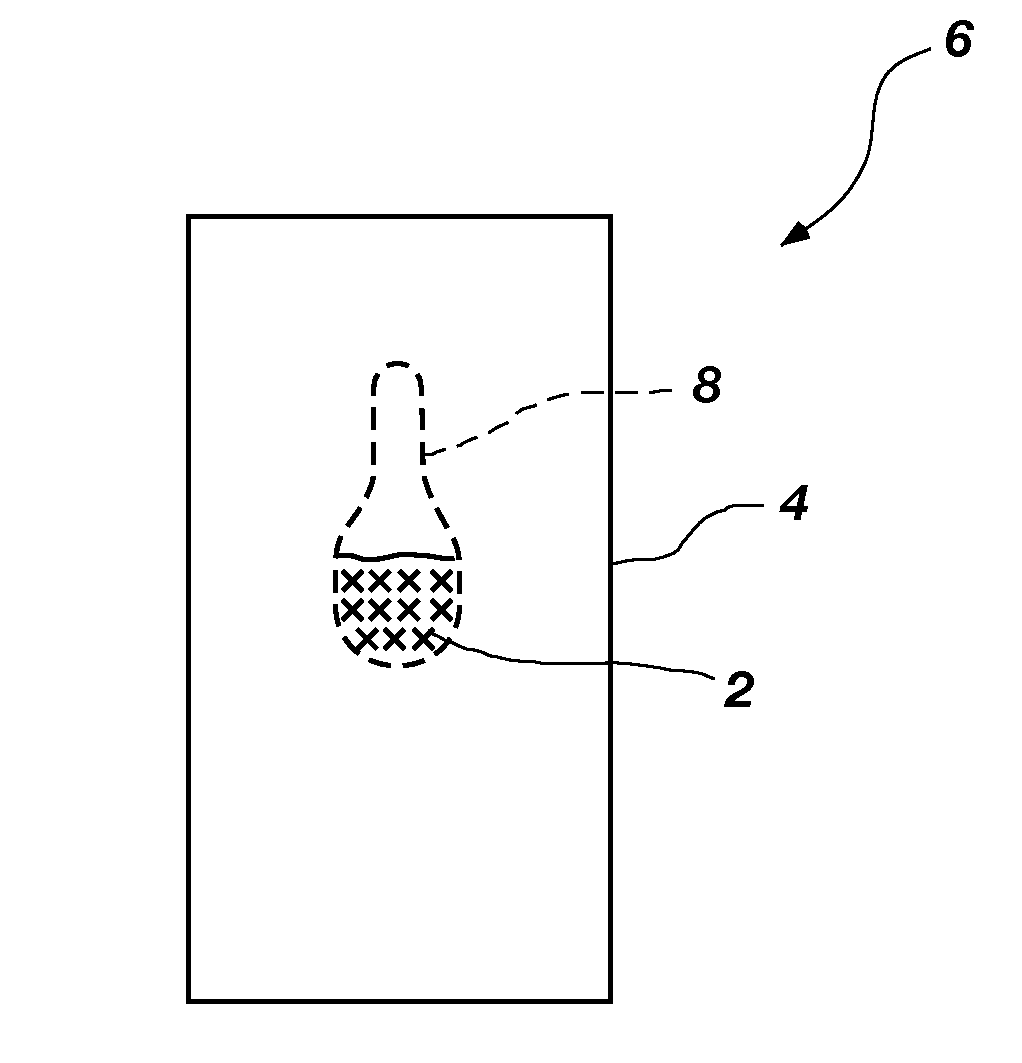

Detection method using an electrochemically-assisted alpha detector for nuclear measurement in a liquid medium

ActiveUS8888981B2Avoid formingSatisfactory conductivityCellsPhotography auxillary processesLiquid mediumActinide

An in situ method for detecting alpha particles contained in a liquid medium, which uses a system which includes a counter-electrode and an alpha particle detector including a substrate made of an intrinsic semiconductor material sandwiched between two electrical contacts, wherein the contact intended to be in contact with the liquid medium is made of boron-doped diamond. By forming a particular electrolyte 8 and by causing a current to flow between counter-electrode and the boron-doped diamond contact in contact with the liquid medium, actinides or polonium present in the liquid medium may be concentrated on the boron-doped diamond contact, and by this means the detection limit of the alpha emitters may be lowered.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Building material product using radioactive blast furnace slag as blending material and method for processing sewage water

