Method for preparing 3, 3 ', 4, 4'-biphenyltetracarboxylic dianhydride

A technology of biphenyltetracarboxylic dianhydride and biphenyltetracarboxylic acid, which is applied in the field of preparation of 3,3', can solve the problems of high production cost of biphenyltetracarboxylic acid, achieve the effects of eliminating residues, simple industrial production, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Preparation of palladium-copper carbon-supported catalyst:

[0023] Weigh 0.42g solid CuCl 2 , dissolved in 100 ml of pure water, add 20 g of 5% palladium carbon catalyst into the solution, raise the temperature to 80°C, adjust the pH to 11 with aqueous sodium hydroxide solution, let it stand for 1 hour, stir and keep the temperature, add 10% aqueous sodium formate 8 g, keep warm for 8 hours, drop to room temperature, filter, wash with 260 ml of water, and drain to obtain a palladium-copper carbon-supported catalyst, which is set aside.

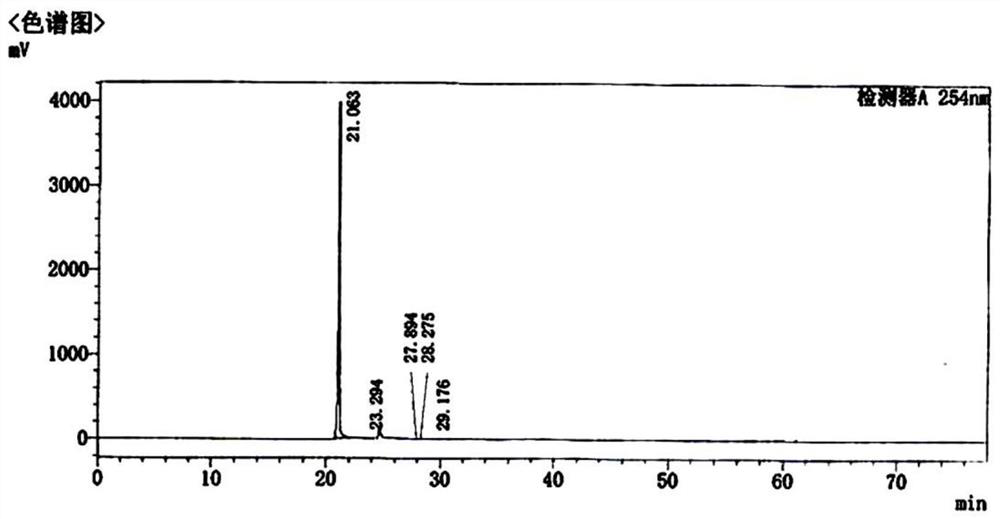

[0024] Preparation of 3,3',4,4'-biphenyltetracarboxylic dianhydride:

[0025] Put 336.2ml of pure water and 59.3g of sodium hydroxide into a 1000ml four-necked reaction flask equipped with a peristaltic pump, a thermometer and stirring, stir and dissolve, then add 110g of chlorophthalic acid monosodium salt mixture (4-chlorophthalic acid Diformic acid monosodium salt 75.1%, 4,5-dichlorophthalic acid monosodium salt 10.3%, 3-chloropht...

Embodiment 2

[0032] Preparation of palladium-copper carbon-supported catalyst:

[0033] Weigh 0.42g solid CuCl 2 , dissolved in 100 ml of pure water, 20 g of 5% palladium carbon catalyst was added into the solution, the temperature was raised to 80°C, and the pH was adjusted to 11 with aqueous sodium hydroxide solution, left to stand for 1.5 h, stirred and kept at temperature, and 10% sodium formate was added 8g of aqueous solution, continue to keep warm for 8h, cool down, filter, wash with 260ml of water, and drain to obtain a palladium-copper carbon-supported catalyst, which is set aside.

