Novel device for production of ammonium persulfate

A production device and technology of ammonium persulfate, applied in the direction of electrolysis process, electrolysis components, etc., can solve the problems of affecting electrolysis, reducing production efficiency, poisonous lead mud, etc., and achieving the effects of good corrosion resistance, high production efficiency and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

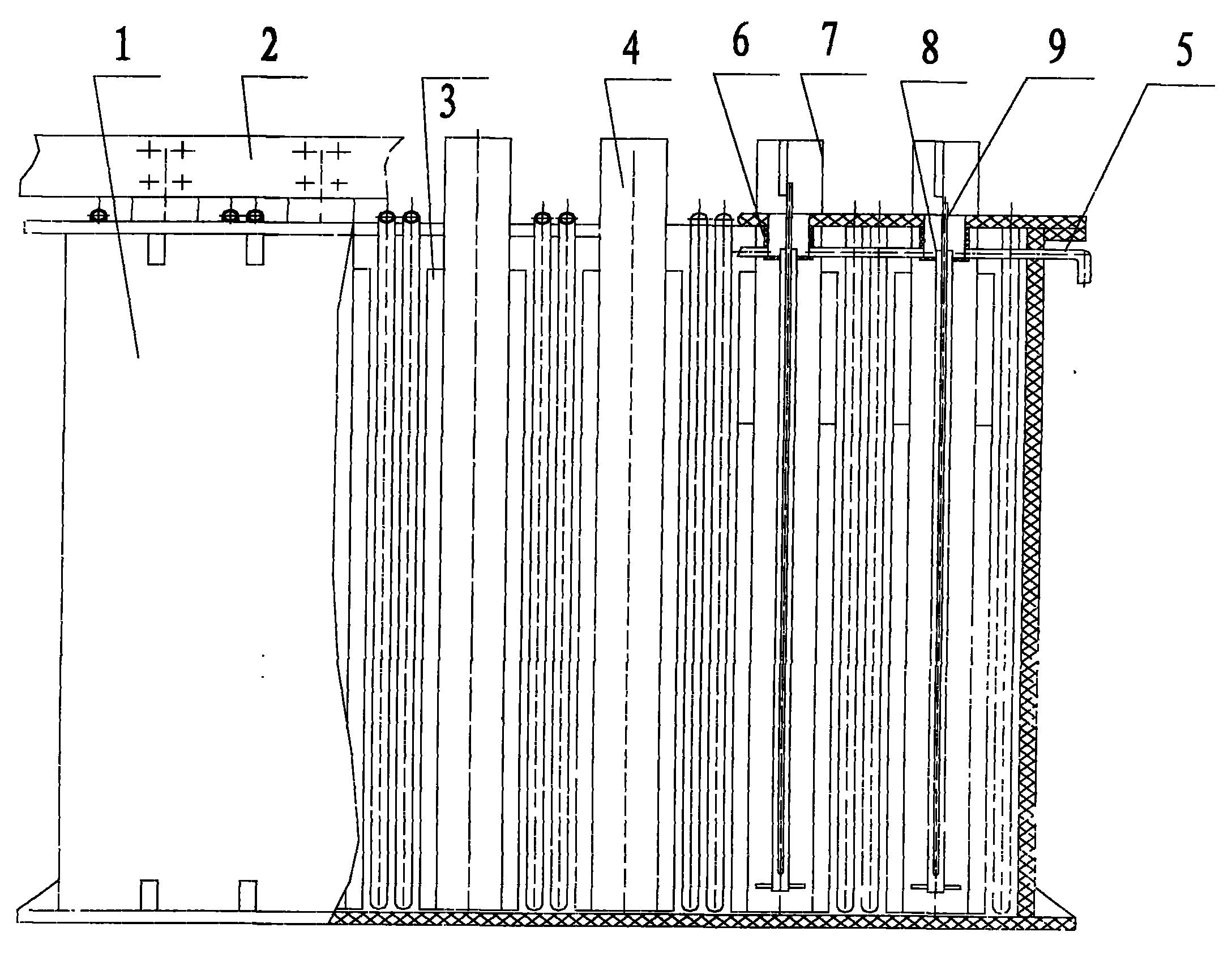

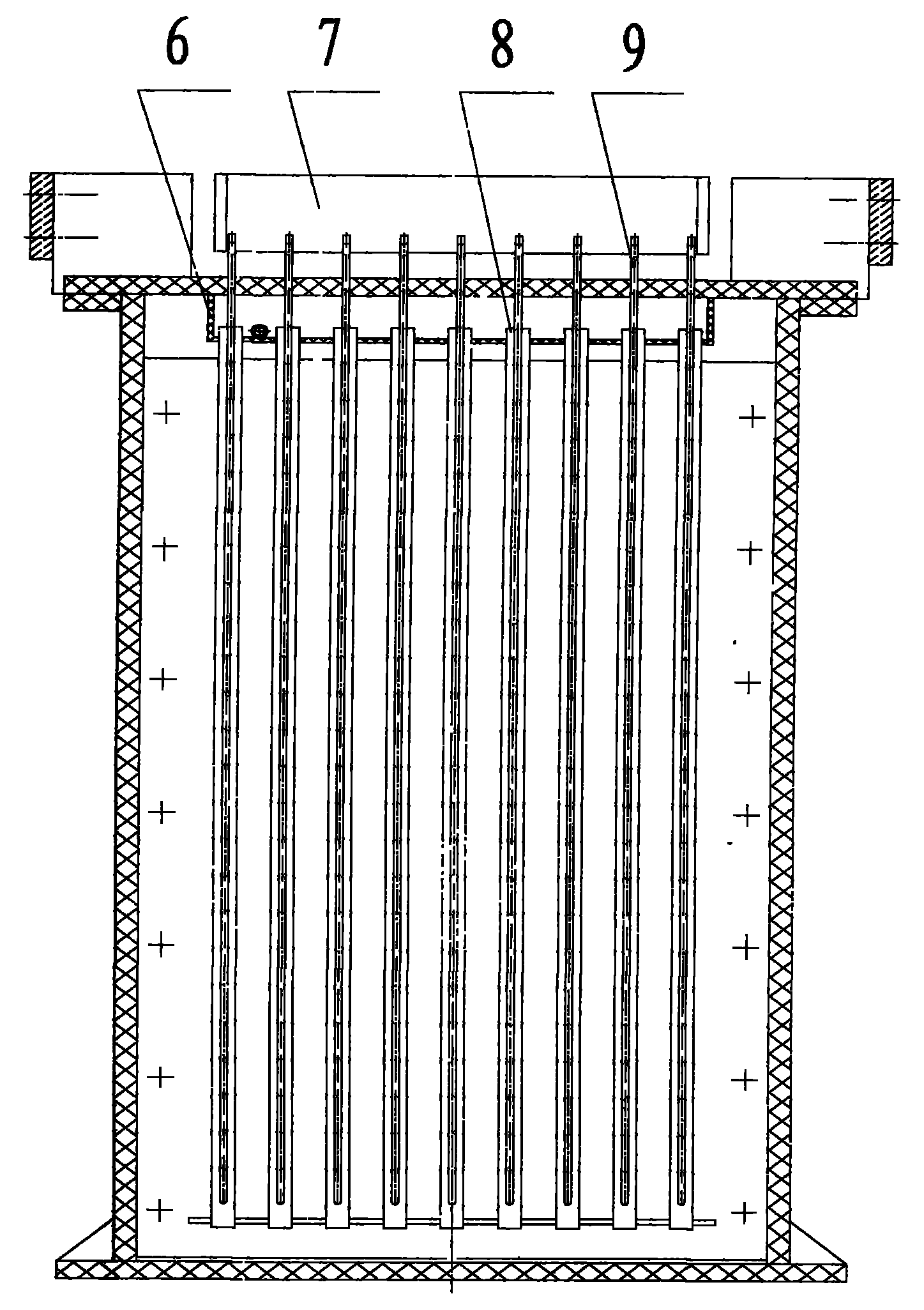