InactiveCN101177341ALow costImprove practicalitySolid waste managementWater/sewage treatment using germicide/oligodynamic-processPoloniumSlag

The invention relates to a building material product using radioactive blast furnace slag as the admixture and the sewage treatment method; wherein, the building material product adopts blast furnace water quenched slag and blast furnace dry slag with radioactive polonium <232> substance as the admixture, which comprises special cement and cement elements used for sewage treatment. The invention has the advantages of low investment for sewage treatment, low use and maintenance cost, wide application range in sewage treatment field and no secondary radioactive pollution. Being used for the sewage treatment, the building material product can degrade COD by 30 to 55 percent, and kill coliform groups above 99 percent, the field radiation safety conforms to the GB6566-2001 standard, and the Alpha value and the Beta value of water after being treated are all lower than the indexes specified in national standards.

Owner:杨忠刚

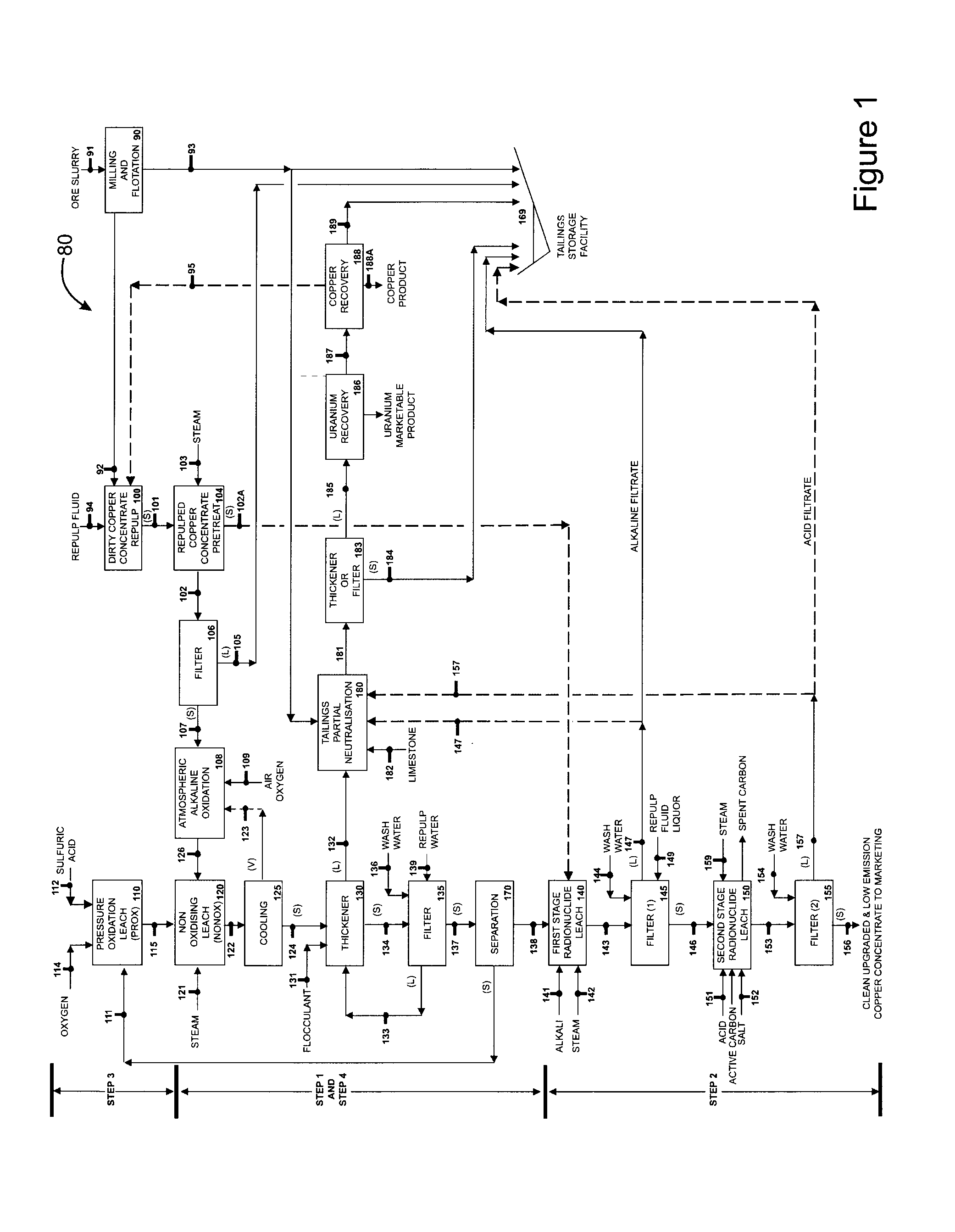

Hydrometallurgical method for the removal of radionuclides from radioactive copper concentrates

