Method for polonium purification and source preparation in aerosol

An aerosol and sample solution technology, applied in the preparation of test samples, etc., can solve the problems affecting the analysis results of the nuclide to be tested, the unstable recovery rate of the purification source test method, etc., and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: Orthogonal Design Test Determines Significant Influencing Factors

[0037] by 209 Po (the activity is preferably 0.03-1.0Bq) is used as the yield tracer, and the method of purifying polonium in the aerosol is first carried out the orthogonal design test, considering the experimental factors and levels of the purification source, including 5 4 factors are considered, and the specific design is shown in Table 1.

[0038] Table 1 The experimental factors and levels considered in the orthogonal design experiment of polonium purification source

[0039]

[0040] Get the leaching solution of the actual aerosol sample (collect the aerosol sample in Taiyuan City, leaching the aerosol sample through the acidification leaching method to obtain the leaching solution), add 209 Po is used as a tracer, and the orthogonal design experiment is carried out, and the factors and levels of the purified source are included in the L 16 (4 5 ) in the experiment table, wit...

Embodiment 2

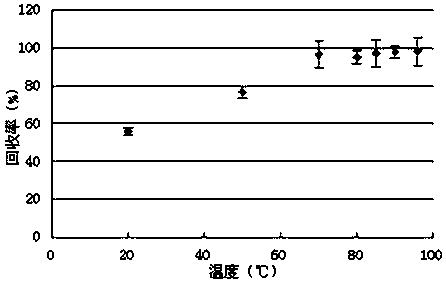

[0045] Embodiment 2: Single factor effect experiment of water bath temperature in constant temperature water bath oscillation

[0046] The temperature of the water bath in the constant temperature water bath oscillation is 20°C (room temperature), 50°C, 70°C, 80°C, 85°C, 90°C, 96°C (boiling water temperature in Taiyuan area), and 3 parallel samples are made at each temperature. Add 50mL0.5mol / LHCl, 0.5mL25% hydroxylamine hydrochloride, 0.2g ascorbic acid to each sample, add 2.0mL accurately 209 Put the Po standard solution in a constant temperature oscillator to purify the source for 2.0h, take out the copper piece, rinse it with distilled water, dry it naturally, and put it into the α spectrometer for measurement. according to 209 The activity of Po is used to calculate the recovery rate of the purified source. The experimental results are shown in figure 2 .

[0047] The experimental results show that: with the increase of temperature, the recovery rate of purified sour...

Embodiment 3

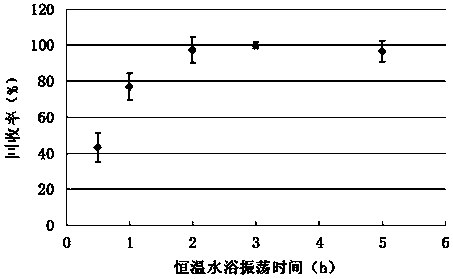

[0048] Embodiment 3: Single factor influence experiment of constant temperature water bath oscillation time

[0049] The constant temperature water bath shaking time was selected as 0.5h, 1.0h, 2.0h, 3.0h, 5.0h, respectively, and each group had 3 parallel samples. Add 100mL0.1mol / LHCl, 0.5mL25% hydroxylamine hydrochloride, 0.2g ascorbic acid to each sample, add 2.0mL accurately 209 Put the Po standard solution in a constant temperature oscillator at boiling water temperature to purify the source for 2.0 hours, take out the copper piece, rinse it, dry it naturally, and put it into the α spectrometer for measurement. according to 209 The activity of Po is used to calculate the recovery rate of the purified source. The experimental results are shown in image 3 .

[0050] The experimental results show that the longer the shaking time in the constant temperature water bath, the higher the recovery rate. When the time is between 2.0h-5.0h, the recovery rate tends to be stable a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com