Method for determination of antimony content in smelting slag

A technology of antimony content and slag, which is applied in the field of determination of antimony content in smelting slag, can solve the problems of inconspicuous end point of antimony titration, inaccurate analysis results, and easily misleading production, so as to improve economic and social benefits, good selectivity, and easy The effect of mastering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] (1) Weigh 0.3000g slag sample and place it in an Erlenmeyer flask;

[0018] (2) Add 1g potassium sulfate, 1g potassium fluoride dihydrate and 30ml sulfuric acid solution (1∶1) to dissolve the sample, then place the sample on an electric hot plate and heat it to decompose. After removing most of the sulfur, cover it with a watch glass. Continue heating on the hot plate to dissolve the sample completely;

[0019] (3) Take off the sample and cool it slightly, add 0.5g hydrazine sulfate, and continue heating for 10-15 minutes;

[0020] (4) Take off the sample and cool it, add 40ml water, 30ml hydrochloric acid (1+1), mix well, add 5ml phosphoric acid, mix well, continue heating on the electric hot plate, and control the temperature at 80℃~90℃;

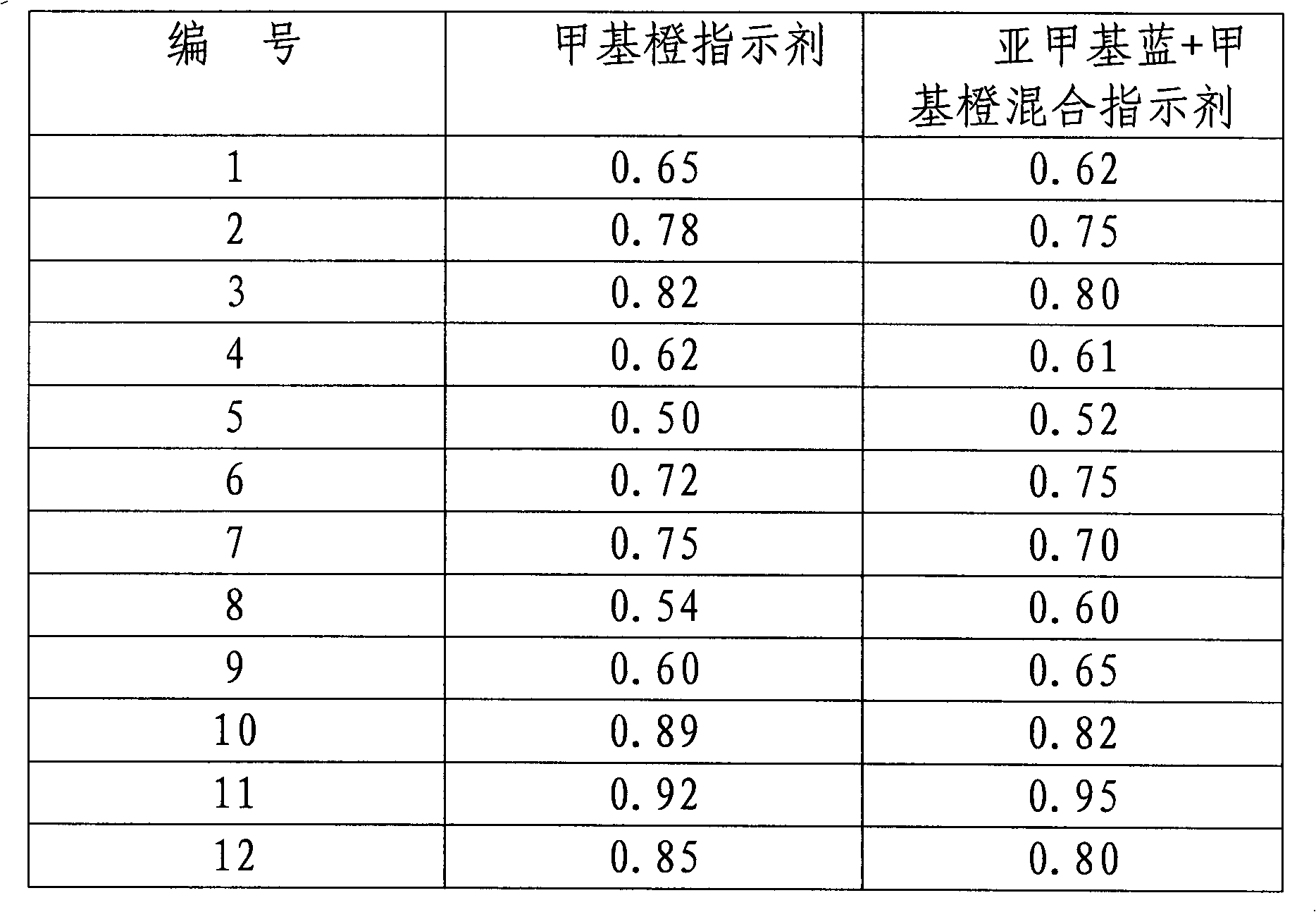

[0021] (5) Remove the sample, add 2 drops of methylene blue and 2 drops of methyl orange as an indicator, titrate with cerium sulfate standard solution until the solution is blue-green, which is the end point, and then calculate based on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com