ActiveUS20150329938A1Suppress boilingLowering of radiumSolvent extractionGold compoundsPoloniumHydrometallurgy

A hydro-metallurgical method 80 for the removal of uranium, thorium, radium, lead, bismuth and polonium and / or other radionuclides from a radioactive copper concentrate to produce an upgraded copper concentrate having lowered emission levels. The method comprises the step of: subjecting the copper concentrate to an acidic leaching process (NONOX leach) 120 using a sulfate and chloride containing lixiviant under electrochemically controlled conditions, to allow at least partial removal of one or more of the radionuclides to produce the lowered emission upgraded copper concentrate, wherein the leaching process is conducted at elevated temperature and under pressure to suppress boiling in the leaching process.

Owner:ORWAY MINERAL CONSULTANTS WA

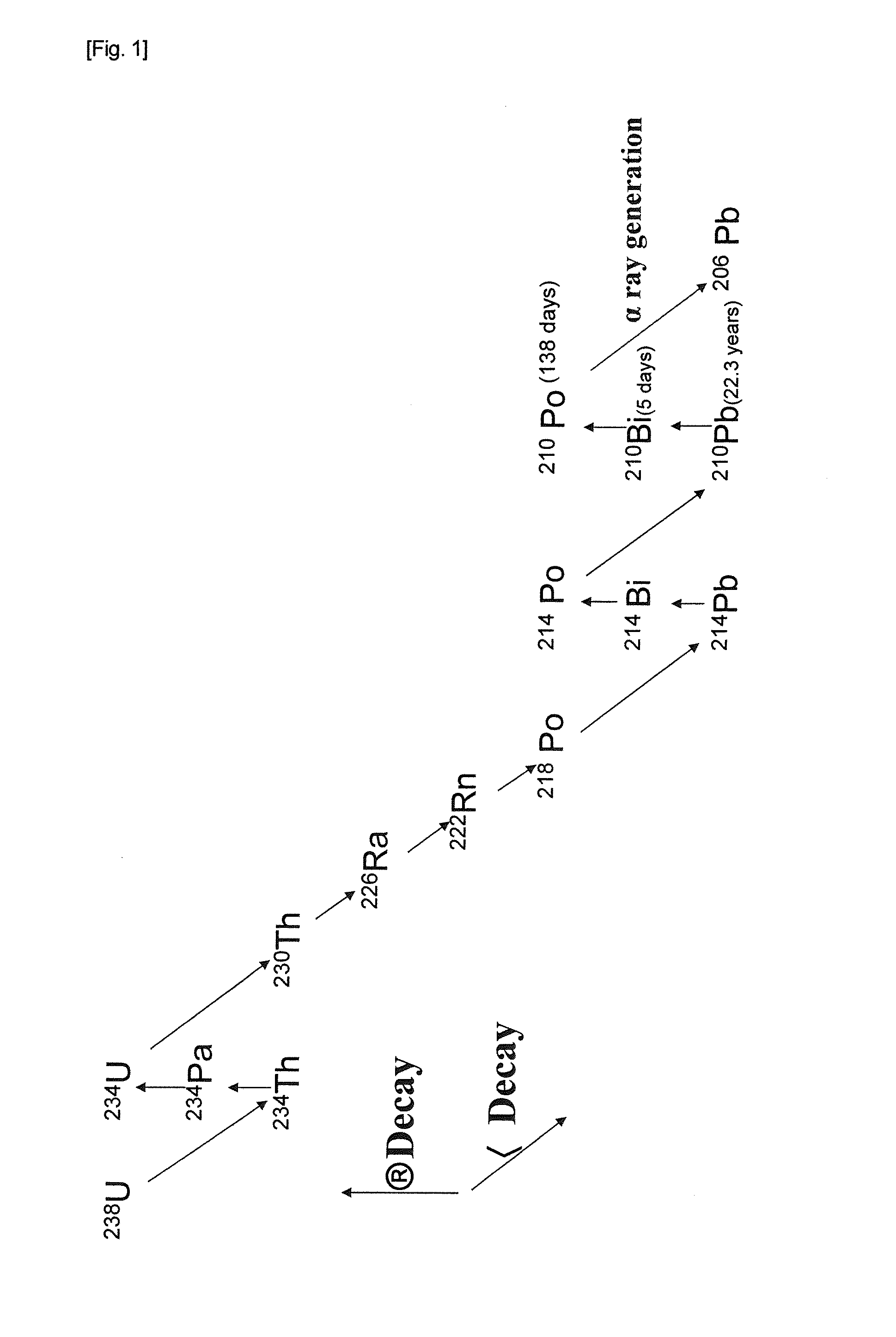

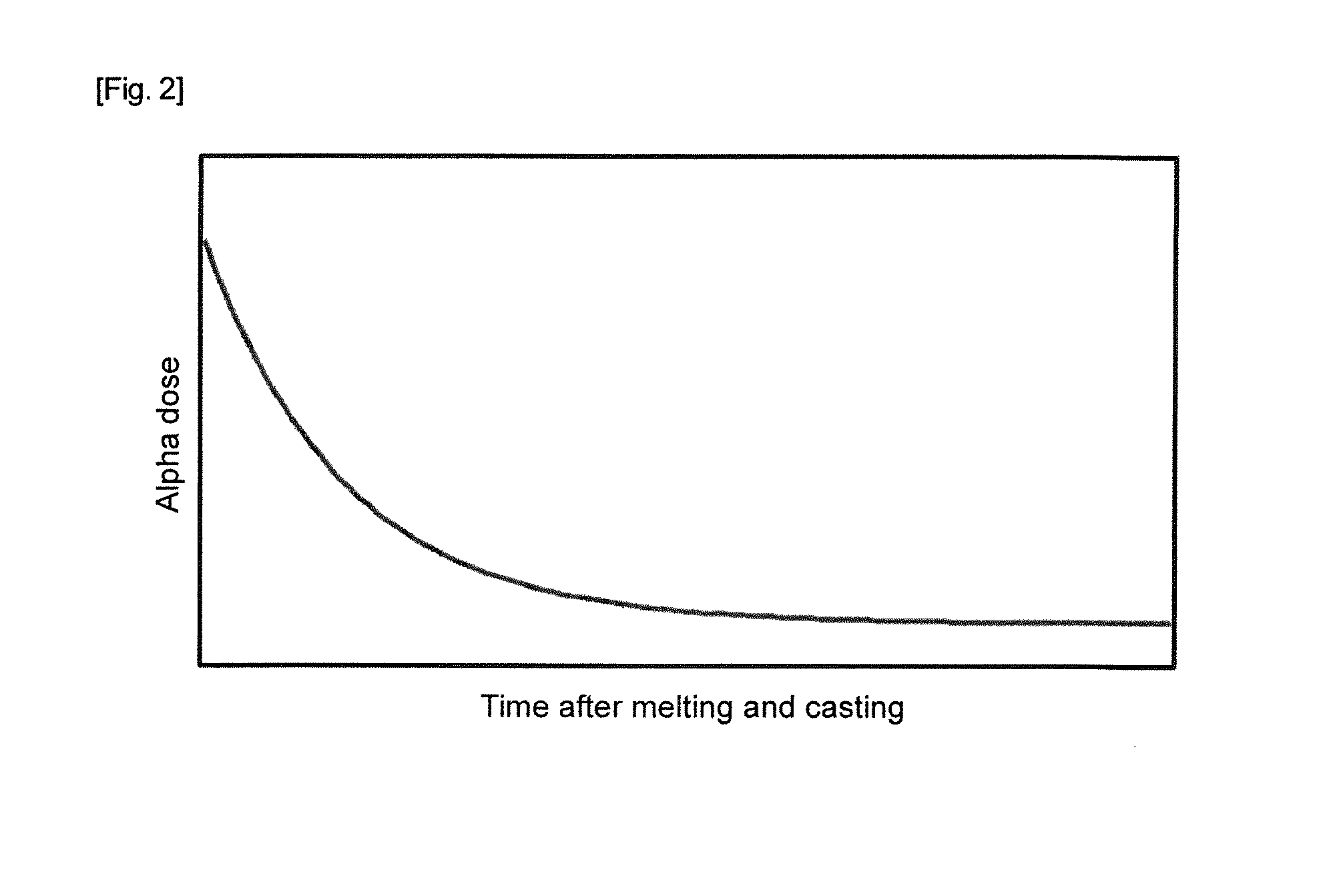

Method of producing low alpha-ray emitting bismuth, and low alpha-ray emitting bismuth

