Method for polonium leaching in aerosol

An aerosol and leaching technology, used in radiation measurement, instruments, measuring devices, etc., can solve the problems of danger to experimenters, loss of polonium, and perchloric acid is prone to explosion, and achieves high leaching rate and reduced volatilization loss. , good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

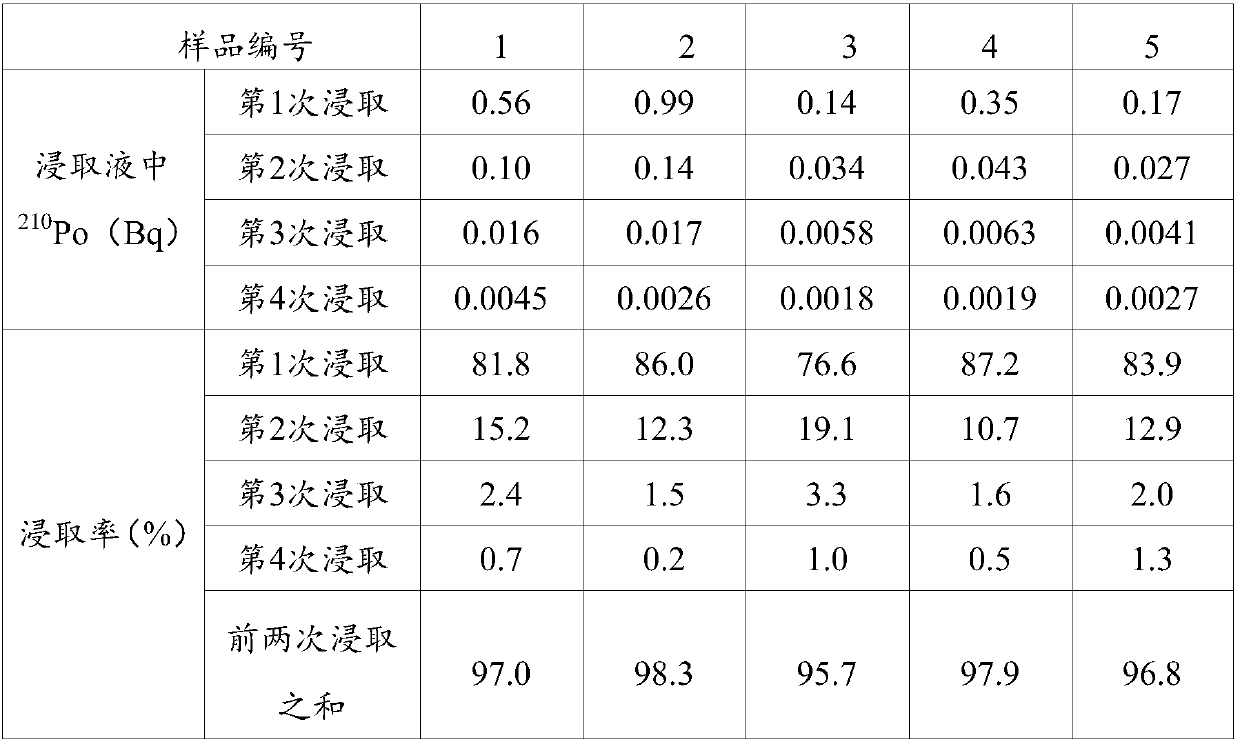

[0031] Example 1: Research on optimization of experimental conditions for polonium leaching in aerosol

[0032] 1) Acid type and concentration

[0033] Use concentrated HCl, 6mol / L HCl, and 6mol / L HCl-HF mixed solution (the volume ratio of 6mol / L HCl and 22.5mol / L HF is 1:1) to filter the filter membrane to obtain the aerosol sample to be tested and heat it to leaching The solution in the device is in a slightly boiling state, keep this state for leaching, a total of 2 times of leaching, each time 2.0h, and combine the two filtrates. Measure after purifying the source (reference method for analysis of polonium-210 in water, standard number: HJ 813-2016, or the method in the following example 2) 210 Po activity concentration. The result shows that concentrated HCl is 69% to the leaching rate of Po, and 6mol / LHCl is 103%, and 6mol / LHCl-HF mixed solution is 90%, so 6mol / LHCl and 6mol / LHCl-HF mixed solution are to 210 The leaching rate of Po is higher. However, because HF will...

