Building material product using radioactive blast furnace slag as blending material and method for processing sewage water

A technology of radioactivity and admixtures, applied in water/sewage treatment, sustainable waste treatment, chemical instruments and methods, etc., can solve problems such as high cost, complicated manufacturing methods, and affecting cement performance, and achieve good frost resistance, The effect of good thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0016] Example 1: Sewage treatment by concrete water pipelines (urban comprehensive sewage)

[0017] will contain low levels of radioactive thorium 232 The blast furnace slag is formulated as the raw material for producing cement according to blast furnace slag: cement clinker: other auxiliary materials = 60:30:8:2 (weight percentage), and the special cement for sewage treatment is produced through the production process, and the cement is classified as special cement: Sand and gravel: admixture=40:50:10 (percentage by weight) is made into a water pipeline, and the sewage is directly contacted with this pipeline for 3 hours. The degradation rate is 40%, and the coliform group is killed by 99%. The α and β values after treatment are all lower than the national standard.

example 2

[0018] Example 2: Concrete sedimentation tank for sewage treatment

[0019] low dose radioactive thorium 232 The blast furnace heavy slag is made into concrete by adding a small amount of water according to blast furnace heavy slag: fly ash: ordinary cement = 50:30:20 (weight percentage), and build a sedimentation tank with the concrete. Let the sewage settle in the pool for 4 hours, the COD degradation rate of the sewage is 50%, the coliform group is killed more than 99%, and the α and β values after treatment are all lower than the national standard.

Description of drawings:

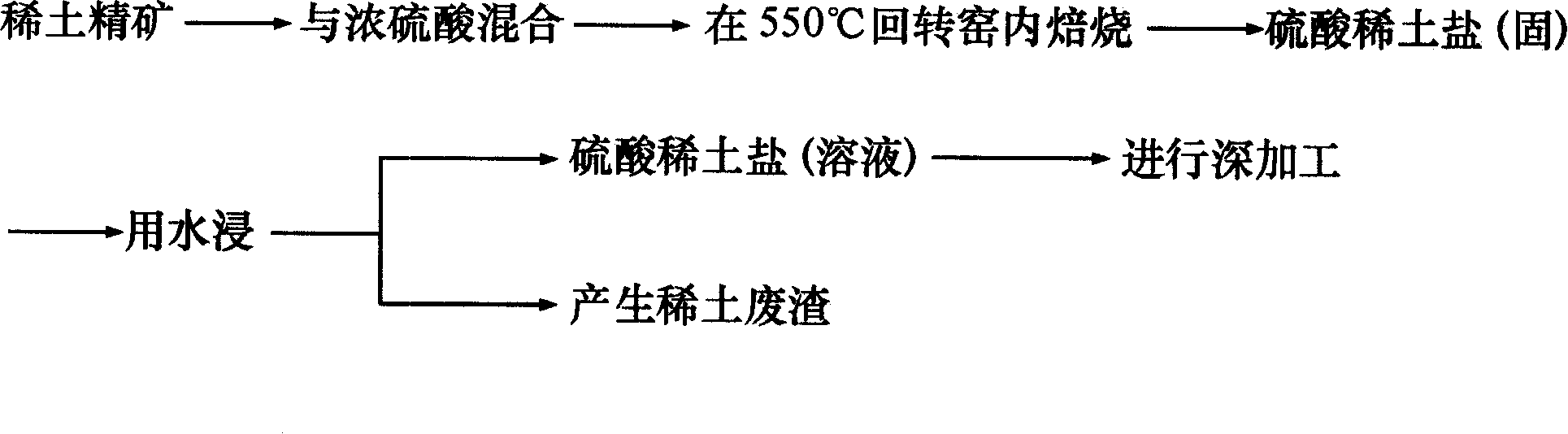

[0020] The accompanying drawing is a process diagram of producing rare earth waste slag.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com