Method for recycling organic solvents of wastewater generated in synthesis of hydrazine hydrate by ketazine method

A ketazine method and organic solvent technology, applied in the field of organic solvent recovery, can solve problems such as difficulty in meeting harmless discharge standards, insufficient recycling, environmental pollution, etc., to solve the problem of excessive organic components and easy automatic control , the effect of solving environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0057] 4. The preparation steps of isopropanol:

[0058] Add 10-12% mass percent of caustic soda (the weight ratio of the azeotrope) to the isopropanol-water binary azeotrope. After stirring and fully dissolving, the solution is layered, and the upper layer is 0.3-0.5% water content. Isopropanol, the lower layer is sodium hydroxide aqueous solution, and the upper layer solution is distilled to obtain a colorless and transparent isopropanol product with a purity of 99.0%.

Embodiment 1

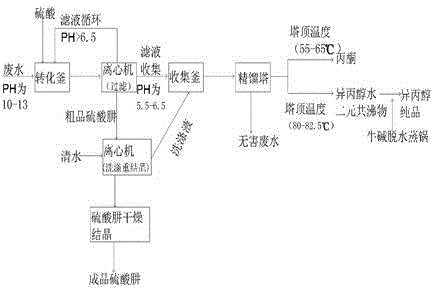

[0060] Such as figure 1 Shown, a kind of recovery method of organic solvent in ketazine method hydrazine hydrate waste water, comprises the following steps:

[0061] Put 7020kg of ketazine method hydrazine hydrate wastewater with a temperature of 0°C-15°C into the reaction conversion kettle through a centrifugal pump, open the drip valve at the bottom of the sulfuric acid high level tank, pass through the rotameter, control the flow rate to 80L / h, and slowly 770Kg of sulfuric acid with a concentration of 93% is added dropwise to the reactor, the amount of pure sulfuric acid added is 10.2% of the mass percentage of the waste water, and the temperature of the liquid in the reactor is controlled at 0-20°C. Turn on the electric stirring to make the materials react evenly. After 30 minutes, a large amount of hydrazine sulfate is formed and precipitated in the kettle. Open the valve at the bottom of the kettle to let the solution enter the centrifuge, start the circulation pump butt...

Embodiment 2

[0065] Example 2, such as figure 1 Shown, a kind of recovery method of organic solvent in ketazine method hydrazine hydrate waste water, comprises the following steps:

[0066] Put 8640kg of ketazine method hydrazine hydrate wastewater with a temperature of 0°C-15°C into the reaction conversion kettle through a centrifugal pump, open the drip valve at the bottom of the sulfuric acid high level tank, and pass through the rotameter to control the flow rate to 80L / h, slowly Add 900 kg of sulfuric acid with a concentration of 98% to the reaction kettle dropwise, the amount of pure sulfuric acid added is 10.2% of the mass percentage of the waste water, and the temperature of the liquid in the reaction kettle is controlled at 0-20°C. Turn on the electric stirring to make the materials react evenly. After 40 minutes, a large amount of hydrazine sulfate is formed and precipitated in the kettle. Open the valve at the bottom of the kettle to let the solution enter the centrifuge, start ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com