Embodiment 2

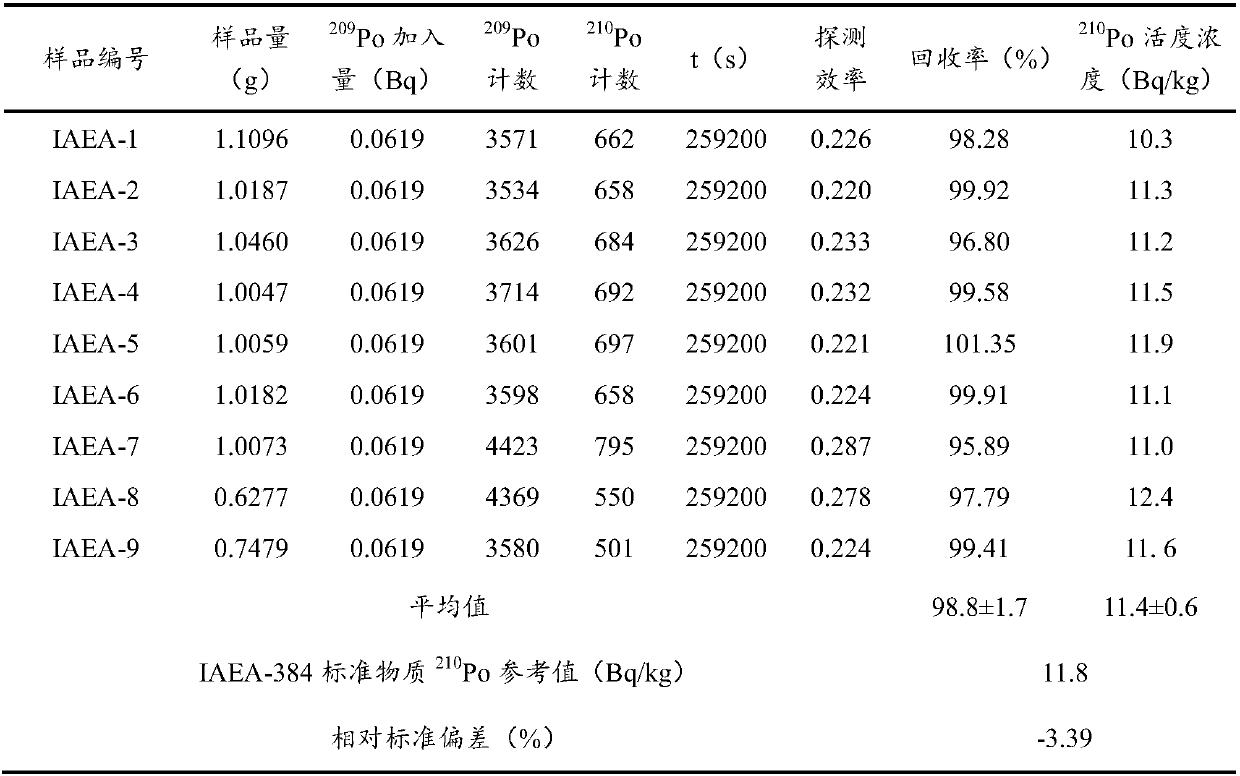

[0039] Embodiment 2: the leaching research of polonium reference material

[0040] On the basis of the research in Example 1, the method for leaching polonium in the following aerosol, the method for purifying the source and the method for purifying the source are selected and determined 210 Po analysis and determination method is used for the research of this embodiment and follow-up embodiment:

[0041] (1) Membrane filtration 600m 3 aerosol samples;

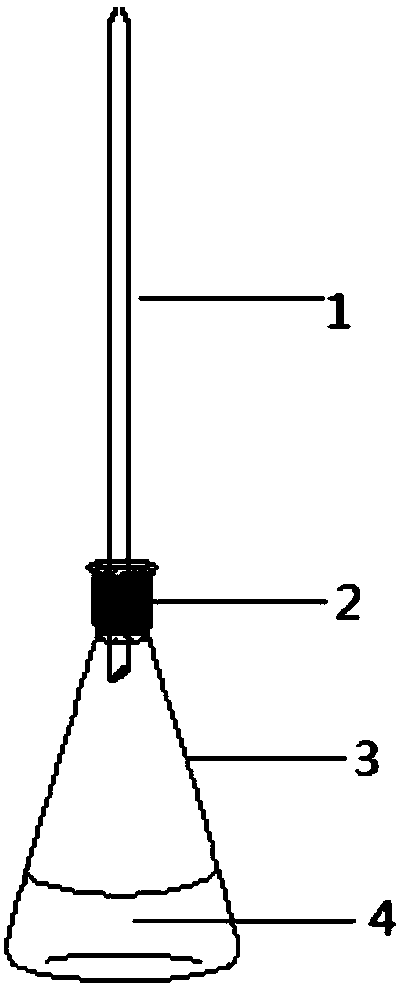

[0042] (2) Cut the filter membrane obtained from the measured aerosol sample into pieces and add figure 1 In the Erlenmeyer flask of the device;

[0043] (3) to figure 1 Add activity of 1Bq to the Erlenmeyer flask 209 Po(Ⅳ) as tracer;

[0044] (4) Add 50ml 6mol / L hydrochloric acid to the leaching device to completely immerse the filter membrane in the solution, then install figure 1 leaching device;

[0045] (5) Heating the leaching device makes the solution in the leaching device in a slightly boiling state, and maintai...

Embodiment 3

[0060] Example 3: Acquisition and leaching analysis of polonium aerosol samples

[0061] From October 2013 to January 2014, aerosol samples were collected by glass fiber filter membrane in Taiyuan area, and the aerosol samples were collected after leaching and purification. 210 Po analysis, the results are shown in Table 3 below.

[0062] Table 3 Analysis and determination results of polonium in aerosol samples

[0063]

[0064] In Table 3 above, according to the measured 209 Po, 210 Po count and 209 Po known activity, can be calculated according to formula (1) in the measured aerosol 210 Po activity concentration:

[0065]

[0066] In formula (1):

[0067] A 210 Po: in the measured aerosol sample 210 Po activity concentration, unit mBq / m 3 (1Bq / m 3 =1000mBq / m 3 );

[0068] A 209 : tracer 210 Amount of Po added, unit: Bq;

[0069] N 210 : on plated sheet 210 Count of Po;

[0070] N 209 : on plated sheet 209 Count of Po;

[0071] V: aerosol volume, un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com