ActiveUS20160160368A1Reduced cell volumeReduce voltagePhotography auxillary processesSemiconductor/solid-state device detailsElectrolysisSemiconductor chip

Provided is low alpha-ray emitting bismuth having an alpha dose of 0.003 cph / cm2 or less. Additionally provided is a method of producing low alpha-ray emitting bismuth, wherein bismuth having an alpha dose of 0.5 cph / cm2 or less is used as a raw material, the raw material bismuth is melted in a nitric acid solution via electrolysis to prepare a bismuth nitrate solution having a bismuth concentration of 5 to 50 g / L and a pH of 0.0 to 0.4, the bismuth nitrate solution is passed through a column filled with ion-exchange resin to eliminate polonium contained in the solution by an ion-exchange resin, and bismuth is recovered by means of electrowinning from the solution that was passed through the ion-exchange resin. Recent semiconductor devices are of high density and high capacity, and therefore are subject to increased risk of soft errors caused by the effects of alpha rays emitted from materials in the vicinity of semiconductor chips. In particular, there is a strong demand for higher purification of solder materials used near semiconductor devices, and there is a demand for low alpha-ray emitting materials. Therefore, the present invention aims to elucidate the phenomenon of alpha ray generation from bismuth, and to provide a low alpha-ray emitting, high-purity bismuth that can be applied to the required materials and a production method thereof, as well as to provide an alloy of low alpha-ray emitting bismuth and tin and a production method thereof.

Owner:JX NIPPON MINING& METALS CORP

Method for detecting coal spontaneous combustion fire source position by polonium-210 method

PendingCN111142167AScientific and efficient prevention and controlNot easy to interfereNuclear radiation detectionCoal spontaneous combustionPolonium

The invention discloses a method for detecting the position of a coal spontaneous combustion fire source through a polonium-210 method. The method comprises the steps of arrangement of detection points, sampling, treatment of a soil sample, polonium-210 analysis, data value analysis and the like. The method provided by the invention is not easily interfered by factors such as interference seasons,weather, sunlight and the like, is obvious in abnormal reaction, has relatively high sensitivity, and has potential application value in the field of accurate detection of the coal spontaneous combustion fire source position.

Owner:CHINA INST FOR RADIATION PROTECTION

Stretch-resistant metal casting

The invention provides a stretch-resistant metal casting, and particularly relates to the field of metal castings. The casting is prepared from 90-110 parts of iron, 0.5-1.5 parts of polonium, 1-3 parts of iridium, 1-2 parts of osmium, 1-2 parts of palladium, 1-10 parts of molybdenum, 1-5 parts of manganese, 1-5 parts of zirconium, 1-2 parts of yttrium, 1-3 parts of silicon, 1-5 parts of copper, 1-4 parts of scandium, 1-2 parts of chromium, 1-2 parts of tellurium, 1-3 parts of nickel and other unavoidable trace impurities. The stretch-resistant property is good, the service life of the castingis prolonged, the production efficiency is improved, and the production safety is ensured.

Owner:江苏东顺合金材料有限公司

Electroplating sampling detection method of 210Po in chemical prospecting sample of mineral exploration by polonium method

ActiveCN108120626AImprove work efficiencyWide measurement rangePreparing sample for investigationRadiation measurementWater bathsPolonium

The invention belongs to the field of 210Po detection method, and particularly discloses an electroplating sampling detection method of 210Po in a chemical prospecting sample of mineral exploration bya polonium method. The method comprises the following steps: airing or drying a sample in time, grinding until the granularity is less than 417mu m to obtain a specimen, and filling into a bag for later use; weighing the specimen, putting into a beaker, adding ascorbic acid, and adding a hydrochloric acid solution 1#; putting a pre-treated copper sheet into the beaker, and shaking in a constant-temperature shaking bath at 60 DEG C for 110-130 minutes; taking out the sheet after shaking is completed, washing with tap water, and drying the sheet for detecting; measuring the alpha counting ratealpha on the sheet copper surface on a low-background alpha measurement instrument after the sheet is taken off for 30 minutes, and calculating the specific activity of 210Po according to a formula. The method for detecting 210Po in a chemical prospecting sample by adopting an electroplating sampling method has high working efficiency for field mineral exploration, is not influenced by thorium, climate and the like, has a wide detection range, simple analyzing process and easily controlled measurement condition, and is convenient for popularization and application.