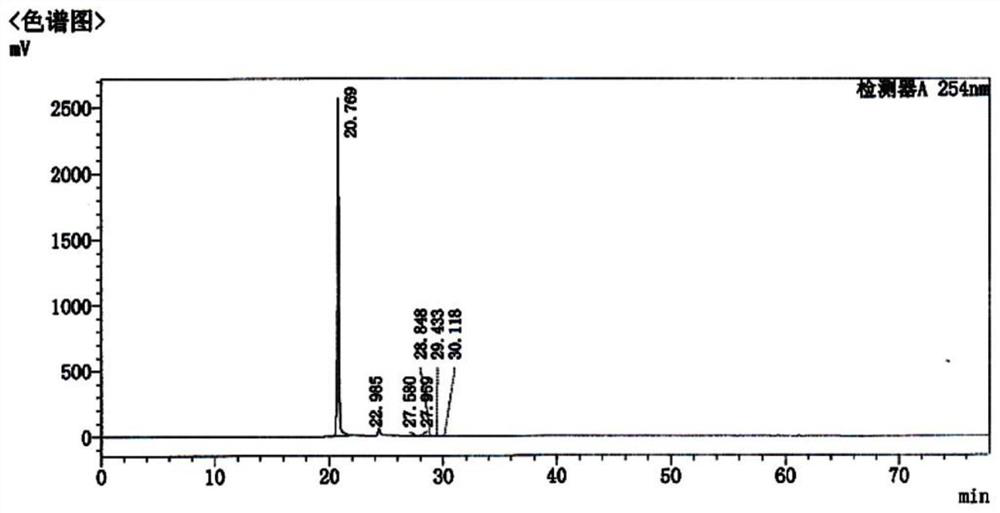

[0034] Preparation of 3,3',4,4'-biphenyltetracarboxylic dianhydride:

[0035]Put 336.2ml of pure water and 59.3g of sodium hydroxide into a 1000ml four-necked reaction flask equipped with a peristaltic pump, a thermometer and stirring, stir and dissolve, then add 110g of chlorophthalic acid monosodium salt mixture (4-chlorophthalic acid Diformic acid monosodium salt 79.6%, 4,5-dichlorophthalic acid ...

Embodiment 3

[0042] Preparation process of palladium-copper carbon-supported catalyst:

[0043] Weigh 0.42g solid CuCl 2 , dissolved in 100 ml of pure water, take 20 g of 5% palladium carbon catalyst and add it into the solution, raise the temperature to 100°C, adjust the pH to 11 with aqueous sodium hydroxide solution, let it stand for 1 hour, stir and keep the temperature, add 10% aqueous sodium formate 8g, continue to keep warm for 12h, cool down, filter, wash with 260 ml of water, and drain to obtain a palladium-copper carbon-supported catalyst, which is set aside.

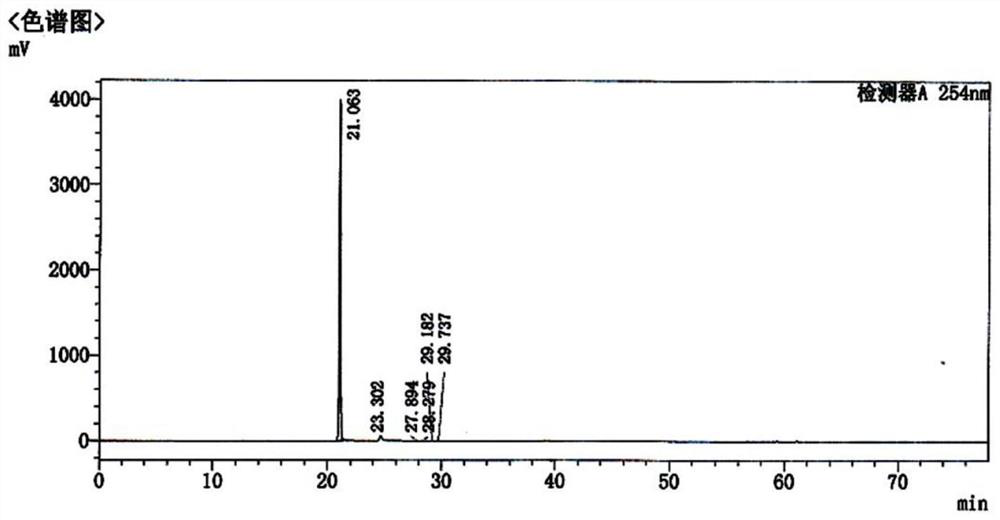

[0044] Preparation of 3,3',4,4'-biphenyltetracarboxylic dianhydride:

[0045] Put 336.2ml of pure water and 59.3g of sodium hydroxide into a 1000ml four-necked reaction flask equipped with a peristaltic pump, a thermometer and stirring, stir and dissolve, then add 110g of chlorophthalic acid monosodium salt mixture (4-chlorophthalic acid Diformic acid monosodium salt 76.6%, 4,5-dichlorophthalic acid monosodium salt 13.9%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com