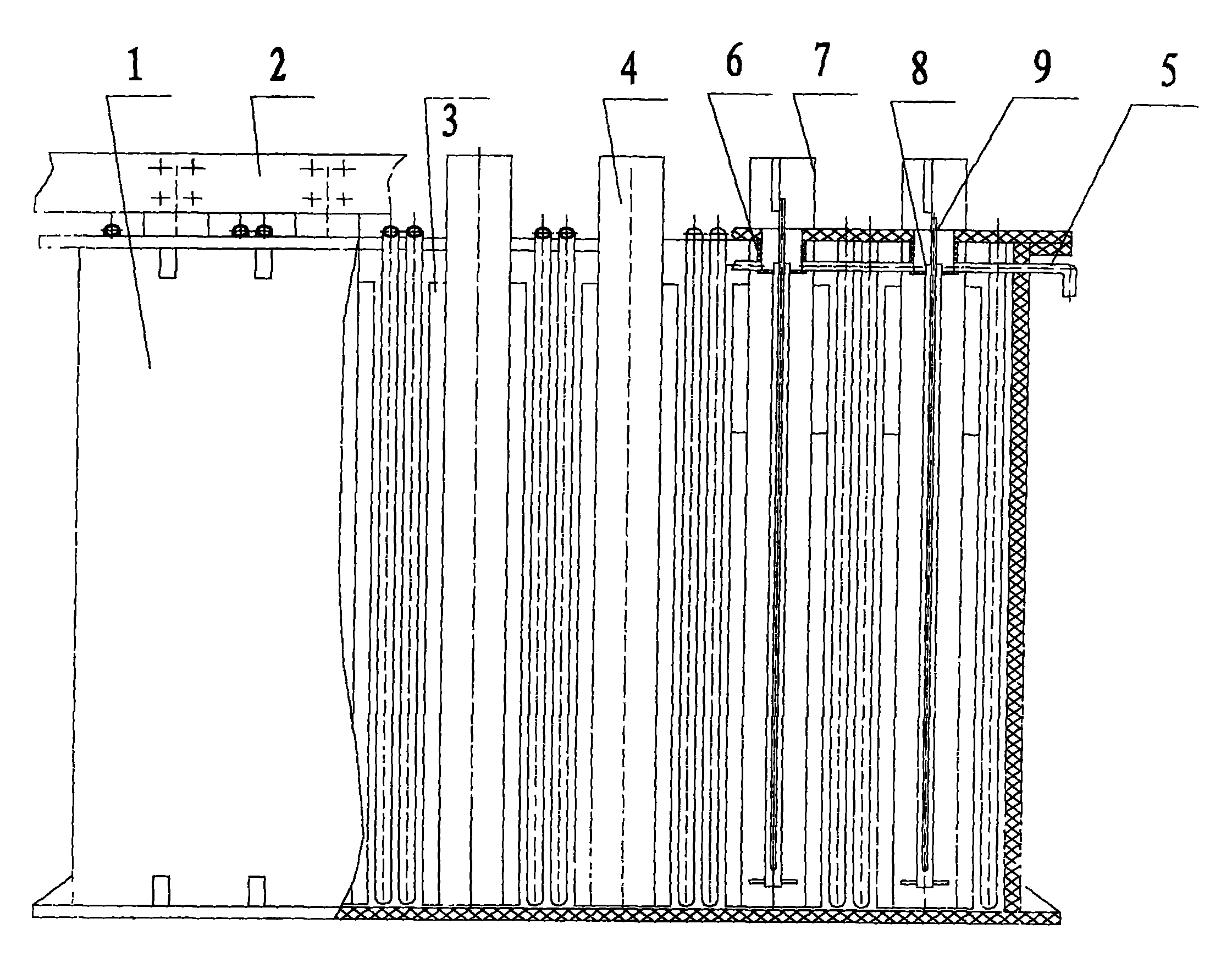

[0016] The following is a detailed description of the technical solutions of the present invention through the accompanying drawings.

[0017] Such as figure 1 and 2 Shown, the production device of a kind of novel ammonium persulfate of the present invention, manufacture electrolyzer 1 with plastic plate, adopt graphite cathode plate 3 as negative electrode, and place in electrolyzer 1, graphite cathode plate 3 adopts high strength The high-purity graphite screw is fixed on the graphite conductive rod 4, and the upper end of the graphite conductive rod 4 is connected with the negative electrode copper bar 2. The anode is made of a titanium rod 9 spirally wound around polonium wire and welded, and placed in a ceramic diaphragm tube 8. The lower end of the diaphragm tube 8 is closed, and the upper end is opened and inserted on the bottom plate of the plastic box 6. The upper end of the plastic box 6 is Opening, so that the titanium rod 9 is connected with the positive electrod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com