Owner:核工业二三0研究所

Twin induced plastic steel with high elongation percentage and high hole expansion rate and manufacture method thereof

ActiveCN102400036BImprove mechanical propertiesAvoid reduction in hole expansion rateNiobiumManganese

The invention provided twin induced plastic steel with a high elongation percentage and a high hole expansion rate and a manufacture method thereof, the steel consists of 0.30 to 0.70 % of carbon, less than or equal to 1.0 % of silicon, 10 to 20% of manganese, less than or equal to 1.0 % of aluminum, 0.005 to 0.20% of polonium, 0.005 to 0.30% of Ra, 0.004 to 0.05% of nitrogen, less than or equal to 0.2% of niobium, less than or equal to 0.3 % of vanadium, less than or equal to 1 of copper and the balance of Fe. The method comprises the following steps of: (1) smelting: smelting by a vacuum furnace, allowing the molten steel to stand for 3-5 min, casting at a casting temperature of 1450-1550 DEG C; (2) hot rolling: heating the casting blank at a temperature of 1150 to 1200 DEG C, with a heating rate of 10-15 DEG C / min, performing heat preservation for 20 to 40 minutes, rolling at an initial rolling temperature of 1150-850 DEG C, stopping rolling at a finishing rolling temperature of 900-600 DEG C, rapidly cooling to room temperature at a rate of more than or equal to 20 DEG C / second after rolling; (3) cold rolling: performing cold rolling with a reduction ratio of the hot rolled plate being 40%-80% ; (4) heat treatment: performing heat treatment at a temperature of 600 to 1000 DEG C, rapidly cooling to room temperature at a rate of more than or equal to 20 DEG C / second after heat preservation for 3 to 10 minutes. The steel of the invention has low cost, a simple method, good quality of the product surface, an excellent processing property and an integrated mechanical property.

Owner:ANGANG STEEL CO LTD

Producing method of high steam pressure chalcogen alloy block

InactiveCN103572228AImprove uniformityAvoid oxidation reactionsVacuum evaporation coatingSputtering coatingIndiumSteam pressure

The invention provides a producing method of high steam pressure chalcogen alloy block. The producing method is to prepare chalcogen (one of gallium, indium, thallium, germanium, tin, lead, antimony, bismuth, selenium, tellurium or polonium) having 0.5-30 atomic percent and metallic materials having the left atomic percent in a predetermined atomic percent, and are placed in a ceramic container for vacuum melting. The alloy melting soup is cooled in a gas or liquid manner, and is condensed and shaped into a casting blank which is crushed into alloy powder. Uniform alloy powder is obtained through screening, and block alloy can be produced by cold press molding and hot pressed sintering. Accordingly, the block alloy having over 99% of high purity, content difference controlled within plus or minus 1%, fine particles and over 90% of density.

Owner:THINTECH MATERIALS TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Method for preparing [alpha] measurement source of polonium according to micro precipitation method Method for preparing [alpha] measurement source of polonium according to micro precipitation method](https://images-eureka.patsnap.com/patent_img/9dc2d1de-3ad3-43e8-a5ac-c973a8893e88/HDA0001201591260000011.png)

![Method for preparing [alpha] measurement source of polonium according to micro precipitation method Method for preparing [alpha] measurement source of polonium according to micro precipitation method](https://images-eureka.patsnap.com/patent_img/9dc2d1de-3ad3-43e8-a5ac-c973a8893e88/HDA0001201591260000021.png)

![Method for preparing [alpha] measurement source of polonium according to micro precipitation method Method for preparing [alpha] measurement source of polonium according to micro precipitation method](https://images-eureka.patsnap.com/patent_img/9dc2d1de-3ad3-43e8-a5ac-c973a8893e88/HDA0001201591260000031.png)